Professional Documents

Culture Documents

Maintenance Manual LH 350 Flight Helmet: Confidential Industry

Maintenance Manual LH 350 Flight Helmet: Confidential Industry

Uploaded by

nelson vasquezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Manual LH 350 Flight Helmet: Confidential Industry

Maintenance Manual LH 350 Flight Helmet: Confidential Industry

Uploaded by

nelson vasquezCopyright:

Available Formats

CONFIDENTIAL INDUSTRY

MAINTENANCE MANUAL

LH 350 FLIGHT HELMET

Ref : 180722 – PP0200175 ind00 1/18

CONFIDENTIAL INDUSTRY

Table of Contents

Topic Page

Table of Contents 2/19

WARNING 3/19

DESCRIPTION OF HELMET 4/19

GUARANTEE 5/19

PREAMBLE 6/19

CHINSTRAP 7/19

CLOTHING 8/19

OUTER VISOR 9/19

INNER VISOR 10/19

NVG HARD COVER 11/19

THE INNER IMPACT CAP 12 and 13/19

NECK PAD 14/19

ACCESS TO ELECTRONIC CARD 15/19

ELECTRONIC CARD 16/19

INSPECTION VERIFICATION 17/19

AND MAINTENANCE REQUIREMENTS

MANDATORY INSPECTION 18/19

AND REPLACEMENT CRITERIA

Ref : 180722 – PP0200175 ind00 2/18

CONFIDENTIAL INDUSTRY

WARNING

Thank you for placing your trust in MSA products.

Please read these instructions carefully before using your helmet.

Failure to observe these instructions could reduce the amount of protection your

helmet provides.

Your helmet will only provide maximum protection if all of the MSA components are used with

it. Furthermore, any change made to your helmet or failure to use one of the original

helmet components will imply improper use of the equipment, and will discharge MSA

of any liability.

In an ongoing effort to improve its products, MSA hereby reserves the right to alter them at no

notice.

To guarantee sufficient protection, the helmet must be adapted and adjusted to the

wearer’s head size.

Your helmet is designed such that the pressure built up when it is knocked is absorbed

by the partial destruction or damage to the outer and inner cap; even if such damage is

not immediately apparent, we recommend replacing any helmet which has taken a

considerable impact.

The user’s attention is also drawn to the dangers of modifying or removing any of the

original components of the helmet, apart from any modification or removal

recommended by the helmet manufacturer. Under no circumstances should helmets be

adapted for attachment of accessories by any means not recommended by the helmet

manufacturer.

Do not apply any paint, solvents, adhesives or self-adhesive labels, other than those

recommended by the helmet manufacturer’s instructions.

Checks should be made following any apparent impact, carried out by our

maintenance department or a specialist.

The MSA LH 350 flying helmet is designed only for helicopter pilots and crew members. It

ensures a maximum comfort and protection.

Available in three sizes to fit head measuring between 52 cm to 64 cm. It incorporates two

visors; and could receive a wide range of communication systems and Night Vision Goggles

supports, available to order. Please contact us for details.

Each helmet is individually serial numbered to ensure correct identification of the helmet and

a correct record of the service life history of the helmet.

Ref : 180722 – PP0200175 ind00 3/18

CONFIDENTIAL INDUSTRY

LH 350 F L I G H T H E L M E T

DESCRIPTION OF HELMET

The LH350 helmet shell is made of :

• A one-piece shell in high performance composite fibers. The shell covers a large head

protection zone.

• An expanded polystyrene inner padding for impact absorption. It is covered with a velvet

lining for the user's comfort.

• Custom fit pads are used to fit the helmet to the users headform.

The outside coating is flame retardant.

The inner lining is made up of two comfort spacers : the T shaped spacer and the neck spacer

each of these spacer can be personalized with different foam in 3 thickness (4mm, 8mm and 12mm)

which make it possible to obtain a perfect fit for the user's head form.

The lining elements are made up of different thickness foam inserts covered in a ‘patented‘ wicking

material to draw moisture away from the users skin in hot and humid climates and ensure the user’s

comfort.

These two comfort spacers are attached inside the shell by Velcro strips. Adaptation to the user's

head form is made by choosing the foam thickness inside each spacer.

Two protective visors manufactured are fitted to the LH350 :

• Both visors are mounted on the outside of the helmet shell and fully protected by the hard

cover

• Both visors can be adjusted to suit the users requirements.

The acoustic protection system is made up of :

• Two injection molded thermoplastic earcups, with a recess to accommodate the

communication earphones.

• Two earseals for comfort, ergonomically shaped.

• Specific acoustic foam.

These earcups ensure correct acoustic protection and are fixed inside the shell by Velcro spacers.

The chinstrap is made of a synthetic fire-proof fibre strap with a clipping buckle. A leather chinstrap

covers the strap to ensure user’s comfort at the chin.

8

A helmet protective bag.

Serial Number, Helmet Log Card and Modification Record.

Every MSA flight helmet is supplied with a helmet log card recording the manufacturing and model

details of the helmet, in addition to recording modifications and Level 3 repairs to the helmet.

Each helmet is individually serial numbered to ensure correct identification of the helmet and a

correct record of the service life history of the helmet.

Ref : 180722 – PP0200175 ind00 4/18

CONFIDENTIAL INDUSTRY

GUARANTEE

All of our models, accessories, and spare parts are meticulously inspected before leaving

the factory.

MSA helmets and their options are guaranteed for one year from the date of purchase.

Guarantee provides for parts and labor repair or replacement of the helmet and components arising

from any mechanical or electrical failure or defect which may occur during normal operating

conditions as described in the helmet Instruction Manual supplied with each helmet.

Ref : 180722 – PP0200175 ind00 5/18

CONFIDENTIAL INDUSTRY

PREAMBLE

Important : for any repair install the helmet at least on the helmet protecting bag

Necessary tools :

- 20, 15 and 10 TORX key

- 7 mm combination wrench

- 2 mm hexagonal screw driver

- Flat blade screwdriver

- Threadlocking low strength (LOCTITE 222 or equivalent )

Ref : 180722 – PP0200175 ind00 6/18

CONFIDENTIAL INDUSTRY

1. Chinstrap:

Tools: 20 and 15 TORX keys, 7 mm combination wrench and flat blade screwdriver.

Dismantling duration: 1 minute.

Mounting duration: 2 minutes.

Open the chinstrap.

20 TORX key

7 mm combination

wrench

2 Inside detail

15 TORX key

Inside detail

4 points chinstrap disassembly

Left and right chinstrap dismantle:

1 front fixation points: unscrew the outer screw with the 20 key TORX while maintaining inner

helmet nut with 7 mm combination wrench (remove the nut cap with the screw driver before ),

2 rear fixation points : unscrew the inner helmet screw with the 15 TORX key.

Proceed in the reverse order to reassemble.

Warning: Apply Threadlocking low strength on the inner TORX screw back fixation point before

mounting.

When removing the chin-cup; check that the buckle is correctly positioned, the opened side of

the buckle towards the outside of the helmet.

Ref : 180722 – PP0200175 ind00 7/18

CONFIDENTIAL INDUSTRY

2. Clothing:

Tools: none.

Dismantling duration: 20 seconds.

Mounting duration: 45 seconds.

LH 350 helmet includes 2 comfort parts and spacers:

• 1 adjustable, comfortable T-shaped spacer with 4 mm, 8mm and 12mm thick foam,

• Comfort neck spacer with 4 mm, 8mm and 12mm thick foams,

• Self-gripping spacers for ear cup adjustment.

Those elements are fixed inside the helmet by self gripping tapes.

When changing the foam in the T shaped spacer and in the comfort neck spacer, insure that the

chosen foams are well positioned. Check the presence of the trapezoid insert with the comfort

neck spacer.

4mm thickness foam (no hole)

8mm thickness foam (1 hole)

12mm thickness foam (2 holes)

Ref : 180722 – PP0200175 ind00 8/18

CONFIDENTIAL INDUSTRY

3. Outer visor :

Tools : none.

Dismantling duration: 2 minutes.

Mounting duration: 2 minutes.

Unscrew the 2 captive screws on the right and left sides.

Raised the hard cover by rotating back side the hinge.

hinge

Remove the outer visor by sliding outside the hard cover

Proceed in the reverse order to reassemble.

Warning

When replacing the hard cover, ensure that the lug is securely in place beneath the base. See

below.

Screw up the captive screws on the right and left sides.

lug

Opened position Closed position

Ref : 180722 – PP0200175 ind00 9/18

CONFIDENTIAL INDUSTRY

4. Inner visor :

Tools : none.

Dismantling duration: 2 minutes.

Mounting duration: 2 minutes.

Lower the inner visor

Unscrew the 2 captive screws on the right and left sides.

Raised the hard cover by rotating back side the hinge

hinge

base cover .

1

1- Open the left and right base covers by rotating upwards

(do not unscrew anything).

2- Disengage the visor interfaces from their axis of rotation.

visor interface

Proceed in the reverse order to reassemble.

Warning

When replacing the hard cover, in closed position, ensure that the lug is securely in place

beneath the base.

lug

Opened position Closed position

Screw up the captive screws on the right and left sides.

Ref : 180722 – PP0200175 ind00 10/18

CONFIDENTIAL INDUSTRY

5. NVG hard cover :

Tools : 2 mm ALEN screw driver.

Dismantling duration: 2 minutes.

Mounting duration: 3 minutes.

Unscrew the 2 captive screws on the right and left sides.

Unscrew the 2 ALEN screws on the hinge.

Proceed in the reverse order to reassemble.

Warning

When replacing the hard cover, ensure that the lug is securely in place beneath the base. See

below.

.

lug

Opened position Closed position

Screw up the captive screws on the right and left sides

Ref : 180722 – PP0200175 ind00 11/18

CONFIDENTIAL INDUSTRY

6. The inner impact cap:

Tools : 15 TORX key

Dismantling duration: 5 minutes.

Mounting duration: 8 minutes.

To dismantle the inner cap :

- remove all the comfort parts (T spacer, neck spacer),

- remove the two ear cups,

- dismantle the chinstrap (see chap. 2),

Remove the

neck pad

Remove the stud

Remove the inner left and right

inner padding

Remove the blocking pieces

on each side of the shell

Inner detail

15 TORX key

Ref : 180722 – PP0200175 ind00 12/18

CONFIDENTIAL INDUSTRY

Pull the rear side of the inner impact cap to release

the inner cap of the shell

Then pull the front part of the inner cap

Proceed in the reverse order to reassemble.

Warning for neck pad mounting see § 7.

Ref : 180722 – PP0200175 ind00 13/18

CONFIDENTIAL INDUSTRY

7. Neck pad mounting :

Tools: 2 mm ALEN screw driver,

Mounting duration: 1 minutes.

Outside the shell, partly unscrew the 4

screws with 2 mm ALEN screw driver.

Inside the shell : insert the 2

clamps of the neck pad in the

electronic card support seating.

Outside the shell, screw the 4 screws with 2 mm ALEN screw driver.

Ref : 180722 – PP0200175 ind00 14/18

CONFIDENTIAL INDUSTRY

8. Access to the electronic card:

Tools: 2 mm ALEN screw driver, 15 TORX key

Dismantling duration: 3 minutes.

Mounting duration: 4 minutes.

Unscrew the 4 screws with 2 mm

ALEN screw driver

Remove the cover to have access

to the electronic card

Unplug the cable plug

on the card.

Remove the cable for a complete access

to the electronic card.

Unscrew the cable maintain

screw with the 15 TORX key.

Proceed in the reverse order to reassemble.

Ref : 180722 – PP0200175 ind00 15/18

CONFIDENTIAL INDUSTRY

9. Electronic card

Tools : flat blade screwdriver

Dismantling duration: 1 minute.

Mounting duration: 2 minutes.

See § 8 for access to electronic card.

Unplug the 3 JST plugs

Left earphone

Right earphone

Microphone.

Left Right

Microphone

earphone earphone

Pull out the card with the flat

blade screwdriver screw driver as shown.

Proceed in the reverse order to reassemble.

Ref : 180722 – PP0200175 ind00 16/18

CONFIDENTIAL INDUSTRY

10. Inspection, Verification and Maintenance Requirements.

The MSA range of flight helmets is designed as a modular solution to meet the

requirements of helicopters pilots and crew members. The helmet is designed to

require minimal maintenance intervention and recommended servicing or repair is on

an ‘ON CONDITION BASIS’.

Accordingly, a full periodic service program is not recommended or required in

support of the LH350 flight helmets.

Listed below is a recommended schedule of servicing which may be adopted by

users of the LH350 flight helmet.

MSA do not recommend a program of servicing which involves complete

disassembly of the helmet on a periodic basis.

The helmet is designed and engineered to enter and remain in operational service

until such time as corrective maintenance is required for unserviceabilities of the

helmet shell, visor system or communications package.

Inspection, Verification and Maintenance Matrix:

Basic Controls* Before each

flight

Cleanness and working of the visors Yes

Attendance of the comfort pads Yes

Chinstrap status working and fixation points Yes

Functional check of communications Yes

Hard cover fixation points Yes

Fixation points of electronic box Yes

Periodic Controls* Every:

Tightening and working of: inner and outer visors, communication 3 months

system, anti cable tear-out system

State of the visors and fixation system 3 months

State of the pads 3 months

State of comfort ear set 3 months

State of the chin strap and working of the locking system 3 months

State of the shell (single impact use) 3 months

Cleaning as specified in User Manual 2 months

Major Spare Parts Replacement* (Forecast Replacement Every:

Interval)

Inner visor 5 years

Outer visor 5 years

TSHAPED SPACER NECK PAD SPACER 2 years

Comfort ear seal

Chinstrap 2 years

Inner cap 5 years

Shell 10 years

Note: Inspection criteria based on a standard 200 hours annual usage period.

Ref : 180722 – PP0200175 ind00 17/18

CONFIDENTIAL INDUSTRY

11. Mandatory Inspection & Replacement Criteria

This section details the mandatory actions and inspections required when a helmet suffers a

confirmed impact incident OR when routine maintenance reveals damage consistent with an

impact incident.

Mandatory actions and inspection requirements are detailed in the matrix listed below.

Mandatory Inspection & Replacement Criteria Matrix:

ACTION TO BE TAKEN Condition

Mandatory Replacement Requirement – Confirmed

Impact:

The helmet shell is designed for single impact use ONLY.

• The helmet shell and protective integrity is considered CONFIRMED

compromised following a confirmed impact; IMPACT

• The helmet shell is to be removed from service immediately

following a confirmed impact and rendered unusable or

destroyed.

Mandatory Inspection Requirement Unconfirmed

Impact:

Where damage consistent with helmet impact is displayed. The

helmet is to be inspected for the following;

• Indentation, cracking or deformation of the composite fibers

shell and hard cover;

• Damage to the composite shell construction including cut or Mandatory

frayed fibers; Inspection if

• Removal of outer protective coating resulting in the Impact

degradation of the gel coating exposure of composite fibers; Suspected

• Dislodgement or deformation of the impact cap;

• Damage to the visor adjustment and rotation mechanisms;

• Damage to the chinstrap webbing, buckle assembly and

fixation points;

• Inspection to be recorded on helmet log card.

If damage consistent with an impact is confirmed - Mandatory

Replacement is required.

User & Operational Maintenance Responsibility

All helmet users and operational maintenance units are responsible for reporting

known or suspected impact incidents and damage to helmet shells. Operational

maintenance units are responsible for ensuring the required inspection criteria are

met in assessing the continued serviceability of the helmet.

Failure to withdraw a damaged helmet shell from operational use will relieve MSA

from any liability in the event of helmet failure.

Ref : 180722 – PP0200175 ind00 18/18

You might also like

- Original PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFDocument41 pagesOriginal PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFcynthia.stewart295100% (37)

- Cardinal 748Document47 pagesCardinal 748Juan MontufarNo ratings yet

- Precise Spindle ManualDocument17 pagesPrecise Spindle Manualmarkp8767No ratings yet

- SECTION 501-05: Interior Trim and Ornamentation 2010 Fusion, Milan, MKZ, Fusion Hybrid, Milan Hybrid Workshop Manual Removal and InstallationDocument5 pagesSECTION 501-05: Interior Trim and Ornamentation 2010 Fusion, Milan, MKZ, Fusion Hybrid, Milan Hybrid Workshop Manual Removal and InstallationMarinNo ratings yet

- Stanadyne db2435 4942Document4 pagesStanadyne db2435 4942nelson vasquezNo ratings yet

- Stanadyne db2435 4942Document4 pagesStanadyne db2435 4942nelson vasquezNo ratings yet

- AP YMCA Level 3 Mock Paper - Sports MassageDocument11 pagesAP YMCA Level 3 Mock Paper - Sports Massagemy name0% (1)

- IP8519Document11 pagesIP8519WilfredoNo ratings yet

- Kubota VC5030 RTVX900 - X1120D Wiper Kit (172 Degree) Rev. - , 6 PagesDocument7 pagesKubota VC5030 RTVX900 - X1120D Wiper Kit (172 Degree) Rev. - , 6 PagesmartinNo ratings yet

- CT6073Document3 pagesCT6073Philipus MNo ratings yet

- Series TY-FRL - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coverage General DescriptionDocument6 pagesSeries TY-FRL - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coverage General DescriptionnicolasNo ratings yet

- EN 397 EN 166 EN 170 EN 50365: PrecautionsDocument2 pagesEN 397 EN 166 EN 170 EN 50365: Precautionsnebojsha77No ratings yet

- EasyGlider Pro ManualDocument18 pagesEasyGlider Pro ManualCristian Cortez MirandaNo ratings yet

- Signode PN-114 and PNR-114 Operation Parts and Safety ManualDocument20 pagesSignode PN-114 and PNR-114 Operation Parts and Safety ManualMaintenance SteelMartNo ratings yet

- Tyco SprinklerDocument3 pagesTyco SprinklerVitor BrandaoNo ratings yet

- Honda Goldwing GL1800 Hitch Installation Guide Bushtec Motorcycle TrailersDocument13 pagesHonda Goldwing GL1800 Hitch Installation Guide Bushtec Motorcycle TrailersthegodofgodesNo ratings yet

- .Au - Welding Equipment - BOC - IPRM - S10-SafetyDocument49 pages.Au - Welding Equipment - BOC - IPRM - S10-SafetyJR ZookNo ratings yet

- Alfra Rotabest Midi 5050 Operation ManualDocument13 pagesAlfra Rotabest Midi 5050 Operation Manualsudofim2006No ratings yet

- Fig34 Im Ibr16 22inDocument12 pagesFig34 Im Ibr16 22inLGTNo ratings yet

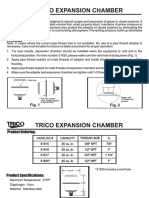

- Expansion ChamberDocument2 pagesExpansion ChamberGabriel DittamoNo ratings yet

- 180TCD Brake ManualDocument5 pages180TCD Brake ManualJose GonzalezNo ratings yet

- Technical Manual For The Strobe XB15UL/ULC Manuel Technique Du Stroboscope XB15UL/ULCDocument12 pagesTechnical Manual For The Strobe XB15UL/ULC Manuel Technique Du Stroboscope XB15UL/ULCCaptainNo ratings yet

- YoshimuraDocument7 pagesYoshimuraNguon MadolyNo ratings yet

- Instruction Manual Impulse SealersDocument8 pagesInstruction Manual Impulse Sealersmariopilar100% (1)

- SB-14-016 11MY-14MY Allison Torque Converter Lockup ModificationDocument15 pagesSB-14-016 11MY-14MY Allison Torque Converter Lockup ModificationPhil B.No ratings yet

- Special Response SprinklerDocument4 pagesSpecial Response SprinklerAhrian BenaNo ratings yet

- Sisto-C: 1. InstallationDocument1 pageSisto-C: 1. InstallationEric LarrondoNo ratings yet

- Description/Suggested Specifications: Extra Large Tapcon For Extra Large Challenges!Document2 pagesDescription/Suggested Specifications: Extra Large Tapcon For Extra Large Challenges!blessed cccNo ratings yet

- Installation Guide DomeDocument7 pagesInstallation Guide DomeNguyen Ha Duy TrungNo ratings yet

- Nissan Tow Hitch InstallationDocument2 pagesNissan Tow Hitch InstallationalvinNo ratings yet

- SBKJ - Spiral Tubeformer 1602 Decoiler DVC1000Document18 pagesSBKJ - Spiral Tubeformer 1602 Decoiler DVC1000rinconvega0% (1)

- J04259 Aileron Heated Grips 2008Document8 pagesJ04259 Aileron Heated Grips 2008twinjaysNo ratings yet

- Manual BS 1000853 4 USDocument12 pagesManual BS 1000853 4 USRao ImranNo ratings yet

- Install Z1 Q50 Q60 Urethane Differential BushingDocument6 pagesInstall Z1 Q50 Q60 Urethane Differential BushingFer OrdazNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- Street Series: CBR-1000RRDocument3 pagesStreet Series: CBR-1000RR김재치No ratings yet

- Flange Spreader: Parts List and Operating Instructions ForDocument6 pagesFlange Spreader: Parts List and Operating Instructions ForTitanplyNo ratings yet

- TFP110 08 2018Document6 pagesTFP110 08 2018SamiYousifNo ratings yet

- Iprm S10-Safety d5Document72 pagesIprm S10-Safety d5Ali ClubistNo ratings yet

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Pennbarry Fumex IOM v6Document22 pagesPennbarry Fumex IOM v6RanielNo ratings yet

- Minka Aire Artemis ManualDocument23 pagesMinka Aire Artemis Manualhappy crackNo ratings yet

- TycoDocument10 pagesTycoTahseenNo ratings yet

- Yoshimura r77 Exhaust System Yamaha Fz092014Document3 pagesYoshimura r77 Exhaust System Yamaha Fz092014Felipeorozco98No ratings yet

- AspxDocument27 pagesAspxBrayan Sánchez ParedesNo ratings yet

- BERGEON ToolDocument12 pagesBERGEON ToolGene4MoNo ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- Mechanical SealDocument27 pagesMechanical SealMauricio Carestia100% (1)

- Asa de AndorinhaDocument10 pagesAsa de AndorinhajosimarNo ratings yet

- A6V12101474Document6 pagesA6V12101474hanselozgumusNo ratings yet

- HKS Manual GT86 BRZ SuperchargerDocument41 pagesHKS Manual GT86 BRZ SuperchargerAntonino AlduinaNo ratings yet

- SB-14-019 05MY-07MY Allison Torque Converter Lockup ModificationDocument15 pagesSB-14-019 05MY-07MY Allison Torque Converter Lockup ModificationPhil B.No ratings yet

- M806 ManualDocument21 pagesM806 ManualcoinsertelcaNo ratings yet

- Mechanical Seal Installation InstructionDocument4 pagesMechanical Seal Installation InstructionSandi AslanNo ratings yet

- JDIcon Ultra S Product CatalogueDocument4 pagesJDIcon Ultra S Product CatalogueCamilo Flores VerdugoNo ratings yet

- 05b Rotary ActuatorDocument8 pages05b Rotary ActuatorJeannette Bobadilla ContrerasNo ratings yet

- 4500 9 HDF 1 2 - Splicing - InstructionsDocument24 pages4500 9 HDF 1 2 - Splicing - InstructionsOWEMNo ratings yet

- Installation Guide For Adventurer 5M EnclosureDocument36 pagesInstallation Guide For Adventurer 5M EnclosureZeic EngenhariaNo ratings yet

- Flush Bonded Windows: ToolsDocument42 pagesFlush Bonded Windows: ToolsMoto UputstvaNo ratings yet

- Installation Instructions For High Hose Retriever For Model 9800A/2600A With Vapor RecoveryDocument2 pagesInstallation Instructions For High Hose Retriever For Model 9800A/2600A With Vapor RecoveryMiller Alexander Mora VargasNo ratings yet

- Street Series: Yamaha R3 Yamaha MT-03Document5 pagesStreet Series: Yamaha R3 Yamaha MT-03Alex PlevakoNo ratings yet

- SMR 301 WP Installation ManualDocument19 pagesSMR 301 WP Installation ManualCarlos de la VegaNo ratings yet

- SECTION 501-35: Body Repairs 2010 Fusion, Milan, MKZ, Fusion Hybrid, Milan Hybrid Workshop Manual Removal and InstallationDocument8 pagesSECTION 501-35: Body Repairs 2010 Fusion, Milan, MKZ, Fusion Hybrid, Milan Hybrid Workshop Manual Removal and InstallationMarinNo ratings yet

- Hawke ControlEx Connectors Assembly AI500Document12 pagesHawke ControlEx Connectors Assembly AI500Tony Caroline MorganNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Gma 350H InstallationDocument49 pagesGma 350H Installationnelson vasquezNo ratings yet

- Installation Manual: AV-30 Multi-Mode IndicatorDocument17 pagesInstallation Manual: AV-30 Multi-Mode Indicatornelson vasquezNo ratings yet

- Transponder: Pilot's GuideDocument4 pagesTransponder: Pilot's Guidenelson vasquezNo ratings yet

- Understanding Engine Color CodesDocument2 pagesUnderstanding Engine Color Codesnelson vasquezNo ratings yet

- Why Take Unnecessary Risks When: You FlyDocument2 pagesWhy Take Unnecessary Risks When: You Flynelson vasquezNo ratings yet

- Mentoring Best PracticesDocument20 pagesMentoring Best Practicesnelson vasquez100% (1)

- Safety Tips: Flying Your DroneDocument1 pageSafety Tips: Flying Your Dronenelson vasquezNo ratings yet

- Gi275 Pilots Guide PDFDocument250 pagesGi275 Pilots Guide PDFnelson vasquezNo ratings yet

- AMC-030 Aircraft Parts HandlingDocument8 pagesAMC-030 Aircraft Parts Handlingnelson vasquezNo ratings yet

- Gi275 Autopilot Compatibility2 PDFDocument1 pageGi275 Autopilot Compatibility2 PDFnelson vasquezNo ratings yet

- Gi 275 STC Maintenance ManualDocument120 pagesGi 275 STC Maintenance Manualnelson vasquez100% (1)

- Gi275 Autopilot Compatibility2 PDFDocument1 pageGi275 Autopilot Compatibility2 PDFnelson vasquezNo ratings yet

- Barfield 1811d ManualDocument64 pagesBarfield 1811d Manualnelson vasquezNo ratings yet

- The Kap Autopilot SystemDocument26 pagesThe Kap Autopilot Systemnelson vasquezNo ratings yet

- Msa Gallet La100 Flight HelmetDocument14 pagesMsa Gallet La100 Flight Helmetnelson vasquezNo ratings yet

- Heliport Product Selector PDFDocument19 pagesHeliport Product Selector PDFnelson vasquezNo ratings yet

- Avionics: Ramp Test SetDocument12 pagesAvionics: Ramp Test Setnelson vasquez100% (1)

- kx165 and kx155 Brochure PDFDocument6 pageskx165 and kx155 Brochure PDFnelson vasquezNo ratings yet

- Saft 203212 Whi Vaseline PDFDocument14 pagesSaft 203212 Whi Vaseline PDFnelson vasquezNo ratings yet

- Taking Wireless Freedom To A New Level: Tiger Performance Products, IncDocument6 pagesTaking Wireless Freedom To A New Level: Tiger Performance Products, Incnelson vasquezNo ratings yet

- Annual Report 2018 04 BothSN PDFDocument168 pagesAnnual Report 2018 04 BothSN PDFjoenediath9345No ratings yet

- Brgy Health Center ProposalDocument8 pagesBrgy Health Center ProposalChristian Joseph Beringuel NietesNo ratings yet

- Sample History Dissertation AbstractDocument4 pagesSample History Dissertation AbstractIDon'TWantToWriteMyPaperSingapore100% (1)

- Purpose RediscoveredDocument102 pagesPurpose RediscoveredErnest NguboNo ratings yet

- 1Registration-View Registration 230pm PDFDocument14 pages1Registration-View Registration 230pm PDFNeil CNo ratings yet

- Gpi ProjectDocument60 pagesGpi Projectrushikesh kakadeNo ratings yet

- Email Boarding Pass (Web Check In) Goindigo - inDocument1 pageEmail Boarding Pass (Web Check In) Goindigo - inVyas Narayan DewanganNo ratings yet

- List of Students Applied For Upgradation 2020-21Document7 pagesList of Students Applied For Upgradation 2020-21Shivansh BansalNo ratings yet

- 2015 - Fracking Minding The Gaps - INGLESDocument14 pages2015 - Fracking Minding The Gaps - INGLESGersonMendozaUscateguiNo ratings yet

- Linked PDFDocument196 pagesLinked PDFroparts clujNo ratings yet

- Other Publications by CADCIM Technologies: Autodesk Revit Architecture TextbooksDocument2 pagesOther Publications by CADCIM Technologies: Autodesk Revit Architecture Textbooksankit suriNo ratings yet

- HuaweiDocument84 pagesHuaweiJainiti PrasadNo ratings yet

- Sambuena, Jayson Sambuena, Jayson: Patricia B. Remigio Raygie P. Sabalbarino Patricia B. Remigio Raygie P. SabalbarinoDocument2 pagesSambuena, Jayson Sambuena, Jayson: Patricia B. Remigio Raygie P. Sabalbarino Patricia B. Remigio Raygie P. SabalbarinojaysonNo ratings yet

- GX71 GX51 PDFDocument18 pagesGX71 GX51 PDFRepresentaciones y Distribuciones FALNo ratings yet

- Analysis of Paraquat Dichloride in Pesticides Using UV-Spectrophotometer.Document14 pagesAnalysis of Paraquat Dichloride in Pesticides Using UV-Spectrophotometer.OFURUM FRANKLYNNo ratings yet

- University of Tripoli HS120: - C. - D. Dense Regular Connective TissueDocument4 pagesUniversity of Tripoli HS120: - C. - D. Dense Regular Connective TissueAnn AnooshNo ratings yet

- Chapter 1 (Part 2) : Computer Networking: A Top Down ApproachDocument25 pagesChapter 1 (Part 2) : Computer Networking: A Top Down ApproachHassan RazaNo ratings yet

- Article Debate en 6 CkäDocument5 pagesArticle Debate en 6 CkäkerstinbergekNo ratings yet

- Practice Problems In, R and ChartsDocument2 pagesPractice Problems In, R and ChartsChand Patel100% (1)

- Cardenas-Claros & Gruba 2013) .Document23 pagesCardenas-Claros & Gruba 2013) .Dukhayel AldukhayelNo ratings yet

- Prepared By: P2Lt Joyce Angeline D Valencia NCDocument23 pagesPrepared By: P2Lt Joyce Angeline D Valencia NCJoan ErbelecNo ratings yet

- Thesis Statement For A Research Paper On CareersDocument7 pagesThesis Statement For A Research Paper On Careersyscgudvnd100% (1)

- Understanding Leadership and Empowerment in The Workplace: Banutu-Gomez Michael BaDocument24 pagesUnderstanding Leadership and Empowerment in The Workplace: Banutu-Gomez Michael BalopmidNo ratings yet

- Comparing Effectiveness of Family Planning Methods: How To Make Your Method More EffectiveDocument1 pageComparing Effectiveness of Family Planning Methods: How To Make Your Method More EffectiveGabrielle CatalanNo ratings yet

- The Chemistry of Essential Oils and Artificial Perfumes IIDocument370 pagesThe Chemistry of Essential Oils and Artificial Perfumes IIKenan CengicNo ratings yet

- STS PPTTTTDocument13 pagesSTS PPTTTTJannah FateNo ratings yet

- Class 9 GrammarDocument32 pagesClass 9 GrammarPerajothi PalanirajaNo ratings yet