Professional Documents

Culture Documents

Front End Engineering Design 2 (Feed 2) Onshore Pipeline Senipah - Ru V Balikpapan Datasheet For Pipeline Special Item (Appendix A) Pt. Istana Karang Laut

Front End Engineering Design 2 (Feed 2) Onshore Pipeline Senipah - Ru V Balikpapan Datasheet For Pipeline Special Item (Appendix A) Pt. Istana Karang Laut

Uploaded by

Ruri IswadiCopyright:

Available Formats

You might also like

- BQ With Priced (Water Tank)Document107 pagesBQ With Priced (Water Tank)INTAN FARHANA MOHD ROSLANNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Calculation Sheet: WT-CAL-CO2-003Document4 pagesCalculation Sheet: WT-CAL-CO2-003babu100% (1)

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Shut Down Valve Sample DatasheetsDocument6 pagesShut Down Valve Sample DatasheetsBABILIN V100% (1)

- Datasheet Valve ПДНГ 0440 22Document3 pagesDatasheet Valve ПДНГ 0440 22Ngoc Huyen NguyenNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- Design Calculations For SS316L Waste Water Storage Tank-Tk01-Rev01Document10 pagesDesign Calculations For SS316L Waste Water Storage Tank-Tk01-Rev01AzhaghiaNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Bill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127, Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127, Tahun 2013moddysNo ratings yet

- Data Sheet For Barred Tee 010719Document1 pageData Sheet For Barred Tee 010719Heru Agung SetyantoNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- Data Sheet Válvula de Seguridad y AlivioDocument4 pagesData Sheet Válvula de Seguridad y Aliviorenzo condeNo ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- Bill of Quantity: Fabrikasi 5 (Lima) Unit Tube Bundle 11-E-108, 11-E-109, 11-E-110A, 11-E-110B, 11-E-122, Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 5 (Lima) Unit Tube Bundle 11-E-108, 11-E-109, 11-E-110A, 11-E-110B, 11-E-122, Tahun 2013moddysNo ratings yet

- Fabrication of Gas Purging FittingsDocument2 pagesFabrication of Gas Purging Fittingsjiao longNo ratings yet

- Data Sheet For Gas FilterDocument1 pageData Sheet For Gas FilterKhánh TrầnNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Flange CalculationDocument48 pagesFlange CalculationAndi SuntoroNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Data Sheet For Injection Quill AssemblyDocument4 pagesData Sheet For Injection Quill AssemblysudjonoNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary Abaratu50% (2)

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Datasheet 1Document1 pageDatasheet 1Thắng Trần QuangNo ratings yet

- MJ Spec NI-346-21R1-MS New Eoan AssociatesDocument1 pageMJ Spec NI-346-21R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Bill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127 Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127 Tahun 2013moddysNo ratings yet

- Mrir P PP5 001Document20 pagesMrir P PP5 001nguyenquocbao1990No ratings yet

- VMS - 5Document1 pageVMS - 5ritoh8657No ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocument2 pagesPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- Report No. (Số báo cáo) : MRIR-P-PP5-002 Page (Trang) : 10 of 10 Inspection Date (Ngày kiểm tra) :9/29/2020 Material Receiving Inspection Report For Pipe MaterialsDocument20 pagesReport No. (Số báo cáo) : MRIR-P-PP5-002 Page (Trang) : 10 of 10 Inspection Date (Ngày kiểm tra) :9/29/2020 Material Receiving Inspection Report For Pipe Materialsnguyenquocbao1990No ratings yet

- Mrir P PP5 002Document11 pagesMrir P PP5 002nguyenquocbao1990No ratings yet

- Design of Long Distance Oil PipelineDocument21 pagesDesign of Long Distance Oil PipelineHaseeb Khawaja100% (1)

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhNo ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Swing Check Valve Data Sheet: Comision Federal de ElectricidadDocument1 pageSwing Check Valve Data Sheet: Comision Federal de Electricidadjos ToricesNo ratings yet

- Expansion Bellow SpecificationDocument1 pageExpansion Bellow SpecificationASHWINI BHOSALENo ratings yet

- Piping Fitting Spec Rev 0 AFCDocument1 pagePiping Fitting Spec Rev 0 AFCsobariNo ratings yet

- Basis of Design - PIG LAUNCHER 16 DESIGN 2014Document27 pagesBasis of Design - PIG LAUNCHER 16 DESIGN 2014Andreas Schlager100% (1)

- Vertical CompressDocument47 pagesVertical CompressSivi NallamothuNo ratings yet

- Carlos Caballero Industria Metalurgica S.R.L.: Carretera A Cotoca KM 1 1/2 Tel. (591) 3 3492929 Santa Cruz - BoliviaDocument58 pagesCarlos Caballero Industria Metalurgica S.R.L.: Carretera A Cotoca KM 1 1/2 Tel. (591) 3 3492929 Santa Cruz - Boliviayoselin Ayala RamosNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Data Sheet For Plug ValveDocument2 pagesData Sheet For Plug ValveTauqueerAhmadNo ratings yet

- At200 + KM26Document5 pagesAt200 + KM26João Paulo PiresNo ratings yet

- Rev.2 Calculation Tag# HAA10AA201Document4 pagesRev.2 Calculation Tag# HAA10AA201psaayoNo ratings yet

- Sizing PSV Broady Valvitalia-R4Document18 pagesSizing PSV Broady Valvitalia-R4Anggun RushNo ratings yet

- Basis of Design - Pig Reciever 16 Design 2014Document27 pagesBasis of Design - Pig Reciever 16 Design 2014Andreas SchlagerNo ratings yet

- Pipeline Repair Project FEED 2Document18 pagesPipeline Repair Project FEED 2Nurcahyo Djati W100% (4)

- Liquip TrapDocument1 pageLiquip TrapKhánh TrầnNo ratings yet

- Os SPM CVX19001 1245 042Document5 pagesOs SPM CVX19001 1245 042DarshAwadNo ratings yet

- DS For PG in ISTADocument1 pageDS For PG in ISTAmarlrobles03081992No ratings yet

- Valves: Make: Kitz Coo: TaiwanDocument6 pagesValves: Make: Kitz Coo: TaiwanDeepak JoyNo ratings yet

- Solid Filter - DatasheetDocument1 pageSolid Filter - Datasheetbmanojkumar16No ratings yet

- Data Sheet-Ball ValveDocument2 pagesData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Válvula Check SHCV - DatasheetDocument9 pagesVálvula Check SHCV - DatasheetFabio GiehlNo ratings yet

- Gearbox Parts ManualDocument57 pagesGearbox Parts ManualRELOJERIANo ratings yet

- Rs419 Ring Scanner Spec SheetDocument3 pagesRs419 Ring Scanner Spec SheetJames HowardNo ratings yet

- ANALISA JALAN BETON Fc'30 Mpa TEBAL 20 CMDocument52 pagesANALISA JALAN BETON Fc'30 Mpa TEBAL 20 CMnixonNo ratings yet

- BROCHURE Low Range DIGI Water KitDocument2 pagesBROCHURE Low Range DIGI Water KitZts MksNo ratings yet

- Tutorial ActuatorsDocument4 pagesTutorial ActuatorsImfarosha EmmaNo ratings yet

- Orbital-Welding Facts enDocument52 pagesOrbital-Welding Facts ene.vicente.caballeroNo ratings yet

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoNo ratings yet

- Brgy Ordinance Solid WasteDocument7 pagesBrgy Ordinance Solid WasteJolina AlcantaraNo ratings yet

- Drilling Mud BasicsDocument7 pagesDrilling Mud Basicsdavid100% (1)

- WD25TC-IN WD35TC-IN WD50TC-IN WD71TC-IN WD25TC-M WD35TC-M: Split Type Room Air Conditioner Operation ManualDocument36 pagesWD25TC-IN WD35TC-IN WD50TC-IN WD71TC-IN WD25TC-M WD35TC-M: Split Type Room Air Conditioner Operation ManualCarmelo EscribanoNo ratings yet

- Pro 36 AdDocument2 pagesPro 36 Adkaniappan sakthivelNo ratings yet

- s058 - Résine D'accrochageDocument1 pages058 - Résine D'accrochageBen Abdallah BecemNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General InformationMina MagdyNo ratings yet

- Rock Bolt Capacity CalculationDocument2 pagesRock Bolt Capacity CalculationROHIT PADHARIA100% (1)

- SCI Stainless ForgedDocument12 pagesSCI Stainless ForgedBrandon TrocNo ratings yet

- Requirement For Fatigue AssessmentDocument3 pagesRequirement For Fatigue AssessmentyogacruiseNo ratings yet

- BD ND Angle of Repose PDFDocument4 pagesBD ND Angle of Repose PDFDilnesa EjiguNo ratings yet

- Final Mems NemsDocument29 pagesFinal Mems NemsNawnit LockedNo ratings yet

- CNC Web Handout 20091001Document25 pagesCNC Web Handout 20091001Daniel MabengoNo ratings yet

- Dse4120 Manual PDFDocument30 pagesDse4120 Manual PDFnhocti007No ratings yet

- Astm A 615 Steel 2015Document8 pagesAstm A 615 Steel 2015wenming chenNo ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- Advanced Insulationfor Subsea ApplicationDocument2 pagesAdvanced Insulationfor Subsea ApplicationAforbajeNo ratings yet

- Mdgassupplysystemgroup 5medical 170124160041Document30 pagesMdgassupplysystemgroup 5medical 170124160041Azmi PatarNo ratings yet

- Aluminium Sheet Grade 19000 SuppliersDocument10 pagesAluminium Sheet Grade 19000 Supplierssanghvi overseas incNo ratings yet

- Beam DesignDocument17 pagesBeam Designvaram1No ratings yet

- 05 - 3 ProtectorsDocument35 pages05 - 3 ProtectorsAndre Damara100% (1)

- OpelDocument21 pagesOpelAndreia FlorescuNo ratings yet

- 4011 - Hit Re 500-SD PDFDocument1 page4011 - Hit Re 500-SD PDFBaterdene BaachkaNo ratings yet

Front End Engineering Design 2 (Feed 2) Onshore Pipeline Senipah - Ru V Balikpapan Datasheet For Pipeline Special Item (Appendix A) Pt. Istana Karang Laut

Front End Engineering Design 2 (Feed 2) Onshore Pipeline Senipah - Ru V Balikpapan Datasheet For Pipeline Special Item (Appendix A) Pt. Istana Karang Laut

Uploaded by

Ruri IswadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Front End Engineering Design 2 (Feed 2) Onshore Pipeline Senipah - Ru V Balikpapan Datasheet For Pipeline Special Item (Appendix A) Pt. Istana Karang Laut

Front End Engineering Design 2 (Feed 2) Onshore Pipeline Senipah - Ru V Balikpapan Datasheet For Pipeline Special Item (Appendix A) Pt. Istana Karang Laut

Uploaded by

Ruri IswadiCopyright:

Available Formats

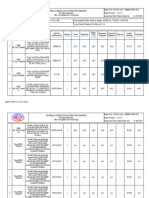

FRONT END ENGINEERING DESIGN 2 (FEED 2)

ONSHORE PIPELINE

SENIPAH - RU V BALIKPAPAN

DATASHEET FOR PIPELINE SPECIAL ITEM

(APPENDIX A)

PT. ISTANA KARANG LAUT

Client : PT. PERTAMINA GAS Equipment : Barred Tee 24" x 16" PT. ISTANA

Location : SENIPAH, BALIKPAPAN Number Required : 1 EA

Tag Number :

1 Tee Size (Run dia. X Branch dia.) 24" x 16"

2 Location Senipah Station

3 Pipeline Service Natural Gas

4 Design Code ASME B31.8

5 Tee Steel Grade (MSS SP 75) WPHY 65

6 Dimension Standard Material MSS SP 75

BARRED TEE CHARACTERISTICS

7 End Connection Bevel Ends (Note 2, 3, & 4)

8 Tee Pressure Rating 300 Lbs

9 Bar Steel Material ASTM A 283 or Equivalent

10 No. of Bars (scrapper guides) (Note 1)

11 Dimension of Bar (Thk x Height) (Note 1)

12 Ambient Temperature 26 °C

13 Design Temperature 65.5 °C

Design Pressure 708 psig

Corrosion Allowance 3 mm

Field Hydrostatic Test Pressure 1062 psig

Impact Test Temperature -10 °C

14 Total Quantity 1 ea

15 Reference SNBP2-10-PRO-DRW-0008 (Piping & Instrument Diagram Pig Launcher)

MATCHING MATCHING

16 Steel Grade API 5L X65

HEADER

PIPE AT

17 Nominal Outside Diameter 609.6 mm (24")

18 Nominal Wall Thickness 12.7 mm (0.5")

20 Steel Grade API 5L X65 (for pipe) and A694 F65 (for flange)

BRANCH

PIPE AT

21 Nominal Outside Diameter 355.6 mm (Note 5)

22 Nominal Wall Thickness 25.4 mm (1.0")

29 Radiography Test Yes

TESTING AND CERTIFICATION

30 Magnetic Particle Yes, according to ASME Sec. VIII

Ultrasonic Test Yes, according to ASTM A578

Leak Test No

Impact Test Yes (Impact requirement shall comply with tee steel grade WPHY 65

Hydrostatic Pressure Test Yes

31 Dielectric & Resistance Test No

32 Certificate Vendor Specialty

NOTES:

1. Size and quantity of bar to be designed by Vendor. Design Factor = 0.5 as per ASME B31.8

2. Tees shall be supplied without pup piece

3. Bevel protector shall be used to protect end bevels at both ends of main header

4. Tees with branch outlet neck shall be supplied with Welding Neck (WN) flange, welded and tested with the tee.

5. The nominal internal diameter of the tee outlet shall match the down stream pipe diameter

6. Internal bars shall be welded with full penetration welds.

7. See general illustration drawing (reference only).

Document No : SNBP2-00-PL-DTS-002

Sheet No. : 1 of 2 Rev. : A

DATASHEET FOR PIPELINE SPECIAL ITEM Contract. No. :

You might also like

- BQ With Priced (Water Tank)Document107 pagesBQ With Priced (Water Tank)INTAN FARHANA MOHD ROSLANNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Calculation Sheet: WT-CAL-CO2-003Document4 pagesCalculation Sheet: WT-CAL-CO2-003babu100% (1)

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Shut Down Valve Sample DatasheetsDocument6 pagesShut Down Valve Sample DatasheetsBABILIN V100% (1)

- Datasheet Valve ПДНГ 0440 22Document3 pagesDatasheet Valve ПДНГ 0440 22Ngoc Huyen NguyenNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- Design Calculations For SS316L Waste Water Storage Tank-Tk01-Rev01Document10 pagesDesign Calculations For SS316L Waste Water Storage Tank-Tk01-Rev01AzhaghiaNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Bill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127, Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127, Tahun 2013moddysNo ratings yet

- Data Sheet For Barred Tee 010719Document1 pageData Sheet For Barred Tee 010719Heru Agung SetyantoNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- Data Sheet Válvula de Seguridad y AlivioDocument4 pagesData Sheet Válvula de Seguridad y Aliviorenzo condeNo ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- Bill of Quantity: Fabrikasi 5 (Lima) Unit Tube Bundle 11-E-108, 11-E-109, 11-E-110A, 11-E-110B, 11-E-122, Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 5 (Lima) Unit Tube Bundle 11-E-108, 11-E-109, 11-E-110A, 11-E-110B, 11-E-122, Tahun 2013moddysNo ratings yet

- Fabrication of Gas Purging FittingsDocument2 pagesFabrication of Gas Purging Fittingsjiao longNo ratings yet

- Data Sheet For Gas FilterDocument1 pageData Sheet For Gas FilterKhánh TrầnNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Flange CalculationDocument48 pagesFlange CalculationAndi SuntoroNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Data Sheet For Injection Quill AssemblyDocument4 pagesData Sheet For Injection Quill AssemblysudjonoNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary Abaratu50% (2)

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Datasheet 1Document1 pageDatasheet 1Thắng Trần QuangNo ratings yet

- MJ Spec NI-346-21R1-MS New Eoan AssociatesDocument1 pageMJ Spec NI-346-21R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Bill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127 Tahun 2013Document3 pagesBill of Quantity: Fabrikasi 4 (Empat) Unit Tube Bundle 11-E-106, 11-E-118B, 11-E-119, 11-E-127 Tahun 2013moddysNo ratings yet

- Mrir P PP5 001Document20 pagesMrir P PP5 001nguyenquocbao1990No ratings yet

- VMS - 5Document1 pageVMS - 5ritoh8657No ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocument2 pagesPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- Report No. (Số báo cáo) : MRIR-P-PP5-002 Page (Trang) : 10 of 10 Inspection Date (Ngày kiểm tra) :9/29/2020 Material Receiving Inspection Report For Pipe MaterialsDocument20 pagesReport No. (Số báo cáo) : MRIR-P-PP5-002 Page (Trang) : 10 of 10 Inspection Date (Ngày kiểm tra) :9/29/2020 Material Receiving Inspection Report For Pipe Materialsnguyenquocbao1990No ratings yet

- Mrir P PP5 002Document11 pagesMrir P PP5 002nguyenquocbao1990No ratings yet

- Design of Long Distance Oil PipelineDocument21 pagesDesign of Long Distance Oil PipelineHaseeb Khawaja100% (1)

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhNo ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Swing Check Valve Data Sheet: Comision Federal de ElectricidadDocument1 pageSwing Check Valve Data Sheet: Comision Federal de Electricidadjos ToricesNo ratings yet

- Expansion Bellow SpecificationDocument1 pageExpansion Bellow SpecificationASHWINI BHOSALENo ratings yet

- Piping Fitting Spec Rev 0 AFCDocument1 pagePiping Fitting Spec Rev 0 AFCsobariNo ratings yet

- Basis of Design - PIG LAUNCHER 16 DESIGN 2014Document27 pagesBasis of Design - PIG LAUNCHER 16 DESIGN 2014Andreas Schlager100% (1)

- Vertical CompressDocument47 pagesVertical CompressSivi NallamothuNo ratings yet

- Carlos Caballero Industria Metalurgica S.R.L.: Carretera A Cotoca KM 1 1/2 Tel. (591) 3 3492929 Santa Cruz - BoliviaDocument58 pagesCarlos Caballero Industria Metalurgica S.R.L.: Carretera A Cotoca KM 1 1/2 Tel. (591) 3 3492929 Santa Cruz - Boliviayoselin Ayala RamosNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Data Sheet For Plug ValveDocument2 pagesData Sheet For Plug ValveTauqueerAhmadNo ratings yet

- At200 + KM26Document5 pagesAt200 + KM26João Paulo PiresNo ratings yet

- Rev.2 Calculation Tag# HAA10AA201Document4 pagesRev.2 Calculation Tag# HAA10AA201psaayoNo ratings yet

- Sizing PSV Broady Valvitalia-R4Document18 pagesSizing PSV Broady Valvitalia-R4Anggun RushNo ratings yet

- Basis of Design - Pig Reciever 16 Design 2014Document27 pagesBasis of Design - Pig Reciever 16 Design 2014Andreas SchlagerNo ratings yet

- Pipeline Repair Project FEED 2Document18 pagesPipeline Repair Project FEED 2Nurcahyo Djati W100% (4)

- Liquip TrapDocument1 pageLiquip TrapKhánh TrầnNo ratings yet

- Os SPM CVX19001 1245 042Document5 pagesOs SPM CVX19001 1245 042DarshAwadNo ratings yet

- DS For PG in ISTADocument1 pageDS For PG in ISTAmarlrobles03081992No ratings yet

- Valves: Make: Kitz Coo: TaiwanDocument6 pagesValves: Make: Kitz Coo: TaiwanDeepak JoyNo ratings yet

- Solid Filter - DatasheetDocument1 pageSolid Filter - Datasheetbmanojkumar16No ratings yet

- Data Sheet-Ball ValveDocument2 pagesData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Válvula Check SHCV - DatasheetDocument9 pagesVálvula Check SHCV - DatasheetFabio GiehlNo ratings yet

- Gearbox Parts ManualDocument57 pagesGearbox Parts ManualRELOJERIANo ratings yet

- Rs419 Ring Scanner Spec SheetDocument3 pagesRs419 Ring Scanner Spec SheetJames HowardNo ratings yet

- ANALISA JALAN BETON Fc'30 Mpa TEBAL 20 CMDocument52 pagesANALISA JALAN BETON Fc'30 Mpa TEBAL 20 CMnixonNo ratings yet

- BROCHURE Low Range DIGI Water KitDocument2 pagesBROCHURE Low Range DIGI Water KitZts MksNo ratings yet

- Tutorial ActuatorsDocument4 pagesTutorial ActuatorsImfarosha EmmaNo ratings yet

- Orbital-Welding Facts enDocument52 pagesOrbital-Welding Facts ene.vicente.caballeroNo ratings yet

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoNo ratings yet

- Brgy Ordinance Solid WasteDocument7 pagesBrgy Ordinance Solid WasteJolina AlcantaraNo ratings yet

- Drilling Mud BasicsDocument7 pagesDrilling Mud Basicsdavid100% (1)

- WD25TC-IN WD35TC-IN WD50TC-IN WD71TC-IN WD25TC-M WD35TC-M: Split Type Room Air Conditioner Operation ManualDocument36 pagesWD25TC-IN WD35TC-IN WD50TC-IN WD71TC-IN WD25TC-M WD35TC-M: Split Type Room Air Conditioner Operation ManualCarmelo EscribanoNo ratings yet

- Pro 36 AdDocument2 pagesPro 36 Adkaniappan sakthivelNo ratings yet

- s058 - Résine D'accrochageDocument1 pages058 - Résine D'accrochageBen Abdallah BecemNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General InformationMina MagdyNo ratings yet

- Rock Bolt Capacity CalculationDocument2 pagesRock Bolt Capacity CalculationROHIT PADHARIA100% (1)

- SCI Stainless ForgedDocument12 pagesSCI Stainless ForgedBrandon TrocNo ratings yet

- Requirement For Fatigue AssessmentDocument3 pagesRequirement For Fatigue AssessmentyogacruiseNo ratings yet

- BD ND Angle of Repose PDFDocument4 pagesBD ND Angle of Repose PDFDilnesa EjiguNo ratings yet

- Final Mems NemsDocument29 pagesFinal Mems NemsNawnit LockedNo ratings yet

- CNC Web Handout 20091001Document25 pagesCNC Web Handout 20091001Daniel MabengoNo ratings yet

- Dse4120 Manual PDFDocument30 pagesDse4120 Manual PDFnhocti007No ratings yet

- Astm A 615 Steel 2015Document8 pagesAstm A 615 Steel 2015wenming chenNo ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- Advanced Insulationfor Subsea ApplicationDocument2 pagesAdvanced Insulationfor Subsea ApplicationAforbajeNo ratings yet

- Mdgassupplysystemgroup 5medical 170124160041Document30 pagesMdgassupplysystemgroup 5medical 170124160041Azmi PatarNo ratings yet

- Aluminium Sheet Grade 19000 SuppliersDocument10 pagesAluminium Sheet Grade 19000 Supplierssanghvi overseas incNo ratings yet

- Beam DesignDocument17 pagesBeam Designvaram1No ratings yet

- 05 - 3 ProtectorsDocument35 pages05 - 3 ProtectorsAndre Damara100% (1)

- OpelDocument21 pagesOpelAndreia FlorescuNo ratings yet

- 4011 - Hit Re 500-SD PDFDocument1 page4011 - Hit Re 500-SD PDFBaterdene BaachkaNo ratings yet