Professional Documents

Culture Documents

Magnesium Acetate: - (A) Manufacturing Process

Magnesium Acetate: - (A) Manufacturing Process

Uploaded by

Shankar kumar roy0 ratings0% found this document useful (0 votes)

104 views2 pagesThe document describes the manufacturing process of magnesium acetate. Magnesium carbonate is slowly added to a vessel containing acetic acid and process water, and stirred for 2 hours to allow the chemical reaction to complete. The mixture is then unloaded into a nutch and sent to centrifugation to separate out the magnesium acetate. The solid product is dried and pulverized before being packed. The mother liquor is recycled for use in the next batch along with additional fresh water. The process flow chart details the inputs, outputs, and recycling of materials involved in the production of 1000kg of magnesium acetate with no waste water generation.

Original Description:

Original Title

7) Magnesium Acetate

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes the manufacturing process of magnesium acetate. Magnesium carbonate is slowly added to a vessel containing acetic acid and process water, and stirred for 2 hours to allow the chemical reaction to complete. The mixture is then unloaded into a nutch and sent to centrifugation to separate out the magnesium acetate. The solid product is dried and pulverized before being packed. The mother liquor is recycled for use in the next batch along with additional fresh water. The process flow chart details the inputs, outputs, and recycling of materials involved in the production of 1000kg of magnesium acetate with no waste water generation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

104 views2 pagesMagnesium Acetate: - (A) Manufacturing Process

Magnesium Acetate: - (A) Manufacturing Process

Uploaded by

Shankar kumar royThe document describes the manufacturing process of magnesium acetate. Magnesium carbonate is slowly added to a vessel containing acetic acid and process water, and stirred for 2 hours to allow the chemical reaction to complete. The mixture is then unloaded into a nutch and sent to centrifugation to separate out the magnesium acetate. The solid product is dried and pulverized before being packed. The mother liquor is recycled for use in the next batch along with additional fresh water. The process flow chart details the inputs, outputs, and recycling of materials involved in the production of 1000kg of magnesium acetate with no waste water generation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

(7) Magnesium Acetate:-

(A)Manufacturing Process:

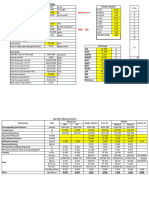

Take process water in vessel. Add Acetic acid. Then charge magnesium carbonate slowly. Then free

stirring 2 hrs. .If reaction completed. Then unload in Nutch. Then centrifuge and drying &

pulverised.Magnesium Acetate packed in bag.ML will be reused in next batch.

(B)Chemical Reaction:-

MgCO3 + 2CH3COOH Mg (CH3COO)2 + CO2 + H2O

84.31 120 142.39 44 18

(C) Process Flow Chart:-

Acetic Acid:843kgs

Magnesium carbonate: 592kgs

Fresh water: 800 lit

ML Recycle: ( 700Ltr ML+100Lit water)

Vessel

Nutch ML Use in next batch: 600Ltr

Centrifuge ML use in next batch: 100Ltr

Dryer Water loss 225 Ltr during drying.

Pulverise

Packed

Finish Product: Magnesium Acetate:

1000Kg

Water Consumption: Nil/Mt Magnesium Acetate

Waste Water Generation: Nill

SR.NO Name Of Raw INPUT Name Of OUTPUT QTY IN KG

. Materials QTY IN KG Materials

1 Magnesium Carbonate 592 Mother Liquor 700 Lit for reuse

2 Acetic Acid 843 CO2 GAS 310 kg CO2

3 Water 800 Water loss in 225 KG

drying

4 Magnesium 1000 KG

Acetate.

TOTAL 2235 Kg 2235 KG

You might also like

- 60 KLPD Grain-Based Distillery - A SnapshotDocument9 pages60 KLPD Grain-Based Distillery - A SnapshotAmrit Agarwal100% (2)

- Combined Mass and Energy Balance For Citric Acid ProductionDocument47 pagesCombined Mass and Energy Balance For Citric Acid ProductionShermal Fernando50% (2)

- 17) Calcium Propionate Manufacturing ProcessDocument2 pages17) Calcium Propionate Manufacturing ProcessShankar kumar roy100% (3)

- 2.8 Material and Energy Balance Across Lime Hydrator 2.8.1 Material Balance of Lime HydratorDocument6 pages2.8 Material and Energy Balance Across Lime Hydrator 2.8.1 Material Balance of Lime HydratorRichard ObinnaNo ratings yet

- 17) Calcium Propionate Manufacturing ProcessDocument2 pages17) Calcium Propionate Manufacturing ProcessShankar kumar roy100% (3)

- 18.) Calcium Stearate: (A) Manufacturing ProcessDocument2 pages18.) Calcium Stearate: (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 21.) Potassium Oxalate: (A) Manufacturing ProcessDocument2 pages21.) Potassium Oxalate: (A) Manufacturing ProcessShankar kumar roy100% (1)

- 19.) Copper Gluconate: - (A) Manufacturing ProcessDocument2 pages19.) Copper Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 20.) Calcium Gluconate: - (A) Manufacturing ProcessDocument2 pages20.) Calcium Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Flowdiagram of Disperse Blue 79Document4 pagesFlowdiagram of Disperse Blue 79kanji63No ratings yet

- Material Balance Around Tubular Reactor:: ReactionDocument7 pagesMaterial Balance Around Tubular Reactor:: ReactionAnonymous KsRdWoYtNo ratings yet

- Thermowise Storage Vessels IntDocument12 pagesThermowise Storage Vessels IntIrishadoreStevlandOliphantNo ratings yet

- Ceramic Products Manufacture: University of Khartoum Faculty of Engineering Department of Chemical EngineeringDocument31 pagesCeramic Products Manufacture: University of Khartoum Faculty of Engineering Department of Chemical EngineeringsmendozaNo ratings yet

- 0 0 1211812181211ManufacturingProcessDocument17 pages0 0 1211812181211ManufacturingProcessLUISNo ratings yet

- Bayers Process ReactionsDocument23 pagesBayers Process Reactionsgullipalli srinivasa raoNo ratings yet

- Mass Balance CPC Blue CrudeDocument4 pagesMass Balance CPC Blue Crudedinkad29No ratings yet

- Kaolite LI Monolithics Up To 2600°F (1427°C) : Datasheet Code US: 3-14-103 SDS: 103 / 153Document3 pagesKaolite LI Monolithics Up To 2600°F (1427°C) : Datasheet Code US: 3-14-103 SDS: 103 / 153luisNo ratings yet

- Production of Oxalic Acid Term PaperDocument16 pagesProduction of Oxalic Acid Term PaperSanket SutharNo ratings yet

- Heat BalanceDocument33 pagesHeat BalanceIrshad Hussain100% (2)

- Tissue Culture Items For One YearDocument2 pagesTissue Culture Items For One YearsheenaNo ratings yet

- 9.2 Water - Tutorial Sheet - 2Document1 page9.2 Water - Tutorial Sheet - 2LakshayNo ratings yet

- Acid Purification and RecoveryDocument4 pagesAcid Purification and RecoverythiagoNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFsundarNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFAbhisek BhattacharyaNo ratings yet

- Mass Balance Data For Mass Balance M.W G/gmolDocument39 pagesMass Balance Data For Mass Balance M.W G/gmolHarshil TejaniNo ratings yet

- Isolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)Document17 pagesIsolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)zawNo ratings yet

- Silica Removal During Lime Softening in Water Treatment PlantDocument10 pagesSilica Removal During Lime Softening in Water Treatment PlantLouay MansourNo ratings yet

- Biogas PDFDocument18 pagesBiogas PDFkarácsonyi krampuszNo ratings yet

- Water Treatement PresentationDocument22 pagesWater Treatement Presentationtez zaroNo ratings yet

- Exibitions Seabin: Proposed By: - Siddharth AbstractDocument18 pagesExibitions Seabin: Proposed By: - Siddharth AbstractIshika SinghNo ratings yet

- Session 19 v5Document16 pagesSession 19 v5Fabio RizzoNo ratings yet

- Water and Its Treatment-5,6Document3 pagesWater and Its Treatment-5,6Tushar SharmaNo ratings yet

- A01 269Document11 pagesA01 269jaimeNo ratings yet

- 5 1865 11 (3) 2013 IjcsDocument9 pages5 1865 11 (3) 2013 IjcsMorrayNo ratings yet

- Aplicaciones Tituladores - Determinacion de Aluminio en Aluminio Ore (Aplicacion M466A-2010)Document7 pagesAplicaciones Tituladores - Determinacion de Aluminio en Aluminio Ore (Aplicacion M466A-2010)Margot Valverde PonceNo ratings yet

- Presentation On DM PlantDocument16 pagesPresentation On DM PlantVenkat Dora100% (4)

- Axsorb 911 - Technical Data Sheet-EnglishDocument2 pagesAxsorb 911 - Technical Data Sheet-Englishanwar sadatNo ratings yet

- Technical Specification: Design, Fabrication, Supply, Testing and Commissioning of D.M Water PlantDocument27 pagesTechnical Specification: Design, Fabrication, Supply, Testing and Commissioning of D.M Water PlantTASLEEMNo ratings yet

- Magnesium Alloys: Raw Material ProductionDocument25 pagesMagnesium Alloys: Raw Material Productionmohamad hafizNo ratings yet

- CET® Onsite Alternate EnergyDocument7 pagesCET® Onsite Alternate EnergyPrashant DeshmaneNo ratings yet

- AmmoniaDocument49 pagesAmmoniaAnonymous fhKOhG6No ratings yet

- Applied ChemistryDocument6 pagesApplied Chemistryyenireddy harimadhavareddyNo ratings yet

- Tutorial Crystallization PDFDocument5 pagesTutorial Crystallization PDFara_1909No ratings yet

- Lecture 3 - Improving Performance - RegenerationDocument2 pagesLecture 3 - Improving Performance - RegenerationHussain AbbasNo ratings yet

- Power Generation by Bagasse FuelDocument48 pagesPower Generation by Bagasse FuelShawala AzharNo ratings yet

- Water in Textile ProcessingDocument3 pagesWater in Textile ProcessingDr. S. P. Mishra100% (1)

- 0 0 17 Apr 2015 1131040001SummaryoftheProjectDocument4 pages0 0 17 Apr 2015 1131040001SummaryoftheProjectPatelNo ratings yet

- BomDocument3 pagesBomsandeepNo ratings yet

- Problems For Chapter 8: Power Cycles: A. The Rankine CycleDocument48 pagesProblems For Chapter 8: Power Cycles: A. The Rankine CycleEUGENE AICHANo ratings yet

- Total 全合成1Document36 pagesTotal 全合成12967449CEE100% (2)

- Basic Energy Balance For 1000Kg Feed - Palm Oil HunterDocument2 pagesBasic Energy Balance For 1000Kg Feed - Palm Oil Hunteruma shankar balakrishnanNo ratings yet

- Zeolite or Permutit Process:: Na O - Al O - Xsio - Yh ODocument11 pagesZeolite or Permutit Process:: Na O - Al O - Xsio - Yh O056 Jatin GavelNo ratings yet

- UofFloridaWBL KCl-Ammonium 20181101Document11 pagesUofFloridaWBL KCl-Ammonium 20181101DC KrnaNo ratings yet

- Proposal - Suheung Vina 30.05.2023 (Rev) To Kim LeeDocument17 pagesProposal - Suheung Vina 30.05.2023 (Rev) To Kim LeedaniNo ratings yet

- An Industrialreport ON Urea Plant atDocument17 pagesAn Industrialreport ON Urea Plant atDeep GajjarNo ratings yet

- LOCTITE ABLESTIK 2600BT en - GLDocument2 pagesLOCTITE ABLESTIK 2600BT en - GLJess OrtonNo ratings yet

- Steam CalculatorDocument6 pagesSteam Calculatorthermaxteja2016No ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- 4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberDocument5 pages4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberShankar kumar royNo ratings yet

- 21.) Potassium Oxalate: (A) Manufacturing ProcessDocument2 pages21.) Potassium Oxalate: (A) Manufacturing ProcessShankar kumar roy100% (1)

- 19.) Copper Gluconate: - (A) Manufacturing ProcessDocument2 pages19.) Copper Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Indole Synthesis - Something Old, Something NewDocument13 pagesIndole Synthesis - Something Old, Something NewShankar kumar royNo ratings yet

- 20.) Calcium Gluconate: - (A) Manufacturing ProcessDocument2 pages20.) Calcium Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 18.) Calcium Stearate: (A) Manufacturing ProcessDocument2 pages18.) Calcium Stearate: (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Standard Operating ProcedureDocument8 pagesStandard Operating ProcedureShankar kumar royNo ratings yet

- Parahydroxy Acetophenone SynthesisDocument1 pageParahydroxy Acetophenone SynthesisShankar kumar royNo ratings yet

- Facility and AHU ValidationDocument63 pagesFacility and AHU ValidationShankar kumar roy100% (3)

- Ethoxy CarbazepineDocument27 pagesEthoxy CarbazepineShankar kumar royNo ratings yet