Professional Documents

Culture Documents

7660 PULSA Series: Engineered Products

7660 PULSA Series: Engineered Products

Uploaded by

TaQuangDucOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7660 PULSA Series: Engineered Products

7660 PULSA Series: Engineered Products

Uploaded by

TaQuangDucCopyright:

Available Formats

ENGINEERED PRODUCTS

7660 PULSA Series®

A work horse that can pump over 1700 gph (6435 lph) and up to 3625 psi (250 bar), the

PULSA Series® 7660 was designed to provide years of dependable liquid metering. It features

rugged, heavy duty construction combined with traditional PULSA Series precision. Like every

PULSA Series pump, the 7660 is the result of over 70 years of pump research, development and

testing. Our flat diaphragm or unique HYDRAtube® head design, along with a variety of wet end

materials, offers a diverse range of fluid handling solutions. The PULSA Series 7660 is commonly

used for applications in industries such as chemical processing, petrochemical, oil & gas,

water & wastewater treatment, and power.

It is the value leader in its category.

Applications

corrosion inhibitors, anti-scalants, slurries,

disinfection, pH and odor control

Flow

up to 1734 gph (6563 lph)

Pressure

up to 3625 psi (250 bar)

Temperature

up to 180°F (82°C)

API-675 • CE • ATEX

Hydraulic diaphragm metering delivers more than you expect.

Standard materials of construction Controls HYDRAtube® design

• Wet end: 316LSS, GF-PTFE, PVC • PULSAmatic® - stroke length • The solution for sheer sensitive

• Diaphragm: PTFE NEMA Type 4X & Type 7 and high viscosity fluids

• Pump body: Cast Iron • VFD - motor speed • Straight flow-through path

• Valve ball: 316LSS, Alumina Ceramic Leak detection • Double diaphragm safety

• Valve gaskets: PTFE • PULSAlarm® • Optional slurry valves

Connection types Pressure based • Robust Ductile Iron housing

• NPT IP66 NEMA Type 7/4X • Elastomeric HYDRAtube

• Raised-face Flange Duplex configurations • ChemAlarm® leak detection

PULSA Series® 7660

Flow & Pressure Envelope by Piston Size (inches)

Flow (lph) Flow (lph)

0 50 100 150 200 250 300 350 400 450 500 550 0 1000 2000 3000 4000 5000 6000 7000

4000 275

350 1.5 24

250

3500 0.56

225 300 21

3000

200

2.0 18

Pressure (bar)

Pressure (bar)

Pressure (psi)

Pressure (psi)

250

2500 175

15

150 200

2000 0.75

125 12

2.5

150

1500 100 9

3.0

1.0 75 100 3.25

1000 6

3.5

50 4.0

500 50 4.5

1.25 3

25

0 0 0 0

0 15 30 45 60 75 90 105 120 135 150 0 200 400 600 800 1000 1200 1400 1600 1800

Flow (gph) Flow (gph)

Features & Benefits Specifications

• Full motion stroke length control yields Materials 316LSS, PVC, GF-PTFE Max temp 180°F (82°C)

0-100% linear flow adjustment over a Diaphragm type Flat, Flat LD, Tube Min temp 40°F (4.4°C)

10:1 turndown range Motor power up to 5 hp (4kW) Accuracy ±1%

• Hydraulically balanced diaphragm for long Motor frame NEMA 143T/145T, Standards API-675, CE, ATEX

life and reduced service costs IEC 80B3

• Proven hydraulic management system

assures consistent performance and rapid Dimensions

recovery from system upsets

• Material options for safety, durability and

chemical compatibility

• Sealed drive protects against atmospheric

contamination and assures long service life 18

457.2

• Easy maintenance KOPkit® (Keep on

Pumping kit) saves time and money

Custom Engineering

48 15

• Exotic materials: Alloy C, Alloy 20, Monel, Inches

1219.2 381

DuplexSS, PVDF Millimeters Approximate shipping weight: 600 lb (272 kg)

• Extended temperature ranges The dimensions shown may differ depending on pump configuration.

From -40°F (-40°C) to 700°F (371°C)

Remote heads and jackets For More Information, Contact Your Authorized

Pulsafeeder Engineered Products Representative

• Custom electronic controls

REPRESENTATIVE LOOKUP

• Multiplex configurations

VISIT OUR

• Pneumatic stroke control

• Extended pressures to 5000 psi / 345 bar

• Degassing valve

• Chemical feed systems Pulsafeeder Engineered Products

7660spec_Rev0714

• Application consulting 2883 Brighton Henrietta Town Line Rd.

Rochester, NY 14623

Phone: +1 (585) 292-8000

Spec Pulsafeeder. pulsa@idexcorp.com • pulsa.com

Get more than you expect. Pulsafeeder is an ISO 9001:2008 and 14001:2004 certified company.

© Copyright 2014 Pulsafeeder. All rights reserved.

You might also like

- Lesson01 FT125 Overview SiemensDocument10 pagesLesson01 FT125 Overview SiemensใบบอนสิชลNo ratings yet

- Using The Nomenclatures and Electrical DrawingsDocument26 pagesUsing The Nomenclatures and Electrical DrawingsphongNo ratings yet

- 45Kg Cylinder & Valve Assembly PN.81-100067-002Document4 pages45Kg Cylinder & Valve Assembly PN.81-100067-002max_powerNo ratings yet

- PURGING SYSTEM 2 - DUPONT Disco - Purge - ProcedureDocument6 pagesPURGING SYSTEM 2 - DUPONT Disco - Purge - ProcedureGunawan SasmitoNo ratings yet

- Industrial Safety Supply, Inc.: Francisco A. LopezDocument29 pagesIndustrial Safety Supply, Inc.: Francisco A. Lopezart031125100% (1)

- 200 X 150 CNHA 5 45 - Horizontal Split Case Pump Data SheetDocument5 pages200 X 150 CNHA 5 45 - Horizontal Split Case Pump Data Sheetسمير البسيونىNo ratings yet

- Luftansa Technical Training - APU Training ManualDocument98 pagesLuftansa Technical Training - APU Training ManualRobert100% (2)

- PO Purchase Order in ExcelDocument2 pagesPO Purchase Order in ExcelAziz Khan LodhiNo ratings yet

- 2012 CQT BokDocument12 pages2012 CQT BokRob WillestoneNo ratings yet

- Tecumseh Throttle and Carburetor LinkageDocument2 pagesTecumseh Throttle and Carburetor LinkageAl Brunelle100% (1)

- Odoo HR PDFDocument17 pagesOdoo HR PDFRejoy Radhakrishnan100% (1)

- Coding System of Strain Gauges-AGS-TECH VersionDocument8 pagesCoding System of Strain Gauges-AGS-TECH VersionsergiojgsNo ratings yet

- Installation Instructions Model ZIC-4A: Zone Indicating CardDocument24 pagesInstallation Instructions Model ZIC-4A: Zone Indicating CardMiguel CoronadoNo ratings yet

- VOLK Valves CatalogDocument46 pagesVOLK Valves Catalogkumar.arunk6784100% (1)

- Water Quality AnalyzerDocument1 pageWater Quality AnalyzerVictor BiacoloNo ratings yet

- World Leading Company: 3S Co., LTDDocument24 pagesWorld Leading Company: 3S Co., LTDTaQuangDuc100% (2)

- Tomoe Vlave General - CatalogueDocument555 pagesTomoe Vlave General - Cataloguevitcon87No ratings yet

- DiagramDocument35 pagesDiagramAriciuAdrianNo ratings yet

- KingdaDocument45 pagesKingdaPascual Daga Deudor0% (1)

- 1200034A01 A enDocument206 pages1200034A01 A enAshutosh PendkarNo ratings yet

- ANSI ValvesDocument28 pagesANSI ValvesBenadict JoshuaNo ratings yet

- Armstrong PDFDocument8 pagesArmstrong PDFSanthosh ThekkethottiyilNo ratings yet

- Test Certificate For Multi-Turn Actuators: Setting and Functional TestDocument1 pageTest Certificate For Multi-Turn Actuators: Setting and Functional TestSouvik DaluiNo ratings yet

- Concentration Naoh Vs ConductivityDocument10 pagesConcentration Naoh Vs Conductivitynisasoberi0% (1)

- Frese OPTIMA Design Guide SEP 12 PDFDocument16 pagesFrese OPTIMA Design Guide SEP 12 PDF윤병택No ratings yet

- Siemens Sinamics G120 PM250 Power Module Manual PDFDocument78 pagesSiemens Sinamics G120 PM250 Power Module Manual PDFmiguel1077No ratings yet

- Cylinder Valve Outlets and Connections - RevDocument4 pagesCylinder Valve Outlets and Connections - RevDimas Ali Akbar Hawkin'sNo ratings yet

- ABB Change Over Switches PDFDocument104 pagesABB Change Over Switches PDFmohammad hazbehzadNo ratings yet

- Concept C-Series: Adhesive Melters The EconomicalsDocument4 pagesConcept C-Series: Adhesive Melters The EconomicalsAhmed Awasha100% (1)

- AMETEK Stock ListDocument27 pagesAMETEK Stock Listdido fidoNo ratings yet

- HitecsaDocument28 pagesHitecsaleonelNo ratings yet

- Motor Protection Voltage UnbalanceDocument7 pagesMotor Protection Voltage UnbalancehaamadhNo ratings yet

- GD350A VFD Manual - V1.2 PDFDocument416 pagesGD350A VFD Manual - V1.2 PDFNewton DattaNo ratings yet

- General Catalog: Butterfly Valves Knife Gate Valves Pinch ValvesDocument30 pagesGeneral Catalog: Butterfly Valves Knife Gate Valves Pinch ValvesNikhil JaiswalNo ratings yet

- D758 Minipurge ManualDocument34 pagesD758 Minipurge ManualratheeshkumardNo ratings yet

- Petersenplgpckrcats PDFDocument112 pagesPetersenplgpckrcats PDFEdixon ZambranoNo ratings yet

- Assembly Instructions: Electronic Position Transmitter EWG 01.1 Removal and Fi TtingDocument4 pagesAssembly Instructions: Electronic Position Transmitter EWG 01.1 Removal and Fi TtingyzNo ratings yet

- As 1432-2004 Copper Tubes For Plumbing Gas Fitting and Drainage ApplicationsDocument7 pagesAs 1432-2004 Copper Tubes For Plumbing Gas Fitting and Drainage ApplicationsSAI Global - APACNo ratings yet

- Nissei 1245aDocument1 pageNissei 1245aMantos SihmantoNo ratings yet

- 40GKX Cassette DX OldDocument18 pages40GKX Cassette DX OldinkblueNo ratings yet

- Terasaki Tecs MCB Catalogue - v9 PDFDocument12 pagesTerasaki Tecs MCB Catalogue - v9 PDFshareyhouNo ratings yet

- MasterPact NW25H1Document3 pagesMasterPact NW25H1Phước Thọ NguyễnNo ratings yet

- Solenoid Valves 3/2 5/2 531Document4 pagesSolenoid Valves 3/2 5/2 531luthfie4uNo ratings yet

- Franke Sinfonia Parts Breakdown - 032515Document133 pagesFranke Sinfonia Parts Breakdown - 032515Juan Carlos MunozNo ratings yet

- Level Monitor DATUM SCU500 LOOPDocument20 pagesLevel Monitor DATUM SCU500 LOOPJose Manuel Vazquez ZarcoNo ratings yet

- 1.5 APS Powder Insert: Parts List PL 41001 EN 13Document18 pages1.5 APS Powder Insert: Parts List PL 41001 EN 13Alexandre VecaNo ratings yet

- Norgren Catalouge PDFDocument22 pagesNorgren Catalouge PDFjaydee45No ratings yet

- Catalogue Khớp Nối Mềm Rắc CoDocument2 pagesCatalogue Khớp Nối Mềm Rắc CoVietHienNo ratings yet

- Sri Lanka Valve Standard 1184Document15 pagesSri Lanka Valve Standard 1184Allen VargheseNo ratings yet

- BVH2100es Buses de CampoDocument52 pagesBVH2100es Buses de Campoewis02No ratings yet

- 1-Piece Instrumentation, 40G and 40 Series: Part NoDocument2 pages1-Piece Instrumentation, 40G and 40 Series: Part Nozidanejason8No ratings yet

- Start-Up Sheet For CompressorsDocument1 pageStart-Up Sheet For CompressorsGreg LundyNo ratings yet

- Td005b - Sensor SPM 42000Document1 pageTd005b - Sensor SPM 42000PaulRicharZuritaLaureanoNo ratings yet

- Engineering Packaged Fire Pump SystemDocument7 pagesEngineering Packaged Fire Pump Systemhamdy ibrahimNo ratings yet

- Bom Sp4081ab PDFDocument10 pagesBom Sp4081ab PDFBraulioMosqueraUribeNo ratings yet

- Contactor and StarterDocument106 pagesContactor and StarterththeeNo ratings yet

- Plano Electrico PDFDocument133 pagesPlano Electrico PDFerwincastro79No ratings yet

- (Inches) (MM) : Standard SAE US Wrench/Spanner Size Metric Wrench/Spanner SizeDocument5 pages(Inches) (MM) : Standard SAE US Wrench/Spanner Size Metric Wrench/Spanner SizemusaveerNo ratings yet

- Electr - Connect.diagram Elektroschaltplan: Neutraubling Plant WerkDocument62 pagesElectr - Connect.diagram Elektroschaltplan: Neutraubling Plant WerkNghĩa Man ĐứcNo ratings yet

- Caterpillar XQ1000 Containerized Diesel Generator SetDocument10 pagesCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryNo ratings yet

- pulsa_series_7120_data_sheetDocument2 pagespulsa_series_7120_data_sheetdegrsacNo ratings yet

- Etna UL-FM Datasheet 100-32-750 ENG05Document8 pagesEtna UL-FM Datasheet 100-32-750 ENG05Prach MeanithNo ratings yet

- Threaded Ball Valves s20 fs20 PB en UsDocument2 pagesThreaded Ball Valves s20 fs20 PB en UsismaeljcoorpNo ratings yet

- 2CP EN 60HzDocument10 pages2CP EN 60HzMoutaz IsmailNo ratings yet

- R4E400-AB23-05 EbmpapstDocument9 pagesR4E400-AB23-05 EbmpapstTaQuangDucNo ratings yet

- 18,21. Naidian CatalogueDocument31 pages18,21. Naidian CatalogueTaQuangDucNo ratings yet

- S3 AD 1 55A4B Taik ElectricDocument2 pagesS3 AD 1 55A4B Taik ElectricTaQuangDucNo ratings yet

- 110,121. FRL Unit 2 PC Catalogue STNCDocument5 pages110,121. FRL Unit 2 PC Catalogue STNCTaQuangDucNo ratings yet

- LC1D32M7 SchneiderDocument7 pagesLC1D32M7 SchneiderTaQuangDucNo ratings yet

- World Leading Company: 3S Co., LTDDocument24 pagesWorld Leading Company: 3S Co., LTDTaQuangDuc100% (2)

- LXW5 Series DelixiDocument3 pagesLXW5 Series DelixiTaQuangDucNo ratings yet

- 200W Single Output Switching Power Supply: SeriesDocument3 pages200W Single Output Switching Power Supply: SeriesTaQuangDucNo ratings yet

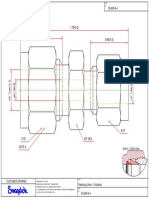

- SS 600 6 4 SwagelokCompany 2DSalesDrawing 04 08 2022Document1 pageSS 600 6 4 SwagelokCompany 2DSalesDrawing 04 08 2022TaQuangDucNo ratings yet

- Hauptkatalog 2017 KAP2 en PDFDocument160 pagesHauptkatalog 2017 KAP2 en PDFTaQuangDucNo ratings yet

- 3SE5 SiemensDocument100 pages3SE5 SiemensTaQuangDucNo ratings yet

- T424TS040XPK AshcroftDocument6 pagesT424TS040XPK AshcroftTaQuangDucNo ratings yet

- CZ3047 CZ3035 CZ3036 ProduktuebersichtDocument1 pageCZ3047 CZ3035 CZ3036 ProduktuebersichtTaQuangDucNo ratings yet

- Micom Agile P841: Grid SolutionsDocument8 pagesMicom Agile P841: Grid SolutionsTaQuangDucNo ratings yet

- Ae963 Load Cell TecsisDocument16 pagesAe963 Load Cell TecsisTaQuangDucNo ratings yet

- OsiSense XS & XT - XSAV11801Document6 pagesOsiSense XS & XT - XSAV11801TaQuangDucNo ratings yet

- TSP121 Abb DS - TSP1X1 - en - F01Document56 pagesTSP121 Abb DS - TSP1X1 - en - F01TaQuangDucNo ratings yet

- Load Pin, Models F5308, F53C8, F53S8 Messachse, Typen F5308, F53C8, F53S8Document64 pagesLoad Pin, Models F5308, F53C8, F53S8 Messachse, Typen F5308, F53C8, F53S8TaQuangDucNo ratings yet

- Ngu N 24VDC Mean Well S-201-24Document3 pagesNgu N 24VDC Mean Well S-201-24TaQuangDucNo ratings yet

- 3RV13414JC10 - Datasheet - enDocument5 pages3RV13414JC10 - Datasheet - enTaQuangDucNo ratings yet

- Ngu N 48VDC Mean Well SP-500-48Document2 pagesNgu N 48VDC Mean Well SP-500-48TaQuangDucNo ratings yet

- Easy9 MCBs - EZ9F34250Document2 pagesEasy9 MCBs - EZ9F34250TaQuangDucNo ratings yet

- Electrical Data: PL320 ApplicationsDocument1 pageElectrical Data: PL320 ApplicationsTaQuangDucNo ratings yet

- Easy9 MCBs - EZ9F34225Document2 pagesEasy9 MCBs - EZ9F34225TaQuangDucNo ratings yet

- Aptomat C65N Multi - 9 - 17951Document2 pagesAptomat C65N Multi - 9 - 17951TaQuangDucNo ratings yet

- Battery Charger PMI Industrial DC Catalogue PDFDocument8 pagesBattery Charger PMI Industrial DC Catalogue PDFTaQuangDucNo ratings yet

- Aptomat C65N Multi - 9 - 17867Document2 pagesAptomat C65N Multi - 9 - 17867TaQuangDucNo ratings yet

- Tele E3ZM20 0900766b80dc73a2Document3 pagesTele E3ZM20 0900766b80dc73a2TaQuangDucNo ratings yet

- Omron MM - Ds - e - 5 - 4 - csm57Document17 pagesOmron MM - Ds - e - 5 - 4 - csm57TaQuangDucNo ratings yet

- IDEC RU - ExtractsDocument7 pagesIDEC RU - ExtractsTaQuangDucNo ratings yet

- Nde Testing Work Requisition Register Flexible Program Management - Ho CONTRACT FOR NDE SERVICE No: SA-9415-0001-TF-SCI-05Document12 pagesNde Testing Work Requisition Register Flexible Program Management - Ho CONTRACT FOR NDE SERVICE No: SA-9415-0001-TF-SCI-05zat572000No ratings yet

- Circulation in A LaundryDocument4 pagesCirculation in A LaundryDyna Wylene GardoniaNo ratings yet

- Tootekataloog EngDocument8 pagesTootekataloog EngGonçalo FerreiraNo ratings yet

- Electrical Documentation: TD10004560 EN 00Document305 pagesElectrical Documentation: TD10004560 EN 00ilham senoymakNo ratings yet

- "Result: ": //#1#: Use MD'S Update Method. Use Data - To - Hash - Tobytearray As Input To MD'S Update MethodDocument2 pages"Result: ": //#1#: Use MD'S Update Method. Use Data - To - Hash - Tobytearray As Input To MD'S Update MethodHugoNo ratings yet

- Perkins 4.41Document2 pagesPerkins 4.41spez88100% (1)

- Garlock PDFDocument8 pagesGarlock PDFnNo ratings yet

- Name Plate Drawing 1200-E-4006: Document TitleDocument2 pagesName Plate Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

- SAP Change Log TablesDocument2 pagesSAP Change Log TablesBoban VasiljevicNo ratings yet

- Assignment 1 A Day in The LifeDocument1 pageAssignment 1 A Day in The LifeJatin SinghNo ratings yet

- Case Study Slum RehabilitationDocument5 pagesCase Study Slum RehabilitationBerisha PearlNo ratings yet

- Hss Tools and AppilcationDocument17 pagesHss Tools and AppilcationMeena SivasubramanianNo ratings yet

- Case Study 1Document12 pagesCase Study 1Mujtaba Ali100% (2)

- Mediciones CEMS - ZZ-025-0802EDocument4 pagesMediciones CEMS - ZZ-025-0802EdcarunchioNo ratings yet

- Detroit DieselDocument8 pagesDetroit DieselAnonymous xFV7bg7QNo ratings yet

- Production Planning Master DataDocument21 pagesProduction Planning Master DataAmir AliNo ratings yet

- IIITA-Allahabad Contact DetailsDocument5 pagesIIITA-Allahabad Contact DetailsbhuvneshNo ratings yet

- Led Lb12e Chassis 32lv5500-TaDocument116 pagesLed Lb12e Chassis 32lv5500-TaJuan Carlos GamarraNo ratings yet

- CyberterrorismDocument12 pagesCyberterrorismkekjNo ratings yet

- Zvldor - Quot 20211013073547Document2 pagesZvldor - Quot 20211013073547ULLAS KRISHNAN J NNo ratings yet

- GCV405-RCII-Chapter 12 - Introduction To Seismic Design - Norms and StandardsDocument3 pagesGCV405-RCII-Chapter 12 - Introduction To Seismic Design - Norms and StandardsOec EngNo ratings yet

- Swift Tutorial PDFDocument23 pagesSwift Tutorial PDFShubham GuptaNo ratings yet

- Collect Stats DBMS JobDocument4 pagesCollect Stats DBMS Jobpat985946No ratings yet

- Opto Electronic Devices Important QuestionsDocument4 pagesOpto Electronic Devices Important QuestionsSathyan Chandran100% (1)

- 7 OrderReshop 18.1 Implementation GuideDocument295 pages7 OrderReshop 18.1 Implementation Guidesubhayan.nittNo ratings yet