Professional Documents

Culture Documents

RD Cantelever Retaining Wall 3.0m

RD Cantelever Retaining Wall 3.0m

Uploaded by

ayan khanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RD Cantelever Retaining Wall 3.0m

RD Cantelever Retaining Wall 3.0m

Uploaded by

ayan khanCopyright:

Available Formats

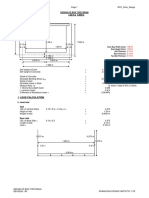

DESIGN OF CANTELEVER RETAINING WALL 3.

3m

INPUT DATAS RD

GRADE OF CONCRETE fck 25 N/mm2

GRADE OF STEEL f y 500 N/mm2 Soil Ws KN/Sqm θ Rg θ Mean µ β Fr bet soil & wall

Sand 17-20 25-35 30 0.55 29

ANGLE OF REPOSE OF SOIL θ 30 DEG Medium Clay 16-18 14-28 21 0.4 22

BULK DENSITY OF SOIL Ws 20 KN/m3 Soft Clay 15-17 4-16 10 0.33 18

SOIL SAFE BEARING CAPACITY SBC 100 KN/m2

ANGLE OF SURCHARGE OF FILL C 0 DEG

COEFFT OF FRICTION µ 0.5

COS C 1.000

COS θ 0.866

COEFFT OF ACTIVE PRESSURE Ka 0.334 0.334 Ka= Cos C((Cos C- Sqrt(Cos C^2-Cos θ^2))/(Cos C+ Sqrt(Cos C^2-Cos θ^2))) = ((1-SIN(θ))/(1+SIN(θ))^2

COEFFT OF PASSIVE PRESSURE Kp 2.998 1/ka

HEIGHT OF FILLING H 2.30 mtr

MIN DEPTH OF FDN h 0.56 mtr h=SBC/Ws*(1-sin θ /1+sin θ )^2

PROVIDE DEPTH OF FDN D h/4= 0.575 1.00 mtr 1.00 DEPTH=H/4 AND NOT LESS THAN MIN DEPTH/ 1.00Mtr DEPTH OF FDN

TOTAL HT OF WALL Ht=H+D 3.30 mtr Ht=H+DEPTH

CONST α 0.311 α= 1- q0/(2γH) α=TOE WIDTH/BASE WIDTH

Toe Length TL 0.80 mtr 0.80 αBm

Heel Length HL 0.55 mtr B- αBm-T1

CALCULATED BASE WIDTH B(MIN) Bm 1.65 mtr H*(Sqrt((1-sino/1+sino)/(1-k * (3*k+1)))*H Vaz Rat Page 437

PROVIDE BASE WIDTH B B 1.90 mtr 1.90 GENERALLY B=Ht/3 AND NOT LESS THAN B(MIN)

SURCHARGE ps ps 0.00 KN/m GIVE VALUE=0 IF THERE IS NO SURCHARGE

BASE SLAB THICK D(MIN) 280 220 mm 170 D=Ht/12 to Ht/20

PROVIDE BASE SLAB THICK D 450 mm 450 BASE SLAB THICKNESS

WALL THICK AT BOTTOM T(MIN) 330 275 mm 220 T=Ht/10 to H/15

PROVIDE WALL THICK AT BOTTOM T1 550 mm 550 WALL THICKNESS AT BOT

PROVIDE WALL THICK AT TOP T2 300 mm 300 Th at Top T2 = T1/2 WALL THICKNESS AT TOP

CHECK FOR BEARING PRESSURE

WT OF BASE SLAB/FOOTING W1 21.38 KN/m W1=B*D*25

WT OF STEM/ WALL RECTANGLE PART W2 21.38 KN/m W2=(T1)*(H-D)*25

WT OF STEM/ WALL TRIANGLE PART W3 8.91 KN/m W3=(T2-T1)/2*(H-D)*25

WT OF REAR SOIL OVER HEEL W4 31.35 KN/m W4=ALPHA*B*(Ht-D)*Ws+Ps*ALPHA*

WT/ AXIAL LOAD FROM COLUMN W5 0.00 KN/m AXIAL LOAD FROM COLUMN IN LINE WITH RETAING WALL

TOTAL STABILISING VERTICAL FORCE W 83.01 KN/m W=W1+W2+W3+W4

HORIZONTAL EARTH PRESSURE Ph 27.09 KN/m P1=Ka*Ws*Ht*Ht/2

HORIZONTAL SURCHARGE Ps 0.00 KN/m Ps=ps*Ht NAME FORCE LVR ARM MOM @ Toe

TOTAL HORIZONTAL PRESSURE V 27.09 KN/m W1 21.38 0.95 20.31

DISTANCE OF W1 FROM TOE FRONT TIP X1 X1 0.95 mtr X1=B/2 W2 21.38 0.95 20.31

DISTANCE OF W2 FROM TOE FRONT TIP X2 0.95 mtr ALPHA*B+T1/2 W3 8.91 0.97 8.68

DISTANCE OF W3 FROM TOE FRONT TIP X3 0.97 mtr ALPHA*B+T1+(T2-T1)/3 W4 31.35 2.07 64.92

DISTANCE OF W3 FROM TOE FRONT TIP X4 2.07 mtr X3=B-ALPHA*B/2 W5 0.00 0.95 0.00

DISTANCE OF W3 FROM TOE FRONT TIP X5 0.95 mtr W 83.01 1.38 114.21

HT OF HORT FORCE Y1 FROM TOE TOP Y1 0.95 mtr Y1=Ht/3 Ph 27.09 0.95 25.74

HT OF SUR FORCE Y2 FROM TOE TOP Y2 1.43 mtr Y2=Ht/2 Pv 0.00 1.43 0.00

DIST OF ΣVERT REACTION FROM TOE FRONT TIP 1.38 mtr W1*X1+W2*X2+W3*X3/(V ) V 27.09 0.95 25.74

CALCULATION OF PRESSURE R 87.32 1.01 88.47

REACTION OF FORCES 87.32 KN R=V*V+H*H

DIST OF REACTION FROM TOE X 1.01 m X=(W1*X1+W2*X2+W3*X3+Ph*Y1+Ps*Y2)/R

ECCENTRICITY e FROM CETRE OF BASE SLAB 0.06 m e=X-B/2 (- SIGN FOR RESULTANT FORCECHECK

AWAY TO Pmax < SBC

HEAL SIDE OF STEM SLAB)

PRESSURE AT TOE TIP Pmax 0 52.42 KN/m2 100 Pmax=W/B(1+6*e/B) CHECK Pmin>O

PRESSURE AT HEEL TIP Pmax 0 34.96 KN/m2 100 Pmin=W/B(1-6*e/B)

PRESSURE AT TOE FACE OF VER STEM 45.07 KN/m2 CHECK FOS>1.5

PRESSURE AT HEEL FACE OF VER STEM 40.01 KN/m2 CHECK FOS>1.5

FOS AGAINST OVERTURNING 5.65 SAFE FOS=(W1*X1+W2*X2+W3*X3)/(P*Y1+Ps*Y2)

FOS AGAINST SLIDING 1.53 SAFE FOS=u*W/(Ph+Ps)

NO SHEAR KEY REQUIRED

DESIGN OF SHEAR KEY

PERMISSIBLE SHEAR STRESS Tc 0.33 N/mm2 FROM IS 456 TABLE FOR M25= 0.29/MM2 FOR M30=0.29N/MM2

THICKNESS OFKEY 0 mm 0 THICKNESS OF KEY=(P+Ps)*1.5/Tc SHEAR KEY THICK

DEPTH OF KEY 0.00 m 0

KEY REINFORCEMENT 0 mm2

PROVIDE DIA OF STEEL BAR 12 mm

SPACING OF BARS 0 mm Max Shear Stress

CHECK FOR SLIDING Grade of Concrete M 25

Pp=Kp*P, Where Kp 3.00 Max SS N/Sqmm 3.1

PASSIVE EARTH PRESSURE Pp 119.96 KN/m2 fck 25

TOTAL PASSIVE FORCE Pf 0.00 KN Design Shear Strength

TOTAL SLIDING FORE Ph 36.32 KN 100 As/bd β SS N/Sqmm

Wt. Of Soil Between Base and shear

0 KN

key bottom level 0.20 14.51 0.331

ΣW 83 KN

FOS AGAINST SLIDING 1.14 SAFE

DESIGN OF BASE SLAB

DESIGN OF TOE SLAB

EFFECTIVE DEPTH OF TOE d 375 mm d=D-COVER

SPAN OF TOE L1 0.80 m L1=B-B2-T

WT OF FOOTING W4 11.25 KN/m W4=D*25

MAX BM AT BASE OF TOE Mt 18.00 KN-m Mt=(W4+Pmax)*L1*L1/2

SHEAR FORCE Vmax 23.90 KN V=(Pmax*(L1-d))*1.5

DESIGN OF TOE SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 500 As per IS 456 Pg.No.70

Base width 1.0 Mtr Max Depth of Nutral Axis

Max BM Mx 18.00 KN-M fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

BM = (Const*fck) bd^2 3.318 bd^2 250 0.53 d

Calculated Eff Depth of Slab 74 mm 364 415 0.48 d

Adopt Effective Depth d 370 mm 500 0.46 d

Use Dia of Slab rft 12 mm 550 0.44 d

Adopt Cover for Slab 75 mm Limiting Moment of resistance MR = Const * b*d^2 N mm

Over all Depth of Base Slab D 450 mm Const= 0.36*fck*Xm(1-0.42*Xm)

Width of Slab considered for Cal 1000 mm Steel

Grade of Concrete M 25 Concrete M Fe 250 Fe 415 Fe 500 Fe 550

Grade of Steel Fe 500 15 2.229 2.067 1.991 1.949

a= 0.87 *(fy^2/fck) 8700 20 2.972 2.755 2.655 2.598

b= -0.87 fy -435 25 3.715 3.444 3.318 3.248

c= m= Mu/(bd^2) 0.13 30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.13 0.030 113 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 629 Sqmm

Min Area of Steel 0.15 % (Temp Rft) 675 Sqmm

Max area of Tensile Steel = 0.04 bD 18000 Sqmm

Provide Area of Tension Steel 675 Sqmm

Area of One Bar 113.14 Sqmm 12 mm Dia

SBC

Spacing of Main Bars 160 mm 12 mm Dia 100

Min Area of Steel 0.12 % 540 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

675 Sqmm

Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm 12 mm Dia

Spacing of Distribution Bars 160 mm 12 mm Dia

DESIGN/ CHECK FOR TOE SLAB TO RESIST SHEAR

Grade of Concrete M 25 Max Shear Stress

Effective Depth 370 mm Grade of Concrete M 25

Over allDepth of Slab 450 mm Max SS N/Sqmm 3.1

Dia of Shear rft 12 mm fck 25

Area of One Bar 113.14 Sqmm Design Shear Strength

Spacing of Bars 160 mm 100 As bd β SS N/Sqmm

Max Shear Force wL/2 23.90 KN 0.19 15.19 0.324

Percentage of Tensile Steel 100At/2bd = 0.19 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.324 N/ Sqmm As per IS 456 Clause 40.2.1.1

Calculated k Value 1.00 Value of K

For 450 mm thick slab, k= 1.00 Ds >300 275 250 225 200

k 1.00 1.05 1.10 1.15 1.20

Permissible Max Shear Stress 0.324 N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

Nominal Shear stress Vu/bd 0.06 N/ Sqmm

Shear Check Safe

DESIGN OF HEELSLAB

SPAN OF HEEL L2 0.55 M HL

PRESSURE AT HEEL Wp 37.48 KN/m2 Wp=(P2+P4)/2

WT OF SOIL OVER HEEL W5 57.00 KN/m W5=Ws*(Ht-D)

WT OF HEEL W6 11.25 KN/m W6=25*D

MAX BM AT HEEL Mh 4.65 KN-m Mh=Wp+W5+W6)*L2*L2

SHEAR FORCE Vmax 8.31 KN V=(Pheel*(L2-d))*1.5

DESIGN OF HEEL SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 500

Base width 1.0 Mtr Max Depth of Nutral Axis

Max BM Mx 4.65 KN-M fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

BM = (Const*fck) bd^2 3.318 bd^2 250 0.53 d

Calculated Eff Depth of Slab 37 mm 364 415 0.48 d

Adopt Effective Depth d 370 mm 500 0.46 d

Use Dia of Slab rft 12 mm 550 0.44 d

Adopt Cover for Slab 70 mm Limiting Moment of resistance MR = Const * b*d^2 N mm

Over all Depth of Base Slab D 445 mm Const= 0.36*fck*Xm(1-0.42*Xm)

Width of Slab considered for Cal 1000 mm Steel

Grade of Concrete M 25 Concrete M Fe 250 Fe 415 Fe 500 Fe 550

Grade of Steel Fe 500 15 2.229 2.067 1.991 1.949

a= 0.87 *(fy^2/fck) 8700 20 2.972 2.755 2.655 2.598

b= -0.87 fy -435 25 3.715 3.444 3.318 3.248

c= m= Mu/(bd^2) 0.03 30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.03 0.008 29 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 629 Sqmm

Min Area of Steel 0.15 % (Temp Rft) 667.5 Sqmm

Max area of Tensile Steel = 0.04 bD 17800 Sqmm

Provide Area of Tension Steel 668 Sqmm

Area of One Bar 113.14 Sqmm 12 mm Dia

Spacing of Main Bars 160 mm 12 mm Dia

Min Area of Steel 0.12 % 534 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

667.5 Sqmm

Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm 12 mm Dia

Spacing of Distribution Bars 160 mm 12 mm Dia

DESIGN/ CHECK FOR HEEL SLAB TO RESIST SHEAR

Max Shear Stress

Grade of Concrete M 25 Grade of Concrete M 25

Effective Depth 370 mm Max SS N/Sqmm 3.1

Over allDepth of Slab 445 mm fck 25

Dia of Shear rft 12 mm Design Shear Strength

Area of One Bar 113.14 Sqmm 100 As bd β SS N/Sqmm

Spacing of Bars 160 mm 0.19 15.19 0.324

Max Shear Force wL/2 8.31 KN

Percentage of Tensile Steel 100At/2bd = 0.19 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.324 N/ Sqmm

Calculated k Value 1.00 Value of K

For 445 mm thick slab, k= 1.00 Ds >300 275 250 225 200

k 1.00 1.05 1.10 1.15 1.20

Permissible Max Shear Stress 0.324 N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

Nominal Shear stress Vu/bd 0.02 N/ Sqmm

Shear Check Safe

DESIGN OF STEM WALL

SPAN OF WALL L3 2.75 M L3=Ht-D

MAX BM AT BOTTOM OF WALL Mw 38.61 KN-m Mw=Ph* Ht/3+Ps*Ht/2

L3*L3+PsL3*L3/2

SHEAR FORCE Vmax 27.09 KN V=(Pheel*(L2-d))*1.5

DESIGN OF STEM WALL TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 500

Base width 1.0 Mtr Max Depth of Nutral Axis

Max BM Mx 38.61 KN-M fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

BM = (Const*fck) bd^2 3.318 bd^2 250 0.53 d

Calculated Eff Depth of Slab 108 mm 459 415 0.48 d

Adopt Effective Depth d 460 mm 500 0.46 d

Use Dia of Stem Wall rft 16 mm 550 0.44 d

Adopt Cover for Stem wall 75 mm Limiting Moment of resistance MR = Const * b*d^2 N mm

Over all Depth of Base Slab D 545 mm Const= 0.36*fck*Xm(1-0.42*Xm)

Width of Slab considered for Cal 1000 mm Steel

Grade of Concrete M 25 Concrete M Fe 250 Fe 415 Fe 500 Fe 550

Grade of Steel Fe 500 15 2.229 2.067 1.991 1.949

a= 0.87 *(fy^2/fck) 8700 20 2.972 2.755 2.655 2.598

b= -0.87 fy -435 25 3.715 3.444 3.318 3.248

c= m= Mu/(bd^2) 0.18 30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.18 0.042 195 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 782 Sqmm

Min Area of Steel 0.15 % (Temp Rft) 817.5 Sqmm

Max area of Tensile Steel = 0.04 bD 21800 Sqmm

Provide Area of Tension Steel 818 Sqmm

Area of One Bar 201.14 Sqmm 16 mm Dia

Spacing of Main Bars 240 mm 16 mm Dia

Min Area of Steel 0.12 % 654 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

817.5 Sqmm

Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm 16 mm Dia

Spacing of Distribution Bars 240 mm 16 mm Dia

CURTAILMENT REINFORCEMENT

DEPTH FROM TOP OF EMBANKMENT 1.65 Mtr

AREA OF REINFORCEMENT 408.75 Sqmm

Use Dia of Stem Wall rft 16 mm 20

Area of One Bar 201.14 Sqmm

Spacing of Distribution Bars 480 mm 16 mm Dia

DISTRIBUTION STEEL

DEPTH FROM TOP OF EMBANKMENT 1.65 Mtr

AREA OF REINFORCEMENT 817.5 Sqmm

Use Dia of Stem Wall rft 16 mm 16

Area of One Bar 201.14 Sqmm

Spacing of Distribution Bars 240 mm 16 mm Dia

DESIGN/ CHECK FOR STEM WALL TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 460 mm Max Shear Stress

Over allDepth of Slab 545 mm Grade of Concrete M 25

Dia of Shear rft 16 mm Max SS N/Sqmm 3.1

Area of One Bar 201.14 Sqmm fck 25

Spacing of Bars 240 mm Design Shear Strength

Max Shear Force wL/2 27.09 KN 100 As bd β SS N/Sqmm

0.18 15.93 0.317

Percentage of Tensile Steel 100At/2bd = 0.18 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.317 N/ Sqmm

Calculated k Value 1.00 Value of K

For 545 mm thick slab, k= 1.00 Ds >300 275 250 225 200

k 1.00 1.05 1.10 1.15 1.20

Permissible Max Shear Stress 0.317 N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

Nominal Shear stress Vu/bd 0.06 N/ Sqmm

Shear Check Safe

You might also like

- Code Examples For dsPIC30F4011Document28 pagesCode Examples For dsPIC30F4011Minh VuNo ratings yet

- Complete RCC Design Very ImportantDocument41 pagesComplete RCC Design Very ImportantAmal PremachandranNo ratings yet

- Retaining Wall DesignDocument120 pagesRetaining Wall DesignMohammed HanafiNo ratings yet

- Input Datas: N/mm2 N/mm2 DEG KN/m3 KN/m2 DEGDocument117 pagesInput Datas: N/mm2 N/mm2 DEG KN/m3 KN/m2 DEGradhi_rads89No ratings yet

- Retaining Wall 2Document124 pagesRetaining Wall 2shaikh ismailNo ratings yet

- Design of Budda Statue in EluruDocument13 pagesDesign of Budda Statue in EluruD.V.Srinivasa RaoNo ratings yet

- PCC Retaining Wall13!2!16Document3 pagesPCC Retaining Wall13!2!16kadaliNo ratings yet

- ESTIMATE Box 1Document26 pagesESTIMATE Box 1ankit hardahaNo ratings yet

- PCC Return WallDocument19 pagesPCC Return Wallneeta rautelaNo ratings yet

- BRIDGE - Construction of 6m Span of Single Vent Slab Culvert at SeelamuthaiyapuramDocument9 pagesBRIDGE - Construction of 6m Span of Single Vent Slab Culvert at SeelamuthaiyapuramDr. Balaji N CNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 10-Jul-2018 134 CHG - R68Document12 pagesSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 10-Jul-2018 134 CHG - R68Mahendra SuryavanshiNo ratings yet

- Cantiliver Retaing WallDocument14 pagesCantiliver Retaing WallMonjit GogoiNo ratings yet

- Design of CW Channel For Section 'A-A'Document30 pagesDesign of CW Channel For Section 'A-A'Hemant SonawadekarNo ratings yet

- BeamDocument4 pagesBeamAnkit SuriNo ratings yet

- 250kLD STP STR DesignDocument68 pages250kLD STP STR Designraghu kiranNo ratings yet

- Retaining WallDocument74 pagesRetaining WallNikhilNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- Abutment A1 On Counterfort Wall - 03.07.2020 1.04 PMDocument34 pagesAbutment A1 On Counterfort Wall - 03.07.2020 1.04 PMVikas KushwahaNo ratings yet

- 408010745-Rigid-Pavement-xls CopiedDocument17 pages408010745-Rigid-Pavement-xls CopiedrajNo ratings yet

- 0.3 - Design BasisDocument3 pages0.3 - Design BasisPowerhouse Shaft100% (1)

- Slab-Design-2 Way - ISDocument5 pagesSlab-Design-2 Way - ISKamran AliNo ratings yet

- Areva T& D India Limited: Design of Circular Sump Input DataDocument2 pagesAreva T& D India Limited: Design of Circular Sump Input DatajatinNo ratings yet

- Cantilever RCC WallDocument15 pagesCantilever RCC WallPraveen Kumar0% (1)

- VZM MC Portico Slope Slab DesignDocument204 pagesVZM MC Portico Slope Slab Designraghu kiranNo ratings yet

- 2F Floor (S4)Document6 pages2F Floor (S4)Zulkiflee TaugNo ratings yet

- Retaining Wall For Water PressureDocument9 pagesRetaining Wall For Water Pressuresudipta mandalNo ratings yet

- Thrust Block 12.5degDocument3 pagesThrust Block 12.5degbalu rNo ratings yet

- Brest Wall Stability DesignDocument3 pagesBrest Wall Stability DesignHarish Kumar MahavarNo ratings yet

- Setting PageDocument28 pagesSetting Pagevishnumani3011No ratings yet

- Cant - RW2 (With Surcharge)Document30 pagesCant - RW2 (With Surcharge)Bilal A BarbhuiyaNo ratings yet

- PCC Return Wall PDFDocument3 pagesPCC Return Wall PDFNavarun VashisthNo ratings yet

- Bar Bending Schedule (BBS) Project Name:-For A2 Abutment Cap at Br. No. 1282/1 (R1)Document6 pagesBar Bending Schedule (BBS) Project Name:-For A2 Abutment Cap at Br. No. 1282/1 (R1)sonuNo ratings yet

- RCC Retaining WallSDocument23 pagesRCC Retaining WallSTarunNo ratings yet

- One Way Simply Supported Slab: #Value!Document25 pagesOne Way Simply Supported Slab: #Value!Kanaiyalal N. ShethNo ratings yet

- CRW 13MRDocument25 pagesCRW 13MRraghu kiranNo ratings yet

- RCC Members Desgns Is456&Is3370Document25 pagesRCC Members Desgns Is456&Is3370RAJESHWARRAO BANDARI100% (1)

- Foundation 122 MT TransformerDocument1 pageFoundation 122 MT TransformervibishnanNo ratings yet

- RCC - Slab BeamDocument6 pagesRCC - Slab Beampatel nikunj rNo ratings yet

- Design of Two Cell Box StructureDocument15 pagesDesign of Two Cell Box StructureHarish Kumar MahavarNo ratings yet

- Combined FootingDocument15 pagesCombined FootingAnish NeupaneNo ratings yet

- NBC105-2020 Torsion Irregularity Check-2021!08!12Document2 pagesNBC105-2020 Torsion Irregularity Check-2021!08!12Prakash Singh RawalNo ratings yet

- 01-08-2022-RCC Drain Upto 2.0m HTDocument25 pages01-08-2022-RCC Drain Upto 2.0m HTamirNo ratings yet

- STUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and ThrustDocument9 pagesSTUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and Thrustraja mistry100% (1)

- Beam DesignA1-A2 1 ST FloorDocument25 pagesBeam DesignA1-A2 1 ST FloorIshwor PrajapatiNo ratings yet

- Column Design ExcelDocument4 pagesColumn Design Excelvimal patelNo ratings yet

- Retaining Wall Excel SheetDocument6 pagesRetaining Wall Excel SheetJohn Nixt100% (1)

- Counter Fort Retaining WallDocument12 pagesCounter Fort Retaining Wallharsh brarNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- Retaining-Walls Design RajghatDocument34 pagesRetaining-Walls Design RajghatRam Samujh SharmaNo ratings yet

- Design of Dog Legged Staircase: Name of Student Class/Division Batch WL WL Roll No. Input Data Value UnitDocument6 pagesDesign of Dog Legged Staircase: Name of Student Class/Division Batch WL WL Roll No. Input Data Value UnitSUDHIR GAYAKE100% (1)

- C.C Drain DesignDocument2 pagesC.C Drain DesignSeph RjyNo ratings yet

- RRM Gravity DamDocument12 pagesRRM Gravity DamLivian TeddyNo ratings yet

- Design-Pad-Chimney-Foundation-1 For Tower SUTETDocument42 pagesDesign-Pad-Chimney-Foundation-1 For Tower SUTETBonnico NicoNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Section Properties: Properties of Tata Structura (Circular Hollow Sections) YST 310 GradeDocument1 pageSection Properties: Properties of Tata Structura (Circular Hollow Sections) YST 310 GradeZankar R ParikhNo ratings yet

- Retaining Wall DesignDocument106 pagesRetaining Wall DesignHAITHAM ALINo ratings yet

- Retaining Wall DesignDocument5 pagesRetaining Wall DesignGsUpretiNo ratings yet

- Design of R.C.C. Retaining WallDocument5 pagesDesign of R.C.C. Retaining WallAmit KushwahaNo ratings yet

- Retaining Wall DesignDocument18 pagesRetaining Wall DesignSahinur RahamanNo ratings yet

- Isolated Footing BumaatDocument6 pagesIsolated Footing BumaatJaphet BumaatNo ratings yet

- Retaining Wall DesignDocument18 pagesRetaining Wall DesignGalih PutraNo ratings yet

- RIICOGrievance Inst 1212Document3 pagesRIICOGrievance Inst 1212ayan khanNo ratings yet

- Unit 2Document32 pagesUnit 2ayan khanNo ratings yet

- O.T.S. 9'-8"x4'-0": FAN FANDocument1 pageO.T.S. 9'-8"x4'-0": FAN FANayan khanNo ratings yet

- I.C. I.C.: Shower AreaDocument1 pageI.C. I.C.: Shower Areaayan khanNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor Planayan khanNo ratings yet

- SWM Final SORDocument153 pagesSWM Final SORayan khanNo ratings yet

- Janania - Estimate km0-12.240Document45 pagesJanania - Estimate km0-12.240ayan khanNo ratings yet

- Suwal Dam Estimate RWSLIPDocument19 pagesSuwal Dam Estimate RWSLIPayan khanNo ratings yet

- Typ PDFDocument1 pageTyp PDFayan khanNo ratings yet

- Ganda Nala Design PDFDocument1 pageGanda Nala Design PDFayan khanNo ratings yet

- Mathcad - Slopedfoot-Bearing-PressureDocument2 pagesMathcad - Slopedfoot-Bearing-Pressureayan khanNo ratings yet

- Final Design of DrainDocument17 pagesFinal Design of Drainayan khan0% (1)

- Deck Slab DesignDocument3 pagesDeck Slab Designayan khanNo ratings yet

- Trends 11 Syllabus 5&6Document8 pagesTrends 11 Syllabus 5&6Victor John DagalaNo ratings yet

- Gardening Is Beneficial For Health: A Meta-AnalysisDocument8 pagesGardening Is Beneficial For Health: A Meta-AnalysisHaritha DeviNo ratings yet

- Foreign Part A: Fire Suppression System S/N Description Unit Foam Proportioning Unit Vertical Bladder Type Ul ListedDocument6 pagesForeign Part A: Fire Suppression System S/N Description Unit Foam Proportioning Unit Vertical Bladder Type Ul ListedNakoraNo ratings yet

- EPP201 Pass Paper Revision Questions 1Document9 pagesEPP201 Pass Paper Revision Questions 1Boey Keen HuangNo ratings yet

- Canon BJC-3000 Printer: Error CodesDocument1 pageCanon BJC-3000 Printer: Error Codeseu mibNo ratings yet

- Eat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Document2 pagesEat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Miruna MocleașăNo ratings yet

- Sampling Distribution of Sample Means Using The Central Limit TheoremDocument6 pagesSampling Distribution of Sample Means Using The Central Limit TheoremGil Barry Nacario OrdoñezNo ratings yet

- EFI Installation Manual Rotax 4-1 Rev5Document26 pagesEFI Installation Manual Rotax 4-1 Rev5Esteban POPO ECHEVERRYNo ratings yet

- Drive Test Project - MobileDocument23 pagesDrive Test Project - MobileSuhana SabudinNo ratings yet

- 1976 - Susan Leigh Star - LeighDocument3 pages1976 - Susan Leigh Star - LeighEmailton Fonseca Dias100% (1)

- Adria Supersonic - Brochure 2024Document44 pagesAdria Supersonic - Brochure 2024paul.armstrong1971No ratings yet

- DermatomycosesDocument2 pagesDermatomycosesRay CullenNo ratings yet

- Internal Audit Checklist Food Safety-MRDocument5 pagesInternal Audit Checklist Food Safety-MRRavi BaghelNo ratings yet

- Swecs External 22072013 - Product - v1Document20 pagesSwecs External 22072013 - Product - v1Amir Asyraf SuhailiNo ratings yet

- Matanglawin: The Philippines Growing Plastic ProblemDocument8 pagesMatanglawin: The Philippines Growing Plastic ProblemChelsea Marie CastilloNo ratings yet

- Tvonics DTR Fp1600 User GuideDocument32 pagesTvonics DTR Fp1600 User Guidevince_thomas7654No ratings yet

- FM and TMDocument445 pagesFM and TMKrishna Singh100% (1)

- Sri VidyameditationDocument24 pagesSri VidyameditationClaudia ShanNo ratings yet

- Codigos de Diodos Zener PDFDocument6 pagesCodigos de Diodos Zener PDFEduardo Perez100% (1)

- Grade 6 MathDocument12 pagesGrade 6 Mathapi-264682510No ratings yet

- Revision For Grade 11 Students I. Choose A, B, C or D That Best Fits Each Blank in The SentencesDocument10 pagesRevision For Grade 11 Students I. Choose A, B, C or D That Best Fits Each Blank in The SentencesPhương Nguyễn0% (2)

- ProjectDocument76 pagesProjectMohammed GaberNo ratings yet

- Equine Facilitated TherapyDocument100 pagesEquine Facilitated TherapyBasil Donovan Fletcher100% (1)

- Magb1 User Guide v1.1 EngDocument51 pagesMagb1 User Guide v1.1 EngPsu ChandasiriNo ratings yet

- Staining Techniques in Biological StudiesDocument52 pagesStaining Techniques in Biological StudiesRamyaAbhishekShenoyNo ratings yet

- NCR 7403 Uzivatelska PriruckaDocument149 pagesNCR 7403 Uzivatelska Priruckadukindonutz123No ratings yet

- A7D/A7DP: Ultra-Small, Low-Cost, Push-Operated SwitchesDocument5 pagesA7D/A7DP: Ultra-Small, Low-Cost, Push-Operated SwitchesHerbitus DuininhoNo ratings yet

- Model Based Control Design: Alf IsakssonDocument17 pagesModel Based Control Design: Alf IsakssonSertug BaşarNo ratings yet

- Spectrophotometer UseDocument4 pagesSpectrophotometer UseEsperanza Fernández MuñozNo ratings yet