Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsUS4021497

US4021497

Uploaded by

عبداللە عمر ابراهیمchem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- کتێبی فێربونی مایکرۆسۆفت ئێکسڵ .Document105 pagesکتێبی فێربونی مایکرۆسۆفت ئێکسڵ .عبداللە عمر ابراهیمNo ratings yet

- Chapter One Polynomials: 1-1 Introduction Definition 1.1: A Monomial in Variable X Is An Expression of The Form C XDocument28 pagesChapter One Polynomials: 1-1 Introduction Definition 1.1: A Monomial in Variable X Is An Expression of The Form C Xعبداللە عمر ابراهیمNo ratings yet

- Acetic Acid: Biosynthesis and Fermentation Process - Industries - BiotechnologyDocument7 pagesAcetic Acid: Biosynthesis and Fermentation Process - Industries - Biotechnologyعبداللە عمر ابراهیمNo ratings yet

- Membrane FiltrationDocument16 pagesMembrane Filtrationعبداللە عمر ابراهیمNo ratings yet

- Product Stewardship Summary: Ethylhexanol-2Document7 pagesProduct Stewardship Summary: Ethylhexanol-2عبداللە عمر ابراهیمNo ratings yet

- Sheet No. 1 (2017-2018) : Q1) Solve The Following Using Laplace TransformsDocument1 pageSheet No. 1 (2017-2018) : Q1) Solve The Following Using Laplace Transformsعبداللە عمر ابراهیمNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 2%Document7 pagesPlagiarism Checker X Originality Report: Similarity Found: 2%عبداللە عمر ابراهیمNo ratings yet

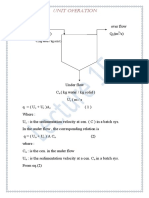

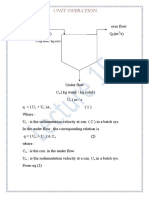

- Unit Operation: (KG Water / KG Solid)Document4 pagesUnit Operation: (KG Water / KG Solid)عبداللە عمر ابراهیمNo ratings yet

- PCX - Report - PDF HunarDocument8 pagesPCX - Report - PDF Hunarعبداللە عمر ابراهیمNo ratings yet

- Sheet NO.3Document12 pagesSheet NO.3عبداللە عمر ابراهیمNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 51%Document6 pagesPlagiarism Checker X Originality Report: Similarity Found: 51%عبداللە عمر ابراهیمNo ratings yet

- Chemical Reaction Engineering (CRE) Is TheDocument46 pagesChemical Reaction Engineering (CRE) Is Theعبداللە عمر ابراهیمNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- Equipment of Settling and Sedimentation: Unit OperationDocument3 pagesEquipment of Settling and Sedimentation: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- Unit Operation: (KG Water / KG Solid)Document4 pagesUnit Operation: (KG Water / KG Solid)عبداللە عمر ابراهیمNo ratings yet

US4021497

US4021497

Uploaded by

عبداللە عمر ابراهیم0 ratings0% found this document useful (0 votes)

8 views4 pageschem

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentchem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views4 pagesUS4021497

US4021497

Uploaded by

عبداللە عمر ابراهیمchem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

United States Patent 1

Adam et al.

an 4,021,497

145) May 3, 1977

[54] PRODUCTION OF 2-ETHYLHEXANOL-(1)

BY HYDROGENATION OF

2-ETHYLHEXEN-(2)-AL-(1)

[75] Inventors: Karl Adam, Ludwigshafen; Erich

Haarer, Bad Durkheim, both of

Germany

(73) Assignee: Badische Anilin- & Soda-Fabrik

Aktiengeselischaft, Ludwigshafen

(Rhine), Germany

(22) Filed: May 30, 1972

[21] Appl. No.: 257,536

Related U.S. Application Data

[63] Continuation-in-part of Ser. No. 860,435, Sept. 23,

1969, abandoned, which is a continuation-in-part of

Ser. No. 647,204, June 19, 1967, abandoned.

[30] Foreign Application Priority Data

June 25, 1966 Germany 1269605

[52] US.CL 260/638 B; 252/437

(51) Int. cht COTE 29/14

[58] Fleld of Search .. 260/638 B

(56) References Cited

UNITED STATES PATENTS

2,750,429 6/1956 DeNora etal. 26016384

2,753,366 7/1956 Pistor 260/638 A

3,125,605 3/1964 Buchner eta 260/638. A

3,260,683 7/1966 Endler 260/638 A

3,478,112 11/1969 Adam et a 2601638 A

FOREIGN PATENTS OR APPLICATIONS

1,269,605 6/1968 Germany 260/638 B

Primary Examiner—Joseph E. Evans

Attorney, Agent, or Firm—Johnston, Keil, Thompson &

Shurtleff

(37) ABSTRACT

‘An improved process for the production of 2-ethylhex-

anol-{1) which comprises. contacting. 2-ethylhexen-

(2)-al-(1) in an inert solvent with hydrogen at pres-

sures of 1 to 500 atmospheres gauge and at tempera-

tures of 80° to 200° C in the presence of a hydrogena-

tion catalyst consisting essentially of cobalt and/or

nickel and of copper and manganese and 0.5 to 15% by

weight calculated as phosphorus pentoxide and based

‘on the metal content of said catalyst exclusive of sup-

port of pyrophosphoric acid or polyphosphoric acid in

free form and/or in the form of at least one salt of said

metals. The alcohol produced is used as a solvent or for

the production of plasticizers for polyvinyl chloride.

3 Claims, No Drawings

4,021,

1

PRODUCTION OF 2-ETHYLHEXANOL-(1) BY

HYDROGENATION OF

2-ETHYLHEXEN-(2)-AL-(1)

‘This application is a continuation-in-part of applica- s

tion Ser. No. 860,435, filed Sept. 23, 1969, now aban-

doned, the latter being a continuation-in-part of appli-

cation Ser. No. 647,204, filed June 19, 1967, also now

abandoned.

‘This invention relates to a process for the production

of saturated alcohols by hydrogenation of aldehydes in

the presence of catalysts which in addition to nickel

and/or cobalt contain copper and manganese.

‘The catalytic hydrogenation of aldehydes or ketones

to form saturated alcohols under various conditions of

pressure and temperature has been known for a long

time. The catalysts used are the metals of groups I 10

VIll of the Periodic System and mixtures of the same

conventionally used for hydrogenation, if desired with

an addition of other catalysts, such as metal oxides,

silicates or phosphates. The catalysts may be used ei-

ther supported or unsupported and the hydrogenation

‘may be carried out in the absence or presence of inert

diluents. A process for the hydrogenation of carbonyl

compounds is described in US. Pat. No. 2,983,734 in

which Raney nickel containing 0.5 to 3% by weight of

chromium is used. It is moreover known from German

Printed Application No. 1,003,702 that aldehydes can

bbe hydrogenated in two stages with catalysts which

contain 5 to 30% by weight of copper, 3 to 20% by

‘weight of nickel and 0 to 5% by weight of chromium

oxide. In another process, described in German Printed

Application No. 1,115,232, aldehydes are hydroge-

nated in two stages in the presence of catalysts contain-

ing nickel and cobalt and which have a nickel content

of preferably less than 15%. Methods are also known

from British patent specifications Nos. 938,028 and

906,527 in which copper catalysts and nickel catalysts

are Used in separate beds in the hydrogenation of alde-

hnydes. According to another method described in Brit

ish patent specification No. 907,166 the first catalyst

bbed consists of a copper catalyst and the second cata-

lyst bed consists of a copper-nickel catalyst, the ratio of

‘copper to nickel being from 5: 1 to 20: 1. The alcohols

prepared by the abovementioned methods do not sat-

isfy requirements as regards purity. Owing to the rapid

decrease in activity of the catalysts, the hydrogenation

proceeds only incompletely so that non-hydrogenated

‘compounds and other impurities remain in the product

and these cannot be completely removed by distilla-

tion. The impurities cause the alcohols to discolor dur-

ing further use, for example for esterification.

It is an object of this invention to provide an im-

proved process in which 2-ethylhexanol-(1) is obtained

0 pure that it does not discolor in further processing. It

is another object of the invention to provide a process

in which the catalysts used have a long life while retain-

ing a constant high activity. Iti further an object of the

invention to provide a process in which high space-time

yields are achieved.

‘These and other objects are achieved in accordance

with this invention by contacting 2-ethylhexen-(2)-al-

(J) in an inert solvent with hydrogen at superatmos-

pheric pressure and elevated temperature in the pres-

fence of hydrogenation catalysts in a process which

‘comprises the improvement of using hydrogenation

catalysts consisting essentially of nickel and/or cobalt,

and of copper and manganese and 0.5 to 15% by

20

2s

20

35

40

45

50

ss

60

6s

497

2

‘weight, calculated as phosphorus pentoxide and based

on the metal content of said catalyst exclusive of sup-

port, of pyrophosphoric or polyphosphoric acid in free

form and/or in the form of at least one salt of said

metals

‘The hydrogenation is carried out at pressures of from

1 to 500 atmospheres gauge, preferably at pressures of

from 200 to 400 atmospheres gauge. Temperatures of

80° to 200° C are advantageously used. Particularly

good results are achieved by using temperatures of

from 100? to 180° C.

Its advantageous to carry out the hydrogenation in

the presence of an inert solvent, Suitable solvents are

media which are inert under the reaction conditions,

such as hydrocarbons, for example cyclohexane; ot

alcohols, such as ethanol and propanol. It is particu-

larly advantageous to use as the diluent the 2-ethylhex-

anol-(1) formed in the hydrogenation.

‘The hydrogenation catalysts consist essentially of

nickel and/or cobalt and copper and manganese and

0.5 to 15%, preferably 1 to 10% by weight, calculated

as phosphorus pentoxide and based on the metal con-

tent of said catalyst exclusive of support, of pyrophos-

phoric or polyphosphoric acid in free form and/or in

the form of at least one salt of said metals. The catalysts

‘may also contain small amounts of activators such as

chromium, silver, palladium or ruthenium. All percent-

ages relate to the content of the individual components,

determined analytically in the finished catalysts, the

metals being given as such and the pyrophosphoric

acids or polyphosphoric acid or their salts being given

as anhydrides, ic. independently of the actual state of

‘combination. The catalysts may be used unsupported.

In this case the individual components of the catalyst

are mixed in the form of compounds which can be

reduced with hydrogen at elevated temperatures, such

as the oxides, hydroxides, oxalates, ammoniates or

formates, with an addition of the stated amounts of the

said acids which change upon heating into theit pyro or

poly form, heated, preferably to 300° to 700° C, and

then reduced with hytrogen, advantageously at 200° to

350° C. In a preferred method of preparing the cata-

ists, the metals and acids are coprecipitated from a

solution with sodium carbonate and the precipitate is

heated, for example in a muffle furnace, at about 300°

to 700° C. The mixture is ‘and press-molded

into tablets or pellets and then reduced with hydrogen

at clevated temperature. It is also possible to apply the

‘metal salts and the acids to a carrier, such as fuller's

earth, silicic acid, silica gel, aluminum oxide or sil

cates, to heat them, for example in a muffle furnace, to

about 300° to 700° C and then to reduce them with

hydrogen as described. It has proved to be particularly

advantageous to effect precipitation of the metal com-

ponents and the acids onto a powdered carrier, of to

effect coprecipitation with the carrier from a solution,

for example with sodium carbonate, to heat the precipi

tate at about 300° to 700° C for example in a muffle

furnace and then to reduce it with hydrogen as de-

scribed.

‘The according to the invention may for ex-

ample be carried out by forcing hydrogen to the point

of saturation in a high pressure container into the alde-

hyde to be reduced in the presence of a catalyst of the

said composition at the said temperature and pressure

conditions. On a commercial scale the process is ad

vantageously carried out continuously by charging a

vertical high pressure tube with the catalyst, metering

4,021,497

3

in aldehyde at the top and supplying hydrogen counter-

‘current or cocurrent under the stated conditions at the

same time. In a particularly advantageous continuous

method, the aldehyde is fed into the top of the high

pressure tube with abouut 0.5 to 10 times the amount,

preferably once to five times the amount, of hydroge-

nated product, with reference to the aldehyde used. A

crude alcohol is obtained which is distinguished by a

particularly low consumption of bromine solution, The

crude alcohol is then fractionally distilled for purifica-

tion. The distilled alcohols give particularly slight dis-

colorations in a discoloration test which is carried out

by heating with concentrated sulfuric acid and photo-

metric comparison of the mixture with water which has

been distilled twice.

‘The 2-cthylhexanol-(1) prepared by the process ac-

cording to the invention is suitable asa solvent and for

the production of plasticizers for plastics (cf. Ullmanns

Encyclopadie der technischen Chemie (1900), volume

12, pages 30 to 32).

‘The invention is illustrated by the following Exam-

ples in which parts are by weight unless stated other-

wise; parts by weight bear the same relation to parts by

volume as the kilogram to the liter.

EXAMPLE |

A solution of 5,640 parts of aluminum nitrate, 838

parts of nickel nitrate (6 molecules of water of crystalli-

zation), 189 parts of copper nitrate (3 molecules of

water of crystallization), 36.5 parts of manganese ni-

trate (6 molecules of water of crystallization) and 7.1

parts of 85% by weight phosphoric acid in 20,000 parts

by volume of water at 50° C is allowed to flow while

stirring into a solution of 3,150 parts of anhydrous

sodium carbonate in 15,000 parts by volume of water.

‘The precipitate is filtered off by suction and washed as

free as possible from sodium ions with water. The

‘washed filter cake is dried at 110° C and then heated to

300° C. The product is powdered and moulded into

pellets having a diameter of 4 mm. The pellets are

charged into a vertical high pressure tube having a

capacity of 1,700 parts by volume and reduced with

hydrogen at 270° C. The finished catalyst contains

nickel, copper and manganese in the ratio by weight of

17.0: :0.7 and 1.2% by weight of phosphorus pentox-

ide with reference to nickel, copper and manganese.

345 parts by volume of 2-ethylhexen-(2)-al-(1) and

560 parts by volume of crude-2-ethylhexanol-(1) dis-

charged from the high pressure tube are fed per hour at

160° Cand under a pressure of 300 atmospheres gauge

of hydrogen to the top of the high pressure tube. To

remove heat, the hydrogen is recycled through a heat

exchanger. 916 parts by volume per hour of crude

2-ethylhexanol-(1) is obtained which according to gas

chromatographic analysis has a purity of 97.5% by

weight. The yield is 99.5% of the theory with reference

to 98% by weight 2-ethylhexen-(2)-al-(1). 100 g of the

undistilled alcohol uses up 0.8 mi of N/I bromine solu-

tion. The aldehyde content is 0.01% by weight. The

crude 2-ethylhexanol-(1) is then fractionally distilled

and the following test is carried out to determine the

discoloration:

98 g of distilled 2-ethylhexanol-(1) is mixed with 7 ml

of concentrated sulfuric acid and heated for 1 hour at

95° to 100° C while stirring, and then allowed to cool.

‘The discoloration is measured against twice distilled

water in a Zeiss Elko-Il photometer. A photometric

15

20

2s

35

6s

4

value of 99.5 is obtained, double distilled water giving.

a value of 100.

EXAMPLE 2

‘A solution of 3,500 parts of cobalt nitrate’ (6H.0),

769 parts of copper nitrate (31,0), 262 paris of man-

ganese nitrate (6H,O) and 47 parts of 85% by weight

phosphoric acid in 8,000 parts of water is allowed to

flow into a solution of 1,700 parts of anhydrous sodium

carbonate in 8,000 parts by volume of water. The pre-

Cipitate is worked up as described in Example 1. The

finished catalyst contains cobalt, copper and manga-

nese in the ratio 71 : 20.0 : 5.0 and 2.9% by weight of

phosphorus pentoxide with reference to cobalt, manga-

nese and copper.

345 parts by volume of 2-ethylhexen-2-al(1) and

860 parts by volume of crude 2-ethylhexanol-(1) are

supplied at 160° C per hour under a hydrogen pressure

of 300 atmospheres gauge to the top of the high pres-

sure tube described in Example 1 which is filled with

the above catalyst. The hydrogen is recycled as in Ex-

ample 1. 1,216 parts by volume of the crude 2-ethyl-

hexanol-(1) is obtained per hour; according to gas

chromatographic analysis it is 96.0% by weight pure.

‘The yield is 97.7% with reference to 98.2% by weight

2-ethylhexen-2-al-(1). 100 g of the crude 2-ethylhex-

anol uses up 0.6 ml N/1 bromine solution. The distilled

2ethylhexanol-(1) has a photometric value of 99.0

after a discoloration test with sulfuric acid.

EXAMPLE 3

A solution of 864 parts of cobalt nitrate (6H,O), 227

parts of copper nitrate (31,0), 46.6 parts of manga-

nese nitrate (6H,O) and 7 parts of 85% by weight phos-

phoric acid in 4,000 parts of water is allowed to flow

while stirring at 40° C into a solution of 440 parts of

anhydrous sodium carbonate in 4,000 parts by volume

of water in which 812 parts of aluminum oxide is sus-

pended. Working up is carried out asin Example 1. The

finished catalyst contains cobalt : copper :

in the ratio by weight 17.5 : 6 : 0.7 and 1.8% by

of phosphonis pentoxide with reference to cobalt and

manganese.

2.ethylhexen-2-al-(1) is hydrogenated under the con-

ditions given in Example 2. 1,216 parts by volume per

hour of 2-ethylhexanol-(1) is obtained which after gas

chromatographic analysis is 96.7% by weight pure. The

yield is 98.5%. 100 g of crude 2-ethylhexanal-(1) con-

‘umes 0.8 ml of N/I bromine solution. After distilla-

tion, the 2-ethylhexanol gives a photometric value of

99.0 in the discoloration test with sulfuric acid

EXAMPLE 4

‘A solution of 502 parts of nickel nitrate (6H,O), 345,

parts of cobalt nitrate (6H,0), 228 parts of copper

nitrate (3H,O), 36.6 parts of manganese nitrate

(6H,O) and 7.0 parts of 85% by weight phosphoric acid

in 4,000 parts by volume of water is allowed to flow at

40° C while stirring into a suspension of 812 parts of

aluminum oxide ina solution of 440 parts of anhydrous

sodium carbonate in 4,000 parts by volume of water.

‘The product is worked up as in Example 1. The finished

catalyst contains nickel, cobalt, copper and manganese

in the ratio by weight 10 : 7: 4 : 0.6 and 1.85% by

weight of phosphorus pentoxide with reference to co-

balt, nickel and manganese.

2ethylhexen-2-al(1) is reduced under the same

conditions as in Example 2. 1,216 parts by volume of

4,021,497

5

crude 2-ethythexanol-(1) is obtained per hour; accord-

ing to gas chromatographic analysis it is 97.0% by

‘weight pure. The yield is 98.9% of the theory. 100 g of

the crude 2-ethylhexanol-(1) consumes 0.8 ml of N/T

bromine solution. The pure 2-ethylhexanol-(1), after

distillation, has a photometric value of 99.0 in a discol-

oration test with sulfuric acid.

Expressed.on a weight percentage basis, the metal

content of the catalysts used in the foregoing examples

is:

Bample

1 149%

29%

ne

220%

dose

tes

3s

2 52s

3 ° on

‘ 463% 235,

‘The copper content ranges from 18.59% to 24.8% and.

the manganese content ranges from 2.8 to 5.2%, with

the remainder of the total of 100% being nickel and/or

cobalt.

We claim:

1, A process for the production of 2-ethylhexanol-(1)

which comprises contacting with hydrogen 2-ethylhex-

en-(2)-al-(1) dissolved in 2-ethythexanol-(1) as the

inert solvent at a pressure of 1 to 500 atmospheres

gauge and a temperature of 80° to 200° C, in the pres-

‘ence of a hydrogenation catalyst consisting essentially

of cobalt, copper and manganese wherein, based on

said metals, the cobalt content is 72.3% to 73.9%, the

‘copper content is 20.9% to 24.8% and the manganese

10

2s

30

3s

40

45

so

35

60

6s

6

content is 2.9% to 5.2% and 0.5 to 15% by weight,

calculated as phosphorus pentoxide and based on the

‘metal content of said catalyst exclusive of support, of

pyrophosphoric acid or polyphosphoric acid in free

form or partly or wholly in the form of at least one salt

of said metals.

2. A process for the production of 2-ethylhexanol-(1)

which cor contacting with hydrogen 2-ethylhex-

en-(2)-al-(1) dissolved in 2-ethylhexanol-(1) a5 the

inert solvent at a pressure of 1 to 500 atmospheres

gauge and a temperature of 80° to 200° C, in the pres-

ence of a hydrogenation catalyst consisting essentially

of nickel, copper and m: at respective weight

percentages, sed on said metals, of 74.9%, 22.0%

and 3.1%, and 0.5 to 15% by weight, calculated as,

phosphorus pentoxide and based on the metal content

Of said catalyst exclusive of support, of pyrophosphoric

acid or polyphosphoric acid in free form or partly or

‘wholly in the form of at least one salt of said metals.

3. A process for the production of 2-ethylhexanol-(1)

which comprises contacting with hydrogen 2-ethylhex-

en-(2)-al-(1) dissolved in 2-ethylhexanol-(1) as the

inert:solvent at a pressure of 1 to 500 atmospheres

‘gauge and a temperature of 80° to 200° C, in the pres-

ence of a hydrogenation catalyst consisting essentially

of nickel, cobalt, copper and manganese in respective

‘weight percentages, based on said metals, of 46.3%

32.4%, 18.5% and 2.8%, and 0.5 to 15% by weight,

calculated as phosphorus pentoxide and based on the

metal content of said catalyst exclusive of support, of

pyrophosphoric acid or polyphosphoric acid in free

form or partly or wholly in the form of at least one salt

of said metals.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- کتێبی فێربونی مایکرۆسۆفت ئێکسڵ .Document105 pagesکتێبی فێربونی مایکرۆسۆفت ئێکسڵ .عبداللە عمر ابراهیمNo ratings yet

- Chapter One Polynomials: 1-1 Introduction Definition 1.1: A Monomial in Variable X Is An Expression of The Form C XDocument28 pagesChapter One Polynomials: 1-1 Introduction Definition 1.1: A Monomial in Variable X Is An Expression of The Form C Xعبداللە عمر ابراهیمNo ratings yet

- Acetic Acid: Biosynthesis and Fermentation Process - Industries - BiotechnologyDocument7 pagesAcetic Acid: Biosynthesis and Fermentation Process - Industries - Biotechnologyعبداللە عمر ابراهیمNo ratings yet

- Membrane FiltrationDocument16 pagesMembrane Filtrationعبداللە عمر ابراهیمNo ratings yet

- Product Stewardship Summary: Ethylhexanol-2Document7 pagesProduct Stewardship Summary: Ethylhexanol-2عبداللە عمر ابراهیمNo ratings yet

- Sheet No. 1 (2017-2018) : Q1) Solve The Following Using Laplace TransformsDocument1 pageSheet No. 1 (2017-2018) : Q1) Solve The Following Using Laplace Transformsعبداللە عمر ابراهیمNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 2%Document7 pagesPlagiarism Checker X Originality Report: Similarity Found: 2%عبداللە عمر ابراهیمNo ratings yet

- Unit Operation: (KG Water / KG Solid)Document4 pagesUnit Operation: (KG Water / KG Solid)عبداللە عمر ابراهیمNo ratings yet

- PCX - Report - PDF HunarDocument8 pagesPCX - Report - PDF Hunarعبداللە عمر ابراهیمNo ratings yet

- Sheet NO.3Document12 pagesSheet NO.3عبداللە عمر ابراهیمNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 51%Document6 pagesPlagiarism Checker X Originality Report: Similarity Found: 51%عبداللە عمر ابراهیمNo ratings yet

- Chemical Reaction Engineering (CRE) Is TheDocument46 pagesChemical Reaction Engineering (CRE) Is Theعبداللە عمر ابراهیمNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- Equipment of Settling and Sedimentation: Unit OperationDocument3 pagesEquipment of Settling and Sedimentation: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- Unit Operation: (KG Water / KG Solid)Document4 pagesUnit Operation: (KG Water / KG Solid)عبداللە عمر ابراهیمNo ratings yet