Professional Documents

Culture Documents

Binder Systems For: Vehicle Refinishing Coatings

Binder Systems For: Vehicle Refinishing Coatings

Uploaded by

Maxiliano MACKEVICIUSCopyright:

Available Formats

You might also like

- Pressure Vessel Compliance ChecklistDocument3 pagesPressure Vessel Compliance Checklistpineda44444100% (2)

- Oracle E-Business Suite R12 Projects PreSales Specialist AssessmentDocument15 pagesOracle E-Business Suite R12 Projects PreSales Specialist AssessmentQoba100% (1)

- Sap SD Interview Questions With AnswersDocument247 pagesSap SD Interview Questions With Answersrohit360deg83% (6)

- Americhem Corporate PresentationDocument14 pagesAmerichem Corporate PresentationCarlos CardenasNo ratings yet

- 7 Habits of Highly Effective PeopleDocument34 pages7 Habits of Highly Effective PeopleLucu100% (3)

- Scrap Calculation in Sap PPDocument13 pagesScrap Calculation in Sap PPRahul pawadeNo ratings yet

- Procurement Contracts R12 RNDocument60 pagesProcurement Contracts R12 RNDuygu CoşkunNo ratings yet

- Binders For: Architectural CoatingsDocument8 pagesBinders For: Architectural CoatingsAPEX SON100% (1)

- Chempart SC 400 TDSDocument1 pageChempart SC 400 TDSmarco_ravelo_10No ratings yet

- SellosDocument40 pagesSellosJavier PerezNo ratings yet

- OEM Market Brochure - Letter - 0120-LoDocument5 pagesOEM Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- Cat. Parker Chomerics Engineered Materials GroupDocument52 pagesCat. Parker Chomerics Engineered Materials GroupAlejandro GilNo ratings yet

- Polymer Selection GuideDocument28 pagesPolymer Selection GuideSIA BHANJINo ratings yet

- Archroma - Passion For Hometextiles DigitalDocument8 pagesArchroma - Passion For Hometextiles DigitalNguyễn Huy CườngNo ratings yet

- PP-Selection-Guide Hyujdi PDFDocument20 pagesPP-Selection-Guide Hyujdi PDFparijat patelNo ratings yet

- JTBaker Solid Phase ExtractionDocument16 pagesJTBaker Solid Phase Extractionerminb1525No ratings yet

- Product Data Sheet of Resin DM 470-300 PDFDocument4 pagesProduct Data Sheet of Resin DM 470-300 PDFPrashant ShindeNo ratings yet

- Orientation For New StaffDocument33 pagesOrientation For New StaffEyqa RazaliNo ratings yet

- Arkema Generalbrochure SmallDocument9 pagesArkema Generalbrochure SmallRajNo ratings yet

- IndustrialCoatings Selection GuideDocument56 pagesIndustrialCoatings Selection GuideAllen KamNo ratings yet

- PerstorpDocument98 pagesPerstorpArif FajarNo ratings yet

- Archroma Passion-For-Hometextiles Brochure LOWDocument8 pagesArchroma Passion-For-Hometextiles Brochure LOWginanjarpNo ratings yet

- BASF Construction Solutions Product Guide 2017 LRDocument32 pagesBASF Construction Solutions Product Guide 2017 LRzaryab khan100% (1)

- Waterborne Additives Brochure 2022 enDocument13 pagesWaterborne Additives Brochure 2022 enHelene Di marcantonioNo ratings yet

- Archroma Passion-For-Toweling 210630Document10 pagesArchroma Passion-For-Toweling 210630Nguyễn Huy CườngNo ratings yet

- Product - Overview - EN Antiveining CoatingDocument12 pagesProduct - Overview - EN Antiveining CoatingSachin KumbharNo ratings yet

- 22-1239 Corrosion Catalog 2022-En LRDocument12 pages22-1239 Corrosion Catalog 2022-En LRΓεώργιος ΠαπουτσόγλουNo ratings yet

- Derakane Momentum 411-350Document3 pagesDerakane Momentum 411-350DidikHariantoNo ratings yet

- Archroma - Passion For Fashion Knits - 190606Document8 pagesArchroma - Passion For Fashion Knits - 190606abhishek_ict50% (2)

- Filtros PecoDocument36 pagesFiltros PecoPedro Luis Choque Mamani100% (1)

- NBR Leaflet Krynac 4955vp Ultrahigh 150dpiwebDocument2 pagesNBR Leaflet Krynac 4955vp Ultrahigh 150dpiwebSikanderNo ratings yet

- Archroma Passion For Printing 190606 NewDocument10 pagesArchroma Passion For Printing 190606 NewSUDIPTA KARNo ratings yet

- Archroma - Passion For PrintingDocument10 pagesArchroma - Passion For PrintingNguyễn Huy Cường100% (1)

- Archroma - Passion For Printing - 190606 New PDFDocument10 pagesArchroma - Passion For Printing - 190606 New PDFZille HusnainNo ratings yet

- Derakane 411 Data SheetDocument3 pagesDerakane 411 Data SheetJUAN BAGNODNo ratings yet

- 2016 Industrial-Coatings SelGuide r1 LResDocument40 pages2016 Industrial-Coatings SelGuide r1 LResjoy7898No ratings yet

- Clariant Brochure Masterbatches and Combibatches For Textiles and Fibers 201010 ENDocument6 pagesClariant Brochure Masterbatches and Combibatches For Textiles and Fibers 201010 ENcristiNo ratings yet

- Asta Chemical Company ProfileDocument9 pagesAsta Chemical Company ProfileNura Alam SiddiqueNo ratings yet

- Drilling Fluid PDFDocument23 pagesDrilling Fluid PDFcristinelbNo ratings yet

- Ascom - General Intro Sep 2013Document40 pagesAscom - General Intro Sep 2013AzizNo ratings yet

- Fluid Solutions - BrochuresDocument4 pagesFluid Solutions - BrochuresRashid Khalifa RehmanNo ratings yet

- GI EMEAI Sell Sheet ECOATDocument4 pagesGI EMEAI Sell Sheet ECOATSy Nguyen VietNo ratings yet

- ACOUSTICRYL™ AV-1331 Copolymer Emulsion: Regional Product Availability DescriptionDocument3 pagesACOUSTICRYL™ AV-1331 Copolymer Emulsion: Regional Product Availability DescriptionJaved ShaikhNo ratings yet

- Well Head Sealing Guide PDFDocument4 pagesWell Head Sealing Guide PDFQaiser Hafeez100% (1)

- Synolac 4097 WD 75Document2 pagesSynolac 4097 WD 75monrmNo ratings yet

- Scomi Drilling FluidDocument23 pagesScomi Drilling FluidVaijayanti JoshiNo ratings yet

- Thermoplastic Piping Technical Manual: PVC, CPVC, PP, PVDFDocument48 pagesThermoplastic Piping Technical Manual: PVC, CPVC, PP, PVDFPervezNo ratings yet

- Archroma Passion For Carpets Brochure LOWDocument12 pagesArchroma Passion For Carpets Brochure LOWDHRUVNo ratings yet

- Metal Claddings: Producing With QualityDocument48 pagesMetal Claddings: Producing With Qualityhelder.fradeNo ratings yet

- Bs Image UsDocument32 pagesBs Image Uskaniappan sakthivelNo ratings yet

- Archroma Passion For Activewear Brochure 19Document8 pagesArchroma Passion For Activewear Brochure 19vijaydani090No ratings yet

- Arkema Global Coatings Offer 2014Document12 pagesArkema Global Coatings Offer 2014Ahmed TahaNo ratings yet

- 166 LDocument104 pages166 LKSBNo ratings yet

- PCR July 18 PDFDocument52 pagesPCR July 18 PDFOsamaAliMoussaNo ratings yet

- The World of Lapp: Innovations 2020Document56 pagesThe World of Lapp: Innovations 2020Marco Antonio Jordán AguadoNo ratings yet

- Passion For Automotive: Best-In-Class Innovation, Application and SolutionsDocument9 pagesPassion For Automotive: Best-In-Class Innovation, Application and SolutionsLuis Gamarra VicunaNo ratings yet

- Arlanxeo CR BayprenDocument7 pagesArlanxeo CR Bayprenmostafa shafizadehNo ratings yet

- Zebra Labeling Solutions Fact Sheet en UsDocument4 pagesZebra Labeling Solutions Fact Sheet en UsclaytonNo ratings yet

- Chem Resist Resin Ribbon Spec Sheet en UsDocument2 pagesChem Resist Resin Ribbon Spec Sheet en UsDavid BaylissNo ratings yet

- Paper - and - Packaging SASOL PDFDocument8 pagesPaper - and - Packaging SASOL PDFMaximiliano MackeviciusNo ratings yet

- Catalog 4800 Parker Industrial HoseDocument230 pagesCatalog 4800 Parker Industrial HoseNEFTALI VARGAS MANDUJANONo ratings yet

- Inometa Protek Coatings en LowDocument16 pagesInometa Protek Coatings en LowsakthivelNo ratings yet

- Synolac 4060 Wda 90Document2 pagesSynolac 4060 Wda 90monrmNo ratings yet

- Grasa MalleusDocument1 pageGrasa MalleusJorge CurisacaNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Ec tech report architectural and decorative coatings: Water-based and sustainableFrom EverandEc tech report architectural and decorative coatings: Water-based and sustainableVincentz Network GmbH & Co KGNo ratings yet

- Example of Design FMEA WorksheetDocument5 pagesExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிNo ratings yet

- Being - Really The - Black Sheep - in The GMAT Family - GMAT Sentence Correction (SC)Document6 pagesBeing - Really The - Black Sheep - in The GMAT Family - GMAT Sentence Correction (SC)Deepti AgarwalNo ratings yet

- Enterpreneurship Development Programme (Edp) For Pmegp Beneficiaries 1Document2 pagesEnterpreneurship Development Programme (Edp) For Pmegp Beneficiaries 1Ravi Kumar MogilsettiNo ratings yet

- M2024 BM IA Research Proposal HL SLDocument10 pagesM2024 BM IA Research Proposal HL SLtina.jainNo ratings yet

- Stillwater Gazette 8-5-22Document32 pagesStillwater Gazette 8-5-22Keith AndersonNo ratings yet

- Sales Price: Mark-Up On Total Variable Cost Per BatchDocument8 pagesSales Price: Mark-Up On Total Variable Cost Per BatchNikita SharmaNo ratings yet

- St. Dominic Savio College of Law Commercial Law ReviewDocument4 pagesSt. Dominic Savio College of Law Commercial Law ReviewJeffreyReyesNo ratings yet

- Sales Probability CalculatorDocument4 pagesSales Probability CalculatorshbawonoNo ratings yet

- QuotationDocument2 pagesQuotationAjeet Kumar PandeyNo ratings yet

- Rapid Niche Profits PDFDocument56 pagesRapid Niche Profits PDFAbster1No ratings yet

- RO11 BRMA0999100059748310 TextDocument38 pagesRO11 BRMA0999100059748310 TextCristina CobzaruNo ratings yet

- Multiple ChoiceDocument18 pagesMultiple ChoiceAngel moodyNo ratings yet

- QSR Restaurants IndiaDocument14 pagesQSR Restaurants IndiaadvminalNo ratings yet

- Modern Architecture Magazine TemplateDocument12 pagesModern Architecture Magazine TemplateBreanna CIel E. CabahitNo ratings yet

- Ros Rof A534794Document1 pageRos Rof A534794Ankit GuptaNo ratings yet

- Vocational Training Course Portfolio: Public Price Offshore Safety & Survival (OPITO Approved)Document10 pagesVocational Training Course Portfolio: Public Price Offshore Safety & Survival (OPITO Approved)tduyhaoNo ratings yet

- Daily Time Record Daily Time Record: (NAME) (NAME)Document1 pageDaily Time Record Daily Time Record: (NAME) (NAME)Lord Kile BaterzalNo ratings yet

- From Solvay Magazine 56 Dec 2013Document33 pagesFrom Solvay Magazine 56 Dec 2013chb2No ratings yet

- Master Degrees Ranking 2016 - Best Masters Ranking Sustainable Development and Environmental Management - WorldwideDocument8 pagesMaster Degrees Ranking 2016 - Best Masters Ranking Sustainable Development and Environmental Management - WorldwideAulia QisthiNo ratings yet

- Supplier Selection Assignment FinalDocument10 pagesSupplier Selection Assignment FinalKhanh Linh Bui100% (1)

- Industry 4.0 Revolution PowerPoint TemplatesDocument16 pagesIndustry 4.0 Revolution PowerPoint Templatesvikesh kumar100% (1)

- Metro Cash and CarryDocument25 pagesMetro Cash and CarrySahar Sultan33% (3)

- Acer Inc - Taiwan's Rampaging DragonDocument21 pagesAcer Inc - Taiwan's Rampaging DragonBiroz69100% (2)

- Jurisprudence On Investment ScamsDocument46 pagesJurisprudence On Investment ScamsaljazzerusadNo ratings yet

Binder Systems For: Vehicle Refinishing Coatings

Binder Systems For: Vehicle Refinishing Coatings

Uploaded by

Maxiliano MACKEVICIUSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Binder Systems For: Vehicle Refinishing Coatings

Binder Systems For: Vehicle Refinishing Coatings

Uploaded by

Maxiliano MACKEVICIUSCopyright:

Available Formats

Coating Resins

Binder Systems for

Vehicle Refinishing

Coatings

• Comprehensive solutions for

clearcoats, basecoats,

primers, and monocoats

• Sustainable solvent and

waterborne systems

• Global manufacturing grid

and technical support

INNOVATIVE BINDERS TAILORED TO YOUR

REFINISHING REQUIREMENTS

Your customers look for outstanding coating solutions: flexibility, fast-drying,

durability and low VOC. At Arkema, we design and deliver a full offer of binders

to meet your needs.

Comprehensive formulating A trusted expertise: Global development

options: • Specific quality requirements: resources:

• Systems for metal and plastic starbright, low color resins, • Worldwide reach with facilities

coatings, for vehicle refinishing with consistent physical in all regions

and commercial transportation properties • The resources of a large

• One or two-components • Dedicated vehicle refinish chemical group integrated

systems, solvent or water based development and application into acrylic and methacrylic

• Conventional, high or very teams, backed by synthesis monomers

high solids binders laboratories • Seamless supply chain with an

• For use with air-mix or airless on-time delivery rate close to

spraying guns 100 percent

• Polyester powder resins • Expertise in HSE and regulatory

• Additives for rheology affairs to support your

control, flow and levelling development across regions

and dispersion

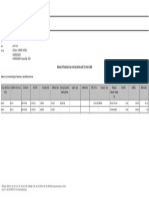

Clearcoat/

Technology Primer Basecoat Monocoat Features

Topcoat

Solventborne Outstanding durability, hardness and gloss.

SYNOCURE® • • • •

acrylics 2K From standard to very-high solid systems

Solventborne Thermosetting and thermoplastic 1K systems.

SYNOCRYL® •

acrylics 1K Broad CAB compatibility

Oil-free High flexibility resins. Used also in blends for

SYNOLAC® • • •

polyesters excellent surface properties

Solventborne

SYNOLAC® • • Short and medium oil. For air or oven curing

alkyds

Waterborne High gloss and durability. Also suitable for

SYNAQUA® • • •

acrylics 2K direct-to-metal

Waterborne Self-crosslinkable latex with outstanding corrosion

ENCOR® •

acrylics 1K protection

Good things happen when

chemistry gets personal.

Innovation. Opportunity. Growth. Yes, we have

expertise, resources, and exceptional waterborne and

solventborne products. But you will hear similar claims

from our competitors. We believe what sets Arkema

apart is understanding – your goals…your applications…

you. Open, honest collaboration, listening, and action.

These are the things that move practical innovation

forward and enable us to help you keep your customers

on the road.

COATING RESINS GLOBAL RESOURCES

Arkema France - A French «Société Anonyme» registered with the Commercial and Companies Register of Nanterre (France) under number 319 632 790

China/Asia Pacific/India Europe – Middle East – Africa North America South America

Changshu – production plant Verneuil-en-Halatte – research center Arkema Coating Resins – production plant Coatex/Arkema Coating Resins –

Changshu, Jiangsu Province 60550 Verneuil-en-Halatte, France Alsip, IL São Paulo production plant

PCR Araçariguama, São Paulo, Brazil

ARKEMA GmbH – production plant Arkema Coating Resins – production plant

Changshu – technical center Niederlassung Arkema Coating Resins Grand Rapids, MI Coatex/Arkema Coating Resins –

Changshu, Jiangsu Province Flurstraße technical center

PCR 08056 Zwickau, Germany Arkema Coating Resins – production plant Araçariguama, São Paulo, Brazil

North Kansas City, MO

Guangzhou Technical Service and ARKEMA S.R.L. – production plant

Application Centre Boretto Italy Arkema Coating Resins – production plant

Science City, Guangzhou, China Hahnville, LA

Dircom - 4534 E/03.2017/10 - Coating - Photos: Shutterstock and iStock - Design: Cook Marcomm

ARKEMA S.R.L. – technical center

Arkema Coatings Malaysia Sdn. Bhd. – Boretto Italy Arkema Coating Resins – production plant

general office Torrance, CA

81700 Pasir Gudang Johor Malaysia ARKEMA S.R.L.– production plant

Gissi (CH) Italy Arkema Coating Resins – production plant

Arkema Coating Resins Malaysia Sdn. Bhd. Mobile, AL

– production plant Arkema Coating Resins SAU –

production plant Arkema Coating Resins – research center

PLO 491, Jalan Keluli, Pasir Gudang,

Mollet del Vallès (Barcelona), Spain Cary, NC

Johor, Malaysia

Arkema Coating Resins SAU – Arkema Coating Resins – technical center

Navi Mumbai, India, – production plant,

production plant North Kansas City, MO

technical service

Navi Mumbai, Maharashtra 400706, India Sant Celoni (Barcelona), Spain

Arkema Coating Resins SAU –

technical center

Sant Celoni (Barcelona), Spain

Arkema B.V. – production plant

Brummen, The Netherlands

Vlissingen – production plant

Ritthem, The Netherlands

For full contact information, visit arkemacoatingresins.com

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of

the product and of the information referred to herein are beyond our control, Arkema expressly disclaims any and all liability as to any results obtained or arising from any

use of the product or reliance on such information; NO WARRANTY OF FITNESS FOR ANY PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. The information provided herein

relates only to the specific product designated and may not be applicable when such product is used in combination with other materials or in any process. The user should

thoroughly test any application before commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an

inducement to infringe any patent and the user is advised to take appropriate steps to be sure that any proposed use of the product will not result in patent infringement. See

SDS for Health & Safety Considerations.

Arkema has implemented a Medical Policy regarding the use of Arkema products in medical devices applications that are in contact with the body or circulating bodily fluids

(http://www.arkema.com/en/social-responsibility/responsible-product-management/medical-device-policy/index.html) Arkema has designated medical grades to be used

for such medical device applications. Products that have not been designated as medical grades are not authorized by Arkema for use in medical device applications that are

in contact with the body or circulating bodily fluids. In addition, Arkema strictly prohibits the use of any Arkema products in medical device applications that are implanted in

the body or in contact with bodily fluids or tissues for greater than 30 days. The Arkema trademarks and the Arkema name shall not be used in conjunction with customers’

medical devices, including without limitation, permanent or temporary implantable devices, and customers shall not represent to anyone else, that Arkema allows, endorses

or permits the use of Arkema products in such medical devices.

It is the sole responsibility of the manufacturer of the medical device to determine the suitability (including biocompatibility) of all raw materials, products and components,

including any medical grade Arkema products, in order to ensure that the final end-use product is safe for its end use; performs or functions as intended; and complies with

all applicable legal and regulatory requirements (FDA or other national drug agencies). It is the sole responsibility of the manufacturer of the medical device to conduct all

necessary tests and inspections and to evaluate the medical device under actual end-use requirements and to adequately advise and warn purchasers, users, and/or learned

intermediaries (such as physicians) of pertinent risks and fulfill any postmarket surveillance obligations. Any decision regarding the appropriateness of a particular Arkema

material in a particular medical device should be based on the judgment of the manufacturer, seller, the competent authority, and the treating physician.

ENCOR®, SYNAQUA®, SYNOLAC®, SYNOCRYL® and SYNOCURE® are

registered trademarks of Arkema Inc. Arkema – Coating Resins Headquarters: Arkema France

410 Gregson Dr. 420, rue d’Estienne d’Orves

Cary, NC 27511 92705 Colombes Cedex – France

USA Tél. : 33 (0)1 49 00 80 80

Tel.: ( +1) 919 469 6700 Fax : 33 (0)1 49 00 83 96

arkemacoatingresins.com 1-800-777-8227 arkema.com

You might also like

- Pressure Vessel Compliance ChecklistDocument3 pagesPressure Vessel Compliance Checklistpineda44444100% (2)

- Oracle E-Business Suite R12 Projects PreSales Specialist AssessmentDocument15 pagesOracle E-Business Suite R12 Projects PreSales Specialist AssessmentQoba100% (1)

- Sap SD Interview Questions With AnswersDocument247 pagesSap SD Interview Questions With Answersrohit360deg83% (6)

- Americhem Corporate PresentationDocument14 pagesAmerichem Corporate PresentationCarlos CardenasNo ratings yet

- 7 Habits of Highly Effective PeopleDocument34 pages7 Habits of Highly Effective PeopleLucu100% (3)

- Scrap Calculation in Sap PPDocument13 pagesScrap Calculation in Sap PPRahul pawadeNo ratings yet

- Procurement Contracts R12 RNDocument60 pagesProcurement Contracts R12 RNDuygu CoşkunNo ratings yet

- Binders For: Architectural CoatingsDocument8 pagesBinders For: Architectural CoatingsAPEX SON100% (1)

- Chempart SC 400 TDSDocument1 pageChempart SC 400 TDSmarco_ravelo_10No ratings yet

- SellosDocument40 pagesSellosJavier PerezNo ratings yet

- OEM Market Brochure - Letter - 0120-LoDocument5 pagesOEM Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- Cat. Parker Chomerics Engineered Materials GroupDocument52 pagesCat. Parker Chomerics Engineered Materials GroupAlejandro GilNo ratings yet

- Polymer Selection GuideDocument28 pagesPolymer Selection GuideSIA BHANJINo ratings yet

- Archroma - Passion For Hometextiles DigitalDocument8 pagesArchroma - Passion For Hometextiles DigitalNguyễn Huy CườngNo ratings yet

- PP-Selection-Guide Hyujdi PDFDocument20 pagesPP-Selection-Guide Hyujdi PDFparijat patelNo ratings yet

- JTBaker Solid Phase ExtractionDocument16 pagesJTBaker Solid Phase Extractionerminb1525No ratings yet

- Product Data Sheet of Resin DM 470-300 PDFDocument4 pagesProduct Data Sheet of Resin DM 470-300 PDFPrashant ShindeNo ratings yet

- Orientation For New StaffDocument33 pagesOrientation For New StaffEyqa RazaliNo ratings yet

- Arkema Generalbrochure SmallDocument9 pagesArkema Generalbrochure SmallRajNo ratings yet

- IndustrialCoatings Selection GuideDocument56 pagesIndustrialCoatings Selection GuideAllen KamNo ratings yet

- PerstorpDocument98 pagesPerstorpArif FajarNo ratings yet

- Archroma Passion-For-Hometextiles Brochure LOWDocument8 pagesArchroma Passion-For-Hometextiles Brochure LOWginanjarpNo ratings yet

- BASF Construction Solutions Product Guide 2017 LRDocument32 pagesBASF Construction Solutions Product Guide 2017 LRzaryab khan100% (1)

- Waterborne Additives Brochure 2022 enDocument13 pagesWaterborne Additives Brochure 2022 enHelene Di marcantonioNo ratings yet

- Archroma Passion-For-Toweling 210630Document10 pagesArchroma Passion-For-Toweling 210630Nguyễn Huy CườngNo ratings yet

- Product - Overview - EN Antiveining CoatingDocument12 pagesProduct - Overview - EN Antiveining CoatingSachin KumbharNo ratings yet

- 22-1239 Corrosion Catalog 2022-En LRDocument12 pages22-1239 Corrosion Catalog 2022-En LRΓεώργιος ΠαπουτσόγλουNo ratings yet

- Derakane Momentum 411-350Document3 pagesDerakane Momentum 411-350DidikHariantoNo ratings yet

- Archroma - Passion For Fashion Knits - 190606Document8 pagesArchroma - Passion For Fashion Knits - 190606abhishek_ict50% (2)

- Filtros PecoDocument36 pagesFiltros PecoPedro Luis Choque Mamani100% (1)

- NBR Leaflet Krynac 4955vp Ultrahigh 150dpiwebDocument2 pagesNBR Leaflet Krynac 4955vp Ultrahigh 150dpiwebSikanderNo ratings yet

- Archroma Passion For Printing 190606 NewDocument10 pagesArchroma Passion For Printing 190606 NewSUDIPTA KARNo ratings yet

- Archroma - Passion For PrintingDocument10 pagesArchroma - Passion For PrintingNguyễn Huy Cường100% (1)

- Archroma - Passion For Printing - 190606 New PDFDocument10 pagesArchroma - Passion For Printing - 190606 New PDFZille HusnainNo ratings yet

- Derakane 411 Data SheetDocument3 pagesDerakane 411 Data SheetJUAN BAGNODNo ratings yet

- 2016 Industrial-Coatings SelGuide r1 LResDocument40 pages2016 Industrial-Coatings SelGuide r1 LResjoy7898No ratings yet

- Clariant Brochure Masterbatches and Combibatches For Textiles and Fibers 201010 ENDocument6 pagesClariant Brochure Masterbatches and Combibatches For Textiles and Fibers 201010 ENcristiNo ratings yet

- Asta Chemical Company ProfileDocument9 pagesAsta Chemical Company ProfileNura Alam SiddiqueNo ratings yet

- Drilling Fluid PDFDocument23 pagesDrilling Fluid PDFcristinelbNo ratings yet

- Ascom - General Intro Sep 2013Document40 pagesAscom - General Intro Sep 2013AzizNo ratings yet

- Fluid Solutions - BrochuresDocument4 pagesFluid Solutions - BrochuresRashid Khalifa RehmanNo ratings yet

- GI EMEAI Sell Sheet ECOATDocument4 pagesGI EMEAI Sell Sheet ECOATSy Nguyen VietNo ratings yet

- ACOUSTICRYL™ AV-1331 Copolymer Emulsion: Regional Product Availability DescriptionDocument3 pagesACOUSTICRYL™ AV-1331 Copolymer Emulsion: Regional Product Availability DescriptionJaved ShaikhNo ratings yet

- Well Head Sealing Guide PDFDocument4 pagesWell Head Sealing Guide PDFQaiser Hafeez100% (1)

- Synolac 4097 WD 75Document2 pagesSynolac 4097 WD 75monrmNo ratings yet

- Scomi Drilling FluidDocument23 pagesScomi Drilling FluidVaijayanti JoshiNo ratings yet

- Thermoplastic Piping Technical Manual: PVC, CPVC, PP, PVDFDocument48 pagesThermoplastic Piping Technical Manual: PVC, CPVC, PP, PVDFPervezNo ratings yet

- Archroma Passion For Carpets Brochure LOWDocument12 pagesArchroma Passion For Carpets Brochure LOWDHRUVNo ratings yet

- Metal Claddings: Producing With QualityDocument48 pagesMetal Claddings: Producing With Qualityhelder.fradeNo ratings yet

- Bs Image UsDocument32 pagesBs Image Uskaniappan sakthivelNo ratings yet

- Archroma Passion For Activewear Brochure 19Document8 pagesArchroma Passion For Activewear Brochure 19vijaydani090No ratings yet

- Arkema Global Coatings Offer 2014Document12 pagesArkema Global Coatings Offer 2014Ahmed TahaNo ratings yet

- 166 LDocument104 pages166 LKSBNo ratings yet

- PCR July 18 PDFDocument52 pagesPCR July 18 PDFOsamaAliMoussaNo ratings yet

- The World of Lapp: Innovations 2020Document56 pagesThe World of Lapp: Innovations 2020Marco Antonio Jordán AguadoNo ratings yet

- Passion For Automotive: Best-In-Class Innovation, Application and SolutionsDocument9 pagesPassion For Automotive: Best-In-Class Innovation, Application and SolutionsLuis Gamarra VicunaNo ratings yet

- Arlanxeo CR BayprenDocument7 pagesArlanxeo CR Bayprenmostafa shafizadehNo ratings yet

- Zebra Labeling Solutions Fact Sheet en UsDocument4 pagesZebra Labeling Solutions Fact Sheet en UsclaytonNo ratings yet

- Chem Resist Resin Ribbon Spec Sheet en UsDocument2 pagesChem Resist Resin Ribbon Spec Sheet en UsDavid BaylissNo ratings yet

- Paper - and - Packaging SASOL PDFDocument8 pagesPaper - and - Packaging SASOL PDFMaximiliano MackeviciusNo ratings yet

- Catalog 4800 Parker Industrial HoseDocument230 pagesCatalog 4800 Parker Industrial HoseNEFTALI VARGAS MANDUJANONo ratings yet

- Inometa Protek Coatings en LowDocument16 pagesInometa Protek Coatings en LowsakthivelNo ratings yet

- Synolac 4060 Wda 90Document2 pagesSynolac 4060 Wda 90monrmNo ratings yet

- Grasa MalleusDocument1 pageGrasa MalleusJorge CurisacaNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Ec tech report architectural and decorative coatings: Water-based and sustainableFrom EverandEc tech report architectural and decorative coatings: Water-based and sustainableVincentz Network GmbH & Co KGNo ratings yet

- Example of Design FMEA WorksheetDocument5 pagesExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிNo ratings yet

- Being - Really The - Black Sheep - in The GMAT Family - GMAT Sentence Correction (SC)Document6 pagesBeing - Really The - Black Sheep - in The GMAT Family - GMAT Sentence Correction (SC)Deepti AgarwalNo ratings yet

- Enterpreneurship Development Programme (Edp) For Pmegp Beneficiaries 1Document2 pagesEnterpreneurship Development Programme (Edp) For Pmegp Beneficiaries 1Ravi Kumar MogilsettiNo ratings yet

- M2024 BM IA Research Proposal HL SLDocument10 pagesM2024 BM IA Research Proposal HL SLtina.jainNo ratings yet

- Stillwater Gazette 8-5-22Document32 pagesStillwater Gazette 8-5-22Keith AndersonNo ratings yet

- Sales Price: Mark-Up On Total Variable Cost Per BatchDocument8 pagesSales Price: Mark-Up On Total Variable Cost Per BatchNikita SharmaNo ratings yet

- St. Dominic Savio College of Law Commercial Law ReviewDocument4 pagesSt. Dominic Savio College of Law Commercial Law ReviewJeffreyReyesNo ratings yet

- Sales Probability CalculatorDocument4 pagesSales Probability CalculatorshbawonoNo ratings yet

- QuotationDocument2 pagesQuotationAjeet Kumar PandeyNo ratings yet

- Rapid Niche Profits PDFDocument56 pagesRapid Niche Profits PDFAbster1No ratings yet

- RO11 BRMA0999100059748310 TextDocument38 pagesRO11 BRMA0999100059748310 TextCristina CobzaruNo ratings yet

- Multiple ChoiceDocument18 pagesMultiple ChoiceAngel moodyNo ratings yet

- QSR Restaurants IndiaDocument14 pagesQSR Restaurants IndiaadvminalNo ratings yet

- Modern Architecture Magazine TemplateDocument12 pagesModern Architecture Magazine TemplateBreanna CIel E. CabahitNo ratings yet

- Ros Rof A534794Document1 pageRos Rof A534794Ankit GuptaNo ratings yet

- Vocational Training Course Portfolio: Public Price Offshore Safety & Survival (OPITO Approved)Document10 pagesVocational Training Course Portfolio: Public Price Offshore Safety & Survival (OPITO Approved)tduyhaoNo ratings yet

- Daily Time Record Daily Time Record: (NAME) (NAME)Document1 pageDaily Time Record Daily Time Record: (NAME) (NAME)Lord Kile BaterzalNo ratings yet

- From Solvay Magazine 56 Dec 2013Document33 pagesFrom Solvay Magazine 56 Dec 2013chb2No ratings yet

- Master Degrees Ranking 2016 - Best Masters Ranking Sustainable Development and Environmental Management - WorldwideDocument8 pagesMaster Degrees Ranking 2016 - Best Masters Ranking Sustainable Development and Environmental Management - WorldwideAulia QisthiNo ratings yet

- Supplier Selection Assignment FinalDocument10 pagesSupplier Selection Assignment FinalKhanh Linh Bui100% (1)

- Industry 4.0 Revolution PowerPoint TemplatesDocument16 pagesIndustry 4.0 Revolution PowerPoint Templatesvikesh kumar100% (1)

- Metro Cash and CarryDocument25 pagesMetro Cash and CarrySahar Sultan33% (3)

- Acer Inc - Taiwan's Rampaging DragonDocument21 pagesAcer Inc - Taiwan's Rampaging DragonBiroz69100% (2)

- Jurisprudence On Investment ScamsDocument46 pagesJurisprudence On Investment ScamsaljazzerusadNo ratings yet