Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

52 viewsUs3850741 PDF

Us3850741 PDF

Uploaded by

Gandhi YellapuThis patent describes a method for cleaning shell and tube heat exchangers used in hydrocarbon processes. The method involves displacing the process stream in the heat exchanger with a highly aromatic hydrocarbon solvent. Heat from the process stream on the other side of the heat exchanger is then used to dissolve and remove carbonaceous fouling from the side being cleaned. The cleaning requires only 8-24 hours and avoids lengthy shutdowns for maintenance between scheduled outages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Training Manual For CIL & Elution-Final (Reviewed)Document29 pagesTraining Manual For CIL & Elution-Final (Reviewed)mani_mett100% (5)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Aramco Standard List (Total)Document188 pagesAramco Standard List (Total)Norman Morales100% (5)

- Shell and Tube Heat ExchangersDocument5 pagesShell and Tube Heat ExchangersFinny Pratama PuteraNo ratings yet

- Patent US4203906Document9 pagesPatent US4203906Santiago BorgesNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2010/0243521 A1Document14 pagesPatent Application Publication (10) Pub. No.: US 2010/0243521 A1xyz7890No ratings yet

- United States Patent (19) : Primary Examiner-Herbcrt Levine (54) Main Column Separation of FCCDocument7 pagesUnited States Patent (19) : Primary Examiner-Herbcrt Levine (54) Main Column Separation of FCCDuy Thanh NguyễnNo ratings yet

- US5240619Document10 pagesUS5240619Baba DookNo ratings yet

- Phtalic Anhydride PatentDocument9 pagesPhtalic Anhydride PatentRiza Shinta RNo ratings yet

- CokeDocument6 pagesCokeDendy Wahyu RadityaNo ratings yet

- United States Patent (19) : PowellDocument8 pagesUnited States Patent (19) : PowellSpiros LicoudisNo ratings yet

- Temperature Control in A Fluidized Bed Reactor: F. D, HannDocument5 pagesTemperature Control in A Fluidized Bed Reactor: F. D, HannFi FiyundaNo ratings yet

- United States Patent 19: Dumain Et AlDocument10 pagesUnited States Patent 19: Dumain Et AlFi FiyundaNo ratings yet

- Us 4396789Document7 pagesUs 4396789Elias JúniorNo ratings yet

- Patente Cryoplus Linde Us4617039Document13 pagesPatente Cryoplus Linde Us4617039rubenpeNo ratings yet

- Us 4479925Document5 pagesUs 4479925Katherine Benavides VillenaNo ratings yet

- United States PatentDocument11 pagesUnited States Patentxyz7890No ratings yet

- United States Patent (19) : Teyssier Et Al. 11) 4,299,809Document5 pagesUnited States Patent (19) : Teyssier Et Al. 11) 4,299,809apriyansyahNo ratings yet

- Group 6Document30 pagesGroup 6Anwer ShifaNo ratings yet

- United States Patent 1191: Tu (45) Sep. 7, 1982Document4 pagesUnited States Patent 1191: Tu (45) Sep. 7, 1982AdyNo ratings yet

- Acl RecoveryDocument4 pagesAcl Recoveryannisa latifaNo ratings yet

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument3 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of Patentrianne nabilahNo ratings yet

- Heat Recorery S3'stem.s: I. WarrenDocument15 pagesHeat Recorery S3'stem.s: I. WarrenPhilip ShihNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument22 pagesShell and Tube Heat Exchanger Designsuperbugima100% (1)

- US5208393 - Patent Reduction CCl4Document7 pagesUS5208393 - Patent Reduction CCl4aldo BMCNo ratings yet

- Suspension Preheater 1998Document22 pagesSuspension Preheater 1998Sajal Gupta100% (2)

- Paten Produksi Syn GasDocument12 pagesPaten Produksi Syn GasFarras HaidaryNo ratings yet

- Effectiveness of Sootblowers in Boilers Thermal Power StationDocument7 pagesEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123No ratings yet

- Fractionation of PetroleumDocument25 pagesFractionation of PetroleumAnand kesanakurtiNo ratings yet

- United States Patent (19) (11) 3,835,199: Schwartz, Jr. Et AlDocument5 pagesUnited States Patent (19) (11) 3,835,199: Schwartz, Jr. Et AlandiNo ratings yet

- United States Patent (19) : Assistant Examiner-Arthur O. HendersonDocument7 pagesUnited States Patent (19) : Assistant Examiner-Arthur O. HendersonDylan WielfredNo ratings yet

- Paten Sintesis MetanolDocument5 pagesPaten Sintesis MetanolFarras HaidaryNo ratings yet

- US4232179Document10 pagesUS423217931415No ratings yet

- United States PatentDocument10 pagesUnited States PatentRuchita PoilkarNo ratings yet

- Us 4256783Document9 pagesUs 4256783Santiago BorgesNo ratings yet

- US3983180Document7 pagesUS3983180Agustina TriyaniNo ratings yet

- Selecting The Optimum Predistillation Scheme For Heavy Crude OilsDocument8 pagesSelecting The Optimum Predistillation Scheme For Heavy Crude OilsHoàng NhânNo ratings yet

- Us4521532 PDFDocument8 pagesUs4521532 PDFRushi GawadeNo ratings yet

- United States Patent 19) 11) Patent Number: 4,504,274: Anderson 45 Date of Patent: Mar. 12, 1985Document5 pagesUnited States Patent 19) 11) Patent Number: 4,504,274: Anderson 45 Date of Patent: Mar. 12, 1985Adi Gunawan PrasetiaNo ratings yet

- Production of Phosphoric Acid by Dry Kiln Process: Aram NasihDocument8 pagesProduction of Phosphoric Acid by Dry Kiln Process: Aram NasihAram Nasih MuhammadNo ratings yet

- Technical Spec BoilerDocument13 pagesTechnical Spec Boilermochamad RasjidNo ratings yet

- Process For Purification of HCL From Edc PyrolysisDocument6 pagesProcess For Purification of HCL From Edc Pyrolysisu2051721No ratings yet

- Vapour Absorption SystemDocument21 pagesVapour Absorption Systemoyetunde ridwanNo ratings yet

- Rethink Specifications For Fired HeatersDocument7 pagesRethink Specifications For Fired HeatersAhmed SeliemNo ratings yet

- III Iii Iihiiii: United States PatentDocument11 pagesIII Iii Iihiiii: United States Patentista fitriaNo ratings yet

- US7685820Document7 pagesUS7685820icylabchileNo ratings yet

- APV Evaporation HandbookDocument68 pagesAPV Evaporation HandbookМаксим ХилоNo ratings yet

- Ep 09015185 Nwa 1Document9 pagesEp 09015185 Nwa 1jdedfvNo ratings yet

- Upgrade Your Furnace For Clean FuelsDocument4 pagesUpgrade Your Furnace For Clean Fuelssagar1503No ratings yet

- Chemical and Mechanical DesignDocument460 pagesChemical and Mechanical DesignNuriman K-monNo ratings yet

- United States Patent (191: Briickner Et A1Document6 pagesUnited States Patent (191: Briickner Et A1PeterWangNo ratings yet

- US3906961Document7 pagesUS3906961Bayron Ospina MarinNo ratings yet

- US20140378725A1 - Chloride RemovalDocument10 pagesUS20140378725A1 - Chloride RemovalFrancisco CunhaNo ratings yet

- Report On NTPC Industrial Training at Barh (Patna)Document24 pagesReport On NTPC Industrial Training at Barh (Patna)Gautam KumarNo ratings yet

- Heat Exchanger 4Document9 pagesHeat Exchanger 4Karter KhelaNo ratings yet

- Waste Heat Recovery Technologies and Applications: ART-203 Group No:04Document17 pagesWaste Heat Recovery Technologies and Applications: ART-203 Group No:04Sazid ZamanNo ratings yet

- Helixchanger Heat ExchangersDocument7 pagesHelixchanger Heat ExchangersAnonymous QSfDsVxjZNo ratings yet

- Principles of Boiler OperationsDocument35 pagesPrinciples of Boiler Operationseblees100No ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Project Deliverable: ST THDocument46 pagesProject Deliverable: ST THGandhi YellapuNo ratings yet

- Simplified Equations For Saturated Steam PropertieDocument6 pagesSimplified Equations For Saturated Steam PropertieGandhi YellapuNo ratings yet

- Fosso KankeuandBriderDocument8 pagesFosso KankeuandBriderGandhi YellapuNo ratings yet

- MORE Final-Workshop LENZING-caseDocument20 pagesMORE Final-Workshop LENZING-caseGandhi YellapuNo ratings yet

- 2157-7048 1000255 PDFDocument7 pages2157-7048 1000255 PDFGandhi YellapuNo ratings yet

- MSFE CalculationsDocument5 pagesMSFE CalculationsGandhi YellapuNo ratings yet

- PHD Thesis Yashasvi Laxminarayan v2 January 2018 PDFDocument197 pagesPHD Thesis Yashasvi Laxminarayan v2 January 2018 PDFGandhi YellapuNo ratings yet

- Preparation of Resin by Rice Husk Treated With Phosphoric Acid For Removal of ZN From Industrial EffluentDocument5 pagesPreparation of Resin by Rice Husk Treated With Phosphoric Acid For Removal of ZN From Industrial EffluentGandhi YellapuNo ratings yet

- Predicting Ash Properties in Recovery Boilers: January 2010Document14 pagesPredicting Ash Properties in Recovery Boilers: January 2010Gandhi YellapuNo ratings yet

- Bjorn's Corner - Sustainable Air Transport. Part 18. Advanced Hydrogen Gas Turbines - Leeham News and AnalysisDocument5 pagesBjorn's Corner - Sustainable Air Transport. Part 18. Advanced Hydrogen Gas Turbines - Leeham News and AnalysisasfasdfsNo ratings yet

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of AmmoniaDocument12 pagesFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of AmmoniaZAHID HUSSAINNo ratings yet

- Sampling System For Dry Gas Sampling at Rotary Cement Kiln Gas Exit and Calciner Gas ExitDocument20 pagesSampling System For Dry Gas Sampling at Rotary Cement Kiln Gas Exit and Calciner Gas ExitgldiasNo ratings yet

- Practice Problems in Process Equipment DesignDocument19 pagesPractice Problems in Process Equipment DesignRasNo ratings yet

- KyotoCooling Co-Location Impact CPXDocument6 pagesKyotoCooling Co-Location Impact CPXChris FultonNo ratings yet

- Graphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977Document9 pagesGraphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977LeDzungNo ratings yet

- Full Chapter Proceedings of China Sae Congress 2019 Selected Papers China Society of Automotive Engineers PDFDocument53 pagesFull Chapter Proceedings of China Sae Congress 2019 Selected Papers China Society of Automotive Engineers PDFrobert.tardiff909100% (2)

- HVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerryDocument29 pagesHVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerrySuresh KumarNo ratings yet

- Data Book IIIDocument6 pagesData Book IIIDhanish KumarNo ratings yet

- Turmoil CatalogDocument37 pagesTurmoil CatalogChandru RsNo ratings yet

- Panouri SolareDocument52 pagesPanouri SolareValentin GargaritaNo ratings yet

- LNG 3.4.e Floating LNG Production19 19967Document12 pagesLNG 3.4.e Floating LNG Production19 19967Richard HollidayNo ratings yet

- Energy Optimization Study - WorkingDocument17 pagesEnergy Optimization Study - WorkingMufleh IdrisNo ratings yet

- Heat Exchanger ExperimentDocument11 pagesHeat Exchanger ExperimentDhevesh DomunNo ratings yet

- LNG Chain BookDocument106 pagesLNG Chain BookErick Royer Ponce PozoNo ratings yet

- Atlas Copco FD DryersDocument12 pagesAtlas Copco FD DryersSherif AdelNo ratings yet

- Engineering Standard FOR Piping & Instrumentation Diagrams (P & Ids) Original Edition OCT. 1996Document111 pagesEngineering Standard FOR Piping & Instrumentation Diagrams (P & Ids) Original Edition OCT. 1996Kalidass BackNo ratings yet

- Panel Operator-Govind Narayan KiradooDocument4 pagesPanel Operator-Govind Narayan KiradooDodiya NikunjNo ratings yet

- MIE1132H Problem Set 1Document2 pagesMIE1132H Problem Set 1csNo ratings yet

- SHEET4 AnswersDocument20 pagesSHEET4 AnswersHamadaMohassabNo ratings yet

- Chapter 3Document83 pagesChapter 3Biru EsheteNo ratings yet

- Hydro PDFDocument139 pagesHydro PDFVan Quynh100% (2)

- Pasturisation of JuiceDocument3 pagesPasturisation of JuiceAnilZapate0% (1)

- Feasibility (Manicsic)Document22 pagesFeasibility (Manicsic)Jocelyn CorpuzNo ratings yet

- 1.) 250 MW Oil Fired Power Station.: Price: US$ 27 Mill. "As It Is" OnlyDocument11 pages1.) 250 MW Oil Fired Power Station.: Price: US$ 27 Mill. "As It Is" OnlySalam SarkarNo ratings yet

- Nordtec ProposalDocument15 pagesNordtec Proposaluzair khan100% (1)

- 30XA Catalog-2Document30 pages30XA Catalog-2SLNo ratings yet

Us3850741 PDF

Us3850741 PDF

Uploaded by

Gandhi Yellapu0 ratings0% found this document useful (0 votes)

52 views6 pagesThis patent describes a method for cleaning shell and tube heat exchangers used in hydrocarbon processes. The method involves displacing the process stream in the heat exchanger with a highly aromatic hydrocarbon solvent. Heat from the process stream on the other side of the heat exchanger is then used to dissolve and remove carbonaceous fouling from the side being cleaned. The cleaning requires only 8-24 hours and avoids lengthy shutdowns for maintenance between scheduled outages.

Original Description:

Original Title

US3850741.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a method for cleaning shell and tube heat exchangers used in hydrocarbon processes. The method involves displacing the process stream in the heat exchanger with a highly aromatic hydrocarbon solvent. Heat from the process stream on the other side of the heat exchanger is then used to dissolve and remove carbonaceous fouling from the side being cleaned. The cleaning requires only 8-24 hours and avoids lengthy shutdowns for maintenance between scheduled outages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

52 views6 pagesUs3850741 PDF

Us3850741 PDF

Uploaded by

Gandhi YellapuThis patent describes a method for cleaning shell and tube heat exchangers used in hydrocarbon processes. The method involves displacing the process stream in the heat exchanger with a highly aromatic hydrocarbon solvent. Heat from the process stream on the other side of the heat exchanger is then used to dissolve and remove carbonaceous fouling from the side being cleaned. The cleaning requires only 8-24 hours and avoids lengthy shutdowns for maintenance between scheduled outages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

United States Patent (19) 11, 3,850,741

Callahan et al.

(45 Nov. 26, 1974

54 METHOD OF CLEANING HEAT 2,953,514 9/1960 Wilkins................................. 208/95

EXCHANGERS 3,054,700 9/1962 Martin......................... ... 34/2

75) Inventors: Joseph W. Callahan, Sulphur, La., 3,060,064 10/1962 Zingg........... o a - . . . . . . . . . . 13412

Gene R. Laningham, Houston, Tex. Primary Examiner-Delbert E. Gantz

73) Assignee: Cesco, Inc., Houston, Tex. Assistant Examiner-G. E. Schmitkons

22 Filed: May 23, 1973 Attorney, Agent, or Firm-Pravel & Wilson

(21) Appl. No.: 363,279 57 ABSTRACT

52 U.S. Cl.................... 208148 R, 134/20, 134/39,

A method for removing carbonaceous fouling from

shell and tube heat exchangers used in hydrocarbon

134/40 processes which uses as the solvent a highly aromatic

(51 Int. Cl............................ C23g 5/02, C10g 9/16 hydrocarbon and utilizes heat from the process itself

58) Field of Search .......... 208148 R; 13412, 20, 34, to accomplish the removal of the carbonaceous foul

134/40 ing material is disclosed. This method is particularly

56 References Cited

useful to maintain the efficiency of heat exchangers

between scheduled shutdown of particular units for

UNITED STATES PATENTS extensive preventive maintenance.

2,380,340 7/1945 Simpson............................... 134/30 11 Claims, 1 Drawing Figure

PATENTED NOY26 1974 3,850,74,

3,850,741

1. 2

METHOD OF CLEANING HEAT EXCHANGERS of the heat exchanger to cleaned, whether it be the tube

BACKGROUND OF THE INVENTION side or shell exchanger cleaned, whether it be the tube

side or shell stand while the other side operates nor

This invention relates to a method of cleaning shell mally with the process stream flowing therethrough

and tube heat exchangers used in hydrocarbon pro providing the heat which advantageously accelerates

cesses where a cool stream flowing on one side of the the cleaning process on the side of the exchanger being

heat exchanger is heated using the heat from another cleaned. In the practice of this invention, it is found

hotter process stream flowing on the other side of the that it is only necessary to continue the cleaning while

heat exchanger in order to utilize all energy in the par holding the solvent solution in the shell and tube ex

ticular process to its best advantage. It is the usual prac O changer for a period of about 8 to about 24 hours to

tice in the hydrocarbon processing industry, whether it materially increase the heat transfer of the particular

be the refining of petroleum crude oil to usable prod piece of equipment and to return it to an efficient oper

ucts or the conversion of such products in petrochemi ating range. After the cleaning time is finished, the sol

cal plants to further useful materials, to periodically vent which is itself a hydrocarbon can be either bled

shut down units for inspection and preventive mainte 15 out of the heat exchanger by allowing the normal mate

nance. The periodic planned shutdown best utilizes the rial to displace the solvent or it can be, in the case of

maintenance force of the particular plant involved and where the process stream is a crude stream or a waste

is also used to plan production rates to compensate for stream, pushed by said process stream into the process

the period of time when a particular operating unit or itself. This avoids any messy disposal problems for the

plant is shut down for maintenance. In the interim be 20 solvent containing the removed carbonaceous fouling

tween these planned shutdowns, heat exchangers in the materials. Once the solvent and removed fouling mate

hydrocarbon processes become fouled and the effi rial have been displaced from the side of the heat ex

ciency of operating said exchangers decreases, causing changer being cleaned, it is then returned to service in

a loss in energy which is either compensated for by con the process. The method of this invention is particu

suming more energy through the use of heaters, and the 25 larly well adaptable to cleaning the shell and tube heat

like, or by suffering a decrease in production rate in the exchangers in hydrocarbon processes such as the refin

unit. In either case the overall efficiency is decreased ing of petroleum products and the production of petro

and energy is being wasted. chemical materials. One particularly advantageous ap

This loss of efficiency normally occurs just with the plication of this invention is to clean the heat exchang

passage of time due to the formation of deposits which, 30 ers used to preheat crude oil prior to its being charged

in the case of hydrocarbon processing in petroleum re to fractionation towers. The crude is also further

fineries and petrochemical plants, are generally carbo heated in an oven and delivered to fractionation towers

naceous and may be formed by deposition of sus with certain products from the fractionation tower

pended solid material or by the cracking and coking of being passed on the other side of the aforementioned

the fluid streams. 35

heat exchanger to provide the heat for the incoming

Previously, the cleaning of these heat exchangers has crude and also to cool the product from the tower.

required shutting down the unit or the heat exchanger, These crude preheat trains may be only a few heat ex

opening it and removing the tube bundle inside, and changers or a bank of sometimes as many as fifty such

then cleaning the tube side by either drilling, water 40 heat exchangers, depending upon the size of the refin

blast, and more recently, by oxidation of the material ery. As the operation of the heat exchanger continues,

using an oxygen-containing gas with heat (see U.S. Pat. whether the crude is passed on the shell side or the tube

No. 3,054,700). The shell side of the tube bundles have side of the heat exchanger, the exchanger begins to foul

been heretofore cleaned by water blasting, sand blast through the deposition of carbonaceous materials on

ing, acid washing or flame treating while circulating the heat exchange surfaces. The heat transfer is then

coolant through the tubes (U.S. Pat. No. 3,060,064). lowered and, to compensate for this inefficiency, the

All of the above-discussed treatments require excess crude oven must consume more fuel to bring the crude

amounts of down time and, hence; loss of energy and stream to adequate temperature for efficient fraction

for production during the period occurs. It has also ation. This could lead to damage to the oven and, in

been attempted to use certain solvents for cleaning any case, represents a waste of energy which could oth

heat exchanger surfaces, as described in U.S. Pat. No, 50 erwise be conserved.

2,380,340, but the practice using solvents has generally Another instance where the practice of this invention

been disappointing since either several solvents must is particularly applicable is with respect to the preheat

be sequentially used, the time involved of interrupting train to a catalytic reformer unit wherein the incoming

the process use has been excessive, or the degree of feed is heated on one side of the exchanger by the pas

cleaning has not been effective. sage of the hot reformate on the other side. While the

SUMMARY OF THE INVENTION reformate is very clean and does not cause fouling

problems, the bottoms from the unit which are also

In accordance with this invention, therefore, an im used to heat the feed, can cause fouling problems.

proved method for removing carbonaceous fouling When the side containing a bottoms stream that is a

from shell and tube heat exchangers used in hydrocar waste stream is being cleaned, the BTU value in such

bon processes is described whereby the process stream a stream is lost. However, this loss is minimized by the

on one side of the shell and tube heat exchanger is dis fact that the heat exchanger is off stream only a mini

placed with a high-boiling hydrocarbon solvent having mum amount of time.

at least 50 wt. percent aromatic content, a Kauri 65 Those skilled in the art would readily recognize, from

butanol value of at least about 90 and a minimum boil the above-described applications of heat exchangers

ing point of at least about 350F and a maximum boil which may be cleaned through the method of this in

ing point of at least about 500F. Regardless of the side vention, other such applications of the invention.

3,850,741

3. 4.

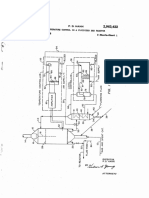

DESCRIPTION OF THE DRAWING flushed from the exchanger into the process stream. Of

course, if the solvent involved were detrimental to the

The drawing attached hereto is a schematic diagram purity of the stream going through the side of the ex

to aid in the explanation of applying the method of this changer being cleaned, then the outlet valve of the ex

invention to a shell and tube heat exchanger in Service changer would be closed and the solvent removed

to conserve energy in hydrocarbon processing plants. through a bleed valve to prevent the contamination of

the feed stream. However, in the case of cleaning the

DESCRIPTION OF THE PREFERRED exchangers for the crude preheat train or the bottoms

EMBODIMENT coolers of certain refinery columns, the process of this

() invention has particular application since the solvent

The heat exchangers in hydrocarbon processing can usually be flushed into the stream without causing

plants, i.e., petroleum refineries and petrochemical any adverse results.

plants, for reasons of economy, perform double duty. The solvent used in the practice of this invention is

That is to say, a hot stream which needs to be cooled a high boiling hydrocarbon having a high aromatic con

is used to supply heat in a shell and tube heat exchanger 15 tent. The solvent, to operate satisfactorily, contains at

to a cooler stream which needs to be heated. In most least about 50 wt. percent aromatics and has a mini

cases, the shell and tube heat exchangers will be found mum initial boiling point at atmospheric pressure of

to be employed in series or parallel, such that one or about 350°F, and preferably about 400F, and a mini

more of the exchangers may be taken out of service for mum upper limit of the boiling range (end point tem

one reason or another without causing the entire unit 20 perature) of at least about 500°F, preferably 600°F

to become shut down. Often it would be found that sev minimum. The solvent will have a Kauri-butanol value

eral heat exchangers would be operated in series where of at least about 90 and preferably from about 100 to

the whole series would be in parallel with other simi about l l 0. The Kauri-butanol test is a well-known stan

larly disposed and aligned heat exchangers. It is one of dard test for solvents. The preferred solvents falling

the particular advantages of the method of this inven within the above specifications, are the heavy aromatic

tion that any down time of heat exchangers is mini naphthas containing from about 75 to about 98 wt. per

mized, thus effecting a significant savings in not only cent aromatic constituents. If desired, or if necessary

energy, but also in production of the hydrocarbon pro for thorough cleaning, a minor amount of chlorinated

cessing unit which is involved, since unit operation is benzenes, particularly ortho-dichlorobenzene, can be

disturbed when an exchanger is out of service. 30

used conjointly with the above described solvents to

As the heat exchangers are operated, carbonaceous clean the heat exchanger. Generally, the chlorinated

material becomes attached to the heating surface and benzene will be used in an amount of about 10 percent

fouling occurs reducing the effectiveness of the heat by volume of the entire solvent, but the amount may

transfer between the heating side and the cooling side, 35

vary within the preferable range of from about 5 to

thus reducing the efficiency of the heat transfer. This about 25 percent by volume. However, it is necessary

heat transfer efficiency, generally designated as the when using a chlorinated hydrocarbon solvent in com

heat transfer coefficient, U, BTU/(hour) (ft.) (F), can bination with the high aromatic solvent in the practice

deteriorate to such a point that the overall efficiency of of this invention to carefully determine whether or not

the unit is jeopardized. It is at this point that the inven 40

such chlorinated hydrocarbons can be allowed to con

tion described herein is especially important, since it taminate the stream which passes through the side of

allows the minimum of down time and the continuation the heat exchanger being cleaned, since chlorinated hy

of operation of the side of the heat exchanger not being drocarbons are known to contaminate certain catalysts.

cleaned.

In the operation of the method of this invention, the 45 For purposes of illustration of the practice of this in

process stream utilizing the side of the exchanger being vention, reference is hereby made to the accompanying

cleaned is displaced with the solvent used in the prac drawing wherein the heat exchanger E represents a

tice of the invention. Of course, the intake feed valve shell and tube heat exchanger typical of those which

would be closed to stop the flow of material through are advantageously used in hydrocarbon processing

the side being cleaned and the solvent would be re 50 plants and, therefore, are particularly adaptable to the

tained in the heat exchanger in contact with the carbo use of practice of this invention. For purposes of this

naceous fouling material and 'cook' under the influ illustration, the tube side of the exchanger will be

ence of the material passing through the other side of cleaned without interrupting the flow of the process

the heat exchanger. This can be accomplished through stream through the shell side. From the following de

either shutting down the heat exchanger and allowing 55 scription, one of ordinary skill in the art will readily be

it to cool before filling with the solvent used in the able to accomplish the cleaning of the shell side of the

practice of this invention and reintroducing the process exchanger by merely applying the stated procedure to

stream to the other side of the heat exchanger, or it can the shell side process stream. During operation on the

be accomplished by simply closing the feed valve to the tube side, the process stream flows through line 10,

side to be cleaned and pumping the solvent into the ex 60 valve 12 and thence through line 14 into the heat ex

changer against the pressure of the outlet side of the ex changer E. A bleed valve 16 is connected to line 14 be

changer to displace the feed material in the exchanger. tween valve 12 and the heat exchanger E. On the exit

Once the exchanger is full, then pumping is ceased and side of the heat exchanger E, the material flowing

the action of the solvent on the carbonaceous fouling through the tube side, whether it be heated or cooled,

takes place. During this time, the outlet valve remains exits the exchanger through line 18, valve 20 and back

open and the exchanger 'floats' against the pressure in to the process through line 22. Connected to line 18 is

the exit line. To put the exchanger back on stream, the a bleeder valve 24. On the shell side of the heat ex

inlet feed valve is merely opened and the solvent changer E the process flow enters through line 26,

3,850,741

5 6

valve 28 and line 30 to which is attached a bleeder bleeder valves 24 and 16 on the tube side and 40 and

valve 32. The material exiting the shell side of the heat 32 on the shell side and, using proper safety precau

exchanger E exits through line 34, valve 36 and returns tions for the material and temperatures and pressures

to the process through line 38. To line 34 is attached involved, drain the exchanger. The exchanger can then

a bleeder valve 40. When cleaning the tube side of the 5 be properly cooled by circulating nitrogen through

heat exchanger, a line 42 is connected to bleeder valve both sides of the heat exchanger. Again for purposes of

16 through an optional check valve 44. The inlet valve illustration, the tube side is used and the high aromatic

12 is closed, the bleeder valve 16 opened and the sol- Solvent is pumped through the bleed valve 16 into the

vent pumped by pump P through line 42, the optional exchanger E with venting through the outlet bleed

check valve 44 and thence through the bleeder valve 10 valve 24. Once the exchanger is full of solvent, the

16, line 14 and into the exchanger E to replace the pro- bleed valves are closed and the outlet valve 20 opened

cess material which is within the exchanger. The to allow the tube side of the heat exchanger to again

amount of solvent pumped is sufficient to fill the ex- "float" on the open outlet valve. The process stream,

changer and force all of the process material out normally flowing through the shell side, will then be al

through the exit valve 20 which remains open during 15 lowed to enter the shell side by opening valve 28 using

the cleaning process of this invention. Once the ex- the normal safety precautions for starting up a shell and

changer is filled, the process material flowing through tube heat exchanger where differential pressures are

the shell side of the heat exchanger E heats the solvent involved. These procedures are well-known to those

in contact with the carbonaceous fouling material and skilled in the art. The process stream will then flow

causes said material to be removed from the heat ex- 20 through the shell side of the heat exchanger E with

change surfaces. This cooking process is allowed to valve 36 having been opened, the bleeder valves, of

continue for at least about 8 and preferably at least course, have been closed.

about 18 hours with the time generally ranging from To return the heat exchanger E to normal process op

about 8 to about 24 hours, preferably from about 18 to eration, the procedure discussed above is to be fol

about 24 hours, depending upon the nature of the car- 25 lowed.

bonaceous fouling. Longer times can be used but as a Those of ordinary skill in the art, after having read

practical matter are rarely necessary and generally con- the above discussion of the process of this invention,

sidered wasteful. will have no trouble applying it to other situations

Once the cleaning has been completed, to return the wherein shell and tube heat exchangers are used in hy

tube side of the heat exchanger to on-stream operation, 30 drocarbon processing.

assuming, for example, the heat exchanger E is a part The following Examples are offered by way of illus

of the crude preheat stream where the heavy aromatic tration of the practice of this invention and should not

solvent would not contaminate or harm the feed be construed as limiting the scope thereof. Many modi

stream; it is only necessary to open the inlet valve 12 fications and variations thereof will be obvious to one

with the bleed valve 16 being closed to allow the pro- 3 of ordinary skill in the art after studying the foregoing

cess fluid, 'crude in this case, to push the heavy aro- discussion and considering the following Examples.

matic solvent out through the exit valve 20 and thence - . ... -

into the process stream. Thus, it is seen from the fore- EXAMPLES 1-4

going description that the heat exchanger has been off

line only a very short period of time, as compared with 40 in the following Examples, the heat exchangers

prior art processes for such heat exchanger cleaning. It cleaned were in the crude preheat train of a refinery

has not even been necessary to discontinue the flow of with incoming crude on one side and hot product from

the material on the shell side of the exchanger. the crude fractionation tower on the other supplying

if it is desired to avoid pushing the solvent into the the heat to cook the solvent. The solvent used was a

process stream, once cleaning is completed, exit valve 45 heavy aromatic naphtha containing 98 wt. percent aro

20 can be closed and bleed valve 24 opened, along with matics and having a boiling range of 405°F to 690°F

inlet valve 12 and the solvent piped away to a remote and a Kauri-butanol value of 105. The inlet crude valve

location in the plant using proper safety precautions in was closed and the crude was displaced from the heat

view of the high temperatures generally involved and 50 exchanger by solvent pumped with a positive displace

the danger of fire which inheres in the handling of hy- ment pump through the inlet bleed valve on the side of

drocarbon materials at high temperatures and pres- the exchanger being cleaned. After a volume sufficient

SCS. : to fill the side of the exchanger being cleaned had been

The use of the method of this invention is adaptable pumped, the positive displacement pump was cut off

to process parameters involved in operating the partic- 55 and the inlet bleed valve was closed. The exit valve on

ular shell and tube heat exchanger involved and such the side of the exchanger being cleaned was left open

process parameters are not critical to the practice of and the heat exchanger was allowed to "float" on the

this invention, but should be kept in mind by the skilled open valve during the time of the cleaning. After the

engineer in order that proper safety precautions be fol- cleaning was complete, the inlet crude valve was

lowed at all times. 60 opened and the solvent, with removed carbonaceous

If desired, the above described cleaning process material, entered the crude stream through the exit

could be carried out by first taking the heat exchanger valve of the exchanger. The pertinent information con

E out of service by closing valves 12, 20, 28 and 36 to cerning the cleaning and the results thereof are set

stop flow of process material in the exchanger and open forth on Tablel below.

TABLE 1.

Heat Transfer Pressure increased

Side Volume Temp. Time, Coefficient Drop,' psi Throughput

Ex, Cleaned Gals. of hr. Before After Design. Before . After bbl/day

1 Tube 500 780 18 12.5 24.4 33 ' , 140 56 2,500

3,850,741

TABLE 1- Continued

Heat Transfer Pressure Increased

Side Volume Temp. Time, Coefficient Drop,' psi Throughput

Ex, Cleaned Gals. op hr. Before After Design. Before After bbl/day

2 Sheil 000 550 24 28.0 10 79 N/A N/A 6,000

3 Tube 750 350 18 25.5 63.6 75 N/A N/A 4,000

4 She 200 785 18 21.0 61.0 33 02 41 6,000

* - U = BTU/(hr)(ft.)(F) for side cleaned

- for side cleaned

- process side

It was estimated that as a result of the cleaning de b. heating the solvent being retained in one side of

scribed in Example a savings of $10,000.00 per the exchanger by passing a process stream through

month resulted from reduced fuel consumption in the the other side of the heat exchanger as in normal

crude oil furnace in the system. operation of the heat exchanger for a period of at

5 r

EXAMPLE 5 least about 8 hours to remove the carbonaceous

- fouling, and

Two exchangers in series in a crude preheat train c. displacing the solvent and removed fouling with

with hot product from the crude fractionation tower on the process stream.

the tube side and incoming crude on the shell side were 2.e The method of claim 1 wherein the solvent and re

cleaned with a solvent having 28 to 30 wt. percent aro 20

moved fouling are displaced into the process stream it

matic content, although it fit the proper boiling range. self.

The shell side of the exchangers were cleaned using the 3. The method of claim 1 wherein the flow of the pro

procedure described in Examples 1-4 for 24 hours. The cess stream on the side not being cleaned remains unin

first exchanger had a shell side heat exchange coeffi terrupted during step (a).

cient, U, of 16.5 before cleaning and 18.6 after clean 25

ing. The second exchanger had a U of 24.5 before 4. The method of claim 1 wherein the heat exchanger

cleaning and a U of 26.0 after cleaning. Tube side tem is taken out of service and cooled prior to step (a).

perature was 476F. The amount of cleaning was unsat 5. The method of claim 1 wherein the solvent in

isfactory. cludes about 10 volume percent of a chlorinated ben

ZCC.

A second cleaning of these two exchangers using the

same process for the same length of time was carried 6. The method of claim 5 wherein the solvent and re

out using the solvent described in Examples 1-4. This moved fouling displaced by the process stream is re

cleaning increased the U on the first exchanger to 32.8 moved from the process.

and the second exchanger to 34.4. Design U on the 7. The method of claim 1 wherein the solvent is a

first exchanger is 42.0 and on the second 44.0. The 35 heavy aromatic naphtha.

crude throughput increase was estimated at 8,000 8. The method of claim 7 wherein the solvent has an

bbl/day. aromatic content of from about 75 wt. percent to 98

wt. percent and a boiling range of from about 400°F

EXAMPLE 6 minimum initial boiling point to about 600°F minimum

In a crude preheat train of a refinery a heat ex- 40 end point and a Kauri-butanol value of from about 100

changer with the incoming crude on the shell side was to about 1 1 0.

cleaned in the manner described in Examples 1-4. The 9. The method of claim 8 wherein the cleaning was

solvent used was 10 percent by volume ortho continued for a period of from about 18 to about 24

dichlorobenzene and 90 percent by volume of the 45 hours.

heavy aromatic naphtha of Example l. The cleaning 10. A method for removing carbonaceous fouling on

took place for a period of 18 hours with a process side the side of a shell and tube heat exchanger carrying

temperature of 450°F. The volume of the shell side was crude oil in the crude preheat train of a petroleum re

1,200 gallons and the flow through said shell side was finery which comprises the steps of:

increased by 2,500 barrels per day after cleaning. The 50 a. displacing the crude in the heat exchanger with a

heat transfer coefficient, U, for the shell side before heavy aromatic naphtha solvent having an aro

cleaning was 24 and after cleaning 67 with a design matic content of from about 75 wt. percent to 98

heat transfer coefficient of 72. wt. percent a Kauri-butanol value of about 105 and

In view of the foregoing description, drawing and Ex a boiling range of from about 405°F to about 690°F

amples, one of ordinary skill in the art may make many without interrupting process flow on the other side

modifications and variations of the above-described in 55 of said heat exchanger;

vention without departing from the scope of the claims b. heating the heavy aromatic naphtha being retained

attached hereto.

We claim: on the crude oil side of the exchanger by passing

1. A method for removing carbonaceous fouling from the hot process stream through the other side of

shell and tube heat exchangers used in hydrocarbon 60 said exchanger as in normal operation of the heat

processes which comprise the steps of: exchanger for a period of from about 18 to about

a. displacing a process stream on one side of the heat 24 hours to remove the carbonaceous fouling; and

exchanger with a hydrocarbon solvent having at c. displacing the solvent and removed fouling by

least about 50 wt. percent aromatic content, a 65 flushing the solvent and removed fouling into the

Kauri-butanol value of at least about 90 and a mini crude stream flow with said crude oil.

1. The method of claim 10 wherein the exit valve of

mum initial boiling point of at least about 350°F the crude oil side remains open during heating of the

and an end point temperature of at least about solvent being retained therein.

500°F, and retaining said solvent in said one side of

the heat exchanger; - k k -k sk sk

You might also like

- Training Manual For CIL & Elution-Final (Reviewed)Document29 pagesTraining Manual For CIL & Elution-Final (Reviewed)mani_mett100% (5)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Aramco Standard List (Total)Document188 pagesAramco Standard List (Total)Norman Morales100% (5)

- Shell and Tube Heat ExchangersDocument5 pagesShell and Tube Heat ExchangersFinny Pratama PuteraNo ratings yet

- Patent US4203906Document9 pagesPatent US4203906Santiago BorgesNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2010/0243521 A1Document14 pagesPatent Application Publication (10) Pub. No.: US 2010/0243521 A1xyz7890No ratings yet

- United States Patent (19) : Primary Examiner-Herbcrt Levine (54) Main Column Separation of FCCDocument7 pagesUnited States Patent (19) : Primary Examiner-Herbcrt Levine (54) Main Column Separation of FCCDuy Thanh NguyễnNo ratings yet

- US5240619Document10 pagesUS5240619Baba DookNo ratings yet

- Phtalic Anhydride PatentDocument9 pagesPhtalic Anhydride PatentRiza Shinta RNo ratings yet

- CokeDocument6 pagesCokeDendy Wahyu RadityaNo ratings yet

- United States Patent (19) : PowellDocument8 pagesUnited States Patent (19) : PowellSpiros LicoudisNo ratings yet

- Temperature Control in A Fluidized Bed Reactor: F. D, HannDocument5 pagesTemperature Control in A Fluidized Bed Reactor: F. D, HannFi FiyundaNo ratings yet

- United States Patent 19: Dumain Et AlDocument10 pagesUnited States Patent 19: Dumain Et AlFi FiyundaNo ratings yet

- Us 4396789Document7 pagesUs 4396789Elias JúniorNo ratings yet

- Patente Cryoplus Linde Us4617039Document13 pagesPatente Cryoplus Linde Us4617039rubenpeNo ratings yet

- Us 4479925Document5 pagesUs 4479925Katherine Benavides VillenaNo ratings yet

- United States PatentDocument11 pagesUnited States Patentxyz7890No ratings yet

- United States Patent (19) : Teyssier Et Al. 11) 4,299,809Document5 pagesUnited States Patent (19) : Teyssier Et Al. 11) 4,299,809apriyansyahNo ratings yet

- Group 6Document30 pagesGroup 6Anwer ShifaNo ratings yet

- United States Patent 1191: Tu (45) Sep. 7, 1982Document4 pagesUnited States Patent 1191: Tu (45) Sep. 7, 1982AdyNo ratings yet

- Acl RecoveryDocument4 pagesAcl Recoveryannisa latifaNo ratings yet

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument3 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of Patentrianne nabilahNo ratings yet

- Heat Recorery S3'stem.s: I. WarrenDocument15 pagesHeat Recorery S3'stem.s: I. WarrenPhilip ShihNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument22 pagesShell and Tube Heat Exchanger Designsuperbugima100% (1)

- US5208393 - Patent Reduction CCl4Document7 pagesUS5208393 - Patent Reduction CCl4aldo BMCNo ratings yet

- Suspension Preheater 1998Document22 pagesSuspension Preheater 1998Sajal Gupta100% (2)

- Paten Produksi Syn GasDocument12 pagesPaten Produksi Syn GasFarras HaidaryNo ratings yet

- Effectiveness of Sootblowers in Boilers Thermal Power StationDocument7 pagesEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123No ratings yet

- Fractionation of PetroleumDocument25 pagesFractionation of PetroleumAnand kesanakurtiNo ratings yet

- United States Patent (19) (11) 3,835,199: Schwartz, Jr. Et AlDocument5 pagesUnited States Patent (19) (11) 3,835,199: Schwartz, Jr. Et AlandiNo ratings yet

- United States Patent (19) : Assistant Examiner-Arthur O. HendersonDocument7 pagesUnited States Patent (19) : Assistant Examiner-Arthur O. HendersonDylan WielfredNo ratings yet

- Paten Sintesis MetanolDocument5 pagesPaten Sintesis MetanolFarras HaidaryNo ratings yet

- US4232179Document10 pagesUS423217931415No ratings yet

- United States PatentDocument10 pagesUnited States PatentRuchita PoilkarNo ratings yet

- Us 4256783Document9 pagesUs 4256783Santiago BorgesNo ratings yet

- US3983180Document7 pagesUS3983180Agustina TriyaniNo ratings yet

- Selecting The Optimum Predistillation Scheme For Heavy Crude OilsDocument8 pagesSelecting The Optimum Predistillation Scheme For Heavy Crude OilsHoàng NhânNo ratings yet

- Us4521532 PDFDocument8 pagesUs4521532 PDFRushi GawadeNo ratings yet

- United States Patent 19) 11) Patent Number: 4,504,274: Anderson 45 Date of Patent: Mar. 12, 1985Document5 pagesUnited States Patent 19) 11) Patent Number: 4,504,274: Anderson 45 Date of Patent: Mar. 12, 1985Adi Gunawan PrasetiaNo ratings yet

- Production of Phosphoric Acid by Dry Kiln Process: Aram NasihDocument8 pagesProduction of Phosphoric Acid by Dry Kiln Process: Aram NasihAram Nasih MuhammadNo ratings yet

- Technical Spec BoilerDocument13 pagesTechnical Spec Boilermochamad RasjidNo ratings yet

- Process For Purification of HCL From Edc PyrolysisDocument6 pagesProcess For Purification of HCL From Edc Pyrolysisu2051721No ratings yet

- Vapour Absorption SystemDocument21 pagesVapour Absorption Systemoyetunde ridwanNo ratings yet

- Rethink Specifications For Fired HeatersDocument7 pagesRethink Specifications For Fired HeatersAhmed SeliemNo ratings yet

- III Iii Iihiiii: United States PatentDocument11 pagesIII Iii Iihiiii: United States Patentista fitriaNo ratings yet

- US7685820Document7 pagesUS7685820icylabchileNo ratings yet

- APV Evaporation HandbookDocument68 pagesAPV Evaporation HandbookМаксим ХилоNo ratings yet

- Ep 09015185 Nwa 1Document9 pagesEp 09015185 Nwa 1jdedfvNo ratings yet

- Upgrade Your Furnace For Clean FuelsDocument4 pagesUpgrade Your Furnace For Clean Fuelssagar1503No ratings yet

- Chemical and Mechanical DesignDocument460 pagesChemical and Mechanical DesignNuriman K-monNo ratings yet

- United States Patent (191: Briickner Et A1Document6 pagesUnited States Patent (191: Briickner Et A1PeterWangNo ratings yet

- US3906961Document7 pagesUS3906961Bayron Ospina MarinNo ratings yet

- US20140378725A1 - Chloride RemovalDocument10 pagesUS20140378725A1 - Chloride RemovalFrancisco CunhaNo ratings yet

- Report On NTPC Industrial Training at Barh (Patna)Document24 pagesReport On NTPC Industrial Training at Barh (Patna)Gautam KumarNo ratings yet

- Heat Exchanger 4Document9 pagesHeat Exchanger 4Karter KhelaNo ratings yet

- Waste Heat Recovery Technologies and Applications: ART-203 Group No:04Document17 pagesWaste Heat Recovery Technologies and Applications: ART-203 Group No:04Sazid ZamanNo ratings yet

- Helixchanger Heat ExchangersDocument7 pagesHelixchanger Heat ExchangersAnonymous QSfDsVxjZNo ratings yet

- Principles of Boiler OperationsDocument35 pagesPrinciples of Boiler Operationseblees100No ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Project Deliverable: ST THDocument46 pagesProject Deliverable: ST THGandhi YellapuNo ratings yet

- Simplified Equations For Saturated Steam PropertieDocument6 pagesSimplified Equations For Saturated Steam PropertieGandhi YellapuNo ratings yet

- Fosso KankeuandBriderDocument8 pagesFosso KankeuandBriderGandhi YellapuNo ratings yet

- MORE Final-Workshop LENZING-caseDocument20 pagesMORE Final-Workshop LENZING-caseGandhi YellapuNo ratings yet

- 2157-7048 1000255 PDFDocument7 pages2157-7048 1000255 PDFGandhi YellapuNo ratings yet

- MSFE CalculationsDocument5 pagesMSFE CalculationsGandhi YellapuNo ratings yet

- PHD Thesis Yashasvi Laxminarayan v2 January 2018 PDFDocument197 pagesPHD Thesis Yashasvi Laxminarayan v2 January 2018 PDFGandhi YellapuNo ratings yet

- Preparation of Resin by Rice Husk Treated With Phosphoric Acid For Removal of ZN From Industrial EffluentDocument5 pagesPreparation of Resin by Rice Husk Treated With Phosphoric Acid For Removal of ZN From Industrial EffluentGandhi YellapuNo ratings yet

- Predicting Ash Properties in Recovery Boilers: January 2010Document14 pagesPredicting Ash Properties in Recovery Boilers: January 2010Gandhi YellapuNo ratings yet

- Bjorn's Corner - Sustainable Air Transport. Part 18. Advanced Hydrogen Gas Turbines - Leeham News and AnalysisDocument5 pagesBjorn's Corner - Sustainable Air Transport. Part 18. Advanced Hydrogen Gas Turbines - Leeham News and AnalysisasfasdfsNo ratings yet

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of AmmoniaDocument12 pagesFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of AmmoniaZAHID HUSSAINNo ratings yet

- Sampling System For Dry Gas Sampling at Rotary Cement Kiln Gas Exit and Calciner Gas ExitDocument20 pagesSampling System For Dry Gas Sampling at Rotary Cement Kiln Gas Exit and Calciner Gas ExitgldiasNo ratings yet

- Practice Problems in Process Equipment DesignDocument19 pagesPractice Problems in Process Equipment DesignRasNo ratings yet

- KyotoCooling Co-Location Impact CPXDocument6 pagesKyotoCooling Co-Location Impact CPXChris FultonNo ratings yet

- Graphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977Document9 pagesGraphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977LeDzungNo ratings yet

- Full Chapter Proceedings of China Sae Congress 2019 Selected Papers China Society of Automotive Engineers PDFDocument53 pagesFull Chapter Proceedings of China Sae Congress 2019 Selected Papers China Society of Automotive Engineers PDFrobert.tardiff909100% (2)

- HVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerryDocument29 pagesHVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerrySuresh KumarNo ratings yet

- Data Book IIIDocument6 pagesData Book IIIDhanish KumarNo ratings yet

- Turmoil CatalogDocument37 pagesTurmoil CatalogChandru RsNo ratings yet

- Panouri SolareDocument52 pagesPanouri SolareValentin GargaritaNo ratings yet

- LNG 3.4.e Floating LNG Production19 19967Document12 pagesLNG 3.4.e Floating LNG Production19 19967Richard HollidayNo ratings yet

- Energy Optimization Study - WorkingDocument17 pagesEnergy Optimization Study - WorkingMufleh IdrisNo ratings yet

- Heat Exchanger ExperimentDocument11 pagesHeat Exchanger ExperimentDhevesh DomunNo ratings yet

- LNG Chain BookDocument106 pagesLNG Chain BookErick Royer Ponce PozoNo ratings yet

- Atlas Copco FD DryersDocument12 pagesAtlas Copco FD DryersSherif AdelNo ratings yet

- Engineering Standard FOR Piping & Instrumentation Diagrams (P & Ids) Original Edition OCT. 1996Document111 pagesEngineering Standard FOR Piping & Instrumentation Diagrams (P & Ids) Original Edition OCT. 1996Kalidass BackNo ratings yet

- Panel Operator-Govind Narayan KiradooDocument4 pagesPanel Operator-Govind Narayan KiradooDodiya NikunjNo ratings yet

- MIE1132H Problem Set 1Document2 pagesMIE1132H Problem Set 1csNo ratings yet

- SHEET4 AnswersDocument20 pagesSHEET4 AnswersHamadaMohassabNo ratings yet

- Chapter 3Document83 pagesChapter 3Biru EsheteNo ratings yet

- Hydro PDFDocument139 pagesHydro PDFVan Quynh100% (2)

- Pasturisation of JuiceDocument3 pagesPasturisation of JuiceAnilZapate0% (1)

- Feasibility (Manicsic)Document22 pagesFeasibility (Manicsic)Jocelyn CorpuzNo ratings yet

- 1.) 250 MW Oil Fired Power Station.: Price: US$ 27 Mill. "As It Is" OnlyDocument11 pages1.) 250 MW Oil Fired Power Station.: Price: US$ 27 Mill. "As It Is" OnlySalam SarkarNo ratings yet

- Nordtec ProposalDocument15 pagesNordtec Proposaluzair khan100% (1)

- 30XA Catalog-2Document30 pages30XA Catalog-2SLNo ratings yet