Professional Documents

Culture Documents

Channel DC/DC Converter IC For Large LCD Panels: Ew Products

Channel DC/DC Converter IC For Large LCD Panels: Ew Products

Uploaded by

Joil AlvesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Channel DC/DC Converter IC For Large LCD Panels: Ew Products

Channel DC/DC Converter IC For Large LCD Panels: Ew Products

Uploaded by

Joil AlvesCopyright:

Available Formats

New Products MB39C313

4-Channel DC/DC Converter IC

for Large LCD Panels

MB39C313

A system power management IC capable of supplying the four types of voltages required

in large LCD panels in a single chip. With built-in switching FET for large current operation,

this product is optimal for applications such as large LCD TVs and monitors.

Overview protection, undervoltage lockout, over temperature protection

● Built-in soft-start circuit independent of loads (Vlogic, Vs)

This product is a system power management IC with a built- ● Frequency setting by input pin: 500kHz/750kHz

in 4-channel power management control block. It consists of a ● Package: TSSOP-28 (with exposed PAD)

2-channel DC/DC converter with switching FET and a 2- ● Lead-free/conforms to RoHS Directive

channel charge pump type DC/DC converter. The DC/DC

converter block offers excellent stability against input voltage

fluctuations with the input voltage feed-forward method. The Functions

output voltage in the charge pump circuit block can be set by

an external resistor using the output voltage feedback method. Figure 1 presents the block diagram of this product.

This product contributes to a reduction in the parts cost as a

result of the built-in switching FET and phase compensator. ■ Power management voltage functions

Generates the voltages for the controller output (Vlogic),

source driver output (Vs), and gate driver output (VGL, VGH)

Product Features required in general LCD panels.

● Power management voltage range: 8V to 14V

Photo 1 External View

● DC/DC converter with built-in switching FET

Step-down converter (Vlogic): Output 1.8V to 3.3V 1.5A (max.)

Step-up converter (Vs): Output 17V (max.) 1.5A (max.)

● Charge pump with output voltage feedback method

Invert charge pump (VGL): 50mA (max.)

Step-up charge pump (VGH): 50mA (max.)

● Excellent line regulation with feed-forward control (Vlogic,

Vs)

● Built-in phase compensator (Vlogic)

● Built-in startup sequence control function

● Sufficient protective functions

Short-circuit protection, overcurrent protection, overvoltage

2008 No.4 FIND Vol.26 1

New Products MB39C313

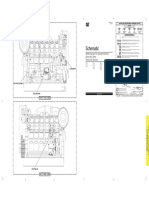

Figure 1 MB39C313 Block Diagram

A BOOT

(SWB+5 V)

VB REG <<Vlogic (Buck)>>

4V 17

FBB L priority Error VINB

Amp1

15 20 21

enb1

1.213 V

PWM A

COMP1

PWM

Vth SWB

Logic DRV 18

1.213 V ± 1.5%

Control

Vlogic (3.3 V/1.5 A Max)

LEVEL

OSC_CTL CONV

0.9V fosc or Current

fosc/2 or Limmit

fosc/4 ILIM

COMP1

0.6V Saw tooth

VINB Generator

B SCP COMP

COMP

B

2 OVP <<Vs (Boost)>>

Error OS

FB L priority COMP 3

1 Amp2

Vs

SS Vth 16.5/1.5 A Max

LEVEL

28 1.146 V ± 0.9%

1.146 V CONV

PWM SW

enb2 Saw tooth 4 5

Logic DRV

Generator

Control

AV IN PWM

COMP2

PGND

6 7

Current

Limmit ILIM GD

27

GD COMP2

1.03 V COMP

C

<<VGL (Negative Charge Pump)>> AVIN

FBN H priority Error

13 Amp3

Current DRN

enb3 C

Control DRV

11 VGL

Logic

(-5 V/50 mA)

Vth

D 0 V ± 36 mV

SUP

<<VGH (Positive Charge Pump)>>

8

FBP L priority Error

14 Amp4

DRP

Current

D

enb4 Control DRV 10

Logic VGH

(23 V/50 mA)

Vth

1.213 V ± 2.1%

FREQ

12

OSC

L:OTP

OTP

DLY1 DLY

25 COMP1 L:Protection

UVLO

1.18 V enb1

L : UVLO

H:Vlogic ON

enb2

H:Vs ON

DLY enb3

DLY2 H:VGL ON

26 COMP2

Vlogic enb4

ss finish H:VGH ON

1.18 V

AVIN

22

EN1

Power 16

VREF EN2

Buffer BGR ON/OFF

9

CTL

VIN=12 V

24 23

REF GND

1.213 V

2008 No.4 FIND Vol.26 2

New Products MB39C313

Vlogic (Vo1): Step-down converter Figure 2 Startup Sequence when EN2 is always set to“H”

The Step-down converter applies the pulse

width modulation (PWM) type with built-in EN2

N-channel switching FET. The input voltage

feed-forward method ensures excellent line

EN1

regulation. The phase compensation constant

DLY2

is set by the built-in compensation circuit VGH

Fall time of each channel

depends on load current

and an external ceramic capacitor. The main and feedback resistance.

Vs

switch for the converter is an N-channel FET Vin Vin

for 3.2A power and the gate drive circuit is

the SWB pin reference (source terminal for Vlogic

0V

N-channel switching FET). Power is supplied

to the gate drive circuit from the built-in 4V DLY1 VGL

power management, and an external capacitor

to operate the capacitive loads is connected to GD

the SWB pin in boot strap.

Vs (Vo2): Step-up converter

Figure 3 Startup Sequence when EN1 and EN2 are set to“H”Separately

The step-up converter operates as an

asynchronous up converter with pulse width

modulation (PWM) type using built-in N- EN2

channel switching FET and an external

flyback diode. It adopts the input voltage

EN1

feed-forward method to ensure excellent line DLY2 Fall time of each

regulation under the voltage mode. Phase VGH channel depends

compensation can be set by an external part. on load current and

Vs feedback resistance.

It operates in successive mode independent of Vin Vin

loads due to the operation of the built-in P-

Vlogic

channel switching FET (ON resistance 10Ω) 0V

connected between the SW pin and the OS

pin along with the external flyback diode. DLY1 VGL

VGL (Vo3): Invert charge pump GD

The invert charge pump operates at a fixed

frequency and the output voltage can be set

by the resistance ratio of the external resistor.

When the charge pump input and driver are connected to can increase the maximum output voltage.

the supplied voltage (VIN), the maximum output voltage is

−VIN+VI OSS. VI OSS includes voltage drops in the output diode ■ Startup sequence

and gate driver. The addition of the charge pump circuit can The startup sequence can be set using EN1 and EN2. The

increase the maximum negative voltage value. startup sequence timing can be adjusted by the capacitors

connected to DLY1 and DLY2.

VGH (Vo4): Step-up charge pump When EN1 is set at“H”with EN2 fixed to“H,”Vlogic

Like the invert charge pump, the step-up charge pump starts up first and VGL starts up after delay time DLY1. Vs and

operates at a fixed frequency and the output voltage can be set VGH start up simultaneously after delay time DLY2 (Figure 2).

by the resistance ratio of the external resistor. By providing the When EN2 is set at“H”with Vlogic already operating with

step-up converter output (Vs) or MB39C313 input (VIN) to EN1 at“H,”the delay time DLY2 starts up from the EN2

the charge pump input (SUP), the maximum output voltage rising edge (Figure 3). If EN2 is set to“H”before Vlogic

becomes VSUP+VS. The addition of the charge pump circuit operates, DLY2 operates after the complete operation of Vlogic.

2008 No.4 FIND Vol.26 3

New Products MB39C313

Figure 4 Application Examples

■ Soft-start function

Vlogic and Vs are equipped with a soft-start

function to prevent inrush current at startup. DC/DC converter DDR

The soft-start period is approximately 1ms for

Vlogic (fixed) and is set by the external

capacitor for Vs.

TCON

■ Various protective functions Down conversion

DC/DC 3.3V

Up conversion DC/DC

16.5V

Source driver

●Vlogic: Step-down converter

Short-circuit protection: Protective circuit

Gate driver

operates at Vlogic output<0.9V. MB39C313 Charge pump LCD panel

23V

Overcurrent protection: Protective circuit

operates at Vlogic output=3.2A. Charge pump

−5V

●Vs: Step-up converter

Overvoltage protection: Protective circuit VIN=8V to 14V

operates at Vs output=18.7V.

Overcurrent protection: Protective circuit

operates at Vs output =3.5A.

●VGL: Invert charge pump: No protective circuit operation Future Development

●VGH: Step-up charge pump: No protective circuit operation

●Undervoltage lockout (UVLO) FUJITSU has developed system power management ICs for

All circuits shut down at AVIN≦6V. LCD panels by integrating D/A converters and DC/DC

●Over temperature protection (OTP) converters using the core of our power management IC analog

Switching is stopped when the junction temperature reaches technology. In the future, we will continue to realize

150℃. developments that address our customer needs in order to enable

Switching is resumed when the junction temperature drops to the further integration of peripheral functions as well as cost

135℃. reduction. ✱

■ Switching frequency

Table 1 presents the switching frequency.

Photo 2 Evaluation Board

Application Examples

Figure 4 presents application examples of this product.

Evaluation Board

We offer an evaluation board to simplify the single unit

evaluation of this product (Photo 2).

Table 1 Switching Frequency

Terminal Setting Switching frequency

H 750kHz

FREQ ※Vlogic (Vo1), Vs (Vo2)

L 500kHz VGL (Vo3), VGH (Vo4)

2008 No.4 FIND Vol.26 4

You might also like

- UN55H6203AFXZADocument62 pagesUN55H6203AFXZAd4rk3100% (2)

- TF 117 Circuit DiagramDocument9 pagesTF 117 Circuit DiagramFrancis TaisantNo ratings yet

- Diode Test Mode in The MultimeterDocument3 pagesDiode Test Mode in The MultimeterAndre nicholsNo ratings yet

- OLED65G6P+WebOS+3 0+UHD+OLED+TV+In-Start+Service+Menu+ScreensDocument8 pagesOLED65G6P+WebOS+3 0+UHD+OLED+TV+In-Start+Service+Menu+ScreensDanielDiasNo ratings yet

- Scrolling 16 2 Led in PICDocument23 pagesScrolling 16 2 Led in PICmalhiavtarsingh100% (3)

- LED Light RepairingDocument11 pagesLED Light RepairingDeepanwita SarNo ratings yet

- 01 Mon - Jun23 Trouble Shooting - Panel (Compatibility Mode)Document51 pages01 Mon - Jun23 Trouble Shooting - Panel (Compatibility Mode)بوند بوندNo ratings yet

- Multimeter Manual MS8226TDocument26 pagesMultimeter Manual MS8226Tluroguita-1No ratings yet

- Au Optronics (Auo) - B101aw06 V0 SchemeDocument5 pagesAu Optronics (Auo) - B101aw06 V0 SchemeDeveloper Awlad50% (2)

- Repairing With secureCRT PDFDocument17 pagesRepairing With secureCRT PDFRohit Suman100% (1)

- FA Mainboard CV512H-B42Document53 pagesFA Mainboard CV512H-B42Salomon ChiquilloNo ratings yet

- STC-ISP-Programmer V6.0 ManualDocument19 pagesSTC-ISP-Programmer V6.0 Manualmejmak100% (1)

- Xilinx PresentationDocument35 pagesXilinx Presentationtrue0soulNo ratings yet

- Service Manual Chassis 2112Document34 pagesService Manual Chassis 2112luigigerulaNo ratings yet

- Electronics Reworking Flex RepairDocument6 pagesElectronics Reworking Flex RepairwilbertylNo ratings yet

- Motherboard and BiosDocument26 pagesMotherboard and BiosJoseph Mediano PogoyNo ratings yet

- DSB-B350S Training ManualDocument46 pagesDSB-B350S Training Manualax63naNo ratings yet

- OLED65B6PUDocument95 pagesOLED65B6PUyakaka33No ratings yet

- Android Controlled Scrolling LED MessageDocument88 pagesAndroid Controlled Scrolling LED Messagedinuarslan75% (4)

- Onsemi ATX PSU DesignDocument37 pagesOnsemi ATX PSU Designusuariojuan100% (1)

- Product Service Training 2015 - v3.0Document86 pagesProduct Service Training 2015 - v3.0Nicu LiviuNo ratings yet

- Jtag Repair For Bricked Cloud Ibox 2 Plus & Cloud - Our Dreambox World - Japhar Sim Forum - HTTP - WWW - Japhar.com - SuperSimDocument4 pagesJtag Repair For Bricked Cloud Ibox 2 Plus & Cloud - Our Dreambox World - Japhar Sim Forum - HTTP - WWW - Japhar.com - SuperSimVladimir ZamuraevNo ratings yet

- CCFL TesterDocument1 pageCCFL TesterSilvia LimaNo ratings yet

- Repair of Broken Power Supply in Apple Time CapsuleDocument4 pagesRepair of Broken Power Supply in Apple Time Capsulepethei100% (2)

- Esquema Elétrico TV Philco LCD Mod PH19Document41 pagesEsquema Elétrico TV Philco LCD Mod PH19AdeniltonNo ratings yet

- Example 3G Config - Option Globetrotter HSDPA USB ModemDocument23 pagesExample 3G Config - Option Globetrotter HSDPA USB ModemCristinel TanaseNo ratings yet

- An Tda937x Ps v1.0 (E)Document141 pagesAn Tda937x Ps v1.0 (E)AndreskoiraNo ratings yet

- TV Haier 32 Led LE32F2220a PDFDocument54 pagesTV Haier 32 Led LE32F2220a PDFJuan Jose100% (1)

- Keithley Model 2000 Multimeter Repair ManualDocument109 pagesKeithley Model 2000 Multimeter Repair Manualwolfovic3932No ratings yet

- Haier 55e3500 Chassis Msd3393 SMDocument54 pagesHaier 55e3500 Chassis Msd3393 SMHamza Abbasi Abbasi100% (2)

- Multitasking With Raspberry Pi by Dogan IbrahimDocument232 pagesMultitasking With Raspberry Pi by Dogan IbrahimrvpilotNo ratings yet

- Mobile Phone ၏ Hardware ပစၥည္းမ်ား ျပဳျပင္ေရး နည္းလမ္းမ်ား (ရဲမင္းေအာင္- Ray Electronic)Document196 pagesMobile Phone ၏ Hardware ပစၥည္းမ်ား ျပဳျပင္ေရး နည္းလမ္းမ်ား (ရဲမင္းေအာင္- Ray Electronic)AkarPhyoeKanbauk1No ratings yet

- Ipa60r1k0ce PDFDocument13 pagesIpa60r1k0ce PDFJose Domingo Maltez VallecilloNo ratings yet

- PC Control Using TV RemoteDocument46 pagesPC Control Using TV RemoteManojKumarNo ratings yet

- Debugger MipsDocument79 pagesDebugger Mipscarver_uaNo ratings yet

- Thgbmbg5d1kbail A19nm 4gb E-Mmc Ver5.0 - e - Rev1.0 - 140807 - Pre-Loading Data ...Document32 pagesThgbmbg5d1kbail A19nm 4gb E-Mmc Ver5.0 - e - Rev1.0 - 140807 - Pre-Loading Data ...Rahmat HidayatNo ratings yet

- Circuit Diagram For WS6908 PDFDocument6 pagesCircuit Diagram For WS6908 PDFdistefano67% (3)

- Diagram Sp2309wc DellDocument92 pagesDiagram Sp2309wc DellLuis Papa100% (1)

- LM386 Audio Amplifier ReportDocument7 pagesLM386 Audio Amplifier ReportDhruvesh AsnaniNo ratings yet

- Features: Hybrid Power Boost (HPB) and Narrow VDC (NVDC) Combo Battery Charger With Smbus InterfaceDocument2 pagesFeatures: Hybrid Power Boost (HPB) and Narrow VDC (NVDC) Combo Battery Charger With Smbus InterfaceRohithRenNo ratings yet

- AIWA AZG-D SvcMnlsDocument59 pagesAIWA AZG-D SvcMnlsavrelecNo ratings yet

- MT6737M Android EMMC ScatterDocument10 pagesMT6737M Android EMMC ScatterАндрей ФазберNo ratings yet

- C-Band Dro LNB Teardown - Kf5obs - IpDocument8 pagesC-Band Dro LNB Teardown - Kf5obs - Ipkhanafzaal2576No ratings yet

- TCL Led24c310a (Tsumv39lv t7s)Document6 pagesTCL Led24c310a (Tsumv39lv t7s)rammerDankovNo ratings yet

- Apple Accessory ProtocolDocument3 pagesApple Accessory ProtocolMalevolic BizkaiaNo ratings yet

- BIOS Disassembly Ninjutsu Uncovered - PrefaceDocument5 pagesBIOS Disassembly Ninjutsu Uncovered - PrefaceRodrigo RochaNo ratings yet

- Presentation BERandMERDocument45 pagesPresentation BERandMEROctavian HuleaNo ratings yet

- Logic Probe 2Document2 pagesLogic Probe 2Cameron RiosNo ratings yet

- Bongkar Laptop Cq41Document15 pagesBongkar Laptop Cq41Andrian AdeNo ratings yet

- RCA LCD26V6SY Service Manual 1.0 PDFDocument33 pagesRCA LCD26V6SY Service Manual 1.0 PDFPocho Pochito100% (1)

- How To Use secureCRT Startup Log FileDocument17 pagesHow To Use secureCRT Startup Log FileMecael DesuyoNo ratings yet

- Philips 28pfl2908h-12 Chassis Vem1.1ela 17mb82sDocument43 pagesPhilips 28pfl2908h-12 Chassis Vem1.1ela 17mb82svios08No ratings yet

- Testing VRMDocument6 pagesTesting VRMdonettNo ratings yet

- Katalog - Indo TV Parts - Indo TV PartsDocument145 pagesKatalog - Indo TV Parts - Indo TV PartstaiayambusuNo ratings yet

- Multifunction Peripherals for PCs: Technology, Troubleshooting and RepairFrom EverandMultifunction Peripherals for PCs: Technology, Troubleshooting and RepairNo ratings yet

- l6566b Ic DatasheetDocument51 pagesl6566b Ic DatasheetDibya DeyNo ratings yet

- Critical Conduction Mode PFC IC FA1A50N: DatasheetDocument26 pagesCritical Conduction Mode PFC IC FA1A50N: Datasheetdtftfernandes9099No ratings yet

- LMC 6494 (Caterpillar D6K)Document31 pagesLMC 6494 (Caterpillar D6K)Joil AlvesNo ratings yet

- High Voltage Bootstrap High Side Driver Features: FN9087.1 Data Sheet October 2002Document7 pagesHigh Voltage Bootstrap High Side Driver Features: FN9087.1 Data Sheet October 2002Joil AlvesNo ratings yet

- LNB Supply and Control-Voltage Regulator: Preliminary InformationDocument9 pagesLNB Supply and Control-Voltage Regulator: Preliminary InformationJoil AlvesNo ratings yet

- BOSCH 40007 (U2 - Caterpilar D6K)Document84 pagesBOSCH 40007 (U2 - Caterpilar D6K)Joil AlvesNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document15 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Joil Alves75% (4)

- Not For New Design: Single LNB Supply and Control Voltage RegulatorDocument20 pagesNot For New Design: Single LNB Supply and Control Voltage RegulatorJoil AlvesNo ratings yet

- Cxa1691bm (S)Document11 pagesCxa1691bm (S)Joil AlvesNo ratings yet

- 12F615-Microchip TechnologyDocument168 pages12F615-Microchip TechnologyJoil AlvesNo ratings yet

- Isolated, Precision Half-Bridge Driver, 0.1 A Output Adum1234Document12 pagesIsolated, Precision Half-Bridge Driver, 0.1 A Output Adum1234Joil AlvesNo ratings yet

- Single-Supply Sensor Interface Amplifier: 20. Alterable From 1 To 160 (VDocument9 pagesSingle-Supply Sensor Interface Amplifier: 20. Alterable From 1 To 160 (VJoil AlvesNo ratings yet

- Parts Manual: Generator SetDocument142 pagesParts Manual: Generator SetCarlos Alberto Ramirez Parra100% (1)

- Insulation Coordination Study of Light Electrified Railway System - Analysis of Lightning OvervoltagesDocument91 pagesInsulation Coordination Study of Light Electrified Railway System - Analysis of Lightning Overvoltagesarshadbaya100% (1)

- Hvac System: (Heating, Cooling & Ventilation)Document39 pagesHvac System: (Heating, Cooling & Ventilation)Selamawit AberaNo ratings yet

- Aits 2223 FT Iii Jeem TD 11 1 23Document16 pagesAits 2223 FT Iii Jeem TD 11 1 23BHOOMI BNo ratings yet

- Automatic Magnetic Motor Free Energy Generator: PG Scholar, EEE, PRIST UniversityDocument11 pagesAutomatic Magnetic Motor Free Energy Generator: PG Scholar, EEE, PRIST UniversityCris VillarNo ratings yet

- Power Plant Terms and FactorsDocument8 pagesPower Plant Terms and FactorsYel AlvaroNo ratings yet

- Pass 3Document10 pagesPass 3Joel JusayNo ratings yet

- SM4512NHKP: Pin Description FeaturesDocument11 pagesSM4512NHKP: Pin Description Featuresqextra33No ratings yet

- This Study Resource Was: Lab Report 7Document2 pagesThis Study Resource Was: Lab Report 7Ivan Felipe RodriguezNo ratings yet

- Right Side View: 3500 Engines For Caterpillar Built Electrical System Generator SetsDocument2 pagesRight Side View: 3500 Engines For Caterpillar Built Electrical System Generator Setsmbgprsms100% (1)

- Technical Specification For 110V, 45A Auto Float-Cum-Boost Battery Charger, 110V, 150 Ah Battery & DCDBDocument24 pagesTechnical Specification For 110V, 45A Auto Float-Cum-Boost Battery Charger, 110V, 150 Ah Battery & DCDBkajale.shrikantNo ratings yet

- Basic Electronics Lab ManualDocument100 pagesBasic Electronics Lab ManualMitchell Cifuentes100% (4)

- Electromagnet 1Document4 pagesElectromagnet 1faisalsmkpnNo ratings yet

- CHEM 205 Chapter 6Document29 pagesCHEM 205 Chapter 6phikjaeNo ratings yet

- Hoja de Datos de Motor TrifasicoDocument4 pagesHoja de Datos de Motor TrifasicoFrancoVioliniNo ratings yet

- 3 Afe 68392519Document40 pages3 Afe 68392519ABDUL GHAFOORNo ratings yet

- Slow Bus ChangeoverDocument7 pagesSlow Bus ChangeoverPandiyan100% (1)

- Ajmer Vidyut Vitran Nigam LTDDocument1 pageAjmer Vidyut Vitran Nigam LTDPrakash prakashNo ratings yet

- 7 e Applied EMCh 5Document38 pages7 e Applied EMCh 5Azmienz HierzanzNo ratings yet

- c3 Fluido Compresible ItfDocument133 pagesc3 Fluido Compresible ItfHsid KaloNo ratings yet

- What Is The Role of Capacitor in AC and DC CircuitDocument5 pagesWhat Is The Role of Capacitor in AC and DC CircuitHassan BhinderNo ratings yet

- Chapter 1 Festo DidacticDocument6 pagesChapter 1 Festo Didacticjesustarin557105No ratings yet

- Chem111.1 Exer8-Sample Calc.v1Document3 pagesChem111.1 Exer8-Sample Calc.v1Snow DropNo ratings yet

- P F E T: General Description FeaturesDocument4 pagesP F E T: General Description Featuresrezha jonNo ratings yet

- Heat Transfer Lecture NotesDocument66 pagesHeat Transfer Lecture NotesJustin100% (1)

- Definitions To Learn For O Level PhysicsDocument3 pagesDefinitions To Learn For O Level PhysicsWilliam SkyNo ratings yet

- TC FLS Sihi Leh 1200 1500 1800 enDocument10 pagesTC FLS Sihi Leh 1200 1500 1800 enGustavo ZavalaNo ratings yet

- Experiment No. 1 Specific Gravity of Hydraulic CementDocument4 pagesExperiment No. 1 Specific Gravity of Hydraulic CementManuel John Contridas PallonesNo ratings yet

- Continuous Distillation UnitDocument3 pagesContinuous Distillation UnitHusna Hafiza Bt. R.AzamiNo ratings yet

- Turbine Meter Tech GuideDocument24 pagesTurbine Meter Tech GuideDenilson Souto Dos Santos100% (1)