Professional Documents

Culture Documents

Section 11 - Heating PDF

Section 11 - Heating PDF

Uploaded by

robbertmdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 11 - Heating PDF

Section 11 - Heating PDF

Uploaded by

robbertmdCopyright:

Available Formats

Section 11

Heating and Ventilation

Section 11 Heating & Ventilation Systems

1 of 6

HEATING AND VENTILATION SYSTEM

General

Ambient air, drawn in by a fan through a vent in the cowling above the cockpit is mixed with hot air (P2),

tapped from the engines, and distributed by pipelines to the cockpit and cabin. Fresh air for the

passengers is admitted by a scoop on each side of the aircraft, just aft of the pilot’s doors, and passes

through the trim panels to the individual louvres above each passenger's head.

A vent just forward of the front windscreen can be operated by a handle in the cockpit to allow fresh air

into the cockpit if desired.

Each pilot’s door is fitted with a sliding window.

A 3-phase AC fan can be switched on to supply ambient air through the heater distribution pipelines if

required.

Fixed vents in the upper rear side walls of the cabin extract the air and ensure the flow through the

aircraft.

Controls and Indications

Three controls are fitted on the overhead panel as shown in Figure 1.

1. A rotary temperature control knob, which automatically switches on the fan when moved from its

COLD/OFF position.

2. A sliding distribution lever which can be set in 3 positions. Aft (OFF), Centre (COCKPIT & CABIN)

and Forward (COCKPIT ONLY). This lever controls a flap valve in the distribution pipelines by a

teleflex control.

3. A ventilation switch on the left-hand side of the overhead panel to allow the fan to be ON when the

temperature controller is at COLD/OFF.

The control for the cockpit ventilation flap is fitted to a cross member just above the instrument panel.

COLD

OFF OFF

COCKPIT & CABIN HOT

COCKPIT

Heater Distribution Regulator Valve

Control Lever & Fan Control

Micro-Switch

VENTIL

OFF

ON

Fan Control Switch

Figure 1 – Heater Control Component Locations

Section 11 Heating & Ventilation Systems

2 of 6

Distributor Valve Control Rod

Thermostat

Valve Control

Mechanism

Pilots Diffuser

Stale Air

Evacuation

Line

Autopilot Hydraulics

Heating Diffuser

De-misting

Diffuser

Front Fresh

Air Vent

Heating-Ventilation

Lower Diffuser

Lower Cabin

Diffuser Unit

Upper Cabin

Diffuser Unit

Figure 3 – Heat Distribution & Airframe Components

Section 11 Heating & Ventilation Systems

3 of 6

Limitations

Because the heater draws compressor air from the engines, it must be switched ‘OFF’ for take-off and

landing.

Distribution

The hot air from the engines compressors passes through a non-return check-valve to the regulation

valve on the transmission decking. A pressure-reducing valve fitted to the regulation valve produces a

control pressure to operate the system. When the regulation valve is opened the hot air passes forward

to the mixing chamber where it is ejected into the ambient air drawn in by the fan.

A thermostat downstream of the mixing chamber cuts off the hot air if the temperature reaches 90°C.

The distribution pipelines direct the air to the four outlets in the bottom of the cabin, the pilots individual

overhead louvres, the Autopilot hydraulic unit in the broom cupboard, the windscreen de-misting

diffusers and the lower screen de-misting diffusers. The supply to the cabin can be cut off by means of

the sliding control in the cockpit when not required.

Electrical Power Supplies

The fan is powered by 3-phase 200V 400 Hz AC current from Primary AC bus bar (CB HEATING

VENTIL). The control DC supply for the fan contactor is from Secondary DC bus 2PP5 (CB HEATING

VENT).

System Operation

Refer to Figure 3. With the temperature control valve in its COLD/OFF position the micro switch (39H) is

open and the needle valve is off its seat allowing the control pressure (reduced P2 air pressure) to flow

away via the vent to atmosphere. There is therefore no control pressure acting under the diaphragm (3)

and the regulation valve is closed preventing P2 air from passing through to the ejector and into the

mixing chamber.

Should the fan switch (43H) now be made the contactor relay (40H) will be energised and the AC

contactor made thus motoring the fan and blowing fresh air through the distribution pipelines.

When the temperature control valve is turned towards the HOT position the cam on the valve makes the

micro-switch (39H) and the fan starts running. Rotating the control closes the needle valve, reducing the

leak of control P2 pressure. The pressure under the diaphragm (3) increases lifting the regulation valve

off its seat and allowing hot air to pass through to the mixing chamber. Thus, the more the rotary control

is turned, the more control pressure is increased and the more hot air is allowed through. The

temperature of the hot air passing through the distribution pipelines depends entirely upon the setting of

the rotary valve.

To prevent overheating of the system a thermostat is fitted just downstream of the mixing chamber.

Should the temperature exceed 90°C the thermostat valve opens and the control pressure leaks away

thus closing the regulation valve under action of the return spring (2).

If the rotary control is not in the COLD/OFF position when starting the engines fuel fumes will enter the

heating ducts and pass into the cabin. To overcome this problem, when the start button is pressed, relay

(48H) is energised and continues to be energised for 45 seconds after starter cut-out, giving an earth for

the supply through the windings of the solenoid valve (47H). The solenoid valve is energised, opening

the needle valve and the control pressure is vented to atmosphere. The regulation valve therefore,

remains closed and no P2 air gets through to the distribution lines during this period.

The Distribution Controller in the cockpit operates the Distribution Flap, which closes off the supply

completely when the control is in its aft position. In the intermediate position the air is distributed to

cockpit and cabin and in the forward position only the cockpit is supplied.

Section 11 Heating & Ventilation Systems

4 of 6

+

Starter

Push-Button

2PP5

P2 Air P2 Air

Double

Check-Valve

T : 45 sec

To Other To Other

Consumers Consumers

48

Regulation Valve

Fan Switch 43

Air Filter

1

1XP1 2

3-PHASE

Pressure Reducing Valve

(Monitors control

P2 air flow rate)

3

40 vent

47

39

Fresh Air Fan

Temp

Control

Needle Valve

Valve

Mixing

‘Closed’

Chamber

vent

Thermostat Opens at 90ºC

Warm Air vent

Distribution Controller

Warm Air

Distribution Flap Key to Figure

1. Regulation Valve

Cockpit Cockpit

Body

OFF

Only & Cabin 2. Return Spring

3 Di h

Figure 3 – Heater Operation

Section 11 Heating & Ventilation Systems

5 of 6

P2 Air Bleed

From Engines

Pressure

Reducing

Solenoid Valve

Valve

Double

Check-Valve

Fan Air

Intake

Mixing Duct

& Thermostat

Fan

Regulator Filter

Valve

Figure 4 – Heater Components

Section 11 Heating & Ventilation Systems

6 of 6

You might also like

- Checklist EC145 PDFDocument276 pagesChecklist EC145 PDFBruno BertozziNo ratings yet

- Maintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)Document59 pagesMaintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)robbertmdNo ratings yet

- Creative Industries MODULE 2Document15 pagesCreative Industries MODULE 2Avin AngelesNo ratings yet

- List of Swiss Aoc HoldersDocument2 pagesList of Swiss Aoc HoldersloicfrevilleNo ratings yet

- Section 13F - Engine Electrical System PDFDocument14 pagesSection 13F - Engine Electrical System PDFrobbertmdNo ratings yet

- Section 13F - Engine Electrical System PDFDocument14 pagesSection 13F - Engine Electrical System PDFrobbertmdNo ratings yet

- Section 13C - Engine Oil System PDFDocument4 pagesSection 13C - Engine Oil System PDFrobbertmdNo ratings yet

- Section 12 - Lighting PDFDocument10 pagesSection 12 - Lighting PDFrobbertmdNo ratings yet

- Section 10 - Ice and Rain PDFDocument14 pagesSection 10 - Ice and Rain PDFrobbertmdNo ratings yet

- Section 9: Pitot Static SystemDocument6 pagesSection 9: Pitot Static SystemrobbertmdNo ratings yet

- Section 4: Airframe Fuel SystemDocument20 pagesSection 4: Airframe Fuel SystemrobbertmdNo ratings yet

- Section 5: Hydraulic SystemsDocument14 pagesSection 5: Hydraulic SystemsrobbertmdNo ratings yet

- Section 17: Audio Voice Alerting Device - AVADDocument4 pagesSection 17: Audio Voice Alerting Device - AVADrobbertmdNo ratings yet

- Section 13H - Engine Malfunctions PDFDocument6 pagesSection 13H - Engine Malfunctions PDFrobbertmdNo ratings yet

- 02a01-28 - T1 - T2 - System Operation IndicatorDocument28 pages02a01-28 - T1 - T2 - System Operation IndicatorFilipeDaumasNo ratings yet

- A109 SP Update 03-2018Document30 pagesA109 SP Update 03-2018Abhishek Kumar SinghNo ratings yet

- 01a-01 - 24 - T1-T2-T4 - First ContactDocument24 pages01a-01 - 24 - T1-T2-T4 - First ContactFilipeDaumasNo ratings yet

- 03a01 24 - T1 StructureDocument24 pages03a01 24 - T1 StructureFilipeDaumasNo ratings yet

- Section 13A - Engine Introduction PDFDocument8 pagesSection 13A - Engine Introduction PDFrobbertmdNo ratings yet

- Section 16: Integrated Health & Usage Monitoring System IhumsDocument6 pagesSection 16: Integrated Health & Usage Monitoring System IhumsrobbertmdNo ratings yet

- A350-A330 ComparaisonDocument191 pagesA350-A330 ComparaisonLOICPHILIPPOTNo ratings yet

- Section 15: Emergency Flotation EquipmentDocument6 pagesSection 15: Emergency Flotation EquipmentrobbertmdNo ratings yet

- 1 Ata 00Document32 pages1 Ata 00Andy Pamelita DiegoNo ratings yet

- Engine Basic ModulesDocument14 pagesEngine Basic ModulesAndy Pamelita DiegoNo ratings yet

- BK117 D2m-HELIONIX-STEP2 FLM EN 2022.11.04 D1Document48 pagesBK117 D2m-HELIONIX-STEP2 FLM EN 2022.11.04 D1Dejan ZlatanovicNo ratings yet

- DDG-1 Issue 1Document6 pagesDDG-1 Issue 1tech.rec.engineerNo ratings yet

- Airbus A318, A319, A320, A321 Aircraft Flight Crew Operating ManualDocument5,446 pagesAirbus A318, A319, A320, A321 Aircraft Flight Crew Operating ManualHamad HamadNo ratings yet

- 14WN Test 2Document7 pages14WN Test 2Ahsan AvioniqueNo ratings yet

- EFB Manual MSFS 2020Document14 pagesEFB Manual MSFS 2020Roberto PepióNo ratings yet

- Search Light WDMDocument52 pagesSearch Light WDMAbdallah MhairatNo ratings yet

- 22 - AutoflightDocument108 pages22 - AutoflightEsang Akan100% (1)

- Bombardier CRJ 00-Environmental Control SystemDocument42 pagesBombardier CRJ 00-Environmental Control SystemVincent GuignotNo ratings yet

- Air Conditionning System: CB - List - 330 200.xls Sheet1Document29 pagesAir Conditionning System: CB - List - 330 200.xls Sheet1Sergio SouzaNo ratings yet

- Section 13E - Engine Fuel System PDFDocument18 pagesSection 13E - Engine Fuel System PDFrobbertmdNo ratings yet

- UNA-OMB-Issue 2 PDFDocument394 pagesUNA-OMB-Issue 2 PDFKola IludiranNo ratings yet

- Bro ATR42MP 2012 PDFDocument16 pagesBro ATR42MP 2012 PDFfranz_zero2No ratings yet

- MMEL LEGACY 450 or 500 - 0008 - R03Document105 pagesMMEL LEGACY 450 or 500 - 0008 - R03Harry NuryantoNo ratings yet

- 5.6 Basic Computer Structure: Basic Maintenance Training Manual Module 5 Digital Technology / EISDocument26 pages5.6 Basic Computer Structure: Basic Maintenance Training Manual Module 5 Digital Technology / EISIvomadnessNo ratings yet

- Service Bulletin: SB MBB-BK117 C-2-67-019Document12 pagesService Bulletin: SB MBB-BK117 C-2-67-019Raymond ZamoraNo ratings yet

- V5585 N229AR WAPL WIHH: This Flight Plan Has Been Calculated With The Latest Winds DataDocument28 pagesV5585 N229AR WAPL WIHH: This Flight Plan Has Been Calculated With The Latest Winds DataFendi Ingin PulangNo ratings yet

- CRJ Mmel Rev.19 13 May 10Document264 pagesCRJ Mmel Rev.19 13 May 10Enrique Gómez EscrihuelaNo ratings yet

- Manual de Operações Erj 190 - 100-200 Farretones 4.0 - 10.5.2019Document100 pagesManual de Operações Erj 190 - 100-200 Farretones 4.0 - 10.5.2019CristianoVelosodeQueirozNo ratings yet

- McDonnell Douglas DC 10 40 Fuel SystemDocument9 pagesMcDonnell Douglas DC 10 40 Fuel SystemEhsan Ul HaqueNo ratings yet

- Weight and Balance Manual MD Yv647tDocument73 pagesWeight and Balance Manual MD Yv647tJesus GutierrezNo ratings yet

- A321 DIFFERENCE GUIDE From A320Document72 pagesA321 DIFFERENCE GUIDE From A320NigelNo ratings yet

- Liebherr A380 Air Management PosterDocument1 pageLiebherr A380 Air Management PosterSathiya SeelanNo ratings yet

- Section 13D - Engine Air System PDFDocument6 pagesSection 13D - Engine Air System PDFrobbertmdNo ratings yet

- Ata 21 Lan-TamDocument520 pagesAta 21 Lan-TamWalter Jair Rodriguez Munoz (LATAM)No ratings yet

- Air Conditioning ATA 21: Student Learning ObjectivesDocument115 pagesAir Conditioning ATA 21: Student Learning ObjectivesBelisario Sergio Llacchas rodasNo ratings yet

- BAE146AVRO 146 RJ Maintenance Training Manual: Engine Starting ATA 80-00Document30 pagesBAE146AVRO 146 RJ Maintenance Training Manual: Engine Starting ATA 80-00Ale Torrico Tamayo100% (1)

- 18 - Vibration and Noise Analysis and AttenuationDocument28 pages18 - Vibration and Noise Analysis and AttenuationEsang Akan100% (1)

- EASA TCDS A.110 Airbus A380Document17 pagesEASA TCDS A.110 Airbus A380kiecard33% (3)

- EC135 B1 R05EN 00 General 06.10.2015.9531Document154 pagesEC135 B1 R05EN 00 General 06.10.2015.9531uncleshera360No ratings yet

- 747 400 61Document4 pages747 400 61almraNo ratings yet

- Dash 8 Q200 Cockpit LayoutDocument13 pagesDash 8 Q200 Cockpit LayoutmohammedredhadjoudiNo ratings yet

- Section 13 - B: Engine Controls & IndicationsDocument6 pagesSection 13 - B: Engine Controls & IndicationsrobbertmdNo ratings yet

- A320fam Iae Ata79 Oil PDFDocument42 pagesA320fam Iae Ata79 Oil PDFshabbirjama103No ratings yet

- P180 Avanti-Ice and Rain ProtectionDocument13 pagesP180 Avanti-Ice and Rain ProtectionravNo ratings yet

- A320 Groundschool Study GuideDocument70 pagesA320 Groundschool Study Guidec727d4ktyNo ratings yet

- Bombardier CRJ 00-Automatic Flight Control SystemDocument32 pagesBombardier CRJ 00-Automatic Flight Control SystemDiego FreireNo ratings yet

- Takeoff Cg/Trim Pos: Before Start ApproachDocument2 pagesTakeoff Cg/Trim Pos: Before Start ApproachCarlos ReyesNo ratings yet

- Aim 2020 1 e PDFDocument494 pagesAim 2020 1 e PDFVikranth DevarajNo ratings yet

- BK117 C-1 Approved Rotorcraft Flight ManualDocument1 pageBK117 C-1 Approved Rotorcraft Flight ManualrobbertmdNo ratings yet

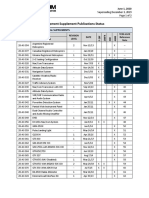

- Enstrom Optional Equipment Supplement Publications Status 6 1 20 PDFDocument2 pagesEnstrom Optional Equipment Supplement Publications Status 6 1 20 PDFrobbertmdNo ratings yet

- 13-08 en PDFDocument148 pages13-08 en PDFrobbertmdNo ratings yet

- Information Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesDocument3 pagesInformation Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesrobbertmdNo ratings yet

- Hs 125 Part 2Document289 pagesHs 125 Part 2Damon Leong100% (1)

- pc-6 Doc 02334r1Document72 pagespc-6 Doc 02334r1robbertmd100% (1)

- Cessna Part 2 PDFDocument263 pagesCessna Part 2 PDFrobbertmdNo ratings yet

- Hs 125 Part 1Document209 pagesHs 125 Part 1Tarmizy MZaki100% (2)

- Maintenance Manual HTCM-006: Part Number 204P2100-101 and - 103Document114 pagesMaintenance Manual HTCM-006: Part Number 204P2100-101 and - 103robbertmd100% (1)

- Maintenance Manual HTCM-002: Helicopter Technology CompanyDocument45 pagesMaintenance Manual HTCM-002: Helicopter Technology CompanyrobbertmdNo ratings yet

- Installation ManualDocument24 pagesInstallation ManualrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 2 LimitationsDocument4 pagesBristow Part B EC155B1 Section 2 LimitationsrobbertmdNo ratings yet

- Component Maintenance Manual, Cargo HookDocument38 pagesComponent Maintenance Manual, Cargo HookrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 4 Normal Procedures PDFDocument28 pagesBristow Part B EC155B1 Section 4 Normal Procedures PDFrobbertmdNo ratings yet

- Section 14 - Autopilot PDFDocument23 pagesSection 14 - Autopilot PDFrobbertmdNo ratings yet

- Section 13D - Engine Air System PDFDocument6 pagesSection 13D - Engine Air System PDFrobbertmdNo ratings yet

- Section 13E - Engine Fuel System PDFDocument18 pagesSection 13E - Engine Fuel System PDFrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 3 Emergency Procedures PDFDocument20 pagesBristow Part B EC155B1 Section 3 Emergency Procedures PDFrobbertmdNo ratings yet

- Section 13C - Engine Oil System PDFDocument4 pagesSection 13C - Engine Oil System PDFrobbertmdNo ratings yet

- Section 13 - B: Engine Controls & IndicationsDocument6 pagesSection 13 - B: Engine Controls & IndicationsrobbertmdNo ratings yet

- Section 15: Emergency Flotation EquipmentDocument6 pagesSection 15: Emergency Flotation EquipmentrobbertmdNo ratings yet

- Section 13G - Engine Fire Protection PDFDocument8 pagesSection 13G - Engine Fire Protection PDFrobbertmdNo ratings yet

- Section 17: Audio Voice Alerting Device - AVADDocument4 pagesSection 17: Audio Voice Alerting Device - AVADrobbertmdNo ratings yet

- Section 7 - Transmission PDFDocument30 pagesSection 7 - Transmission PDFrobbertmdNo ratings yet

- Section 12 - Lighting PDFDocument10 pagesSection 12 - Lighting PDFrobbertmdNo ratings yet

- Section 13H - Engine Malfunctions PDFDocument6 pagesSection 13H - Engine Malfunctions PDFrobbertmdNo ratings yet

- Section 13A - Engine Introduction PDFDocument8 pagesSection 13A - Engine Introduction PDFrobbertmdNo ratings yet

- Section 10 - Ice and Rain PDFDocument14 pagesSection 10 - Ice and Rain PDFrobbertmdNo ratings yet

- b01 - l06 - LX Plot - Aud Canopy - The Twenty-Sided Tavern - 2-25-24Document1 pageb01 - l06 - LX Plot - Aud Canopy - The Twenty-Sided Tavern - 2-25-24Mike WoodNo ratings yet

- Guidebook Hope PDFDocument34 pagesGuidebook Hope PDFDr MukeshNo ratings yet

- Entertainment® Announces Nationwide Restaurant Rebound ProgramDocument3 pagesEntertainment® Announces Nationwide Restaurant Rebound ProgramPR.comNo ratings yet

- WS-C3650-48TQ-L Datasheet: Quick SpecsDocument7 pagesWS-C3650-48TQ-L Datasheet: Quick SpecsTrong Oganort GampoulaNo ratings yet

- Tragedy of FiresDocument11 pagesTragedy of FiresPonciano Jr SabalzaNo ratings yet

- Mehran University 2023 Round 1 PapersDocument30 pagesMehran University 2023 Round 1 PapersHassaan AminNo ratings yet

- DS Series IndicatorDocument2 pagesDS Series IndicatorShreyasi SinhaNo ratings yet

- Apache Commons CLI TutorialDocument12 pagesApache Commons CLI TutorialAravind RadhakrishnanNo ratings yet

- Shortening Estimate of Post Tensioned Floors TN458Document16 pagesShortening Estimate of Post Tensioned Floors TN458Anonymous x9STa9No ratings yet

- BMW Brand AwarenessDocument2 pagesBMW Brand AwarenessrakeshNo ratings yet

- Geotechnical Engineering - Civil - 3RD Sem Regular & Back Exam-2018-19Document2 pagesGeotechnical Engineering - Civil - 3RD Sem Regular & Back Exam-2018-19AkashNo ratings yet

- Lease Approval WorkflowDocument46 pagesLease Approval WorkflowadnanakdrNo ratings yet

- Altimeter SumDocument21 pagesAltimeter Sumsamuelkasoka641No ratings yet

- Summative - 1Document4 pagesSummative - 1David Gideon CabigundaNo ratings yet

- Module19 - Event Tree AnalysisDocument20 pagesModule19 - Event Tree AnalysisMinh ThưNo ratings yet

- 3D MRI Brain Tumor Segmentation Using Autoencoder RegularizationDocument10 pages3D MRI Brain Tumor Segmentation Using Autoencoder RegularizationyogaNo ratings yet

- Course Instructors: Dr. Victor T. Odumuyiwa Dr. Ufuoma C. Ogude Department of Computer Sciences University of LagosDocument22 pagesCourse Instructors: Dr. Victor T. Odumuyiwa Dr. Ufuoma C. Ogude Department of Computer Sciences University of LagosOriola KolawoleNo ratings yet

- Telecom Service Provider RFQDocument4 pagesTelecom Service Provider RFQKatia HasanNo ratings yet

- Pramac Generator Ipl S SeriesDocument66 pagesPramac Generator Ipl S SeriesEduardo de SouzaNo ratings yet

- Application AdminDocument136 pagesApplication Adminxianlei yangNo ratings yet

- Reflective MemoDocument2 pagesReflective Memoapi-583276084No ratings yet

- Contributed Extensive Knowledge On Designing "Freeform SQL Reporting"Document6 pagesContributed Extensive Knowledge On Designing "Freeform SQL Reporting"balaji koppisettiNo ratings yet

- 3HREC AssignmentDocument13 pages3HREC AssignmentEmilyNo ratings yet

- Salesforce1 AppGuide and GalleryDocument40 pagesSalesforce1 AppGuide and GalleryMichelle GonzalezNo ratings yet

- Ict Css12 q4 Las3 Week-5-6Document8 pagesIct Css12 q4 Las3 Week-5-6Edinyn Chavez EscardaNo ratings yet

- Virtual FridgeDocument2 pagesVirtual FridgeKrishnanshu KhilareNo ratings yet

- Acct Statement - XX4077 - 14022023 PDFDocument3 pagesAcct Statement - XX4077 - 14022023 PDFDebashis SurNo ratings yet

- Visualizing Suspended Solids Concentration (SSC) Using Python - by Limzhuan - Towards DevDocument8 pagesVisualizing Suspended Solids Concentration (SSC) Using Python - by Limzhuan - Towards DevPriyadi Dwi SantosoNo ratings yet

- Rear AxleDocument24 pagesRear AxleDmitryNo ratings yet