Professional Documents

Culture Documents

Section 13D - Engine Air System PDF

Section 13D - Engine Air System PDF

Uploaded by

robbertmdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 13D - Engine Air System PDF

Section 13D - Engine Air System PDF

Uploaded by

robbertmdCopyright:

Available Formats

SECTION 13 - D

Engine Air System

Section 13 - D Engine Systems

1 of 6

ENGINE AIR SYSTEMS

Apart from supplying the airflow for combustion, and hence creating power from the engine, there are

internal air circuits required in order to keep the engine operating efficiently.

There are flows for equalising pressures throughout the various components, pressurisation of oil seals,

cooling of internal parts and pressurisation of fuel Start Injector Manifold. Further, some of the control

items in the engine systems require air pressure for operation.

Certain customer services such as the cabin heater use the hot air resulting from compression. Figure 15

gives a general view of the air supply circuits.

P2 Air for Aircraft Systems

• Compressor Bleed Valve Control

• Start Fuel Injector Ventilation

• FCU Acceleration Controller

• Leigh Ice Detector

• Cabin Heater

P1`

Air

Bleed

Valve

P0 Air

P1` Air

Internal Air System

• Pressurisation

• Cooling

• Balance of Forces

Figure 15 – Air Supply Circuits

There are three air pressures in the engine. They are known as –

P0 – Ambient Air Pressure

P1` – Axial Compressor Pressure

Used for bearing pressurisation, cooling and maintaining required balance of forces within the engine.

P2 – Centrifugal Compressor Pressure

Used to control the compressor bleed valve, to ventilate the fuel start injector manifold, for cooling of hot

parts, supply control pressure for the FCU acceleration system, supply cabin heater and the Leigh ice

detector.

Section 13 - D Engine Systems

2 of 6

COMPRESSOR BLEED VALVE

Engine Stall Margin

Refer to Figure 16. This graph shows the various operating lines of the engine. The ‘surge line’ is shown

in red and the engine ‘operating line’ with no bleed valve operation is shown in magenta.

It can be seen that at low compression ratios the magenta ‘operating line’ is close to the red ‘surge line’

with the obvious problem of engine surge.

In order to keep the engine from surging at low power, a bleed valve is fitted to leak air from the front of

the centrifugal compressor. There are two operating lines and these are shown in two green lines on the

graph. The solid green line is the operating line with no ‘off-set’ and the broken green line is the operating

line with the ‘off-set’ selected.

Compression

Ratio

P0 to P2

Operating Line - Bleed Closed

Operating Line - Bleed Open but not Offset

Engine Surge Line

95% Ng

Bleed Offset

85% Ng

Operating Line with Bleed Valves Offset

Air Flow

Figure 16 – Engine Stall Margin

The bleed valve is fitted to the engine to provide an air leak between the axial compressor and the

centrifugal compressor and prevents surging of the axial compressor. This may occur at low Ng (below

85% Ng). This surging is caused by the air slowing down at the centrifugal compressor inlet by cramming

effect. At low Ng the axial compressor output is greater than the centrifugal compressor.

At Ng above 85% when hovering IGE with a strong tailwind the exhaust gases deflected to the engine

intake may be recycled in the engine resulting in a partial stall of the axial compressor.

To remedy this surge problem the bleed valve allows P1` air to escape to atmosphere at the lower

operating range of the engine. The valve is operated by a spring and P2 air and is open until the Ng is

approximately 85% (28,200 RPM). It is then closed.

In a downwind hovering situation there is a tendency for hot exhaust gases to re-circulate into the engine

intakes. This has the effect of reducing the mass flow (less dense air) and can lead to surging. In order

to overcome this problem the bleed value can be opened by means of a button on each collective lever.

This will delay the closing of the bleed valve until 95% Ng (31,500 RPM). This is known as ‘off-set’

selection.

Note - Downwind hovering with bleed valve in normal position is prohibited.

The bleed valves are always off-set for take-off and landing.

Section 13 - D Engine Systems

3 of 6

Cockpit indications

BLEED

OFFSET

34∝ Panel - White BLEED light will illuminate whilst bleed valve is open.

Green OFFSET light when ‘off-set’ selected.

Control is by a push-button on each Collective. Push and release for ‘off-set’. Push and release again for

‘normal’

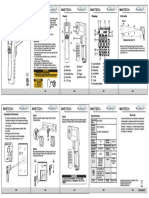

P2 Air Supply For

Normal Valve Operations

P1’ Air Outlet

P2 Air

P2 Offset

Ventilating

Valve

Electrical Connection

P2 Air

For Offset Operations

P0 Air

Compressor Bleed Valve Offset Threshold Solenoid

Figure 17 – Compressor Bleed Valve

Section 13 - D Engine Systems

4 of 6

Bleed Valve Operation

Refer to Figure 18. The system is shown with the bleed valve open and ‘off-set’.

The bleed valve is controlled by the ‘pressure detector’, which compares pressure values P0 and P2.

One of the ‘off-set’ buttons has been operated and the solenoid valve has been energised open.

At low Ng values the bleed valve is open under the action of a return spring the setting of which is higher

than the opposing P2 pressure which is reduced by the leakage created by the ‘normal venting valve’.

When the bleed is open the white BLEED light is illuminated.

When the Values of P2 and P0 correspond to the closing threshold (85% Ng when not ‘off-set’) the

normal venting valve closes and stops the leakage of P2 air.

If in the diagram, the bleed valves were not selected to ‘off-set’, the P2 pressure would now increase in

the bleed valve and close it. The white BLEED light would now go out.

With the bleed valve off-set, the normal venting valve will close at 85% Ng but the solenoid valve is

energised by means of the ‘off-set’ button. This allows the P2 pressure to leak through the ‘off-set venting

valve’. When engine speed reaches 95% Ng, the logic relay opens, the solenoid valve is de-energised

and the ‘off-set venting valve’ is closed thus allowing pressure to build and close the bleed valve.

Whenever the bleed ‘off-set’ is selected, the green OFFSET light will illuminate.

1PP6 2PP6

Collective

OFF-SET Bleed OFF-SET Button

Buttons

‘ON’

Solenoid

Valve

Energised Off-set

‘Open’ Venting

Valve

Opens When

NG > 95% P0

Normal

Logic Circuit Venting

Bleed

Valve P0 P2

Valve

+ BLEED Pressure

Detector

Micro

OFFSET

Switch

34 Alpha Panel

Indicator Light P2 Pressure

P1

P0 Pressure

Figure 18 – Compressor Bleed Valve Operation

Section 13 - D Engine Systems

5 of 6

INTENTIONALLY BLANK

Section 13 - D Engine Systems

6 of 6

You might also like

- B737-Pneumatic Systems SummaryDocument5 pagesB737-Pneumatic Systems SummaryEtienne Gerber100% (2)

- Maintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)Document59 pagesMaintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)robbertmdNo ratings yet

- PW 1500G Final ReportDocument35 pagesPW 1500G Final ReportAhsan100% (1)

- Section 13F - Engine Electrical System PDFDocument14 pagesSection 13F - Engine Electrical System PDFrobbertmdNo ratings yet

- CF6-80C2 SB 72-1516 - 1517 CF6-80E1 SB 72-0523 BSI Guide April 12 - 2019Document18 pagesCF6-80C2 SB 72-1516 - 1517 CF6-80E1 SB 72-0523 BSI Guide April 12 - 2019Ale Torrico TamayoNo ratings yet

- CFM56 C PDFDocument1 pageCFM56 C PDFhamidrezachamaniNo ratings yet

- Section 13F - Engine Electrical System PDFDocument14 pagesSection 13F - Engine Electrical System PDFrobbertmdNo ratings yet

- Section 11 - Heating PDFDocument6 pagesSection 11 - Heating PDFrobbertmdNo ratings yet

- Section 13C - Engine Oil System PDFDocument4 pagesSection 13C - Engine Oil System PDFrobbertmdNo ratings yet

- Section 4: Airframe Fuel SystemDocument20 pagesSection 4: Airframe Fuel SystemrobbertmdNo ratings yet

- Powerplant 2 Lesson Week 1-3Document96 pagesPowerplant 2 Lesson Week 1-3RoselleNo ratings yet

- Section 12 - Lighting PDFDocument10 pagesSection 12 - Lighting PDFrobbertmdNo ratings yet

- Section 10 - Ice and Rain PDFDocument14 pagesSection 10 - Ice and Rain PDFrobbertmdNo ratings yet

- Section 3: Electrical SystemsDocument30 pagesSection 3: Electrical SystemsrobbertmdNo ratings yet

- Section 9: Pitot Static SystemDocument6 pagesSection 9: Pitot Static SystemrobbertmdNo ratings yet

- Section 5: Hydraulic SystemsDocument14 pagesSection 5: Hydraulic SystemsrobbertmdNo ratings yet

- Section 13A - Engine Introduction PDFDocument8 pagesSection 13A - Engine Introduction PDFrobbertmdNo ratings yet

- Training Manual: EASA Part-66 75 Level 3Document23 pagesTraining Manual: EASA Part-66 75 Level 3Luis Enrique La Font FrancoNo ratings yet

- Section 15: Emergency Flotation EquipmentDocument6 pagesSection 15: Emergency Flotation EquipmentrobbertmdNo ratings yet

- The CFM56Document4 pagesThe CFM56Okky Pangestoe WibowoNo ratings yet

- 757 RB211 TR Ops TS JobAidDocument22 pages757 RB211 TR Ops TS JobAidprzytul2007No ratings yet

- Olympus 593 MK 610 Engine RedesignDocument13 pagesOlympus 593 MK 610 Engine RedesignIsrael Alejandro Almaguer AcevedoNo ratings yet

- Gas Turbine Engines - US Army Aviation Course AL0993 WWDocument477 pagesGas Turbine Engines - US Army Aviation Course AL0993 WWinthemoney8No ratings yet

- Jo Kones 2007 No. 3 Vol. 14 CzarneckiDocument6 pagesJo Kones 2007 No. 3 Vol. 14 Czarnecki唐波No ratings yet

- Gas Turbine EngineDocument13 pagesGas Turbine EngineMuhammad Muthohari ShahabNo ratings yet

- #4 TV2 - TV3 Turboshaft Engine Journal IJRPR6639Document17 pages#4 TV2 - TV3 Turboshaft Engine Journal IJRPR6639Lijalem GebrehiwetNo ratings yet

- Rotor Track BalanceDocument7 pagesRotor Track BalanceEric BechhoeferNo ratings yet

- CF34Document55 pagesCF34Debora VitoriaNo ratings yet

- Borescope Training For The WebDocument1 pageBorescope Training For The WebJose RattiaNo ratings yet

- Section 13H - Engine Malfunctions PDFDocument6 pagesSection 13H - Engine Malfunctions PDFrobbertmdNo ratings yet

- Section 16: Integrated Health & Usage Monitoring System IhumsDocument6 pagesSection 16: Integrated Health & Usage Monitoring System IhumsrobbertmdNo ratings yet

- Aero Engine Services: Pt. Nusantara Turbin Dan PropulsiDocument17 pagesAero Engine Services: Pt. Nusantara Turbin Dan PropulsiMeingkarNo ratings yet

- 71-00-00-710-009-B - Vibration Check PDFDocument3 pages71-00-00-710-009-B - Vibration Check PDFEder Luciano100% (1)

- JT8D Fuel SystemDocument8 pagesJT8D Fuel SystemTrifi AJe JaenuriNo ratings yet

- Ata 71 - B1 - Iae V2500Document61 pagesAta 71 - B1 - Iae V2500Abil Gilang -No ratings yet

- 70 Power Plant CFM 56Document152 pages70 Power Plant CFM 56juan carlos balderas silvaNo ratings yet

- Opale 3: Auxiliary Power UnitDocument2 pagesOpale 3: Auxiliary Power UnitpuhumightNo ratings yet

- Overhaul Manual For TSIO-520 SeriesDocument434 pagesOverhaul Manual For TSIO-520 SeriesGregory BurnettNo ratings yet

- Section 17: Audio Voice Alerting Device - AVADDocument4 pagesSection 17: Audio Voice Alerting Device - AVADrobbertmdNo ratings yet

- CFM Flight Ops Support A320Document143 pagesCFM Flight Ops Support A320Marcin100% (1)

- CFM56 5B Esm Rev 72-32-20-200-001-PGK08-001-0 TSN.78 R 20220315Document5 pagesCFM56 5B Esm Rev 72-32-20-200-001-PGK08-001-0 TSN.78 R 20220315Mochsella Bramantio -No ratings yet

- CFM 56-3 Specific Operating InstructionsDocument7 pagesCFM 56-3 Specific Operating InstructionsHubert LindenthalerNo ratings yet

- On The GroundDocument3 pagesOn The Groundroyalairmaroc737No ratings yet

- Tipe Certificate CF700Document4 pagesTipe Certificate CF700Steph Amezquita Benhumea100% (1)

- Rolls-Royce Turbomeca RTM322 - WikipediaDocument21 pagesRolls-Royce Turbomeca RTM322 - WikipediacristianNo ratings yet

- Eec - Pcu - FadecDocument9 pagesEec - Pcu - FadecWilliam XavierNo ratings yet

- CH 01 Propul ThermoDocument16 pagesCH 01 Propul ThermoWilliams LabeNo ratings yet

- ATA 71 PW1100 - Rev. 0 (16-12-19)Document26 pagesATA 71 PW1100 - Rev. 0 (16-12-19)JOSE SANDOVALNo ratings yet

- 002 Turbine Engine Starting System1Document30 pages002 Turbine Engine Starting System1Aishah HanisNo ratings yet

- Engine Inspection QuestionsDocument8 pagesEngine Inspection QuestionsjhonyNo ratings yet

- 623-20 - Intake CowlDocument4 pages623-20 - Intake CowlSeongwoon KimNo ratings yet

- Pw11000-Jm: Line and BaseDocument14 pagesPw11000-Jm: Line and BaseGenaro RodriguezNo ratings yet

- PowerplantDocument14 pagesPowerplantOSCARDELTA100% (2)

- CF6-80C2 72-1278 BSI Instructions Photo GuideDocument21 pagesCF6-80C2 72-1278 BSI Instructions Photo GuideAle Torrico TamayoNo ratings yet

- CA1550Manual Cargador Bateria PDFDocument41 pagesCA1550Manual Cargador Bateria PDFmonoramirexNo ratings yet

- Task Card JT8D (Install Fan Blade)Document3 pagesTask Card JT8D (Install Fan Blade)Raden BurhanNo ratings yet

- @airbus: Issue: Sep 30/85 1 Rev: Dec 01/23Document427 pages@airbus: Issue: Sep 30/85 1 Rev: Dec 01/23JanToreHafell100% (1)

- Understanding The 914 RotaxDocument15 pagesUnderstanding The 914 Rotaxpride3351No ratings yet

- v16 - GE-1015 Jane's Aero Engine March 2000Document11 pagesv16 - GE-1015 Jane's Aero Engine March 2000Marcelo Roberti Rocha FantaguzziNo ratings yet

- Unit 3 Fuel SystemDocument58 pagesUnit 3 Fuel SystemuthiraNo ratings yet

- 02 Cooling SystemDocument17 pages02 Cooling Systemheri setyonoNo ratings yet

- 90 20 1Document4 pages90 20 1Kumar sssssNo ratings yet

- Enstrom Optional Equipment Supplement Publications Status 6 1 20 PDFDocument2 pagesEnstrom Optional Equipment Supplement Publications Status 6 1 20 PDFrobbertmdNo ratings yet

- Maintenance Manual HTCM-002: Helicopter Technology CompanyDocument45 pagesMaintenance Manual HTCM-002: Helicopter Technology CompanyrobbertmdNo ratings yet

- BK117 C-1 Approved Rotorcraft Flight ManualDocument1 pageBK117 C-1 Approved Rotorcraft Flight Manualrobbertmd0% (1)

- Information Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesDocument3 pagesInformation Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesrobbertmdNo ratings yet

- pc-6 Doc 02334r1Document72 pagespc-6 Doc 02334r1robbertmd100% (1)

- Hs 125 Part 2Document289 pagesHs 125 Part 2Damon Leong100% (1)

- Cessna Part 2 PDFDocument263 pagesCessna Part 2 PDFrobbertmdNo ratings yet

- 13-08 en PDFDocument148 pages13-08 en PDFrobbertmdNo ratings yet

- Hs 125 Part 1Document209 pagesHs 125 Part 1Tarmizy MZaki100% (2)

- Component Maintenance Manual, Cargo HookDocument38 pagesComponent Maintenance Manual, Cargo HookrobbertmdNo ratings yet

- Maintenance Manual HTCM-006: Part Number 204P2100-101 and - 103Document114 pagesMaintenance Manual HTCM-006: Part Number 204P2100-101 and - 103robbertmd100% (1)

- Bristow Part B EC155B1 Section 3 Emergency Procedures PDFDocument20 pagesBristow Part B EC155B1 Section 3 Emergency Procedures PDFrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 4 Normal Procedures PDFDocument28 pagesBristow Part B EC155B1 Section 4 Normal Procedures PDFrobbertmdNo ratings yet

- Installation ManualDocument24 pagesInstallation ManualrobbertmdNo ratings yet

- Section 13C - Engine Oil System PDFDocument4 pagesSection 13C - Engine Oil System PDFrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 2 LimitationsDocument4 pagesBristow Part B EC155B1 Section 2 LimitationsrobbertmdNo ratings yet

- Section 13 - B: Engine Controls & IndicationsDocument6 pagesSection 13 - B: Engine Controls & IndicationsrobbertmdNo ratings yet

- Section 15: Emergency Flotation EquipmentDocument6 pagesSection 15: Emergency Flotation EquipmentrobbertmdNo ratings yet

- Section 14 - Autopilot PDFDocument23 pagesSection 14 - Autopilot PDFrobbertmdNo ratings yet

- Section 17: Audio Voice Alerting Device - AVADDocument4 pagesSection 17: Audio Voice Alerting Device - AVADrobbertmdNo ratings yet

- Section 13E - Engine Fuel System PDFDocument18 pagesSection 13E - Engine Fuel System PDFrobbertmdNo ratings yet

- Section 7 - Transmission PDFDocument30 pagesSection 7 - Transmission PDFrobbertmdNo ratings yet

- Section 13H - Engine Malfunctions PDFDocument6 pagesSection 13H - Engine Malfunctions PDFrobbertmdNo ratings yet

- Section 10 - Ice and Rain PDFDocument14 pagesSection 10 - Ice and Rain PDFrobbertmdNo ratings yet

- Section 13G - Engine Fire Protection PDFDocument8 pagesSection 13G - Engine Fire Protection PDFrobbertmdNo ratings yet

- Section 11 - Heating PDFDocument6 pagesSection 11 - Heating PDFrobbertmdNo ratings yet

- Section 13A - Engine Introduction PDFDocument8 pagesSection 13A - Engine Introduction PDFrobbertmdNo ratings yet

- Section 12 - Lighting PDFDocument10 pagesSection 12 - Lighting PDFrobbertmdNo ratings yet

- Manual COC-200 ING PDFDocument2 pagesManual COC-200 ING PDFMichele PriceNo ratings yet

- Installation Manual Small TGAESDocument2 pagesInstallation Manual Small TGAESSaurabhNo ratings yet

- Lead Acid Batteries Installation Operating Maintenance Instructions - Method Statement HQDocument6 pagesLead Acid Batteries Installation Operating Maintenance Instructions - Method Statement HQUsman AliNo ratings yet

- Isuzu Engine-6UZ1X CatalogDocument4 pagesIsuzu Engine-6UZ1X Catalogmadhi vijayNo ratings yet

- Week 7-9Document28 pagesWeek 7-9Sohaib IrfanNo ratings yet

- Aurora - Yarn MercerizingDocument4 pagesAurora - Yarn Mercerizinglieven.verraest6369No ratings yet

- Short-Circuit Current Calculation Application For A.C 3 Phase On Marine and Mobile O Ffshore Installations Based On IEC-61363 StandardDocument8 pagesShort-Circuit Current Calculation Application For A.C 3 Phase On Marine and Mobile O Ffshore Installations Based On IEC-61363 StandardrenegadeNo ratings yet

- Häkan+Rörvall +harmonic+filtersDocument43 pagesHäkan+Rörvall +harmonic+filtersrezaNo ratings yet

- Bower Ps Wind RaDocument37 pagesBower Ps Wind RaMahmoud A. SalemNo ratings yet

- Multi Effect EvaporatorsDocument38 pagesMulti Effect EvaporatorsTajuddin ShaikNo ratings yet

- Jet Fuel ProductionDocument101 pagesJet Fuel Productionshezistic pRoNo ratings yet

- Hes 1250 2015Document74 pagesHes 1250 2015SAUL OSPINONo ratings yet

- Design Sine Wave InverterDocument11 pagesDesign Sine Wave InverterAli MontielNo ratings yet

- Physics ProblemsDocument9 pagesPhysics ProblemsimpacttutorialsNo ratings yet

- Elna (Radial Thru-Hole) RLB SeriesDocument1 pageElna (Radial Thru-Hole) RLB Seriesjghjkhgkh87No ratings yet

- S4030 600F111001FVDocument290 pagesS4030 600F111001FVШибко ЯрикNo ratings yet

- Policy Brief: Towards 100% Renewable Energy by 2050 For Uganda (February 2023)Document4 pagesPolicy Brief: Towards 100% Renewable Energy by 2050 For Uganda (February 2023)Kimbowa RichardNo ratings yet

- QW 5110Document9 pagesQW 5110AminNo ratings yet

- Presentation 1Document1 pagePresentation 1api-281739453No ratings yet

- Rotating Machinery Rotor BalancingDocument15 pagesRotating Machinery Rotor BalancingGunjanNo ratings yet

- Hi Crush FB Silo To Blender Conveyor TechSheetDocument2 pagesHi Crush FB Silo To Blender Conveyor TechSheetsmithyry2014No ratings yet

- EI TR Performance StandardDocument44 pagesEI TR Performance StandardgiampieroNo ratings yet

- Distribution Relays Brochure - FULLDocument68 pagesDistribution Relays Brochure - FULLRaghbendra JhaNo ratings yet

- Parts Manual: 324D & 324D L ExcavatorsDocument1,073 pagesParts Manual: 324D & 324D L ExcavatorsRicky Vil100% (2)

- 440 V AC Class: CapacitorsDocument2 pages440 V AC Class: CapacitorsIgor PNo ratings yet

- Mastech MS6520B User ManualDocument2 pagesMastech MS6520B User ManualNSKMNo ratings yet

- Physics - Burglar AlarmDocument4 pagesPhysics - Burglar AlarmduderamNo ratings yet

- Charger and SwapingDocument40 pagesCharger and SwapingvelukpNo ratings yet

- Internal Chute Installation Manual 6 21 18Document25 pagesInternal Chute Installation Manual 6 21 18cgranados14No ratings yet

- Work Plan & Proposal - LC3 Project - M.P. BirlaDocument7 pagesWork Plan & Proposal - LC3 Project - M.P. BirlaKuldeep SinghNo ratings yet