Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

44 viewsTURBINE COLD START-UP 600 MW - Indicator

TURBINE COLD START-UP 600 MW - Indicator

Uploaded by

Ade Y Saputra600mw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2MLD09-0100-01664365 B: ClientDocument1 page2MLD09-0100-01664365 B: ClientAde Y SaputraNo ratings yet

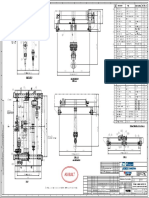

- SEMA AH Hook Block Assly. Sheet 2 3Document1 pageSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraNo ratings yet

- Section:A-A': Typical Power JointDocument1 pageSection:A-A': Typical Power JointAde Y SaputraNo ratings yet

- SEMA MH Hook Block Assly. Sheet 1 3Document1 pageSEMA MH Hook Block Assly. Sheet 1 3Ade Y SaputraNo ratings yet

- Paper Title (Use Style - Paper Title)Document6 pagesPaper Title (Use Style - Paper Title)Ade Y SaputraNo ratings yet

- Cable Sizing and Schedule-R - 02 - (As BUILT)Document6 pagesCable Sizing and Schedule-R - 02 - (As BUILT)Ade Y SaputraNo ratings yet

- Fuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Document18 pagesFuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Ade Y SaputraNo ratings yet

- 3147 Hoist r3Document1 page3147 Hoist r3Ade Y SaputraNo ratings yet

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDocument5 pagesJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraNo ratings yet

- Star - DeltaDocument4 pagesStar - DeltaAde Y SaputraNo ratings yet

- Acsr SPLN 41-7 PDFDocument2 pagesAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- Variable Frequency DriveDocument40 pagesVariable Frequency DriveAde Y Saputra100% (1)

- Tipe NGRDocument4 pagesTipe NGRAde Y SaputraNo ratings yet

- Form A WeekDocument2 pagesForm A WeekAde Y SaputraNo ratings yet

- NGR GarutRev1Document1 pageNGR GarutRev1Ade Y SaputraNo ratings yet

- 50 AMP WELDER ReceptacleDocument2 pages50 AMP WELDER ReceptacleAde Y SaputraNo ratings yet

- Acsr Din en 50182Document1 pageAcsr Din en 50182Ade Y SaputraNo ratings yet

- PPM #7 High Pressureshower Piping ChecklistDocument1 pagePPM #7 High Pressureshower Piping ChecklistAde Y SaputraNo ratings yet

- Buckman Installation Equipment Biocide N FCDocument1 pageBuckman Installation Equipment Biocide N FCAde Y SaputraNo ratings yet

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDocument8 pagesEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraNo ratings yet

- Gantt Chart From Buckman To Install Equipment PPM# 7Document3 pagesGantt Chart From Buckman To Install Equipment PPM# 7Ade Y SaputraNo ratings yet

- Pt. Indah Kiat Pulp & Paper Corp. TBK: Prepared By: Zulhendra / Stepanus M Approv By: RizwanDocument2 pagesPt. Indah Kiat Pulp & Paper Corp. TBK: Prepared By: Zulhendra / Stepanus M Approv By: RizwanAde Y SaputraNo ratings yet

- Specification of Nalco Equipment NO Equipment Name Spesification/Unit QTY Dimension Tag NumberDocument2 pagesSpecification of Nalco Equipment NO Equipment Name Spesification/Unit QTY Dimension Tag NumberAde Y SaputraNo ratings yet

- 2X30Mw Coal Fired Power Plant Project Tawang Moinit - North Sulawesi Design Review Pltu Amurang-MinahasaDocument1 page2X30Mw Coal Fired Power Plant Project Tawang Moinit - North Sulawesi Design Review Pltu Amurang-MinahasaAde Y SaputraNo ratings yet

TURBINE COLD START-UP 600 MW - Indicator

TURBINE COLD START-UP 600 MW - Indicator

Uploaded by

Ade Y Saputra0 ratings0% found this document useful (0 votes)

44 views5 pages600mw

Original Title

TURBINE COLD START-UP 600 mw_indicator

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document600mw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

44 views5 pagesTURBINE COLD START-UP 600 MW - Indicator

TURBINE COLD START-UP 600 MW - Indicator

Uploaded by

Ade Y Saputra600mw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

26th May 2016 TURBINE COLD START-UP 600 mw

Standard Operating Procedure

For

"TURBINE COLD STARTUP

SINO,

Ingex

Page No,

10 Purpose 4

20Scope 4

3.0 Responsibility &

‘4.0 System Description &

4.1 Pe Surtup checks 6

42 Stata?

S50 References 12

(60 Records 12

4

10 Pupose

‘This Procedure i intended to provide guidance and instructions for carving out the startup procedures

of urine

20 Scape

8) This Procedure is applicable to turbine start-up process during col strep, warm start-up ot

startup & very ht star-4pin plant

30 Responsibility

8) Allzhe personne involved in carrying out supervising the above setivities ae required to ensure

‘implementation ofthis procedure and may consult any other relevant documents indicated under

Reference section below,

‘Inthe event of any changes cequred inthe procedure such changes maybe eguested with

operation hea, wo would take appropriate action with approval fom respective departmental

beads

4.0 System Deseiption:

(Startup conditions are determined by the Fist Stage meal tempertue of HP turbine)

1 Cold start: the frst stage metal frp 120°C, (or tarp afer long time sbtdown)

2. Warm start-up Ihe st stage metal tmp >120°C 260°C, (a tarp afer shutdown of

> Thos)

‘Steps as pe Curve:

6-600 pm 150 rn (5 mates)

‘Soak fr S minutes a 600 pm

600-2400 spm @150 ln (12 minutes)

‘Soak for $0 minutes ot 2400 rpm

2400 - 3000 sp 300 sn (2 mints)

[Change fiom TV to GY at 2900 rpm and rise pee up 3000 sp]

[ova time from Ot 3000 rpm~ 114 minutes}

5

Load Rising Rate:

ynehransation# 5% Load — after 120 mintes

3% Load Holding -30 Minutes

Load Raising: 5% 10 30% @3MW/Min, 30% to 50% @EMWIMin, 50% t0 100%

@12 MWimin

5, Warm sar-up I: the Fist stage metal emp "260°C &=<400 0°,

(oe start-up after shutdown of 10-72 hous}

‘Steps as per Curve:

(6-600 sp 00 rm (2 minutes)

‘Soak fr S minutes a 600 pan

600 - 3000 rpm 300 ei (8 msmates)

{Change fom TV to GV at 2900 rpm and rise speed p 0 3000 sp)

[Tal ine from 01 3000 rpm~ 15 mints}

Load Rising Rate:

‘Synchronistion’5% Load flr 20 minutes

5% Loed Holding -15 Minutes

Load Raising 5% to 30% ~@6MEW/Min, 30% 1100%-@12MWMin

4. Mot start-up: the fist stage metal emp 400°C &< 450°C,

(oe start-up after shutdown of 1-10 hours)

‘Steps as pe Curve:

6.3000 sm @ 300 rm (10 minutes)

[Tal time from Oto 3000 rpm = 10 sinus)

Load Rising Rate

‘Synchroistion®5% Load ~ after 15 minutes

5% Load Hing -1 Minutes

‘Load Raising: 5% 10 30% -@9MW/Min, 30% 19100%-@12MW:Min

6

5. Very Ho startup: the fast stage metal cmp 480°C, (Tor start-up afer shutdown of less han

hour)

Steps. as per Curve

0-3000 sp @ 300 (10 minutes)

(Tal ie foes Ot 3000 rpma= 10 mainte)

Load Rising Rate:

‘Synchronistions5% Load after 15 minutes

5% Load Holding -1 Minutes

Load Raising: 5% o 30% -@LSMW/Min, 30% 1o100%.@.90M Min

4.1 Pre Startup Checks

Fire Fighting System

FEW System

ACW System

F CCW System & ensure Expansion tak lvel normal

| Instrument Air Compressor

BIL OI Sytem

Lube Oil System (Maintain Pr at borings > @.083M¢Pa & tenap a bearing outlet 60-70°C)

© Seal Oi System

Generator Sator Water System

F Hydrogen cveuating Blower

1 AirPre Heater

1 Fane Seanner Ae Fan

[ MDBFP with is abe ol system runing in r-cieulaton

1 Boiler drum level /Derator lve /ot wll evel i normal

(Gf required stat Boiler fil pumphot well makeup pump}

CEP runing in re-creation

[All heaters charged through water sie

Vacuum pump & is system

© Boiler Cirealtion Pump

| BSP hopper heating systom

LDO system /HFO System s runing & charged upo bolle in long recirculation,

4.1 Strap

[ Bsre to open all deans of tine proper nd HPAIP system. (should be opened til 20% lod)

[ PueLP cylinder spay system in aut to maintain emp 70* aod Keep vacuum norm

Sur Jacking oi pump. Check & sure acking oi rat header bearing ae normal. (PUI.76-14.7

MPs)

Pu Turning ger into operation and check no any abrasion sound,

[Charge airy steam from another unt, which wil be used to est feed water an nd pinto

‘lt land, whe temperature and pressure reach, to create vacuum.

1 Set inclination of barer to be horizontal postion

© Stet Induced dre fan & mansind func draft -100 Ps

1 Stat Freed draft fan system & msntained furnace daft -50 Ps

Aas ir ow (30-40%) & purge the bole.

Lie the bole.

1 Stat one pland sealing cooking fan nd Open gland scaling regulating valve (keep gland sealing pr

77-21 KPs & temp 120-180" C) and establish condenser vacu,

Get sequzed parameter of drum pressure

Open HP Bypass valve to maintain MS pr 60%

1 AL 240 Mw lad pt other TDBFP in heating,

| Above 300 MW lod put th mil in service and take ut all guns

[Put other TDBEP in service & top MDBFP.

1 At 360 MW lod Burne Tl operaton may pinata to maintain RIL mp.

| Above 400 MW loa pu th ill in sevice

Above S00 MW loa pu 6th milli sevice

E Raise load up-to 600 MW

Putall contol loops all master controle in ato mode,

Warm start-up Cure

‘Warm start-up I Carve

Hot star-up Curve

Very Hot startup Curve

(Cold start-up Curve

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2MLD09-0100-01664365 B: ClientDocument1 page2MLD09-0100-01664365 B: ClientAde Y SaputraNo ratings yet

- SEMA AH Hook Block Assly. Sheet 2 3Document1 pageSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraNo ratings yet

- Section:A-A': Typical Power JointDocument1 pageSection:A-A': Typical Power JointAde Y SaputraNo ratings yet

- SEMA MH Hook Block Assly. Sheet 1 3Document1 pageSEMA MH Hook Block Assly. Sheet 1 3Ade Y SaputraNo ratings yet

- Paper Title (Use Style - Paper Title)Document6 pagesPaper Title (Use Style - Paper Title)Ade Y SaputraNo ratings yet

- Cable Sizing and Schedule-R - 02 - (As BUILT)Document6 pagesCable Sizing and Schedule-R - 02 - (As BUILT)Ade Y SaputraNo ratings yet

- Fuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Document18 pagesFuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Ade Y SaputraNo ratings yet

- 3147 Hoist r3Document1 page3147 Hoist r3Ade Y SaputraNo ratings yet

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDocument5 pagesJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraNo ratings yet

- Star - DeltaDocument4 pagesStar - DeltaAde Y SaputraNo ratings yet

- Acsr SPLN 41-7 PDFDocument2 pagesAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- Variable Frequency DriveDocument40 pagesVariable Frequency DriveAde Y Saputra100% (1)

- Tipe NGRDocument4 pagesTipe NGRAde Y SaputraNo ratings yet

- Form A WeekDocument2 pagesForm A WeekAde Y SaputraNo ratings yet

- NGR GarutRev1Document1 pageNGR GarutRev1Ade Y SaputraNo ratings yet

- 50 AMP WELDER ReceptacleDocument2 pages50 AMP WELDER ReceptacleAde Y SaputraNo ratings yet

- Acsr Din en 50182Document1 pageAcsr Din en 50182Ade Y SaputraNo ratings yet

- PPM #7 High Pressureshower Piping ChecklistDocument1 pagePPM #7 High Pressureshower Piping ChecklistAde Y SaputraNo ratings yet

- Buckman Installation Equipment Biocide N FCDocument1 pageBuckman Installation Equipment Biocide N FCAde Y SaputraNo ratings yet

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDocument8 pagesEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraNo ratings yet

- Gantt Chart From Buckman To Install Equipment PPM# 7Document3 pagesGantt Chart From Buckman To Install Equipment PPM# 7Ade Y SaputraNo ratings yet

- Pt. Indah Kiat Pulp & Paper Corp. TBK: Prepared By: Zulhendra / Stepanus M Approv By: RizwanDocument2 pagesPt. Indah Kiat Pulp & Paper Corp. TBK: Prepared By: Zulhendra / Stepanus M Approv By: RizwanAde Y SaputraNo ratings yet

- Specification of Nalco Equipment NO Equipment Name Spesification/Unit QTY Dimension Tag NumberDocument2 pagesSpecification of Nalco Equipment NO Equipment Name Spesification/Unit QTY Dimension Tag NumberAde Y SaputraNo ratings yet

- 2X30Mw Coal Fired Power Plant Project Tawang Moinit - North Sulawesi Design Review Pltu Amurang-MinahasaDocument1 page2X30Mw Coal Fired Power Plant Project Tawang Moinit - North Sulawesi Design Review Pltu Amurang-MinahasaAde Y SaputraNo ratings yet