Professional Documents

Culture Documents

Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)

Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)

Uploaded by

Clariza TanCopyright:

Available Formats

You might also like

- Fabric For Fashion The Complete Guide2Document273 pagesFabric For Fashion The Complete Guide2M.José Copons Gallo100% (23)

- Methods of Test For ButtonsDocument4 pagesMethods of Test For ButtonsmomofattohNo ratings yet

- Affect of Acid and Alkaline On Tensile Stength of Fibers.Document26 pagesAffect of Acid and Alkaline On Tensile Stength of Fibers.Pranjal Mehta58% (72)

- Brochure ZytexDocument12 pagesBrochure ZytexKinjal PatelNo ratings yet

- Cloth Clothing AnglosaxDocument20 pagesCloth Clothing AnglosaxRamona Argolia Hartley0% (1)

- Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)Document23 pagesSustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)Clariza TanNo ratings yet

- Analysis of Physical Characteristics of Bamboo FabricsDocument5 pagesAnalysis of Physical Characteristics of Bamboo FabricsesatjournalsNo ratings yet

- Analysis of Physical Characteristics of BambooDocument5 pagesAnalysis of Physical Characteristics of BambooInternational Journal of Research in Engineering and TechnologyNo ratings yet

- MVB - Paper Topic - 0331-2021Document9 pagesMVB - Paper Topic - 0331-2021Tonet BercesNo ratings yet

- Effect of Pile Yarn Type On Absorbency, Stiffness, and Abrasion Resistance of Bamboo/Cotton and Cotton Terry Towels Filiz SekerdenDocument7 pagesEffect of Pile Yarn Type On Absorbency, Stiffness, and Abrasion Resistance of Bamboo/Cotton and Cotton Terry Towels Filiz SekerdenSubramani PichandiNo ratings yet

- Paper 7Document13 pagesPaper 7RakeshconclaveNo ratings yet

- Ali PDFDocument9 pagesAli PDFcadetpalangNo ratings yet

- 07 Chapter 2Document103 pages07 Chapter 2Mukesh Manwani100% (1)

- Rejenere Bambu Elyafin - Yapi - Zell - Kler - N - N - Ncelenmes - (#251800) - 218177Document7 pagesRejenere Bambu Elyafin - Yapi - Zell - Kler - N - N - Ncelenmes - (#251800) - 218177Juan David Cubillos SarmientoNo ratings yet

- BambooDocument3 pagesBambooB22 Thiruvengaden R100% (1)

- Review Article A Literature Review On Natural Fibers, Its Properties and Influence of Water Absorption On Mechanical Properties of CompositesDocument9 pagesReview Article A Literature Review On Natural Fibers, Its Properties and Influence of Water Absorption On Mechanical Properties of Compositesmkumar_234155No ratings yet

- Cementitious Composites Reinforced With Vegetable FibersDocument27 pagesCementitious Composites Reinforced With Vegetable FibersDaniel GomesNo ratings yet

- The Hygroscopic Behavior of Plant Fibers: A ReviewDocument12 pagesThe Hygroscopic Behavior of Plant Fibers: A Reviewdeathjester1No ratings yet

- Kenaf FibreDocument10 pagesKenaf FibreIfkar AzmiNo ratings yet

- Poster - A Review On The Use of Estabragh (Milkweed) Fibers in Nonwoven ApplicationsDocument1 pagePoster - A Review On The Use of Estabragh (Milkweed) Fibers in Nonwoven Applicationsmahnaz khakpourNo ratings yet

- 2011 Article1379516711 - Ali PDFDocument9 pages2011 Article1379516711 - Ali PDFSrinivas AyyalasomayajulaNo ratings yet

- A Study On Mechanical Properties of Bamboo Fiber Rei - 2020 - Materials Today PDocument7 pagesA Study On Mechanical Properties of Bamboo Fiber Rei - 2020 - Materials Today PClaudia UngureanuNo ratings yet

- EvaluationofTensileBehaviorofSeaShell JuteFabric PDFDocument7 pagesEvaluationofTensileBehaviorofSeaShell JuteFabric PDFPrince Ghosh EponNo ratings yet

- Biomolecules: Biofunctionalization of Natural Fiber-Reinforced Biocomposites For Biomedical ApplicationsDocument44 pagesBiomolecules: Biofunctionalization of Natural Fiber-Reinforced Biocomposites For Biomedical ApplicationsMd Mahedi HasanNo ratings yet

- A Review On Natural Fibre Based Composites - Structure, Processing and Properties of Vegetable FibresDocument32 pagesA Review On Natural Fibre Based Composites - Structure, Processing and Properties of Vegetable FibresMiritoiu CosminNo ratings yet

- Development and Characterization of Eco-Sustainable Banana Fiber Nonwoven Material: Surface Treatment, Water Absorbency and Mechanical PropertiesDocument12 pagesDevelopment and Characterization of Eco-Sustainable Banana Fiber Nonwoven Material: Surface Treatment, Water Absorbency and Mechanical PropertiesVNo ratings yet

- 11 Antimicrobial Studies of Knitted Fabrics From Bamboo, Soybean and FlaxDocument4 pages11 Antimicrobial Studies of Knitted Fabrics From Bamboo, Soybean and FlaxEngr Md. Nayemul IslamNo ratings yet

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsJorge Gerardo Riascos QuiñonesNo ratings yet

- Materials Today: Proceedings: Jonathan B. Dawit, Hirpa G. Lemu, Yohannes Regassa, Adugna D. AkessaDocument6 pagesMaterials Today: Proceedings: Jonathan B. Dawit, Hirpa G. Lemu, Yohannes Regassa, Adugna D. AkessaHelmi ChaâbeneNo ratings yet

- Mechanical Properties of Natural Cellulose Fibers Reinforced PolymerDocument8 pagesMechanical Properties of Natural Cellulose Fibers Reinforced Polymernurshiyama89No ratings yet

- Materials Today: Proceedings: K. Balasubramanian, N. Rajeswari, R. VishvakDocument5 pagesMaterials Today: Proceedings: K. Balasubramanian, N. Rajeswari, R. VishvakedmealemNo ratings yet

- A Review NF (U)Document10 pagesA Review NF (U)Hazim HamdanNo ratings yet

- Analisa Kekuatan Tarik Dan Bentuk Patahan Komposit Serat Sabuk Kelapa Bermatriks Epoxyterhadap Variasi Fraksi Volume SeratDocument6 pagesAnalisa Kekuatan Tarik Dan Bentuk Patahan Komposit Serat Sabuk Kelapa Bermatriks Epoxyterhadap Variasi Fraksi Volume SeratChartens PratamaNo ratings yet

- Composites: Part A: Hongyan Chen, Menghe Miao, Xin DingDocument7 pagesComposites: Part A: Hongyan Chen, Menghe Miao, Xin DingMikaaeelNo ratings yet

- Methodology For Tensile Tests On Vegetable FibersDocument7 pagesMethodology For Tensile Tests On Vegetable FibersShirly Mae DinongNo ratings yet

- Loa Levis Gigantochloa Scortechinii, Gigantochloa Wrayi, and Schizostachyum Zollingeri Bamboo FibersDocument6 pagesLoa Levis Gigantochloa Scortechinii, Gigantochloa Wrayi, and Schizostachyum Zollingeri Bamboo FibersabdussalamNo ratings yet

- Chapter 2Document15 pagesChapter 2Roem EsmernaNo ratings yet

- Coconut FibreDocument9 pagesCoconut Fibrejs kalyana rama100% (1)

- Innovative Banana Fiber Nonwoven Reinforced Polymer Composites PR - and PostTreatment Effects On Physical and Mechanical PropertiesDocument23 pagesInnovative Banana Fiber Nonwoven Reinforced Polymer Composites PR - and PostTreatment Effects On Physical and Mechanical PropertiesHea TherNo ratings yet

- Influence of Tencel/cotton Blends On Knitted Fabric PerformanceDocument9 pagesInfluence of Tencel/cotton Blends On Knitted Fabric PerformanceEstefania VillamarinNo ratings yet

- Critival Review Mattek 1Document7 pagesCritival Review Mattek 1Agan AuliyaNo ratings yet

- Fpls 10 00411Document23 pagesFpls 10 00411Ýõõ NäNo ratings yet

- 1 s2.0 S246821792100006X MainDocument14 pages1 s2.0 S246821792100006X MainGirmaw YeshanbelNo ratings yet

- Review On Cellulosic Fibers Extracted From Date Palms (Phoenix Dactylifera L.) and Their ApplicationsDocument24 pagesReview On Cellulosic Fibers Extracted From Date Palms (Phoenix Dactylifera L.) and Their ApplicationsHamzaNo ratings yet

- Properties & Application of Bamboo and Bamboo Fibre CompositionDocument6 pagesProperties & Application of Bamboo and Bamboo Fibre CompositionVIKKASH A/L RAJAGOPAL STUDENTNo ratings yet

- A Review of Banana Fiber Impact of Treatment, Filler Materials, Hybrid Composite, and ApplicationDocument12 pagesA Review of Banana Fiber Impact of Treatment, Filler Materials, Hybrid Composite, and Applicational ichlasNo ratings yet

- Effect of Moisture Absorption On The Properties of Natural FiberDocument6 pagesEffect of Moisture Absorption On The Properties of Natural FiberIsmadi IsmadiNo ratings yet

- Chemical Treatment On Rattan Fibers - DurabilityDocument11 pagesChemical Treatment On Rattan Fibers - DurabilityGladys Eras ValladolidNo ratings yet

- Analysis of Mechanical and Wettability PropertiesDocument15 pagesAnalysis of Mechanical and Wettability PropertiesKasia FrątczakNo ratings yet

- Investigationon The Mechanical and Morphological Characteristics of Caryota Urens Spadix Fibre Reinforced With Polyester CompositesDocument10 pagesInvestigationon The Mechanical and Morphological Characteristics of Caryota Urens Spadix Fibre Reinforced With Polyester Compositesdharani kumarNo ratings yet

- Analysis of Mechanical Properties of Natural Waste Particle Reinforced Polymer CompositesDocument10 pagesAnalysis of Mechanical Properties of Natural Waste Particle Reinforced Polymer CompositesGODWIN GNo ratings yet

- Articulo 32Document5 pagesArticulo 32Jhoel CRNo ratings yet

- Report Proj Composite Materials Based On Coconut FiberDocument30 pagesReport Proj Composite Materials Based On Coconut Fibermujeeb100% (1)

- Prasad 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012103 PDFDocument7 pagesPrasad 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012103 PDFlekNo ratings yet

- Ijftr 37 (3) 231-237 PDFDocument7 pagesIjftr 37 (3) 231-237 PDFPriya LathaNo ratings yet

- Natural Fibre CompositeDocument10 pagesNatural Fibre CompositeAdikaNo ratings yet

- 459 896 1 SMDocument8 pages459 896 1 SMTxc LeaderNo ratings yet

- Effect of Different Mercerization Techniques On Tactile Comfort of Cotton FabricDocument6 pagesEffect of Different Mercerization Techniques On Tactile Comfort of Cotton FabricAhmad ButtNo ratings yet

- Materials Today: Proceedings: Ravinder TonkDocument4 pagesMaterials Today: Proceedings: Ravinder TonkIngrid ContrerasNo ratings yet

- Mechanical Characteristics of Bio-Composite Materials Reinforced by Pandanus Tectorius Natural FibersDocument9 pagesMechanical Characteristics of Bio-Composite Materials Reinforced by Pandanus Tectorius Natural FibersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Development and Characterisation of Multi-Layered Jute Fabric-Reinforced HDPE CompositesDocument15 pagesDevelopment and Characterisation of Multi-Layered Jute Fabric-Reinforced HDPE Compositesabilio_j_vieiraNo ratings yet

- Mechanical Performance and Analysis of Banana Fiber Reinforced Epoxy Composites PDFDocument10 pagesMechanical Performance and Analysis of Banana Fiber Reinforced Epoxy Composites PDFAmgad Abd ElmohsenNo ratings yet

- Pretreatments - of - Natural - Fibers - and - Thei PDFDocument20 pagesPretreatments - of - Natural - Fibers - and - Thei PDFVăn ThưNo ratings yet

- Roadmap to Sustainable Textiles and Clothing: Eco-friendly Raw Materials, Technologies, and Processing MethodsFrom EverandRoadmap to Sustainable Textiles and Clothing: Eco-friendly Raw Materials, Technologies, and Processing MethodsNo ratings yet

- Use of Waste Plastics in Cement-Based Co PDFDocument11 pagesUse of Waste Plastics in Cement-Based Co PDFClariza Tan100% (1)

- The in Uence of Some Surfactants On Porous Concrete PropertiesDocument8 pagesThe in Uence of Some Surfactants On Porous Concrete PropertiesClariza TanNo ratings yet

- Shaking Table Tests of Lightly RC Walls Numerical SimulationsDocument31 pagesShaking Table Tests of Lightly RC Walls Numerical SimulationsClariza TanNo ratings yet

- Bamboo Chips Bambusa Vulgaris As An Alternative Li PDFDocument5 pagesBamboo Chips Bambusa Vulgaris As An Alternative Li PDFClariza TanNo ratings yet

- Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)Document23 pagesSustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)Clariza TanNo ratings yet

- Bamboo Chips Bambusa Vulgaris As An Alternative LiDocument5 pagesBamboo Chips Bambusa Vulgaris As An Alternative LiClariza TanNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument25 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsClariza TanNo ratings yet

- Garment DefectsDocument21 pagesGarment DefectsVishwanath Kr100% (2)

- B.tech Textile Tech.Document61 pagesB.tech Textile Tech.Varadharaja GnanaguruNo ratings yet

- Company Grasim ProfileDocument48 pagesCompany Grasim ProfileNitu Saini100% (1)

- Blends DyeingDocument232 pagesBlends DyeingMuhammad Qamar Tusief100% (1)

- Idye Poly BULK InstructionsDocument1 pageIdye Poly BULK InstructionsSimak VrosgkiNo ratings yet

- Development of A Smart Clothing Product Using An ADocument24 pagesDevelopment of A Smart Clothing Product Using An AChetan Gupta GuptaNo ratings yet

- Knitting ReportDocument3 pagesKnitting Reportmuhammadsaeed787No ratings yet

- Crochet Cactus Keychain Amigurumi Free PatternDocument4 pagesCrochet Cactus Keychain Amigurumi Free PatternSofia Arceo Sanchez100% (4)

- WeeWeka SMGussetFOEDocument4 pagesWeeWeka SMGussetFOEneo_5567No ratings yet

- KarnatakaDocument171 pagesKarnatakavenkatesh_182933% (3)

- A9500family enDocument18 pagesA9500family enMahesh vyankatesh lavhareNo ratings yet

- SD Certificate IKEADocument8 pagesSD Certificate IKEARezoanul HaqueNo ratings yet

- Carded or Combed Yarn Is Used. Double-Ply YarnDocument2 pagesCarded or Combed Yarn Is Used. Double-Ply Yarnmaddy_i5No ratings yet

- Fabric ConstructionDocument2 pagesFabric ConstructionrudraNo ratings yet

- Certificado Cinta 3mDocument1 pageCertificado Cinta 3mDollyvelNo ratings yet

- A Research Analysis On GI Tag Craft Puan & Pawndum of MizoramDocument105 pagesA Research Analysis On GI Tag Craft Puan & Pawndum of MizoramShubhra TiwariNo ratings yet

- Compensation and BenefitsDocument10 pagesCompensation and Benefitsapi-226053416100% (1)

- Color and Weave Relationship in Woven FabricsDocument14 pagesColor and Weave Relationship in Woven FabricsAnonymous UoRu4s100% (1)

- TRADE FAIRS 13 08 2020 ChronologicalDocument25 pagesTRADE FAIRS 13 08 2020 ChronologicalJoyel DsouzaNo ratings yet

- Antimicrobial Performance of Medical TextilesDocument14 pagesAntimicrobial Performance of Medical TextilessudhirchughNo ratings yet

- Applications of Textiles in Diversified Fields: Presentation By: T Ravi Kumar 17110066Document10 pagesApplications of Textiles in Diversified Fields: Presentation By: T Ravi Kumar 17110066Nikhil NaniNo ratings yet

- DLLDocument15 pagesDLLtracy carpio0% (1)

- Exhibitor and Visitor Statistics For Heimtextil 2020Document1 pageExhibitor and Visitor Statistics For Heimtextil 2020Ricardo PereiraNo ratings yet

- Unit-3 TextilesDocument50 pagesUnit-3 TextilesbmalsomaNo ratings yet

- As 2212-1979 Elastomeric Hose and Hose Assemblies For Transferring Anhydrous AmmoniaDocument7 pagesAs 2212-1979 Elastomeric Hose and Hose Assemblies For Transferring Anhydrous AmmoniaSAI Global - APACNo ratings yet

- GC4500 Series: © 2016 Koninklijke Philips N.V. All Rights Reserved. 4239 001 04691Document18 pagesGC4500 Series: © 2016 Koninklijke Philips N.V. All Rights Reserved. 4239 001 04691Loredana StiraNo ratings yet

Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)

Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)

Uploaded by

Clariza TanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)

Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)

Uploaded by

Clariza TanCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/231608434

Sustainable Textiles: the Role of Bamboo and a Comparison of Bamboo Textile

properties (Part II)

Article in Journal of Textile and Apparel, Technology and Management · January 2010

CITATIONS READS

31 3,502

1 author:

Marilyn Waite

Village Capital (VilCap)

7 PUBLICATIONS 43 CITATIONS

SEE PROFILE

All content following this page was uploaded by Marilyn Waite on 22 May 2014.

The user has requested enhancement of the downloaded file.

Volume 6, Issue 3, Spring2010

Sustainable Textiles: the Role of Bamboo and a Comparison of

Bamboo Textile properties (Part II)

Marilyn Waite

Engineer for Sustainable Development

Ingéniuer pour le développement durable

Marilyn.waite@gmail.com

ABSTRACT

This paper delves into a subset of engineering for sustainable development—the engineering of

sustainable textiles using bamboo. In particular, the document explores various questions relating

to the subject, including: (1) what constitute sustainable textiles? and (2) what role can bamboo

textiles play in sustainable development? The experiments performed attempt to answer two main

questions: (1) what are the differences in textile properties between chemically-manufactured and

mechanically-manufactured bamboo textiles? and (2) what are the differences in textile properties

between two different species of bamboo (Phyllostachys edulis and Bambusa emeiensis)?

We can look at the textile industry through the lens of the triple bottom line of sustainability. At

present, the industry has a poor track record for social and environmental concerns. The two most

commonly used textile fibres—cotton and polyester—both cause serious environmental problems

in their life cycle. This document focuses on one small aspect of the entire field of sustainable

textiles—materials made from bio-based renewable resources in the form of bamboo species.

The advantages of bamboo as a raw material include its fast renewability, its biodegradability, its

efficient space consumption, its low water use, and its organic status. The advantages of bamboo

fabric are its very soft feel (chemically-manufactured) or ramie-like feel (mechanically-

manufactured), its antimicrobial properties, its moisture wicking capabilities and its anti-static

nature. The main constraints of bamboo textiles are current costs and are those inherent in the

textile industry: energy, water, and chemical requirements that are involved in manufacturing.

The textile properties examined relate to sustainability: wear and tear (and therefore durability)

and moisture wicking (and therefore the need for machine washing and drying). The following

are measured for fibre, yarn, and fabric: tear force, breaking force, breaking tenacity, moisture

absorption and speed of drying, and surface morphology.

The work is divided into two parts. Part 1 addresses bamboo textiles in the context of sustainable

development, providing a historical perspective, sustainable development framework, pertinent

information about bamboo as a plant, and the various manufacturing processes, advantages, and

constraints of the bamboo textile industry. Part 2 addresses the experimental component with a

discussion of limitations, challenges, a system dynamics view of sustainable bamboo textiles, and

final recommendations for sustainability within the textile industry.

Article Designation: Refereed 1 JTATM

Volume 6, Issue 3, Spring2010

IV. Experimental Exploration with sustainable development. The ability to

Bamboo Textiles withstand forces is a key indicator of

durability. The longer a textile lasts, the

A. Introduction more one can prolong its eventual deposit in

landfill, and perhaps the more one can

Bamboo textiles present a noteworthy refrain from replacing and wasting further

opportunity for providing sustainable resources. If a textile can absorb moisture

textiles. Nevertheless, the renewable quickly and dry moisture quickly, then the

properties of bamboo itself do not add much need for mechanical drying and perhaps

to sustainable development if the textiles washing (which are energy intensive) can be

cannot serve a practical purpose. Bamboo lessened.

textiles must exhibit properties appropriate

for its applications, thereby providing the B. Brief Literature Review

end-user with a useful item. This section

summarizes the materials used, methods There are thousands of studies concerning

employed, and results of experiments various fiber, yarn, fabric, and general

performed in order to assess some of the textile properties of various plant fibers.

bamboo textile properties. Topics covered include the sorption

properties of flax fibers, the effects of

There are two main manufacturing methods cultivating methods on the mechanical

currently being employed in the properties of cotton fiber, the determination

manufacture of sustainable textiles— of porosity and cellulose content of plant

chemically-based and mechanically-based fibers, the tensile properties of cocoon silk,

processes. There are also over 1500 species the calculation of elastic properties of

of bamboo globally, of which only a few are natural fibers, etc.

being employed to create textiles. Some

companies use only one species of bamboo There are no current published academic

for bamboo textile manufacturing, while works comparing bamboo textile properties

other companies use many (such as 13 between different bamboo species and

bamboo species) without distinguishing between different bamboo textile

between species and textile properties. The manufacturing processes (chemical versus

experiments performed attempt to answer mechanical). Here, I provide a brief review

two questions regarding bamboo textiles: (1) of pertinent findings in the literature

what are the differences in textile properties concerning bamboo textiles, ranging from

between the chemically-manufactured and studies that seek to improve bamboo fibers

mechanically-manufactured bamboo with surface modification, to comparisons of

textiles, and (2) what are the differences in bamboo fibers with other textile fibers.

textile properties between two different Mwaikambo provides a review of the

species of bamboo used to produce chemical history, properties, and applications of

bamboo (Phyllostachys edulis and Bambusa various plant fibers, including bamboo.

emeiensis)? Mwaikambo presents the chemical

composition, physical properties (such as

The textile properties measured here are as diameter, length, bulk density), and

follows: tear force, breaking force, breaking mechanical properties (such as tensile

tenacity, moisture absorption and speed of strength, failure strain, and Young‘s

drying, and surface morphology. Tests are modulus) of the fibers (Mwaikambo 2006).

performed at various stages of the bamboo

textile manufacturing process: fiber, yarn, Xu, Lu et al investigated the thermal and

and fabric. Comparative testing is necessary structural differences among chemical

to develop and improve products (Lyle bamboo fiber, Tencel (regenerated cellulose

1977), thereby making bamboo textiles more made from the eucalyptus tree‘s wood pulp),

suitable for end-uses. The properties and conventional viscose fibers. The

analyzed have special relevance to pertinent findings are that: (1) chemical

Article Designation: Refereed 2 JTATM

Volume 6, Issue 3, Spring2010

bamboo fibers suggest good water retention Bambusa emeiensis. Phyllostachys edulis is

power due to the many voids in their cross- known as ―Mao zhu‖ in Chinese and

section and (2) chemical bamboo fibers and ―Moso‖ in Japanese; it was formerly known

conventional viscose fibers possess better as Phyllostachys heterocycla pubescens

ability of absorbing and releasing water than (AmericanBambooSociety 2007). This is a

Tencel (Xu, Lu et al. 2007). Xu, Wang et al popular bamboo for construction

analyzed the effects of atmospheric pressure applications, as well as the textile industry.

argon plasma on the surface properties of It was used to provide chemical bamboo

bamboo fibers. They found that (1) cracks, samples and mechanical bamboo samples

pits, and small fragments appear on the fiber from Suzhou Shengzhu Household Co.,

surfaces after plasma treatment, (2) surface based in Suzhou City China. Phyllostachys

roughness increases with longer treatment edulis has a monopodial and scattered

times and larger plasma powers, and (3) rhizome system, and it is distributed

dyeability and hydrophilicity of fibers throughout southwest China (Kanglin 1998).

improves with surface modification using

atmospheric pressure argon plasma Neosinocalamus affinis, now known as

treatment (Xu, Wang et al. 2006). Shen, Liu Bambusa emeiensis 'Chrysotrichus,' was

et al also explored the surface properties of used to provide chemical bamboo samples

chemical bamboo fibers using a column from a manufacturing company based in

wicking technique. Their study was a Shanghai and Sichuan China.

comparison between bamboo fiber and Neosinocalamus affinis has a sympodial and

cotton linter fiber (short fibers that cling to tufted rhizome system, is large sized, is

cottonseeds after long fibers are removed). cultivated at less than 1900 m in altitude,

The principal finding was that bamboo fiber and is widespread in the southwest of China

has more than double the Lewis acid (Kanglin 1998). The company (wishes to

component compared to cotton linter fiber; remain anonymous), uses bamboo fiber

the author suggests that this makes chemical made from bamboo selected from the

bamboo fiber similar to the touch of water, Sichuan Province in China.

since water is found to have the same Lewis

acid component (Shen, Liu et al. 2004). Figure 4.1 indicates the samples collected

including their specifications. The samples

C. Materials from Company A were received in April

2008 and stored at room temperature. The

Bamboo fiber, yarn, and fabric samples were samples from Suzhou Shengzhu Household

collected using two different species of Company were received in May and June

bamboo—Phyllostachys edulis and 2008 and stored at room temperature.

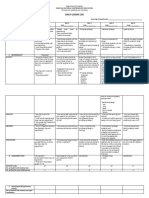

Figure 4.1: Bamboo Samples used in Experiments

Company Sample Type Photograph Specification Amount

Company A 100% Chemical Varied 0.5 kg

(Bambusa emeiensis) Bamboo Raw

Fibre (thick pulp)

100% Chemical 1.56 dtex×38 mm 0.5 kg

Bamboo Fibre (length)

(fine Pulp)

Article Designation: Refereed 3 JTATM

Volume 6, Issue 3, Spring2010

100% Chemical 32 Ne 0.5 kg

Bamboo Yarn Ring spun

100% Chemical 32 Ne 1m

Bamboo Knit Dyed Pink

Fabric

Suzhou Shengzhu 100% Chemical 1.56 dtex×38 mm 0.2 kg

Household Co. Bamboo

(Phyllostachys Fine Pulp Fibre

edulis)

100% Chemical 32 Ne 0.2 kg

Bamboo Yarn Ring spun

100% Chemical 21 Ne 0.2 kg

Bamboo Yarn Ring spun

100% Chemical 21 Ne 0.2 kg

Bamboo Woven Green and White

Fabric Floral Pattern

100% Chemical 32 Ne 0.6 kg

Bamboo Knit Dyed Black

Fabric

100% 5-6 dtex×95 mm 0.2 kg

Mechanical

Bamboo fibre

100% 21 Ne 0.2 kg

Mechanical Blue and White

Bamboo Woven Checkered Pattern

Fabric

To perform the scanning electron embroidery hoop, deionised water, balance,

microscope (SEM) observations, the pipettes and pipette tips, and a beaker. To

CamScan MX2600 was used. In order to perform the mechanical tests, a Hounsfield

conduct the moisture absorption and drying Low Load Electric Screw Machine was

experiments, the following materials were used.

used in addition to fabric: 17cm diameter

Article Designation: Refereed 4 JTATM

Volume 6, Issue 3, Spring2010

D. Methods (earliest stage) chemical bamboo fiber, fine

pulp chemical bamboo fiber, and mechanical

SEM Images bamboo fiber. Ten trials were completed for

each sample type. The following method

Standard test procedures for live specimens was employed:

were used to observe the differences in 1. A rectangular paper frame was

surface morphology among various bamboo constructed with a rectangular cut out.

fibers. The fibers were cut and gold-plated 2. Double-sided tape was then used to apply

as preparation. an adhesive surface to one side of the

paper frame. The rectangular cut out was

Moisture Wicking Tests preserved by cutting through the double-

sided tape.

AATCC Test Method 79-2007 was 3. Five individual fibers were carefully

employed to measure textile absorbency. picked using fine tweezers and placed

The general procedure involves dropping along the rectangular cut.

water from a fixed height onto a taut surface 4. Masking tape was cut and placed along

(made taut through the use of an embroidery both ends of the fibers to hold them in

hoop). The time required for the specular place.

reflection of a water drop to disappear is 5. The paper frame and the attached fibers

recorded as the wetting time. Five readings were then clamped using the Hounsfield

are taken, and the shorter the average time, tensile testing machine.

the more absorbent the fabric. This AATCC 6. Slits were cut through two ends of the

method was slightly modified by using a paper frame so that the only materials

pipette with 50 µL of deionised water pulled during the test were the fibers (and

instead of a burette. To measure the speed of not the fibers plus the paper frame).

drying of the different fabrics, 50 µL of 7. A standard breaking force program was

deionised water was placed on a piece of used with a load range of 5N, a speed of

fabric cut 4 cm wide and 5 cm long. The 100 mm/min, and an extension range of

weight of the fabric was taken before and 10 mm.

after the 50 µL of water was introduced, as

well as at set time intervals until the weight Yarns

of the fabric reached its initial recording.

To measure the tensile properties of yarns,

Mechanical Tests ASTM standard D 2256-02, Standard Test

Method for Tensile Properties of Yarns by

Mechanical tests were completed according the Single-Strand Method, was employed. A

to various internationally-recognized single-stranded yarn is broken on a tension

standards, including those from the testing machine at a predetermined

American Society for Testing and Materials elongation rate (300 ± 10 mm/min) so that

(ASTM), the International Organization for the breaking force is determined. A straight

Standardization (ISO), the British Standards specimen configuration was used with a

Institution (BSI), and the American gage length of 250 ± 3 mm gage length. The

Association of Textile Chemists and breaking force of individual specimens is the

Colorists (AATCC). maximum force to cause the specimen to

rupture as read directly from the tension

Fibers testing machine expressed in Newtons

(ASTM 2003). A total of ten trials were

To measure the breaking force of the performed for each yarn type. The breaking

bamboo fibers, standard test methods had to tenacity of an individual specimen is

be modified to conduct a comparison calculated using equation 1 as follows:

adequate for the short and fine chemical

bamboo fibers. Bamboo fibers were

measured at the following stages: thick pulp

Article Designation: Refereed 5 JTATM

Volume 6, Issue 3, Spring2010

(1) B=F/T E. Results and Discussion

where: B = breaking tenacity, CN per tex

F = breaking force, CN SEM Analysis

T = linear density, tex

The SEM images show various similarities

Fabric and differences among the four bamboo

fiber types analyzed. Both species of

To measure the tear properties of fabric, EN chemical bamboo fiber displayed a tubular

ISO 13937-2:2000, Tear properties of and ribbed (celery-like) longitudinal surface;

fabrics Part 2: Determination of tear force of the cross sections of both species were filled

trouser-shaped test specimens (Single tear with voids (Figure 4.9 and Figure 4.10). The

method), was employed. The test method thick pulp of chemical bamboo fiber has a

uses a test specimen cut to form trouser- rough and very porous surface (Figure 4.11);

shaped legs; the tear force measured is the this is to be expected as it is the closest to

force required to propagate a previously the actual bamboo plant among all of the

started single tear when the force is applied fiber types. Mechanical bamboo fiber

parallel to the cut and the fabric tears in the displayed a bamboo-like longitudinal

direction of applied force (ISO 2000). The section, tubular with nodes (Figure 4.12);

tear force is calculated from the force peaks the cross section displayed some voids,

recorded on the tensile testing machine. A though much fewer than the chemical

total of six trials were performed for each bamboo fibers. The mechanical bamboo

fabric type, three to calculate the tear force fiber also has a higher linear density (5.88

across warp and three to calculate the tear dtex) than the chemical bamboo fibers (1.56

force across weft. dtex).

Figure 4.9: Phyllostachys edulis Chemical Bamboo Fibre

Left: cross-sectional direction (SEM Mag7900X), Right: longitudinal direction, Diameter is 13.4

µm -15.6 µm (SEM Mag3346X)

Article Designation: Refereed 6 JTATM

Volume 6, Issue 3, Spring2010

Figure 4.10: Bambusa emeiensis Chemical Bamboo Fibre

Left: cross-sectional direction (SEM Mag3346X), Right: longitudinal direction (SEM

Mag2086X), Diameter is 12.3 µm -15.2 µm

Figure 4.11: Bambusa emeiensis Chemical Bamboo Fibre (Thick Pulp)

Left: cross-sectional direction (SEM Mag1406X), Right: longitudinal direction (SEM

Mag3152X), Diameter is ≈ 31.5 µm

Figure 4.12: Phyllostachys edulis Mechanical Bamboo Fibre

Left: cross-sectional direction (SEM Mag4476X), Right: longitudinal direction (SEM

Mag1708X), Diameter is ≈ 16 µm

Article Designation: Refereed 7 JTATM

Volume 6, Issue 3, Spring2010

Mechanical Tests cotton, wool, viscose rayon, and polyester

are all below that of the bamboo fibers

The following section provides summaries tested (Figure 4.13 and Figure 4.14);

in table and graph form for the mechanical therefore, bamboo fibers may be more

data gathered. resistant to wear and tear than conventional

fibers. The raw chemical bamboo fiber was

The results for fiber breaking force and not used for comparative purposes (since

breaking tenacity illustrate that only one sample was available at this stage

mechanically-manufactured bamboo fiber is in the manufacturing process); however, it is

more than two times stronger than clear that the strength of the bamboo fibers

chemically-manufactured bamboo. There are is more present before continual processing.

no significant differences between species at Graph 4.1 shows the mechanical testing

the fiber level. The breaking tenacity of results for bamboo fibers.

Figure 4.13: Fibre Breaking Force and Breaking Tenacity Comparison

Average

Sample Bamboo Species Manufacturing Fibre [Breaking Average

No. Method Specification Force Breaking

(CN) Tenacity

(CN/dtex)

Bambusa Chemical

1 emeiensis (thick pulp) Varied 406 ± 106 Varied

Bambusa

2 emeiensis Chemical 1.56 dtex 13.7 ± 2.1 8.75 ± 1.36

Phyllostachys

3 edulis Chemical 1.56 dtex 17.7 ± 2.8 11.4 ± 1.8

Phyllostachys

4 edulis Mechanical 5.88 dtex 146 ± 20 24.9 ± 3.64

Figure 4.14: Tenacity of Conventional Textile Fibres

Name Tenacity Tenacity

(gf/tex) (CN/dtex)

cotton 35 3.5

wool 12 1.2

viscose rayon 20 2

polyester 39.5 3.95

Article Designation: Refereed 8 JTATM

Volume 6, Issue 3, Spring2010

Graph 4.1: Fibre Breaking Force and Breaking Tenacity Comparison

The breaking force and breaking tenacity of there was no significant difference between

bamboo yarn reveal small differences the mechanical properties of different

between species and manufacturing method. bamboo species in yarn form. Figure 4.15

It appears that the processing of fiber into and Graph 4.2 illustrate the mechanical

yarn creates some level of strength testing results for bamboo yarn.

degradation for mechanically-manufactured

bamboo. As with bamboo textile fibers,

Figure 4.15: Yarn Breaking Force and Breaking Tenacity Comparison

Average

Sample Bamboo Manufacturing Yarn Breaking Average Breaking

No. Species Method Specification Force Tenacity (CN/tex)

(Ne Count) (CN)

Bambusa

1 emeiensis Chemical 32 278 ± 16 15.0 ± 0.87

Phyllostachys

2 edulis Chemical 32 240 ± 13 13.0 ± 0.72

Phyllostachys

3 edulis Chemical 21 485 ± 32 17.2 ± 1.1

Phyllostachys

4 edulis Mechanical 21 499 ± 49 17.7 ± 2.1

Article Designation: Refereed 9 JTATM

Volume 6, Issue 3, Spring2010

Graph 4.2: Yarn Breaking Force and Breaking Tenacity Comparison

The fabric tear results show that the woven However, the woven chemical bamboo

fabrics are more resistant to tear forces than fabric sample contained a floral pattern

the knit fabrics. Also, Bambusa emeiensis which almost created a double-layer;

endured a higher tear force than therefore, it is difficult to say with certainty

Phyllostachys edulis. Ironically, that there is a difference in manufacturing

mechanically-manufactured bamboo showed method for these tests. Figure 4.16 and

a much lower resistance to tear force than Graph 4.3 show the mechanical testing

chemically-manufactured bamboo. results for bamboo fabric.

Article Designation: Refereed 10 JTATM

Volume 6, Issue 3, Spring2010

Figure 4.17: Fabric Moisture Absorption Comparison

Sample Bamboo Manufacturing Fabric Average

Number Species Method Specification Warp/Weft Tear Force (N)

Bambusa

1 emeiensis Chemical Knit, Ne=32 Warp 15.6 ± 0.59

Bambusa

emeiensis Chemical Knit, Ne=32 Weft 9.64 ± 0.70

Phyllostachys

2 edulis Chemical Knit, Ne=32 Warp 7.99 ± 0.29

Phyllostachys

edulis Chemical Knit, Ne=32 Weft 5.86 ± 1.20

Phyllostachys

3 edulis Chemical Woven, Ne=21 Warp 64.5 ± 1.9

Phyllostachys

edulis Chemical Woven, Ne=21 Weft 59.2 ± 7.4

Phyllostachys

4 edulis Mechanical Woven, Ne=21 Warp 23.9 ± 2.88

Phyllostachys

edulis Mechanical Woven, Ne=21 Weft 22.1 ± 0.53

Graph 4.3: Fabric Tear Force Comparison

Moisture Wicking Tests the green printed design on Sample 3

(Phyllostachys edulis chemical bamboo

Figure 4.17 indicates the average absorption woven), the average absorption time was

times for a drop of water to be absorbed by 2.45 s; when a drop of water was placed

the corresponding fabric. Phyllostachys onto the cream-colored part of Sample 3

edulis has by far the quickest absorption (flat design), the water absorbed instantly at

time. When a drop of water was placed onto 0.00 s.

Article Designation: Refereed 11 JTATM

Volume 6, Issue 3, Spring2010

Figure 4.17: Fabric Moisture Absorption Comparison

Sample Manufacturing Fabric Average Absorption

Number Bamboo Species Method Specification Time (s)

Bambusa

1 emeiensis Chemical Knit, Ne=32 5864.80

Phyllostachys

2 edulis Chemical Knit, Ne=32 1376.60

Phyllostachys

3 edulis Chemical Woven, Ne=21 0.00-2.45

Phyllostachys

4 edulis Mechanical Woven, Ne=21 162.87

Figure 4.18 shows the total time that each woven made from Phyllostachys edulis. It

fabric took to dry, once wet with one drop of should be noted, however, that the design of

water. The fastest drying fabric was the the chemical bamboo woven fabric could

mechanical bamboo made from have slowed the drying time because of the

Phyllostachys edulis, while the slowest double-layer nature of the pattern.

drying fabric was the chemical bamboo

Figure 4.18: Fabric Moisture Drying Comparison

Sample Manufacturing Fabric Total Time Needed to

Number Bamboo Species Method Specification Dry (s)

Bambusa

1 emeiensis Chemical Knit, Ne=32 6673

Phyllostachys

2 edulis Chemical Knit, Ne=32 2853

Phyllostachys

3 edulis Chemical Woven, Ne=21 8196

Phyllostachys

4 edulis Mechanical Woven, Ne=21 452

Figure 4.19 shows the moisture wicking by the absorption time. Note that lower

capabilities of the fabrics in question. The numbers indicate higher moisture wicking

last column provides the difference between (fast absorption and fast drying).

the time of drying and absorbing normalised

Figure 4.19: Moisture Wicking Properties of Bamboo Fabric α: averaged time from range of

0s to 2.45s

Bamboo Manufacturing Fabric Average Total Time (Dry time-Absorb

Species Method Specification Absorption Needed to time)/Absorb time

Time (s) Dry (s)

Bambusa Chemical Knit, Ne=32 5865 6673 6672

emeiensis

Phyllostachys Chemical Knit, Ne=32 1377 2853 2852

edulis

Phyllostachys Chemical Woven, 1.2α 8196 8195

edulis Ne=21

Phyllostachys Mechanical Woven, 163 452 451

edulis Ne=21

Article Designation: Refereed 12 JTATM

Volume 6, Issue 3, Spring2010

Figure 4.20 shows the graphs of weight change, or slopes of the graphs, are all small

plotted over time after the fabric had and close in value. Graph 4.4 shows the

absorbed water. Note that the rates of moisture wicking results for bamboo fabric.

Figure 4.20: Speed of Drying for Various Types of Bamboo Textile Fabric

Graph 4.4: Moisture Wicking Properties of Bamboo Fabric

F. Conclusion processing. At the fiber level, mechanical

bamboo‘s breaking tenacity is at least twice

There are noticeable differences between as big as chemical bamboo fiber. At the yarn

textile strength in fiber, yarn, and fabric level, there are small differences between

form, with some apparent degradation in species and manufacturing method for

Article Designation: Refereed 13 JTATM

Volume 6, Issue 3, Spring2010

breaking tenacity. At the fabric level, longitudinal section resembled a bamboo as

Bambusa emeiensis has a bigger tear force a tubular shape with nodes. Perhaps there is

and tearing tenacity than Phyllostachys some level of biomimicry in the fibers of

edulis. Nevertheless, specie differences in bamboo that can be further explored.

fabric form are small. The tearing strength

of mechanical bamboo fabric was much There are two main conclusions that are

smaller than chemical bamboo fabric; drawn from the results: the species of

however this could be due to the woven bamboo is not trivial for bamboo textile

design in the chemical bamboo fabric. applications and there are fundamental

differences between the type and function of

The moisture absorption tests revealed well- bamboo textiles that are manufactured

defined differences between species, chemically versus those that are

manufacturing method, and textile manufactured mechanically with the aid of

specification. In general, the woven bamboo enzymes. Currently, many manufacturers

fabric absorbed water much quicker than the who make chemical bamboo fabric add

knit bamboo fabric. In knit chemical various species of bamboo into the mixture,

bamboo textile form, Bambusa emeiensis without consideration of the differences.

took four times longer than Phyllostachys Although the research did not indicate a

edulis to absorb water. In woven form significant difference in mechanical

(species kept constant with Phyllostachys properties such as breaking tenacity between

edulis) the chemical bamboo absorbed water species, moisture wicking properties varied

instantaneously, while the mechanical significantly. There are also some blogs

bamboo took 165 s on average to absorb. stating that mechanically manufactured

Based on these results, chemical bamboo bamboo is better than chemically

woven fabric is better at water absorption manufactured bamboo; the study shows that

than mechanical bamboo woven fabric, but the two textiles are not interchangeable, and

chemical bamboo knit fabric takes a very that their appropriateness will depend on the

long time to absorb. There also is a goals of the application. Three specific

difference in absorption properties between conclusions can be made from the

bamboo species in textile form, and perhaps experimental tests: (1) mechanical bamboo

the same differences can be found in raw fibers are much stronger than those

bamboo in nature. chemically manufactured, but this strength

at the fiber level does not remain consistent

The moisture drying tests revealed that some with further processing in yarn and fabric

fabrics were better at absorbing than drying. form, (2) Phyllostachys edulis exhibits better

Phyllostachys edulis chemical bamboo moisture wicking properties than Bambusa

woven fabric was the quickest to absorb, but emeiensis, (3) mechanical bamboo displays

the longest to dry. This may have been due better moisture wicking properties than

to the double layer of woven material to chemical bamboo. Further work could

create the green floral pattern. When explore more species of bamboo, as well as

manufacturing method and specification how small changes in the manufacturing

were held constant, Phyllostachys edulis process may change the quality of the textile

absorbed and dried faster than Bambusa at the fiber, yarn, and fabric levels. In

emeiensis; this supports the SEM images summary, there is room for many different

since there are more visible voids in the types of species and manufacturing methods

chemical bamboo Phyllostachys edulis for bamboo in the textile industry.

species. However, the fabric that has the V. Bamboo Textiles: the Limits

best moisture wicking property is the

mechanical bamboo made of Phyllostachys A. Limitations

edulis. This sample absorbed water in a

short time (163 s) and dried water in a short This paper shows how the properties of

time (452 s); though it did not show many bamboo can be useful for textile applications

voids in the SEM cross-sectional image, the in the realm of sustainable development.

Article Designation: Refereed 14 JTATM

Volume 6, Issue 3, Spring2010

However, there are many bamboo species 1. To reduce the risk of

and manufacturing steps not explored here overdependence on textile trade by

that would nevertheless, add to the overall local bamboo farmers, diversification

understanding of the subject. Also, since and support from outside

many bamboo textile operations are closed organizations are essential.

off to the public and researchers because of • With the numerous documented

intellectual property issues, there is pertinent and well-established end products

information regarding manufacturing that from bamboo sources, farmers

could not be included in this paper. It is can diversify their product range

important to emphasize that bamboo, or any so as to not become too

single textile source, will not serve as a susceptible to changes in any one

panacea to the sustainability issues of the market.

textile sector. Over-reliance on one source, • For bamboo farms that are

whether it is for energy or for textiles, is owned by small farmers,

contrary to the underlying principles of fair/ethical trade schemes and

sustainable development. In addition, fair/ethical trade support

different materials have different organizations, sustainable textile

mechanical, physical, chemical, and schemes, and connections to

technical properties that will serve for a associations with bamboo

diverse range of applications. bargaining power (such as

INBAR) could be established.

B. Challenges and Possible Mitigation Organizations such as the

Measures Fairtrade Labeling Organizations

(FLO), the Ethical Trading

There are many challenges facing the future Initiative, and Sedex, are all

of bamboo textiles, including: working to promote fair trade

1. The threat that bamboo farming globally. Organizations such as

communities become too dependent Social Accountability

on textile industries and are left with International, The Clean Clothes

little negotiating power with Campaign, the Fair Wear

intermediaries or the global market Foundation, and the International

(Bismarck, Baltazar-y-Jimenez et al. Fair Labor Association, work to

2006) promote ethical working

2. The threat of over-exploitation in conditions.

general and by an introduction of 2. The risk of overexploitation is

heavy machinery (that may damage present with any crop; to keep this

the bamboo rhizome system), as well from occurring with bamboo,

as with chemical pesticides and increased public pressure and

fertilizers. sustainably managed ―bamboo‖ forest

3. The risk of consumer disinterest certifications are suggested.

in ―eco-textiles,‖ or otherwise • Public pressure to keep textiles

similarly labeled textiles that would organic can help to reduce the risk

support the growth in bamboo textiles. of introducing chemicals to

For example, world consumption of bamboo farming. The high yield

sisal and henequen in Mexico and renewable status of bamboo

plummeted, and left many rural also make the use of chemical

families desolate, mostly due to the pesticides and fertilizers less

development of cheaper synthetic attractive than for other textile

polymer materials (Bismarck, raw crops.

Baltazar-y-Jimenez et al. 2006). • Bamboo forests are currently

poorly managed in comparison to

To mitigate some of these risks and address their wood counterparts. Because

the challenges, the following is suggested: bamboo is a non-timber resource,

Article Designation: Refereed 15 JTATM

Volume 6, Issue 3, Spring2010

it is missing in many government buy x number of t-shirts regardless of the

classifications and third-party clothing material); a bamboo item would

certification schemes. The replace a polyester item, for instance. Two

introduction of such measures main items that were left out of the diagram

would ensure that bamboo forests but worth mentioning are the number of

are continually managed in a workers in industry and government/inter-

sustainable manner and would governmental regulation. It is difficult to

engender confidence in predict the effect that an increase or

consumers. decrease in sustainable bamboo textiles

3. There should be increased yet would have on employment in the sector,

clarified public awareness in the mostly because machine automation

subject of sustainable textiles to continues to make jobs obsolete in the

reduce the threat of consumer textile industry. Regulation (including

disinterest. treaties, quotas, tariffs, and taxes) is an

important factor for a sustainable bamboo

The issue of trade agreements in the textile industry. However, it is not included

international textile market is very important here in an attempt to simplify the system

as it impacts the environment, workers, boundaries. Also, regulation is likely to

companies, end-users, and governments address the trade of textiles or the trade of

involved. The influence of government bamboo, but it is not likely to address

decisions on the sector, and therefore on the bamboo textiles specifically unless they

future of bamboo textiles, will not be treated became major world players in the textile

here. It is a complex issue and beyond the market (such as cotton). The relationship

scope of this paper, but it is also worth between the number of people who buy SBT

mentioning that agreements can have both products and the price of SBTs is shown,

positive and negative impacts on the assuming supply (more SBT manufacturers),

communities involved, in both the short run remains constant in the long term. In

and long run. general, a lower price indicates that more

people will be able to buy SBT products.

One aspect of the textile industry that

undermines sustainable textile development There are two main loops. One is a positive,

is the advent of ‗fast fashion.‘ That is, there or reinforcing loop labeled ―sustainable

are increasingly short leading times for new bamboo textile industry.‖ This loop shows

clothing textiles to reach the consumer the positive relationships between public

markets and increasingly short shelf lives of awareness, consumer education, consumer

the new clothing textiles. Figure 5.1 shows a voice, retailer voice, the amount of SBT

simplified causal loop diagram concerning manufacturing and SBT quantity in the

the sustainable bamboo textile industry. It industry, and the number of people who

shows how fast fashion undermines the purchase SBT products. This loop also leads

entire system of a sustainable bamboo textile to show how a sustainable bamboo textile

(SBT) industry, and a sustainable textile industry leads to sustainable bamboo

industry in general. The system boundary is forest/farm certification schemes, as well as

set with two major conditions: (1) textiles sustainable textile research and

are sourced from bamboo and (2) development. The second loop is negative,

sustainability is a prerequisite for each stage or balancing, and it is labeled ―fast fashion

of the life cycle. Therefore, the word in textile industry.‖ This loop indicates how

sustainable in the diagram encompasses the the relationships among quick lead times,

relevant categories such as energy, water consumer consumption of fast fashion, and

use, and chemicals. the price of bamboo textiles leads to a less

sustainable textile industry.

The diagram assumes that the total amount

of textiles in the worldwide textile stream Low prices and fast fashion are interlinked.

remains constant (for example, people will Assuming that one keeps the same budget,

Article Designation: Refereed 16 JTATM

Volume 6, Issue 3, Spring2010

one can buy things more often if the items textile industry, all other things being equal.

are sold at low prices. I will describe one Yet, a truly sustainable textile industry

possible scenario using the fast fashion loop. would lead to a decrease in fast fashion,

As the amount of SBTs increases, the since unnecessary material waste is a key

overall size of the sustainable textile component of sustainability. What is a

industry increases; this then leads to a possible solution? One answer is the

decrease in the amount of fast fashion. As purchase of sustainable textiles that last

fast fashion decreases, consumer longer and are more expensive; people

consumption of fast fashion decreases, and would buy clothes less often (and therefore

subsequently consumer consumption of engender less textile waste and pollution),

SBTs within the fast fashion realm but retailers would make the same profits

decreases. As the latter decreases, the price because goods would be sold at a higher

of SBT products must increase to make up price.

for profit loss (all other things being equal),

and this price change means that there will C. Final Recommendations

be less people who buy SBT products at this

higher price. When the number of people Finally, I propose a sustainable textile mix

who buy SBT products decreases, the for the future, similar to the energy mixes in

amount of SBTs in the industry decreases, which society has a diverse portfolio of

and therefore there is a decrease in the energy sources such as wind, solar, nuclear,

overall sustainable textile industry. Fast coal with carbon capture and storage, oil and

fashion is therefore creating an unpleasant gas, etc. The current textile mix, with a clear

barrier to the sustainable bamboo textile and majority belonging to petroleum-based

overall sustainable textile industries. synthetics and cotton fibers, is presented in

Figure 5.2. Figure 5.3a and 5.3b show textile

The diagram shows that an increase in the mix possibilities, randomly chosen, for the

number of SBTs is adding to a sustainable future.

Article Designation: Refereed 17 JTATM

Volume 6, Issue 3, Spring2010

C. Final Recommendations gas, etc. The current textile mix, with a clear

majority belonging to petroleum-based

Finally, I propose a sustainable textile mix synthetics and cotton fibres, is presented in

for the future, similar to the energy mixes in Figure 5.2. Figure 5.3a and 5.3b show

which society has a diverse portfolio of textile mix possibilities, randomly chosen,

energy sources such as wind, solar, nuclear, for the future.

coal with carbon capture and storage, oil and

Figure 5.2: World Textile Mix (2006)

organic cotton raw silk Textile Mix in 2006

0.05% 0.23%

raw wool cellulosics

1.91% 4.06%

cellulosics

raw cotton synthetics

39.81%

raw cotton

organic cotton

synthetics raw wool

53.95%

raw silk

Note: Chart generated using data provided by Textile Outlook International (Simpson

2007). Organic cotton data taken from the Organic Cotton Fiber Report (Ferrigno 2006).

NB: man-made fibre demand figures are based on production data; natural fibre demand

figures are based on consumption data to avoid inaccuracies arising from wide stock

variations from year to year numbers may not sum precisely due to rounding

Figure 5.3a and 5.3b: Textile Mix

Possibilities (5.3a, left, by fibre category,

5.3b, right, by fibre type)

The role of bamboo textiles in sustainable

development was analysed through a

thorough literature review, expert interviews

and discussions, field visits in China, and

experimental tests. Bamboo textiles present

many solutions to the present unsustainable

Article Designation: Refereed 18 JTATM

Volume 6, Issue 3, Spring2010

nature of textile engineering; however, consider these two elements for the desired

energy, water, and chemical concerns in textile outcome. Further work in this field

manufacturing still must be addressed. There could analyse more bamboo species for

are textile property variations among both textile applications, as well as treat small

species and manufacturing method for variations in manufacturing processes for

bamboo textiles. Thus, it is important to the desired outcomes.

References BambroTex. (2008). Bamboo Nature Anti-U.V.

http://www.bambrotex.com/second/anti_UV

AATCC (2008). A Glossary of AATCC .htm. May 16, 2008.

Standard Terminology. Research Triangle

Park, American Association of Textile Behery, H. (2005). Effect of Mechanical and

Chemists and Colorists. Physical Properties on Fabric Hand. Boca

Raton, Woodhead.

Adams, W. (2007). "Smart Fabrics and

Intelligent Textiles in the UK: Seven Bismarck, A., A. Baltazar-y-Jimenez, et al.

Companies at the Forefront of Innovation." (2006). "Green composites as panacea?

Textile Outlook International May- Socio-economic aspects of green materials."

June(129). Environment, Development and

Sustainability 8: 445–463.

Ahmad, M. and F. A. Kamke (2005). "Analysis

of Calcutta bamboo for structural composite Braungart, M. (2006). Cradle to Cradle.

materials: physical and mechanical Textiles: The Quarterly Magazine of The

properties." Journal of the International Textile Institute. 1.

Academy of Wood Science 39(6).

Chapagain, A. K., A. Y. Hoekstra, et al. (2005).

Allwood, J. M., S. E. Laursen, et al. (2006). The Water Footprint of Cotton

Well Dressed? The present and future Consumption. Value of Water Research

sustainability of clothing and textiles in the Report Series No. 18. Delft, UNESCO-IHE:

United Kingdom. Cambridge, University of 39.

Cambridge Institute for Manufacturing.

Coster, J. D. (2007). "Green Textiles and

AmericanBambooSociety. (2007). Species Apparel: Environmental Impact and

Source List. Strategies for Improvement." Textile

http://americanbamboo.org/SpeciesSourceLi Outlook International November-December

st.html. April 2007. 2007(132).

Anson, R. and G. Brocklehurst (2007). "Trends Durst, S. (2006). The Panda Food in Your

in World Textile and Clothing Trade." Pants. Business 2.0. 7.

Textile Outlook International November-

December 2007(132). Dylewski, A. (2008). A Boost for Bamboo-

based Blouses and Blankets.

ASTM (2003). Annual Book of ASTM http://www.newswise.com/articles/view/539

Standards Section 7: Textiles. West 088/. May 12, 2008.

Conshohocken, American Society for

Testing and Materials. EPEA. (2001). Eco-Intelligent Polyester Fabric:

The First Technical Nutrient.

BambooClothing. (2008). Bam Bamboo www.epea.com/documents/EPEAProductCa

Clothing Frequently Asked Questions. se_VictorInnovatex.pdf. April 20, 2008.

http://www.bambooclothing.co.uk/faqs.html

. May 12, 2008. FAO. (2007). Extent and Characteristics of

Bamboo Resources.

Article Designation: Refereed 19 JTATM

Volume 6, Issue 3, Spring2010

ftp://ftp.fao.org/docrep/fao/010/a1243e/a124 GreenBlue. (2008). Sustainable Textile

3e03.pdf. April 20, 2008. Standard.

http://www.greenblue.org/activities_stm.htm

FAO (2007). The Versatile Bamboo. Non-wood l. April 16, 2008.

News 14. Rome, Food and Agriculture

Organization. Hunter, I. (2003). "Bamboo resources, uses and

trade: the future?" International Network for

Farnie, D. A. and D. J. Jeremy (2004). The fibre Bamboo and Rattan 2(4): 319-326.

that changed the world: the cotton industry

in international perspective, 1600-1900s. Inikori, J. E. (1989). "Slavery and the

Oxford, Oxford University Press. Revolution in Cotton Textile Production in

England." Social Science History 13(4):

343-379.

Farrelly, D. (1984). The Book of Bamboo: A ISO (2000). Textiles -- Tear properties of

comprehensive guide to this remarkable fabrics -- Part 2: Determination of tear force

plant, its uses, and its history. London, of trouser-shaped test specimens (Single tear

Thames and Hudson. method). International Organization for

Standardization. ISO 13937-2:2000.

Fenner, R. A., C. M. Ainger, et al. (2006).

"Widening engineering horizons: addressing Jenkins, D. (2003). The Cambridge history of

the complexity of sustainable development." western textiles. Cambridge, Cambridge

Engineering Sustainability Journal 159 ES4: University Press.

145–154.

Kalliala, E. M. and P. Nousiainen (1999). "Life

Ferrigno, S. (2006). Organic Cotton Fiber Cycle Assessment Environmental Profile of

Report. Cotton and Polyester-Cotton Fabrics."

www.organicexchange.org/Documents/fiber AUTEX Research Journal 1(1): 8-20.

_2006.pdf. April 29, 2008.

Kanglin, W. (1998). Ecology and Habitats of

Ferrigno, S. (2008). Organic Cotton Fibre Price. Bamboos in Yunnan, China. Rome,

Kent: Organic Exchange Farm Development Biodiversity International.

Programme.

Knight, D. (2007). Going Green With Bamboo:

Fletcher, K. (2008). Sustainable Fashion & Versatile Fiber Provides A Popular

Textiles: Design Journeys. London, Alternative to Traditional Hardwood Floors.

Earthscan. Environmental Design and Construction.

Fu, J. (2000). "Moso Bamboo" in China. ABS Lichtenstadt, P. (1864). Improvement in

Magazine. 21. preparing fiber from the bamboo. U. S. P.

Office. United States. 41,627: 1.

Fu, J. (2001). Chinese Moso Bamboo: Its

Importance. ABS Magazine. 22: 5. Lin, G., T. Reijenga, et al. (2003). "Promotion

of Sustainable Buildings in China:

Goswami, B. C., J. G. Martindale, et al. (1978). Integration of Bamboo and Renewable

Textile Yarns: Technology, Structure, and Energy Technologies." Chinese Forestry

Applications. London, John Wiley & Sons. Science and Technology 2(1): 40-45.

GreenBiz. (2006). Global Market Booming for Lin, J., X. He, et al. (2002). "Lignification and

Organic Cotton Products, New Report lignin heterogeneity for various age classes

Shows. of bamboo (Phyllostachys pubescens)

http://www.greenbiz.com/news/news_third.c stems." Physiologia Plantarum 114: 296-

fm?NewsID=30957. April 14, 2008. 302.

Article Designation: Refereed 20 JTATM

Volume 6, Issue 3, Spring2010

Lin, M. (2008). Bamboo Fibre Market Prices. Pure Fiber. (2008). Bamboo Fiber

M. Waite, SuZhou ShengZhhu Household Manufacturing Process. http://www.pure-

Co. Ltd. fiber.com/about_bamboo.html#bamboo_fibe

r_manufacturing. May 2008.

Lin, M. (2008). Suzhou Shengzhu Household

Co Report. M. Waite. Suzhou: Personal Ramachandran, T., K. Rajendrakumar, et al.

Communication. (2003). "Antimicrobial Textiles-An

Overview." IE Journal I.

Litrax. (2008). Bamboo Fiber.

http://www.litrax.com/index.html?lang=en- Ramachandran, T., K. Rajendrakumar, et al.

us&target=front.html. May 12, 2008. (2004). "Antimicrobial Textiles-An

Overview." IE Journal-TX 84.

Lybeer, B. and G. Koch (2005). "A Rodie, J. B. (2007). Quality Fabric of the

Topochemical and semiquantitative study of Month: Spotlight on Bamboo. Textile

the lignification during ageing of bamboo World. March/April.

culms (Phyllostachys Viridiglaucescens)."

IAWA Journal 26(1): 99-109. Sadov, F., M. Korchagin, et al. (1979).

Chemical Technology of Fibrous Materials.

Lyle, D. S. (1977). Performance of Textiles. Moscow, Mir Publishers.

London, John Wiley & Sons.

Schoeser, M. (2003). World textiles: a concise

Lymberis, A. and D. E. D. Rossi (2004). history. London, Thames & Hudson.

Wearable eHealth Systems For Personalised

Health Management: State Of The Art and Shen, Q., D.-S. Liu, et al. (2004). "Surface

Future Challenges (Studies in Health properties of bamboo fiber and a comparison

Technology and Informatics). Lancaster, with cotton linter fibers." Colloids and

IOS Press. Surfaces B: Biointerfaces 35: 193-195.

Magel, E., S. Kruse, et al. (2005). "Soluble Shuang, S. (2008). Bamboo Textile Prices. M.

carbohydrates and acid invertases involved Waite. Beijing.

in the rapid growth of developing culms in

Sasa Palmata (Bean) Camus." Journal of the Simpson, P. (2007). "Global Trends in Fibre

American Bamboo Society 19(1): 23-29. Prices, Production and Consumption."

Textile Outlook International September-

Mankiw, N. G. (2004). Principles of October(131).

Microeconomics. Mason, Thomson South-

Western. Steinfeld, C. (2001). A Bamboo Future.

Environmental Design and Construction.

Marquardt, S. (2007). Global Organic Cotton

Apparel and Home Products Market Tops Taylor, M. (1981). Technology of Textile

One Billion Dollars in 2006, says New Properties. London, Forbes Publications.

Organic Exchange Report.

www.organicexchange.org/Documents/Oct3 Tenbro. (2008). Tenbro.

1press.pdf. April 15, 2008. http://www.tenbro.com/. May 12, 2008.

Mwaikambo, L. Y. (2006). "Review of the Teufel, L. and B. Redl (2006). "Improved

history, properties and application of plant Methods for the Investigation of the

fibres." African Journal of Science and Interaction between Textiles and

Technology 7(2): 120 -133. Microorganisms." Lenzinger Berichte 85:

54-60.

Patterson, P. (2008). Bamboo-zled? Ecotextile

News: 18-20.

Article Designation: Refereed 21 JTATM

Volume 6, Issue 3, Spring2010

TextileWorld (2008). Footprint Introduces ties/cotton/environmental_impacts/agroche

Bamboo Socks. Textile World. micals_use/index.cfm. April 15, 2008.

March/April: 1.

Xu, X., Y. Wang, et al. (2006). "Effects on

US Patent & Trademark Office (2008). surface properties of natural bamboo fibers

Verification of Bamboo Fibre U.S. Patent. treated with atmospheric pressure argon

M. Waite. Washington, D.C. plasma." Surface and Interface Analysis 38:

1211-1217.

Velez, S., J. Dethier, et al. (2000). Grow your Xu, Y., Z. Lu, et al. (2007). "Structure and

own house Simon Velez and Bamboo Thermal Properties of Bamboo Viscose,

Architecture. Weil am Rhein, Vitra Design Tencel, and Conventional Viscose Fiber."

Musuem. Journal of Thermal Analysis and

Calorimetry 89(1).

Vogel, E. and A. Gardner. (2005). Bamboo

Biodiversity Maps. YiChung, W. (2004). "Estimates of biomass

http://www.eeob.iastate.edu/research/bambo and carbon sequestration in Dendrocalamus

o/maps.html. April 18, 2008. latiflorus culms." Chinese Forest Products

Association 23(1): 13-22.

WWF. (2005). Agriculture and Environment:

Cotton, Environmental Impacts of Zehui, J. (2003). Preface. International

Production: Use of Agrochemicals. Workshop on Bamboo Industrial Utilization,

http://www.panda.org/about_wwf/what_we_ Xianning City, INBAR.

do/policy/agriculture_environment/commodi

Article Designation: Refereed 22 JTATM

Volume 6, Issue 3, Spring2010

View publication stats

You might also like

- Fabric For Fashion The Complete Guide2Document273 pagesFabric For Fashion The Complete Guide2M.José Copons Gallo100% (23)

- Methods of Test For ButtonsDocument4 pagesMethods of Test For ButtonsmomofattohNo ratings yet

- Affect of Acid and Alkaline On Tensile Stength of Fibers.Document26 pagesAffect of Acid and Alkaline On Tensile Stength of Fibers.Pranjal Mehta58% (72)

- Brochure ZytexDocument12 pagesBrochure ZytexKinjal PatelNo ratings yet

- Cloth Clothing AnglosaxDocument20 pagesCloth Clothing AnglosaxRamona Argolia Hartley0% (1)

- Sustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)Document23 pagesSustainable Textiles: The Role of Bamboo and A Comparison of Bamboo Textile Properties (Part II)Clariza TanNo ratings yet

- Analysis of Physical Characteristics of Bamboo FabricsDocument5 pagesAnalysis of Physical Characteristics of Bamboo FabricsesatjournalsNo ratings yet

- Analysis of Physical Characteristics of BambooDocument5 pagesAnalysis of Physical Characteristics of BambooInternational Journal of Research in Engineering and TechnologyNo ratings yet

- MVB - Paper Topic - 0331-2021Document9 pagesMVB - Paper Topic - 0331-2021Tonet BercesNo ratings yet

- Effect of Pile Yarn Type On Absorbency, Stiffness, and Abrasion Resistance of Bamboo/Cotton and Cotton Terry Towels Filiz SekerdenDocument7 pagesEffect of Pile Yarn Type On Absorbency, Stiffness, and Abrasion Resistance of Bamboo/Cotton and Cotton Terry Towels Filiz SekerdenSubramani PichandiNo ratings yet

- Paper 7Document13 pagesPaper 7RakeshconclaveNo ratings yet

- Ali PDFDocument9 pagesAli PDFcadetpalangNo ratings yet

- 07 Chapter 2Document103 pages07 Chapter 2Mukesh Manwani100% (1)

- Rejenere Bambu Elyafin - Yapi - Zell - Kler - N - N - Ncelenmes - (#251800) - 218177Document7 pagesRejenere Bambu Elyafin - Yapi - Zell - Kler - N - N - Ncelenmes - (#251800) - 218177Juan David Cubillos SarmientoNo ratings yet

- BambooDocument3 pagesBambooB22 Thiruvengaden R100% (1)

- Review Article A Literature Review On Natural Fibers, Its Properties and Influence of Water Absorption On Mechanical Properties of CompositesDocument9 pagesReview Article A Literature Review On Natural Fibers, Its Properties and Influence of Water Absorption On Mechanical Properties of Compositesmkumar_234155No ratings yet

- Cementitious Composites Reinforced With Vegetable FibersDocument27 pagesCementitious Composites Reinforced With Vegetable FibersDaniel GomesNo ratings yet

- The Hygroscopic Behavior of Plant Fibers: A ReviewDocument12 pagesThe Hygroscopic Behavior of Plant Fibers: A Reviewdeathjester1No ratings yet

- Kenaf FibreDocument10 pagesKenaf FibreIfkar AzmiNo ratings yet

- Poster - A Review On The Use of Estabragh (Milkweed) Fibers in Nonwoven ApplicationsDocument1 pagePoster - A Review On The Use of Estabragh (Milkweed) Fibers in Nonwoven Applicationsmahnaz khakpourNo ratings yet

- 2011 Article1379516711 - Ali PDFDocument9 pages2011 Article1379516711 - Ali PDFSrinivas AyyalasomayajulaNo ratings yet

- A Study On Mechanical Properties of Bamboo Fiber Rei - 2020 - Materials Today PDocument7 pagesA Study On Mechanical Properties of Bamboo Fiber Rei - 2020 - Materials Today PClaudia UngureanuNo ratings yet

- EvaluationofTensileBehaviorofSeaShell JuteFabric PDFDocument7 pagesEvaluationofTensileBehaviorofSeaShell JuteFabric PDFPrince Ghosh EponNo ratings yet

- Biomolecules: Biofunctionalization of Natural Fiber-Reinforced Biocomposites For Biomedical ApplicationsDocument44 pagesBiomolecules: Biofunctionalization of Natural Fiber-Reinforced Biocomposites For Biomedical ApplicationsMd Mahedi HasanNo ratings yet

- A Review On Natural Fibre Based Composites - Structure, Processing and Properties of Vegetable FibresDocument32 pagesA Review On Natural Fibre Based Composites - Structure, Processing and Properties of Vegetable FibresMiritoiu CosminNo ratings yet

- Development and Characterization of Eco-Sustainable Banana Fiber Nonwoven Material: Surface Treatment, Water Absorbency and Mechanical PropertiesDocument12 pagesDevelopment and Characterization of Eco-Sustainable Banana Fiber Nonwoven Material: Surface Treatment, Water Absorbency and Mechanical PropertiesVNo ratings yet

- 11 Antimicrobial Studies of Knitted Fabrics From Bamboo, Soybean and FlaxDocument4 pages11 Antimicrobial Studies of Knitted Fabrics From Bamboo, Soybean and FlaxEngr Md. Nayemul IslamNo ratings yet

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsJorge Gerardo Riascos QuiñonesNo ratings yet

- Materials Today: Proceedings: Jonathan B. Dawit, Hirpa G. Lemu, Yohannes Regassa, Adugna D. AkessaDocument6 pagesMaterials Today: Proceedings: Jonathan B. Dawit, Hirpa G. Lemu, Yohannes Regassa, Adugna D. AkessaHelmi ChaâbeneNo ratings yet

- Mechanical Properties of Natural Cellulose Fibers Reinforced PolymerDocument8 pagesMechanical Properties of Natural Cellulose Fibers Reinforced Polymernurshiyama89No ratings yet

- Materials Today: Proceedings: K. Balasubramanian, N. Rajeswari, R. VishvakDocument5 pagesMaterials Today: Proceedings: K. Balasubramanian, N. Rajeswari, R. VishvakedmealemNo ratings yet

- A Review NF (U)Document10 pagesA Review NF (U)Hazim HamdanNo ratings yet

- Analisa Kekuatan Tarik Dan Bentuk Patahan Komposit Serat Sabuk Kelapa Bermatriks Epoxyterhadap Variasi Fraksi Volume SeratDocument6 pagesAnalisa Kekuatan Tarik Dan Bentuk Patahan Komposit Serat Sabuk Kelapa Bermatriks Epoxyterhadap Variasi Fraksi Volume SeratChartens PratamaNo ratings yet

- Composites: Part A: Hongyan Chen, Menghe Miao, Xin DingDocument7 pagesComposites: Part A: Hongyan Chen, Menghe Miao, Xin DingMikaaeelNo ratings yet

- Methodology For Tensile Tests On Vegetable FibersDocument7 pagesMethodology For Tensile Tests On Vegetable FibersShirly Mae DinongNo ratings yet

- Loa Levis Gigantochloa Scortechinii, Gigantochloa Wrayi, and Schizostachyum Zollingeri Bamboo FibersDocument6 pagesLoa Levis Gigantochloa Scortechinii, Gigantochloa Wrayi, and Schizostachyum Zollingeri Bamboo FibersabdussalamNo ratings yet

- Chapter 2Document15 pagesChapter 2Roem EsmernaNo ratings yet

- Coconut FibreDocument9 pagesCoconut Fibrejs kalyana rama100% (1)

- Innovative Banana Fiber Nonwoven Reinforced Polymer Composites PR - and PostTreatment Effects On Physical and Mechanical PropertiesDocument23 pagesInnovative Banana Fiber Nonwoven Reinforced Polymer Composites PR - and PostTreatment Effects On Physical and Mechanical PropertiesHea TherNo ratings yet

- Influence of Tencel/cotton Blends On Knitted Fabric PerformanceDocument9 pagesInfluence of Tencel/cotton Blends On Knitted Fabric PerformanceEstefania VillamarinNo ratings yet

- Critival Review Mattek 1Document7 pagesCritival Review Mattek 1Agan AuliyaNo ratings yet

- Fpls 10 00411Document23 pagesFpls 10 00411Ýõõ NäNo ratings yet

- 1 s2.0 S246821792100006X MainDocument14 pages1 s2.0 S246821792100006X MainGirmaw YeshanbelNo ratings yet

- Review On Cellulosic Fibers Extracted From Date Palms (Phoenix Dactylifera L.) and Their ApplicationsDocument24 pagesReview On Cellulosic Fibers Extracted From Date Palms (Phoenix Dactylifera L.) and Their ApplicationsHamzaNo ratings yet

- Properties & Application of Bamboo and Bamboo Fibre CompositionDocument6 pagesProperties & Application of Bamboo and Bamboo Fibre CompositionVIKKASH A/L RAJAGOPAL STUDENTNo ratings yet