Professional Documents

Culture Documents

BRS Package5 PDF

BRS Package5 PDF

Uploaded by

sujit kcCopyright:

Available Formats

You might also like

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- Machining Center Master Catalog 7060 A96-181Document977 pagesMachining Center Master Catalog 7060 A96-181Araviinda YereseemeNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Model: BRS5 - (Typically Used For Heavy Equipment Bore Repair)Document1 pageModel: BRS5 - (Typically Used For Heavy Equipment Bore Repair)sujit kcNo ratings yet

- One-Step Integrated Complete Bore Repair SystemsDocument1 pageOne-Step Integrated Complete Bore Repair Systemssujit kcNo ratings yet

- One-Step Integrated Complete Bore Repair System: Model BRS6 - (Popular For Large Diameter Heavy Equipment Bore Repair)Document1 pageOne-Step Integrated Complete Bore Repair System: Model BRS6 - (Popular For Large Diameter Heavy Equipment Bore Repair)sujit kcNo ratings yet

- BOre WeldersDocument22 pagesBOre WeldersLatonya RossNo ratings yet

- One-Step Integrated Complete Bore Repair Systems: Approved Tel: (603) 835-2409 Fax: (603) 835-2609Document1 pageOne-Step Integrated Complete Bore Repair Systems: Approved Tel: (603) 835-2409 Fax: (603) 835-2609sujit kcNo ratings yet

- Line Boring MachinesDocument8 pagesLine Boring Machinesnoviantilisa464No ratings yet

- WeldFit Energy BrochureDocument8 pagesWeldFit Energy BrochureRaymundo AlarconNo ratings yet

- TDS - Flow Element & Measurement SetDocument6 pagesTDS - Flow Element & Measurement SetB Lal MughalNo ratings yet

- Bore Hole MachineDocument8 pagesBore Hole Machineomni_partsNo ratings yet

- Solutions For Mining and Aggregate ApplicationsDocument4 pagesSolutions For Mining and Aggregate ApplicationsWilliam VillamizarNo ratings yet

- Biseladora de CadenaDocument1 pageBiseladora de Cadenaisai4011No ratings yet

- BB8100 Line Boring Machine E 2Document8 pagesBB8100 Line Boring Machine E 2azharzebNo ratings yet

- Cutting Tools in Industrial AutomationDocument22 pagesCutting Tools in Industrial AutomationShazeenNo ratings yet

- BB7100 Boring Machine E 1Document8 pagesBB7100 Boring Machine E 1azharzebNo ratings yet

- Unified SAF SN - Spherical Mounted Roller BearingsDocument6 pagesUnified SAF SN - Spherical Mounted Roller BearingsJose CorbachoNo ratings yet

- Complete CatalogDocument651 pagesComplete CatalogFernando EscriváNo ratings yet

- BB4500 Line Boring MachineDocument12 pagesBB4500 Line Boring MachineLuis Fernando Oropeza CruzNo ratings yet

- Rental Products Orbitalum PDFDocument16 pagesRental Products Orbitalum PDFAshley JacksonNo ratings yet

- CT D - Ploy Velocity StringDocument2 pagesCT D - Ploy Velocity StringAlejandro MonroyNo ratings yet

- Limits and FitsDocument26 pagesLimits and FitsHassan AwaisNo ratings yet

- Torno - Bb5000Document8 pagesTorno - Bb5000Marco BacianNo ratings yet

- CatalogDocument4 pagesCataloglangtu2011No ratings yet

- Elementos de HPDocument8 pagesElementos de HPAndres Elias Fernandez PastorNo ratings yet

- SPR York BW 830 Spec SheetDocument2 pagesSPR York BW 830 Spec SheetOswaldo TolozaNo ratings yet

- New Heights in Sanitation Nuevas Alturas en SaneamientoDocument33 pagesNew Heights in Sanitation Nuevas Alturas en SaneamientoEmanuel RigueroNo ratings yet

- Climax: Model BB6000 Portable Boring BarDocument16 pagesClimax: Model BB6000 Portable Boring BarSomadbsiNo ratings yet

- Shouth Bend Spec - Sheet - 02042021Document2 pagesShouth Bend Spec - Sheet - 02042021Emco MillerNo ratings yet

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیNo ratings yet

- CADET Catalogue - 1Document14 pagesCADET Catalogue - 1Алмаз КенжетаевNo ratings yet

- Fire Hydrant AccessoriesDocument8 pagesFire Hydrant AccessoriesDan Nicole Dadivas100% (1)

- Wathik M. Alhashimi, P.EngDocument32 pagesWathik M. Alhashimi, P.EngShko ArassNo ratings yet

- Liebherr Gear Tools PDFDocument16 pagesLiebherr Gear Tools PDFleosac6No ratings yet

- SDB 206 2 Small Diameter Beveler DatasheetDocument2 pagesSDB 206 2 Small Diameter Beveler DatasheetTulioLopezJNo ratings yet

- Renk Curved Tooth Couplings Basic Construction Series enDocument52 pagesRenk Curved Tooth Couplings Basic Construction Series enhumayun121No ratings yet

- Sunriseiw IronworkersDocument26 pagesSunriseiw IronworkersjvictorvrNo ratings yet

- FL Tool CatalogDocument82 pagesFL Tool CatalogJon Smart100% (2)

- 2production Choke Catalog 2013Document8 pages2production Choke Catalog 2013point blankNo ratings yet

- High Pressure Hose 18974ENDocument8 pagesHigh Pressure Hose 18974ENFotolag JrNo ratings yet

- DESTACO Aerospace Brochure PDFDocument8 pagesDESTACO Aerospace Brochure PDFJ Ferreyra LibanoNo ratings yet

- Sheet Pile Capping Manual-DawsonDocument54 pagesSheet Pile Capping Manual-DawsonSankar CdmNo ratings yet

- Johnston Pump Jts Vertical Turbine PumpDocument6 pagesJohnston Pump Jts Vertical Turbine PumpJhonathan CanzarioNo ratings yet

- Welded Blade Stabilizer: Flow CouplingsDocument1 pageWelded Blade Stabilizer: Flow Couplingsnasreldin3No ratings yet

- Special Purpose LathesDocument33 pagesSpecial Purpose LathesChadaram JagadishNo ratings yet

- Well HandyDocument6 pagesWell HandymtonellyNo ratings yet

- Hangers: Wellhead Control Products, IncDocument8 pagesHangers: Wellhead Control Products, Incclaudio godinezNo ratings yet

- Advance Construction: Presentation On Construction ToolsDocument29 pagesAdvance Construction: Presentation On Construction ToolsANIMESH AGGARWALNo ratings yet

- Wellbore Enlargement DPA RioDocument19 pagesWellbore Enlargement DPA RioAdriana RezendeNo ratings yet

- BORINGDocument4 pagesBORINGPandi VelanNo ratings yet

- Brake Lathe HUNTER 3937TDocument8 pagesBrake Lathe HUNTER 3937TjifijifiNo ratings yet

- ScaffoldCouplers14Document8 pagesScaffoldCouplers14Guatemalan1979No ratings yet

- Paper Roll Clamps: Series ARCDocument4 pagesPaper Roll Clamps: Series ARCphillipdiazNo ratings yet

- CompletionsDocument78 pagesCompletionsHamed GeramiNo ratings yet

- Bb5000 Boring Machine: A Powerful Boring Machine That Can Be Customized To Suit Your NeedsDocument16 pagesBb5000 Boring Machine: A Powerful Boring Machine That Can Be Customized To Suit Your NeedsAyman AlhalfawyNo ratings yet

- SDSF Datasheet 120808Document2 pagesSDSF Datasheet 120808Rex LinNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- NOTICE No. 168/Dt. 17.06.2016: Indian Institute of Technology BhubaneswarDocument3 pagesNOTICE No. 168/Dt. 17.06.2016: Indian Institute of Technology Bhubaneswarsujit kcNo ratings yet

- Ffismq: Ffifr Sffif, Tfittffi TK (Qta-D 4M Tqqpffi FfiDocument1 pageFfismq: Ffifr Sffif, Tfittffi TK (Qta-D 4M Tqqpffi Ffisujit kcNo ratings yet

- Criminal Infringement Notices (CIN) : Police, Fire, Ambulance Crime Stoppers Police Assistance LineDocument2 pagesCriminal Infringement Notices (CIN) : Police, Fire, Ambulance Crime Stoppers Police Assistance Linesujit kcNo ratings yet

- 1पुरस्कृत नामावली 1603959384Document2 pages1पुरस्कृत नामावली 1603959384sujit kcNo ratings yet

- Extension of Submission DateDocument1 pageExtension of Submission Datesujit kcNo ratings yet

- T+r.qur: +R+Q V QH 1@Document3 pagesT+r.qur: +R+Q V QH 1@sujit kcNo ratings yet

- 26.1639109barrier New 1 Part ResultDocument2 pages26.1639109barrier New 1 Part Resultsujit kcNo ratings yet

- Indian Institute of Technology Madras CHENNAI - 600 036Document4 pagesIndian Institute of Technology Madras CHENNAI - 600 036sujit kcNo ratings yet

- Directorate of Research and ExtensionDocument1 pageDirectorate of Research and Extensionsujit kcNo ratings yet

- Iit Kanpur PDFDocument1 pageIit Kanpur PDFsujit kcNo ratings yet

- Persons Till Shrawan Shrawan OnlyDocument4 pagesPersons Till Shrawan Shrawan Onlysujit kcNo ratings yet

- 00.2474061barrier Result Old CourseDocument2 pages00.2474061barrier Result Old Coursesujit kcNo ratings yet

- Agriculture and Forestry University: CG' GWFG Tyf K - F/ LGB) (ZgfnoDocument1 pageAgriculture and Forestry University: CG' GWFG Tyf K - F/ LGB) (Zgfnosujit kcNo ratings yet

- 55.5996691retotaling ResultDocument1 page55.5996691retotaling Resultsujit kcNo ratings yet

- 19.9617268msc ResultDocument1 page19.9617268msc Resultsujit kcNo ratings yet

- Thesis ResultDocument1 pageThesis Resultsujit kcNo ratings yet

- Arrival Departure Data of Nepalese and Foreigners For The Month of Karthik, 2077 B.SDocument4 pagesArrival Departure Data of Nepalese and Foreigners For The Month of Karthik, 2077 B.Ssujit kcNo ratings yet

- Arrival Departure Data of Bhadra, 2077 B.SDocument3 pagesArrival Departure Data of Bhadra, 2077 B.Ssujit kcNo ratings yet

- Persons Till Shrawan Shrawan OnlyDocument4 pagesPersons Till Shrawan Shrawan Onlysujit kcNo ratings yet

- Icsr PR Advt.05 2019 RDocument3 pagesIcsr PR Advt.05 2019 Rsujit kcNo ratings yet

- United Acadamy Admission-Form-2076Document4 pagesUnited Acadamy Admission-Form-2076sujit kcNo ratings yet

- Applications Are Invited For The Temporary Post of "Senior Project Advisor (Part Time) " in The Dept. Ocean Engineering, IIT MadrasDocument4 pagesApplications Are Invited For The Temporary Post of "Senior Project Advisor (Part Time) " in The Dept. Ocean Engineering, IIT Madrassujit kcNo ratings yet

- The Institute of Chartered Accountants of Nepal Application Form For ExaminationDocument1 pageThe Institute of Chartered Accountants of Nepal Application Form For Examinationsujit kcNo ratings yet

- Cash Dividend Deposit Form of NMB Sulav InvestmentDocument1 pageCash Dividend Deposit Form of NMB Sulav Investmentsujit kcNo ratings yet

- Exam - Held 2Document1 pageExam - Held 2sujit kcNo ratings yet

- United Nations Development Programme: 1. Nature of ServicesDocument2 pagesUnited Nations Development Programme: 1. Nature of Servicessujit kcNo ratings yet

- Ffitffi: +ffi Ffi RRM Ffi Ffi Ffi Ffi (Ffi Kfiq EffiqDocument1 pageFfitffi: +ffi Ffi RRM Ffi Ffi Ffi Ffi (Ffi Kfiq Effiqsujit kcNo ratings yet

- Request Form Account ConversionDocument1 pageRequest Form Account Conversionsujit kcNo ratings yet

- 41.7741878thesis NoticeDocument1 page41.7741878thesis Noticesujit kcNo ratings yet

- SF - SafeFlame Data Sheet UVIRDocument2 pagesSF - SafeFlame Data Sheet UVIRVincent GabrielNo ratings yet

- 01 DTMDocument2 pages01 DTMMauro BorgesNo ratings yet

- Faculty - Accountancy - 2022 - Session 2 - Diploma - Maf251Document7 pagesFaculty - Accountancy - 2022 - Session 2 - Diploma - Maf251NUR FARISHA MOHD AZHARNo ratings yet

- CA & Sports Grade 7 Jss Simplified NotesDocument8 pagesCA & Sports Grade 7 Jss Simplified NotesHoseaNo ratings yet

- Mistibushi Servo Drive PDFDocument350 pagesMistibushi Servo Drive PDFnitin hadkeNo ratings yet

- Sentence ConnectorsDocument2 pagesSentence ConnectorsReeta Kannusamy100% (1)

- Roll No. 31 - SportsDocument8 pagesRoll No. 31 - SportsAdnan NawabNo ratings yet

- Piping Engineer: Resume CV: Sponsored LinksDocument7 pagesPiping Engineer: Resume CV: Sponsored Linksravi gurungNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- DS2 - Unit 2-DC MachinesDocument57 pagesDS2 - Unit 2-DC MachinesTommba TommyNo ratings yet

- Syllabus: Cambridge Igcse First Language EnglishDocument52 pagesSyllabus: Cambridge Igcse First Language EnglishNdache PermataNo ratings yet

- 2017 Somali English ABC Bridge PrimerDocument230 pages2017 Somali English ABC Bridge PrimerSky somaliNo ratings yet

- Fresh AHU ComparisonDocument8 pagesFresh AHU Comparisonevo2oo2No ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- IGTM-CT Gas Turbine Meter: Documentation and Technical SpecificationsDocument12 pagesIGTM-CT Gas Turbine Meter: Documentation and Technical Specificationsajitp123No ratings yet

- Analyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriDocument71 pagesAnalyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriAgnys Gomes - DR UNITECNo ratings yet

- Chapter 4Document2 pagesChapter 4Lilia GuzunNo ratings yet

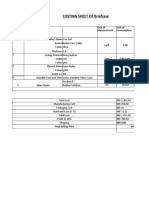

- Costing Breif CaseDocument2 pagesCosting Breif Casehema varshiniNo ratings yet

- Application of Negative Stiffness Devices For Seismic Protection of Bridge StructuresDocument10 pagesApplication of Negative Stiffness Devices For Seismic Protection of Bridge StructuresganeshNo ratings yet

- Chapter 2Document3 pagesChapter 2Johane Grei WallNo ratings yet

- Top 110 Cyber Security Interview Questions & Answers: 1) What Is Cybersecurity?Document21 pagesTop 110 Cyber Security Interview Questions & Answers: 1) What Is Cybersecurity?শ্রী লিমন চন্দ্র মোহন্তNo ratings yet

- 7th Mathematics 1,2,3Document3 pages7th Mathematics 1,2,3Khamalesh C.ANo ratings yet

- (1908) United States Revenue Cutter Service Uniform RegulationsDocument57 pages(1908) United States Revenue Cutter Service Uniform RegulationsHerbert Hillary Booker 2nd100% (3)

- PreviewDocument254 pagesPreviewIgor OkNo ratings yet

- Open Source Tools For Measuring The Internal Quality of Java Software Products A SurveyDocument12 pagesOpen Source Tools For Measuring The Internal Quality of Java Software Products A SurveyStanley UmohNo ratings yet

- Production Planning - 095252Document13 pagesProduction Planning - 095252Jocidelle LubricoNo ratings yet

- CALR - SUPPL X Sequenze PrimersDocument53 pagesCALR - SUPPL X Sequenze PrimersNicoletta ColomboNo ratings yet

- Study of Adhesion Properties of Natural Rubber, Epoxidized Natural Rubber, and Ethylene-Propylene Diene Terpolymer-Based AdhesivesDocument44 pagesStudy of Adhesion Properties of Natural Rubber, Epoxidized Natural Rubber, and Ethylene-Propylene Diene Terpolymer-Based AdhesivesZarathos SinghNo ratings yet

BRS Package5 PDF

BRS Package5 PDF

Uploaded by

sujit kcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BRS Package5 PDF

BRS Package5 PDF

Uploaded by

sujit kcCopyright:

Available Formats

ONE-STEP INTEGRATED COMPLETE BORE REPAIR SYSTEMS

Model: BRS5—(Typically used for heavy equipment bore repair)

BOA408i S1 HYDRAULICS NOT PICTURED TM5

Borewelder Boring bar

+

The Bore Repair Systems, Inc. BRS5 Boring bar & welder package is a popular midsize bore repair system. The bore welder and bor-

ing bar feature the popular, mount anywhere pass-through drive systems. On bores where there may be restricted access, or bores that

are spaced far apart, the pass-through drive design gives you the flexibility to mount where it makes the most sense, such as between

the bores. On jobs such as payloader lift arm bores, the BOA-408i can be center-mounted and can weld out either end of the machine

with one simple operation, without ever losing system center...this is unique to the BOA-408i design. On blind bores, our systems do not

require special cumbersome remote mounting kits or various length bars because with our pass-through design the excess bar simply

comes out of the back end of the machine. The BRS packages share one mount for boring and welding which allows fast setup and

rapid transitions from boring to the welding process.

MODEL: BRS5 Bore welding & machining package— for 24-305mm (1-12”) diameter bore repair

Package (shown above) Includes:

• Bore welding head, 110v or 220v drive with variable feed • Boring bar drive, 110v or 220v drive with variable feed

rotation speed, reversible rotation & feed direction direction (electric drive hydraulic pump)

• Extendable, reversible welding shaft with 90” total ex- • 72” long x 1.75” dia. Bar with dual 1/2” tool ports—

tended reach from bore to bore (expandable) enabling easy bore measurements w/out tool removal

• 10’ 150amp welding conduit with universal end (hi-amp • Centering kit (solid steel cones) with unique one-person

upgrades are available) centering cone spanner tightening system

• Aluminum diamond-plate custom storage cases • Two auxiliary spherical self-aligning bar support bearings

and one primary bar/machine support (adjustable)

• Spare nozzle, tip and diffuser assortment • Sharpened 1/2” square high-speed tool (carbide optional)

• Arc-resistant heatsink style adjustable welding head which • Bore welder to boring bar interface package enables bore

can weld bores from 1.25” to 11.0” dia welder to mount directly to boring bar bearings or support

• Micro welding head for welding bores down to .8” dia • Setup sleeve for easy machine support setup

• Setup manuals & dvd • Tool kit

• Remote weld trigger for partial bore welding or skipping • Boring bar tool extender for sturdy tool holding when ma-

over no-weld areas chining larger bores

• Fully 360 degree adjustable mounting system enabling • Corrosion-resistant materials used throughout both boring

control placement where it is most convenient and welding system for years of shop and field reliability

• 72” long x 1.25” dia bar with dual 3/8” tool ports + tooling • Centering cone & bushing kit for 1.75” to 1.25” conversion

• 48” long x .875” dia bar with 1/4” tool ports + tooling • Centering cone & bushing kit for 1.75” to .875” con-

version

ADD: Accessory kit #KBCC to maximize the versatility of these packages. It contains all of the popular BRS options.

PO Box 59

Www.BoreRepair.com

approved √ Alstead, NH 03602 USA

Pat. 6,137,076 Pat. 6,448,531 Pat. 6,737,608 Tel: (603) 835-2409

Pat. 6,284,995 Pat. 6,486,438 02/2009 Fax: (603) 835-2609

You might also like

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- Machining Center Master Catalog 7060 A96-181Document977 pagesMachining Center Master Catalog 7060 A96-181Araviinda YereseemeNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Model: BRS5 - (Typically Used For Heavy Equipment Bore Repair)Document1 pageModel: BRS5 - (Typically Used For Heavy Equipment Bore Repair)sujit kcNo ratings yet

- One-Step Integrated Complete Bore Repair SystemsDocument1 pageOne-Step Integrated Complete Bore Repair Systemssujit kcNo ratings yet

- One-Step Integrated Complete Bore Repair System: Model BRS6 - (Popular For Large Diameter Heavy Equipment Bore Repair)Document1 pageOne-Step Integrated Complete Bore Repair System: Model BRS6 - (Popular For Large Diameter Heavy Equipment Bore Repair)sujit kcNo ratings yet

- BOre WeldersDocument22 pagesBOre WeldersLatonya RossNo ratings yet

- One-Step Integrated Complete Bore Repair Systems: Approved Tel: (603) 835-2409 Fax: (603) 835-2609Document1 pageOne-Step Integrated Complete Bore Repair Systems: Approved Tel: (603) 835-2409 Fax: (603) 835-2609sujit kcNo ratings yet

- Line Boring MachinesDocument8 pagesLine Boring Machinesnoviantilisa464No ratings yet

- WeldFit Energy BrochureDocument8 pagesWeldFit Energy BrochureRaymundo AlarconNo ratings yet

- TDS - Flow Element & Measurement SetDocument6 pagesTDS - Flow Element & Measurement SetB Lal MughalNo ratings yet

- Bore Hole MachineDocument8 pagesBore Hole Machineomni_partsNo ratings yet

- Solutions For Mining and Aggregate ApplicationsDocument4 pagesSolutions For Mining and Aggregate ApplicationsWilliam VillamizarNo ratings yet

- Biseladora de CadenaDocument1 pageBiseladora de Cadenaisai4011No ratings yet

- BB8100 Line Boring Machine E 2Document8 pagesBB8100 Line Boring Machine E 2azharzebNo ratings yet

- Cutting Tools in Industrial AutomationDocument22 pagesCutting Tools in Industrial AutomationShazeenNo ratings yet

- BB7100 Boring Machine E 1Document8 pagesBB7100 Boring Machine E 1azharzebNo ratings yet

- Unified SAF SN - Spherical Mounted Roller BearingsDocument6 pagesUnified SAF SN - Spherical Mounted Roller BearingsJose CorbachoNo ratings yet

- Complete CatalogDocument651 pagesComplete CatalogFernando EscriváNo ratings yet

- BB4500 Line Boring MachineDocument12 pagesBB4500 Line Boring MachineLuis Fernando Oropeza CruzNo ratings yet

- Rental Products Orbitalum PDFDocument16 pagesRental Products Orbitalum PDFAshley JacksonNo ratings yet

- CT D - Ploy Velocity StringDocument2 pagesCT D - Ploy Velocity StringAlejandro MonroyNo ratings yet

- Limits and FitsDocument26 pagesLimits and FitsHassan AwaisNo ratings yet

- Torno - Bb5000Document8 pagesTorno - Bb5000Marco BacianNo ratings yet

- CatalogDocument4 pagesCataloglangtu2011No ratings yet

- Elementos de HPDocument8 pagesElementos de HPAndres Elias Fernandez PastorNo ratings yet

- SPR York BW 830 Spec SheetDocument2 pagesSPR York BW 830 Spec SheetOswaldo TolozaNo ratings yet

- New Heights in Sanitation Nuevas Alturas en SaneamientoDocument33 pagesNew Heights in Sanitation Nuevas Alturas en SaneamientoEmanuel RigueroNo ratings yet

- Climax: Model BB6000 Portable Boring BarDocument16 pagesClimax: Model BB6000 Portable Boring BarSomadbsiNo ratings yet

- Shouth Bend Spec - Sheet - 02042021Document2 pagesShouth Bend Spec - Sheet - 02042021Emco MillerNo ratings yet

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیNo ratings yet

- CADET Catalogue - 1Document14 pagesCADET Catalogue - 1Алмаз КенжетаевNo ratings yet

- Fire Hydrant AccessoriesDocument8 pagesFire Hydrant AccessoriesDan Nicole Dadivas100% (1)

- Wathik M. Alhashimi, P.EngDocument32 pagesWathik M. Alhashimi, P.EngShko ArassNo ratings yet

- Liebherr Gear Tools PDFDocument16 pagesLiebherr Gear Tools PDFleosac6No ratings yet

- SDB 206 2 Small Diameter Beveler DatasheetDocument2 pagesSDB 206 2 Small Diameter Beveler DatasheetTulioLopezJNo ratings yet

- Renk Curved Tooth Couplings Basic Construction Series enDocument52 pagesRenk Curved Tooth Couplings Basic Construction Series enhumayun121No ratings yet

- Sunriseiw IronworkersDocument26 pagesSunriseiw IronworkersjvictorvrNo ratings yet

- FL Tool CatalogDocument82 pagesFL Tool CatalogJon Smart100% (2)

- 2production Choke Catalog 2013Document8 pages2production Choke Catalog 2013point blankNo ratings yet

- High Pressure Hose 18974ENDocument8 pagesHigh Pressure Hose 18974ENFotolag JrNo ratings yet

- DESTACO Aerospace Brochure PDFDocument8 pagesDESTACO Aerospace Brochure PDFJ Ferreyra LibanoNo ratings yet

- Sheet Pile Capping Manual-DawsonDocument54 pagesSheet Pile Capping Manual-DawsonSankar CdmNo ratings yet

- Johnston Pump Jts Vertical Turbine PumpDocument6 pagesJohnston Pump Jts Vertical Turbine PumpJhonathan CanzarioNo ratings yet

- Welded Blade Stabilizer: Flow CouplingsDocument1 pageWelded Blade Stabilizer: Flow Couplingsnasreldin3No ratings yet

- Special Purpose LathesDocument33 pagesSpecial Purpose LathesChadaram JagadishNo ratings yet

- Well HandyDocument6 pagesWell HandymtonellyNo ratings yet

- Hangers: Wellhead Control Products, IncDocument8 pagesHangers: Wellhead Control Products, Incclaudio godinezNo ratings yet

- Advance Construction: Presentation On Construction ToolsDocument29 pagesAdvance Construction: Presentation On Construction ToolsANIMESH AGGARWALNo ratings yet

- Wellbore Enlargement DPA RioDocument19 pagesWellbore Enlargement DPA RioAdriana RezendeNo ratings yet

- BORINGDocument4 pagesBORINGPandi VelanNo ratings yet

- Brake Lathe HUNTER 3937TDocument8 pagesBrake Lathe HUNTER 3937TjifijifiNo ratings yet

- ScaffoldCouplers14Document8 pagesScaffoldCouplers14Guatemalan1979No ratings yet

- Paper Roll Clamps: Series ARCDocument4 pagesPaper Roll Clamps: Series ARCphillipdiazNo ratings yet

- CompletionsDocument78 pagesCompletionsHamed GeramiNo ratings yet

- Bb5000 Boring Machine: A Powerful Boring Machine That Can Be Customized To Suit Your NeedsDocument16 pagesBb5000 Boring Machine: A Powerful Boring Machine That Can Be Customized To Suit Your NeedsAyman AlhalfawyNo ratings yet

- SDSF Datasheet 120808Document2 pagesSDSF Datasheet 120808Rex LinNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- NOTICE No. 168/Dt. 17.06.2016: Indian Institute of Technology BhubaneswarDocument3 pagesNOTICE No. 168/Dt. 17.06.2016: Indian Institute of Technology Bhubaneswarsujit kcNo ratings yet

- Ffismq: Ffifr Sffif, Tfittffi TK (Qta-D 4M Tqqpffi FfiDocument1 pageFfismq: Ffifr Sffif, Tfittffi TK (Qta-D 4M Tqqpffi Ffisujit kcNo ratings yet

- Criminal Infringement Notices (CIN) : Police, Fire, Ambulance Crime Stoppers Police Assistance LineDocument2 pagesCriminal Infringement Notices (CIN) : Police, Fire, Ambulance Crime Stoppers Police Assistance Linesujit kcNo ratings yet

- 1पुरस्कृत नामावली 1603959384Document2 pages1पुरस्कृत नामावली 1603959384sujit kcNo ratings yet

- Extension of Submission DateDocument1 pageExtension of Submission Datesujit kcNo ratings yet

- T+r.qur: +R+Q V QH 1@Document3 pagesT+r.qur: +R+Q V QH 1@sujit kcNo ratings yet

- 26.1639109barrier New 1 Part ResultDocument2 pages26.1639109barrier New 1 Part Resultsujit kcNo ratings yet

- Indian Institute of Technology Madras CHENNAI - 600 036Document4 pagesIndian Institute of Technology Madras CHENNAI - 600 036sujit kcNo ratings yet

- Directorate of Research and ExtensionDocument1 pageDirectorate of Research and Extensionsujit kcNo ratings yet

- Iit Kanpur PDFDocument1 pageIit Kanpur PDFsujit kcNo ratings yet

- Persons Till Shrawan Shrawan OnlyDocument4 pagesPersons Till Shrawan Shrawan Onlysujit kcNo ratings yet

- 00.2474061barrier Result Old CourseDocument2 pages00.2474061barrier Result Old Coursesujit kcNo ratings yet

- Agriculture and Forestry University: CG' GWFG Tyf K - F/ LGB) (ZgfnoDocument1 pageAgriculture and Forestry University: CG' GWFG Tyf K - F/ LGB) (Zgfnosujit kcNo ratings yet

- 55.5996691retotaling ResultDocument1 page55.5996691retotaling Resultsujit kcNo ratings yet

- 19.9617268msc ResultDocument1 page19.9617268msc Resultsujit kcNo ratings yet

- Thesis ResultDocument1 pageThesis Resultsujit kcNo ratings yet

- Arrival Departure Data of Nepalese and Foreigners For The Month of Karthik, 2077 B.SDocument4 pagesArrival Departure Data of Nepalese and Foreigners For The Month of Karthik, 2077 B.Ssujit kcNo ratings yet

- Arrival Departure Data of Bhadra, 2077 B.SDocument3 pagesArrival Departure Data of Bhadra, 2077 B.Ssujit kcNo ratings yet

- Persons Till Shrawan Shrawan OnlyDocument4 pagesPersons Till Shrawan Shrawan Onlysujit kcNo ratings yet

- Icsr PR Advt.05 2019 RDocument3 pagesIcsr PR Advt.05 2019 Rsujit kcNo ratings yet

- United Acadamy Admission-Form-2076Document4 pagesUnited Acadamy Admission-Form-2076sujit kcNo ratings yet

- Applications Are Invited For The Temporary Post of "Senior Project Advisor (Part Time) " in The Dept. Ocean Engineering, IIT MadrasDocument4 pagesApplications Are Invited For The Temporary Post of "Senior Project Advisor (Part Time) " in The Dept. Ocean Engineering, IIT Madrassujit kcNo ratings yet

- The Institute of Chartered Accountants of Nepal Application Form For ExaminationDocument1 pageThe Institute of Chartered Accountants of Nepal Application Form For Examinationsujit kcNo ratings yet

- Cash Dividend Deposit Form of NMB Sulav InvestmentDocument1 pageCash Dividend Deposit Form of NMB Sulav Investmentsujit kcNo ratings yet

- Exam - Held 2Document1 pageExam - Held 2sujit kcNo ratings yet

- United Nations Development Programme: 1. Nature of ServicesDocument2 pagesUnited Nations Development Programme: 1. Nature of Servicessujit kcNo ratings yet

- Ffitffi: +ffi Ffi RRM Ffi Ffi Ffi Ffi (Ffi Kfiq EffiqDocument1 pageFfitffi: +ffi Ffi RRM Ffi Ffi Ffi Ffi (Ffi Kfiq Effiqsujit kcNo ratings yet

- Request Form Account ConversionDocument1 pageRequest Form Account Conversionsujit kcNo ratings yet

- 41.7741878thesis NoticeDocument1 page41.7741878thesis Noticesujit kcNo ratings yet

- SF - SafeFlame Data Sheet UVIRDocument2 pagesSF - SafeFlame Data Sheet UVIRVincent GabrielNo ratings yet

- 01 DTMDocument2 pages01 DTMMauro BorgesNo ratings yet

- Faculty - Accountancy - 2022 - Session 2 - Diploma - Maf251Document7 pagesFaculty - Accountancy - 2022 - Session 2 - Diploma - Maf251NUR FARISHA MOHD AZHARNo ratings yet

- CA & Sports Grade 7 Jss Simplified NotesDocument8 pagesCA & Sports Grade 7 Jss Simplified NotesHoseaNo ratings yet

- Mistibushi Servo Drive PDFDocument350 pagesMistibushi Servo Drive PDFnitin hadkeNo ratings yet

- Sentence ConnectorsDocument2 pagesSentence ConnectorsReeta Kannusamy100% (1)

- Roll No. 31 - SportsDocument8 pagesRoll No. 31 - SportsAdnan NawabNo ratings yet

- Piping Engineer: Resume CV: Sponsored LinksDocument7 pagesPiping Engineer: Resume CV: Sponsored Linksravi gurungNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- DS2 - Unit 2-DC MachinesDocument57 pagesDS2 - Unit 2-DC MachinesTommba TommyNo ratings yet

- Syllabus: Cambridge Igcse First Language EnglishDocument52 pagesSyllabus: Cambridge Igcse First Language EnglishNdache PermataNo ratings yet

- 2017 Somali English ABC Bridge PrimerDocument230 pages2017 Somali English ABC Bridge PrimerSky somaliNo ratings yet

- Fresh AHU ComparisonDocument8 pagesFresh AHU Comparisonevo2oo2No ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- IGTM-CT Gas Turbine Meter: Documentation and Technical SpecificationsDocument12 pagesIGTM-CT Gas Turbine Meter: Documentation and Technical Specificationsajitp123No ratings yet

- Analyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriDocument71 pagesAnalyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriAgnys Gomes - DR UNITECNo ratings yet

- Chapter 4Document2 pagesChapter 4Lilia GuzunNo ratings yet

- Costing Breif CaseDocument2 pagesCosting Breif Casehema varshiniNo ratings yet

- Application of Negative Stiffness Devices For Seismic Protection of Bridge StructuresDocument10 pagesApplication of Negative Stiffness Devices For Seismic Protection of Bridge StructuresganeshNo ratings yet

- Chapter 2Document3 pagesChapter 2Johane Grei WallNo ratings yet

- Top 110 Cyber Security Interview Questions & Answers: 1) What Is Cybersecurity?Document21 pagesTop 110 Cyber Security Interview Questions & Answers: 1) What Is Cybersecurity?শ্রী লিমন চন্দ্র মোহন্তNo ratings yet

- 7th Mathematics 1,2,3Document3 pages7th Mathematics 1,2,3Khamalesh C.ANo ratings yet

- (1908) United States Revenue Cutter Service Uniform RegulationsDocument57 pages(1908) United States Revenue Cutter Service Uniform RegulationsHerbert Hillary Booker 2nd100% (3)

- PreviewDocument254 pagesPreviewIgor OkNo ratings yet

- Open Source Tools For Measuring The Internal Quality of Java Software Products A SurveyDocument12 pagesOpen Source Tools For Measuring The Internal Quality of Java Software Products A SurveyStanley UmohNo ratings yet

- Production Planning - 095252Document13 pagesProduction Planning - 095252Jocidelle LubricoNo ratings yet

- CALR - SUPPL X Sequenze PrimersDocument53 pagesCALR - SUPPL X Sequenze PrimersNicoletta ColomboNo ratings yet

- Study of Adhesion Properties of Natural Rubber, Epoxidized Natural Rubber, and Ethylene-Propylene Diene Terpolymer-Based AdhesivesDocument44 pagesStudy of Adhesion Properties of Natural Rubber, Epoxidized Natural Rubber, and Ethylene-Propylene Diene Terpolymer-Based AdhesivesZarathos SinghNo ratings yet