Professional Documents

Culture Documents

Hot Work

Hot Work

Uploaded by

jhoniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work

Hot Work

Uploaded by

jhoniCopyright:

Available Formats

Jubail United Petrochemical Company (United) Site Safety Procedures Manual

United Olefins Complex Project

Jubail, Saudi Arabia April, 2001

Page 1 of 5

28. HOT WORK

The Owner may replace this procedure during the pre-commissioning and start-up

phase.

A. SCOPE

This procedure establishes the safe work practices to be used when performing

Hot work in a regulated area on the project. Hot work is to be defined as an open

flame, welding arc, non-explosion proof electrical tools or equipment and any

heat source capable of causing ignition. A properly executed HOT WORK

PERMIT shall be present prior to work.

Within certain areas designated as "OPEN AREAS", a HOT WORK permit will be

issued by the Project Safety Department on a daily basis. The permit will be a blanket

permit addressing all hot work for the defined area. The permit will not address each

individual job specifically, however all hot work will be performed in compliance with

provisions of the permit.

All areas not defined as "OPEN AREAS" will be classified as RESTRICTED. Hot work

performed in restricted areas will be permitted on a task specific basis by the Project

Safety Department or Owner operations personnel. The permit issuer and the

respective supervisor are responsible for inspecting the area the Hot Work is to be

performed.

B. GENERAL

Only employees that have been trained in the safe operations of cutting equipment

may use the equipment. Employees that have successfully completed their craft

certification test applicable to the use of cutting and welding equipment will be deemed

qualified to use cutting equipment. Employees must be familiar with OSHA sections

CFR 1910.254 and 1910.252 (a) (b) and (c).

Operators of equipment should report any equipment defect or safety hazards and

discontinue use of equipment until necessary repairs have been made. Only qualified

personnel shall make repairs.

Areas where welding or burning operation occur must be protected to prevent the

ignition source from generating a fire.

a) Remove any flammable material or liquid from the area. (No aerosol

cans in area)

b) Assign a fire watch.

c) Ensure the fire watch is trained, bear the training color coding on the ID

Badge and that he wears a red reflective vest.

d) Remove or protect combustibles from sparks and slag.

7 June, 2001 GENERAL SITE CONDITIONS AND SAFETY PROCEDURES

28-Hotwork.doc Permits – Hot Work Page 1 of 5

Jubail United Petrochemical Company (United) Site Safety Procedures Manual

United Olefins Complex Project

Jubail, Saudi Arabia April, 2001

Page 2 of 5

e) Contain sparks and slag with welding cloth / fire blanket.

f) Proper barriers or screens must be erected to protect others from the

arc (flash burn).

g) A twenty 10 Kg (20 pound) or larger dry chemical fire extinguisher must

be within 6 meters (20 feet) of any welding, burning or flame work.

h) Keep hoses and leads out of walkways. Inspect all leads, grounds,

clamps, welding machine hoses, gauges, torches and cylinders each

day before use.

i) Avoid breathing fumes. Use exhaust systems, blowers or respirators.

j) No welding or burning is to be done on a closed vessel or tank, or any

vessel or tank that has not been decontaminated. (This includes drums,

barrels, etc.)

k) All hot work equipment must be inspected by a competent inspector and

must bear the current color coded monthly inspection tag to be used.

l) A fire watch will be required when Hot Work is to be performed;

• in all locations where fire may develop;

• where combustible material stored within 11 meters (35 ft.) of Hot

Work;

• combustibles are greater than 11 meters (35 ft.) away but are easily

ignited;

• adjacent to wall or floor openings within a 11 meters (35 ft.) radius of

combustible material; and

• combustible materials are adjacent to the opposite side of metal

partitions, ceilings or roofs.

C. PROTECTIVE CLOTHING

Protective clothing required for welding and burning varies with the size, nature and

location of the work to be performed.

1) Only fire resistant clothing must be worn.

2) All welders shall use flameproof gloves.

3) Clothes should be free from oil and grease

7 June, 2001 GENERAL SITE CONDITIONS AND SAFETY PROCEDURES

28-Hotwork.doc Permits – Hot Work Page 2 of 5

Jubail United Petrochemical Company (United) Site Safety Procedures Manual

United Olefins Complex Project

Jubail, Saudi Arabia April, 2001

Page 3 of 5

4) Flameproof leather (or suitable material) aprons should be considered if long-

term exposure to radiant heat or sparks is anticipated.

C. WELDING (ELECTRIC)

1) All work must have an adequate ground.

2) Welding rods are not to be left in the electrode holder when in use. Used

welding rod stubs are to be put in metal containers.

3) All arcs must be shielded in all construction areas.

4) All machines must be turned off at the end of the shift.

5) An approved welding helmet must be worn. Equipped with no less than a no. 10

filter plate, with safety plate on both sides of the filter plate.

6) Welders must wear a hard hat with the welding helmet.

7) Never perform electric welding from a metal ladder.

8) Welders performing gas shielded arc welding must be familiar with the

American Welding Society Standard A6-1-1966.

D. BURNING (GAS)

1) Before connecting regulators to cylinders, carefully open the cylinder valve a

crack to blow out any foreign particles. After the regulator is connected, stand to

one side of gauge while the cylinder valve is opened. Open the cylinder valve

slowly. Be certain that the second stage of the regulator is closed before

opening the cylinder valve.

2) Open valves on fuel gas cylinders (propane, acetylene, natural gas) a quarter

turn only. Open oxygen cylinder valves completely. The valve wrench must be

kept in place during use.

3) Do not exceed 15 psi on the torch side of the gauge when using acetylene.

4) When lighting a torch, open the fuel gas valve on the torch before opening the

oxygen valve. Use an approved spark lighter.

5) All compressed gas cylinders should be kept in bottle-carts (trolleys) when

transported or in use.

6) All burning rigs must be broken down at the end of the shift, with regulators

removed and protective caps secured.

7) Compressed-gas cylinders must be secured by a chain in a vertical position

while in storage, transit or use.

7 June, 2001 GENERAL SITE CONDITIONS AND SAFETY PROCEDURES

28-Hotwork.doc Permits – Hot Work Page 3 of 5

Jubail United Petrochemical Company (United) Site Safety Procedures Manual

United Olefins Complex Project

Jubail, Saudi Arabia April, 2001

Page 4 of 5

8) Keep oil and grease away from oxygen-regulator hose and fittings. Do not store

wrenches, dies, cutters or other grease-covered tools in the same compartment

with oxygen equipment.

9) Do not use compressed gas to clean your clothing, blow out anchor holes, or

otherwise clean your work area.

10) All hoses, gauges and torches must be inspected regularly.

11) Approved burning goggles must be worn. Use at least No. 4 filter with a safety

lens on both sides of the filter.

12) Never leave a torch in a vessel, tank or other closed container because of the

potential hazard of leakage.

13) Never use oxygen in pneumatic tools to pressurize a container, to blow out

lines, or as a substitute for compressed air or other gases.

14) Place cylinders and hoses where they are not exposed to sparks and slag from

a burning operation.

15) Handle cylinders with care, as follows:

§ Lift to upper levels with approved cages only.

§ Do not strike an arc on cylinders.

§ Do not use cylinders as rollers.

§ Do not lift with slings or by the protective cap.

§ Anti-flashback arrestors shall be installed on the regulator end of the hoses

and a check valve at the torch en of the hoses on all fuel gas and oxygen

cylinders. Some regulators may be designed with an anti-flash arrestor built

into the regulators and may only be used upon approval of the Safety

Department and Owner.

E. RESPIRATORY PROTECTION

Proper ventilation and / or respiratory protection shall provided

whenever there is the potential for the build up of hazardous fumes or

vapors generated from burning, cutting or welding of lead base metals,

exotic metals such as zinc, cadmium, mercury, beryllium or exotic

paints. Hot Work involving exotic metals and or paints to be performed

inside confined space requires the approval of the Project Manager.

7 June, 2001 GENERAL SITE CONDITIONS AND SAFETY PROCEDURES

28-Hotwork.doc Permits – Hot Work Page 4 of 5

Jubail United Petrochemical Company (United) Site Safety Procedures Manual

United Olefins Complex Project

Jubail, Saudi Arabia April, 2001

Page 5 of 5

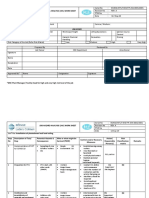

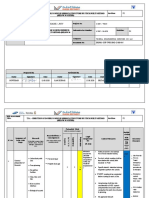

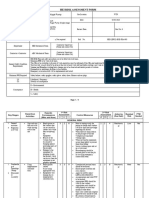

ATTACHMENTS

HOTWORK PERMIT

HOTWORK CHECK LIST

7 June, 2001 GENERAL SITE CONDITIONS AND SAFETY PROCEDURES

28-Hotwork.doc Permits – Hot Work Page 5 of 5

You might also like

- Mineral Oil Safety Regulations 1997Document34 pagesMineral Oil Safety Regulations 1997Otoloko OgheneroNo ratings yet

- Purpose:: Method StatementDocument10 pagesPurpose:: Method StatementIrfan ashrafNo ratings yet

- Iso1295 1Document23 pagesIso1295 1Corina Stanculescu100% (3)

- BMW Motorrad R NineT Urban G - S Owner's ManualDocument163 pagesBMW Motorrad R NineT Urban G - S Owner's ManualramiroNo ratings yet

- Jobs Safety Analysis (JSA)Document4 pagesJobs Safety Analysis (JSA)uttam mishraNo ratings yet

- 675Document2 pages675Rameese MuhammedNo ratings yet

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkip100% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument4 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualjhoni100% (1)

- CPR, AED and First Aid CoursesDocument2 pagesCPR, AED and First Aid CoursesjhoniNo ratings yet

- History of ComputerDocument20 pagesHistory of ComputerSaleh RehmanNo ratings yet

- SAP Shortcut Keys PDFDocument5 pagesSAP Shortcut Keys PDFHarish KumarNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- HOT WORK PERMIT Cutting & Grinding of GRP PipesDocument1 pageHOT WORK PERMIT Cutting & Grinding of GRP Pipesadil khanNo ratings yet

- Assad Ullah Jan: ObjectiveDocument6 pagesAssad Ullah Jan: ObjectiveManda Khel Apna DesNo ratings yet

- Nissar - Permit To Work - JGCDocument32 pagesNissar - Permit To Work - JGCDelta akathehuskyNo ratings yet

- Copy (2) of Jsa For Mechanical Excavation at Brown Field Are Includes WeldingDocument4 pagesCopy (2) of Jsa For Mechanical Excavation at Brown Field Are Includes WeldingViron Baxhia100% (1)

- PMP-TCJV-JSA-023 - 00 Catalyst LoadingDocument4 pagesPMP-TCJV-JSA-023 - 00 Catalyst LoadingHussein Adnan FneishNo ratings yet

- JSA For Blinding and De-Blinding (Opening Process Equipment)Document11 pagesJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- Roof Risk Assessment Template FormDocument10 pagesRoof Risk Assessment Template FormZakaria MtepaNo ratings yet

- Cold Cutting PDFDocument9 pagesCold Cutting PDFAshraf BottaniNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- Materi Hazard - IdentificationDocument61 pagesMateri Hazard - IdentificationRatna CahyaningtyasNo ratings yet

- Tra-Derrick Module Assembly Below 30 MetersDocument37 pagesTra-Derrick Module Assembly Below 30 MetersBenasher IbrahimNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Demolition RISK AssessmentDocument15 pagesDemolition RISK AssessmentAli KaziNo ratings yet

- HIRA - Copper Pipe Brazing WorkDocument2 pagesHIRA - Copper Pipe Brazing Workyogeshraut1910No ratings yet

- JSA For Filter Cleaning by Steam and Water ManuallyDocument22 pagesJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêNo ratings yet

- Hot Work ProcedureDocument6 pagesHot Work ProcedureSCOTTNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- JSA Pile Concrete Works OkDocument9 pagesJSA Pile Concrete Works OkMon Trang NguyễnNo ratings yet

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- Work Permit SystemDocument50 pagesWork Permit SystemBin khammash and sons Co.No ratings yet

- HSE-OS-ST19 Training Slides LiftingDocument46 pagesHSE-OS-ST19 Training Slides LiftingAkif AmjadNo ratings yet

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationBulent AkNo ratings yet

- Lecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionDocument4 pagesLecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionMihajloDjurdjevicNo ratings yet

- 4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseDocument8 pages4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument5 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- SP 1190 4Document35 pagesSP 1190 4shahaludeen ummarNo ratings yet

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- ZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NODocument52 pagesZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NORiaz Ali Khan BangashNo ratings yet

- PTW PresentationDocument15 pagesPTW PresentationSaleem Akhter100% (1)

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- Clearance LetterDocument1 pageClearance LetterMon HuaNo ratings yet

- Master JSA 2052U Blower Removal & Installation Manual LiftingDocument6 pagesMaster JSA 2052U Blower Removal & Installation Manual LiftingOvais FarooqNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Equipment Machinery Safety Checklist-Pdf-EnDocument2 pagesEquipment Machinery Safety Checklist-Pdf-EnOliver Reazon RueloNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- JSA For Cable Joint & Termination WorkDocument2 pagesJSA For Cable Joint & Termination WorkVivek Verma100% (1)

- FCJJ 20 Hydrocar Assembly GuideDocument2 pagesFCJJ 20 Hydrocar Assembly GuideDanna Hernández0% (1)

- Safe Work Practice Dozer OperatorsDocument4 pagesSafe Work Practice Dozer OperatorsMuhammad Ashraf AhmadNo ratings yet

- Hot & Cold Work PermitDocument10 pagesHot & Cold Work PermitSubratNo ratings yet

- TOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEDocument5 pagesTOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEazerNo ratings yet

- 021 - Energy Isolation, Lockout and Tagout ProcedureDocument22 pages021 - Energy Isolation, Lockout and Tagout ProcedureemmyNo ratings yet

- Height Pass FormatDocument1 pageHeight Pass Formatamit kumarNo ratings yet

- Job Hazard Analysis (Drilling)Document2 pagesJob Hazard Analysis (Drilling)jay RNo ratings yet

- Permit To Work Hseprof Com 1691465620Document36 pagesPermit To Work Hseprof Com 1691465620ajidwiyuniarsoNo ratings yet

- JSA - Confined Space EntryDocument5 pagesJSA - Confined Space EntryM Waqas HabibNo ratings yet

- 28 HotworkDocument5 pages28 HotworkMohammed MinhajNo ratings yet

- Hseworking Permit ProcedureDocument14 pagesHseworking Permit ProcedureJatayu PGSNo ratings yet

- Confined Space Awareness: Hazard ControlDocument6 pagesConfined Space Awareness: Hazard ControljhoniNo ratings yet

- Hydrogen Sulfide: Volume XIX No. 1 - 1999Document6 pagesHydrogen Sulfide: Volume XIX No. 1 - 1999jhoniNo ratings yet

- Hoist Safety: Plus: The Safe Choice Safety SecuredDocument6 pagesHoist Safety: Plus: The Safe Choice Safety SecuredjhoniNo ratings yet

- Personal Protective Equipment: Safety Achievement Awards Protect Your HearingDocument14 pagesPersonal Protective Equipment: Safety Achievement Awards Protect Your HearingjhoniNo ratings yet

- Chapter 5 Electrical Safety: TopicDocument7 pagesChapter 5 Electrical Safety: TopicjhoniNo ratings yet

- Electrical Hazards: Safety Achievement Awards Top 10 Electrical Safety TipsDocument16 pagesElectrical Hazards: Safety Achievement Awards Top 10 Electrical Safety TipsjhoniNo ratings yet

- Chemicals and Gases: Safety Achievement Awards Chemical Household ProductsDocument14 pagesChemicals and Gases: Safety Achievement Awards Chemical Household ProductsjhoniNo ratings yet

- Safety Procedure ManualDocument15 pagesSafety Procedure ManualjhoniNo ratings yet

- Safety Procedure PDFDocument110 pagesSafety Procedure PDFjhoniNo ratings yet

- Safety and Health Manual 2001: Wisdom Solutions, LLC 2941 Winding Circle LILBURN, GA 30047Document136 pagesSafety and Health Manual 2001: Wisdom Solutions, LLC 2941 Winding Circle LILBURN, GA 30047jhoniNo ratings yet

- Safety Manual: 2004revisedDocument120 pagesSafety Manual: 2004revisedjhoniNo ratings yet

- Sir 60Document59 pagesSir 60jhoniNo ratings yet

- Summary - MHFA - March - 08 PDFDocument7 pagesSummary - MHFA - March - 08 PDFjhoniNo ratings yet

- Fluor U&O Project Fall Protection and Working at Heights TrainingDocument68 pagesFluor U&O Project Fall Protection and Working at Heights TrainingjhoniNo ratings yet

- FALL PROTECTION Slipstripsfalls - PpsDocument10 pagesFALL PROTECTION Slipstripsfalls - PpsjhoniNo ratings yet

- 062-02-48 Working at HeightDocument6 pages062-02-48 Working at HeightjhoniNo ratings yet

- Bites and Stings First AidDocument3 pagesBites and Stings First AidjhoniNo ratings yet

- Construction Fall ProtectionDocument43 pagesConstruction Fall ProtectionjhoniNo ratings yet

- Fall Protection PanoramaDocument43 pagesFall Protection Panoramajhoni100% (1)

- Transcript Sniff PDFDocument1 pageTranscript Sniff PDFjhoniNo ratings yet

- SW Updates PDFDocument16 pagesSW Updates PDFjhoniNo ratings yet

- Changing Pattern of Trauma Management With Modern TechnologyDocument4 pagesChanging Pattern of Trauma Management With Modern TechnologyjhoniNo ratings yet

- Fall Protection Answer SheetDocument1 pageFall Protection Answer SheetjhoniNo ratings yet

- Fall Protection Quiz: Name: Date: Employee #: ProjectDocument1 pageFall Protection Quiz: Name: Date: Employee #: ProjectjhoniNo ratings yet

- Wfa ProductDocument14 pagesWfa ProductjhoniNo ratings yet

- Shore Health System: Administrative PolicyDocument3 pagesShore Health System: Administrative PolicyjhoniNo ratings yet

- New Instructor Application: MEDIC FIRST AID International, IncDocument2 pagesNew Instructor Application: MEDIC FIRST AID International, IncjhoniNo ratings yet

- Syllabus Psychological First Aid ALHL-1055Document5 pagesSyllabus Psychological First Aid ALHL-1055jhoniNo ratings yet

- Trouble Shooting Brake Drum Wear by MeritorDocument10 pagesTrouble Shooting Brake Drum Wear by MeritorEdo RonaldoNo ratings yet

- Tibco BW Interview QuestionsDocument8 pagesTibco BW Interview Questionsabu1882No ratings yet

- Fisher Control Valve Sourcebook - Power and Severe ServiceDocument220 pagesFisher Control Valve Sourcebook - Power and Severe Servicemtrj59No ratings yet

- Spectroscopy AssignmentDocument5 pagesSpectroscopy Assignmentsadiewang0812No ratings yet

- NTB02 090bDocument10 pagesNTB02 090bPMNo ratings yet

- 10 Accuracy of Prediction Methods For Sound Transmission LossDocument8 pages10 Accuracy of Prediction Methods For Sound Transmission LossJuan Ambrosio MartinezNo ratings yet

- Smart Universal Signal ConditionerDocument4 pagesSmart Universal Signal ConditionerYudi RambutanNo ratings yet

- Product Selector Guide Storage: DescriptionDocument2 pagesProduct Selector Guide Storage: DescriptionppanagosNo ratings yet

- Earth / Clamp Instruction Manual: Version 1.0, Code No. 20 751 282Document8 pagesEarth / Clamp Instruction Manual: Version 1.0, Code No. 20 751 282Bruno DušićNo ratings yet

- M-GE-M-01A How To Reshim The Kiln Tyre - Nov2009Document9 pagesM-GE-M-01A How To Reshim The Kiln Tyre - Nov2009haziqNo ratings yet

- Nobles+Forklift+Jib Care+in+UseDocument5 pagesNobles+Forklift+Jib Care+in+UsePablo Valenzuela ArredondoNo ratings yet

- OMet 1Document1 pageOMet 1Jeuz Llorenz C. ApitaNo ratings yet

- 12-Exhibit 8 - Subcontractors and Vendors - Offshore Integrated Works - Rev GleDocument6 pages12-Exhibit 8 - Subcontractors and Vendors - Offshore Integrated Works - Rev GleIdara OkopidoNo ratings yet

- Lect 5 Reduction of Multiple Subsystems1Document53 pagesLect 5 Reduction of Multiple Subsystems1SśēmǾǿ ŔämáďañNo ratings yet

- Pip Stc01018Document49 pagesPip Stc01018Jose Luis Velasco CadavidNo ratings yet

- MX 5050Document154 pagesMX 5050Vindaloo EstudiosNo ratings yet

- Volca Keys Owner's ManualDocument2 pagesVolca Keys Owner's ManualJimmyPimmyNo ratings yet

- JK Transmission Cat.Document20 pagesJK Transmission Cat.Alexander López VillavicencioNo ratings yet

- VNPX 507sgd-31gc-Gcs - Operator's Manual - 2015Document50 pagesVNPX 507sgd-31gc-Gcs - Operator's Manual - 2015Centrifugal Separator100% (1)

- Nasa - Fully-Coupled Fluid-Structure Vibration Analysis Using NastranDocument84 pagesNasa - Fully-Coupled Fluid-Structure Vibration Analysis Using NastranMinseong KimNo ratings yet

- Questions & Answers For CCC ExamDocument5 pagesQuestions & Answers For CCC ExamDeshbhandhuSenguptaNo ratings yet

- Blower - TrundeanDocument5 pagesBlower - Trundeanwaterlink.faysalNo ratings yet

- RICSCPDEvent Presentation May 2010 Joe MC Caffrey CEMDocument23 pagesRICSCPDEvent Presentation May 2010 Joe MC Caffrey CEMAbu MuhammadNo ratings yet

- ABAP For HANA ABAP Managed Database Procedure Overview 1-2 Sep 2015Document25 pagesABAP For HANA ABAP Managed Database Procedure Overview 1-2 Sep 2015vshlkwatraNo ratings yet

- LEGO 8295 Telescopic Handler Set Parts InventoryDocument12 pagesLEGO 8295 Telescopic Handler Set Parts InventoryrlobetNo ratings yet

- Check Swing Cast Steel A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesCheck Swing Cast Steel A216 WCB Class 150: Pressure Temperature Ratingsbreyca4 bcrNo ratings yet