Professional Documents

Culture Documents

Information Paper On Long-Term Durability of Soil Nail (2012)

Information Paper On Long-Term Durability of Soil Nail (2012)

Uploaded by

Leung LiangCopyright:

Available Formats

You might also like

- Chapter 1-8 Worksheet SolutionsDocument38 pagesChapter 1-8 Worksheet SolutionsNancyNguyen1675% (4)

- RILEM TC 178 (2013) - Methods For Obtaining Dust Samples by Means of Grinding Concrete in OrderDocument8 pagesRILEM TC 178 (2013) - Methods For Obtaining Dust Samples by Means of Grinding Concrete in OrderJosé GomesNo ratings yet

- Foundations For The Pan Pacific Hotel On Pinnacled and Cavernous Limestone, 1985, 8th SEAGC, MalaysiaDocument16 pagesFoundations For The Pan Pacific Hotel On Pinnacled and Cavernous Limestone, 1985, 8th SEAGC, MalaysiafreezefreezeNo ratings yet

- 3291 SinDocument109 pages3291 SinbansaldhruvNo ratings yet

- Pressuremeter Test Suggested Exam Answers (CSE512 Advanced Geotechnical Engineering)Document3 pagesPressuremeter Test Suggested Exam Answers (CSE512 Advanced Geotechnical Engineering)kiddhoNo ratings yet

- Analysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyDocument4 pagesAnalysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyJohn STCNo ratings yet

- 2016 - 04 - 01 - IES - The Singapore Engineer (PG 16-22)Document8 pages2016 - 04 - 01 - IES - The Singapore Engineer (PG 16-22)ThaungMyintNo ratings yet

- GuidelineOnStructuralFireEngineering (Part2)Document62 pagesGuidelineOnStructuralFireEngineering (Part2)Leung LiangNo ratings yet

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- A Case Study of Using Metal Scaffold System For Demountable Grandstand: The Opening Ceremony of Hong Kong 2009 East Asian GamesDocument57 pagesA Case Study of Using Metal Scaffold System For Demountable Grandstand: The Opening Ceremony of Hong Kong 2009 East Asian GamesLeung Liang100% (1)

- Guidelines On Crack Repair in Concrete StructureDocument17 pagesGuidelines On Crack Repair in Concrete StructureLeung Liang100% (1)

- Marking Scheme Q4Document2 pagesMarking Scheme Q4dexterbox1No ratings yet

- 2625 Deep Foundations For High Rise Buildings in Hong KongDocument11 pages2625 Deep Foundations For High Rise Buildings in Hong KongJulio MzpNo ratings yet

- 11 Bolted Connections Part 2 - Sem 2 AY 2015 - 16 - IVLEDocument27 pages11 Bolted Connections Part 2 - Sem 2 AY 2015 - 16 - IVLESteven KuaNo ratings yet

- ICGE 15 KN 04 Endicott PDFDocument10 pagesICGE 15 KN 04 Endicott PDFDiego SerónNo ratings yet

- Hkie Paper 2021Document29 pagesHkie Paper 2021Sol TianNo ratings yet

- Ir DR James LAU Chi WangDocument6 pagesIr DR James LAU Chi WangkzoneasdfNo ratings yet

- Information Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Document37 pagesInformation Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Leung LiangNo ratings yet

- 建築物基礎構造設計規範Document260 pages建築物基礎構造設計規範wilson.nottingham6435100% (2)

- HKSMM4 DaaDocument220 pagesHKSMM4 DaaEaston Cheung0% (1)

- dc16 14Document24 pagesdc16 14Subramanian SaravananNo ratings yet

- Technical References For Mortar and AssociatedDocument8 pagesTechnical References For Mortar and AssociatedLolaNo ratings yet

- Deflection of Permanent FormworkDocument4 pagesDeflection of Permanent FormworkBogdanBNo ratings yet

- SCEA6747Document7 pagesSCEA6747Rahul KolateNo ratings yet

- Landslide Risk Reduction Through Works 35 Years of LPM Programme and Beyond, HKIE 2011Document215 pagesLandslide Risk Reduction Through Works 35 Years of LPM Programme and Beyond, HKIE 2011lamyuwangNo ratings yet

- Zaha Hadid, Aaron Betsky - Zaha Hadid - The Complete Buildings and Projects (1998, Thames & Hudson LTD) - Libgen - LiDocument144 pagesZaha Hadid, Aaron Betsky - Zaha Hadid - The Complete Buildings and Projects (1998, Thames & Hudson LTD) - Libgen - LiParsa RangiNo ratings yet

- Company Profile HumeDocument36 pagesCompany Profile HumeYudith Bdoel AbdullahNo ratings yet

- (CQHP) Guidelines For Structural & Architectural + Annex PDFDocument43 pages(CQHP) Guidelines For Structural & Architectural + Annex PDFflashtronNo ratings yet

- Betopan Betopanplus Eng KKDocument48 pagesBetopan Betopanplus Eng KKkashmir_sefNo ratings yet

- Shear Modulus Ohsaki JapaneseDocument13 pagesShear Modulus Ohsaki Japaneseyin hoe ong100% (1)

- Study of Relationship Between Fines Content and Cohesion of SoilDocument11 pagesStudy of Relationship Between Fines Content and Cohesion of SoilorgaNo ratings yet

- SS EN 1992-2 - 2012 - PreviewDocument12 pagesSS EN 1992-2 - 2012 - PreviewHS EngineeringNo ratings yet

- Martina (2002) - Punching Behavior of Biaxial Hollow SlabsDocument6 pagesMartina (2002) - Punching Behavior of Biaxial Hollow SlabsWanderley NicacioNo ratings yet

- Diaphragm Wall - Soletanch BachyDocument4 pagesDiaphragm Wall - Soletanch BachymlakkissNo ratings yet

- Tamboli 2008 TallBuildingsSustainable.a6b917db A870 4417 8b86 6b19c01f604bDocument0 pagesTamboli 2008 TallBuildingsSustainable.a6b917db A870 4417 8b86 6b19c01f604bsmaliscribdNo ratings yet

- NA To Sls en 1991-1-1Document12 pagesNA To Sls en 1991-1-1Shan Sandaruwan AbeywardeneNo ratings yet

- ELS Sample Questions For 2010 HKPU T3 Top Up Course PDFDocument2 pagesELS Sample Questions For 2010 HKPU T3 Top Up Course PDFYu chung yinNo ratings yet

- 1407 1f CTR PDFDocument353 pages1407 1f CTR PDFThaungMyintNo ratings yet

- AECOM Construction-Handbook-2018 19 PDFDocument7 pagesAECOM Construction-Handbook-2018 19 PDFDurgaPrasadKrishnaNo ratings yet

- SupertallDocument53 pagesSupertallMajdoline SadeddineNo ratings yet

- B3 Tendering Rules PN6Document27 pagesB3 Tendering Rules PN6Eduardo CappellinaNo ratings yet

- BirdSafeBuildingGuidelines PDFDocument59 pagesBirdSafeBuildingGuidelines PDFamvitaNo ratings yet

- CP84-Entry Into and Safe Working in Confined SpacesDocument20 pagesCP84-Entry Into and Safe Working in Confined SpacesSim Guobin100% (1)

- 1a PDFDocument116 pages1a PDFgkutNo ratings yet

- Modular Buildings in Modern Construction: SciencedirectDocument6 pagesModular Buildings in Modern Construction: SciencedirectBhagyaraj KoppishettyNo ratings yet

- HyD Technical Circular No. 3-90Document5 pagesHyD Technical Circular No. 3-90Gary LoNo ratings yet

- Concrete Pipes: Scib Concrete Manufacturing SDN BHDDocument4 pagesConcrete Pipes: Scib Concrete Manufacturing SDN BHDSoonHan WaiNo ratings yet

- Geosythetic Reinforced Unpaved RoadDocument10 pagesGeosythetic Reinforced Unpaved RoadPalak ShivhareNo ratings yet

- SUOS2011Document270 pagesSUOS2011Wong ChingNo ratings yet

- Nist Ncstar 1-2b, WTC InvestigationDocument208 pagesNist Ncstar 1-2b, WTC InvestigationDavid PetersNo ratings yet

- GGF - StakloDocument24 pagesGGF - StakloJelena ĆukNo ratings yet

- Case Study On Structure Collapse: Jacklin Mary - J 121901040Document12 pagesCase Study On Structure Collapse: Jacklin Mary - J 121901040Crazy MechonsNo ratings yet

- Innovative Design and Construction of Composite Steel-Concrete StructuresDocument12 pagesInnovative Design and Construction of Composite Steel-Concrete Structuressusan87No ratings yet

- Technical Manual Whole 09 - BRICKDocument150 pagesTechnical Manual Whole 09 - BRICKMuhamad Zaid Md ZinNo ratings yet

- Designers' Guide To Eurocode 1: Actions On BuildingsDocument13 pagesDesigners' Guide To Eurocode 1: Actions On BuildingsVrajesh SodagarNo ratings yet

- 1670 Evaluation Techniques of Damping in BuildingsDocument9 pages1670 Evaluation Techniques of Damping in BuildingsApetsi AmpiahNo ratings yet

- Singapore Standards EShopDocument2 pagesSingapore Standards EShoplimegreens0% (1)

- Lateral Suport Systems FHWADocument326 pagesLateral Suport Systems FHWADiego Alejandro Flores OrtízNo ratings yet

- Fardis EC8-3 Member Models - 0Document75 pagesFardis EC8-3 Member Models - 0Wendirad BeshadaNo ratings yet

- Sanchita Blacka ND WhiteDocument1 pageSanchita Blacka ND WhiteSanchita JhaNo ratings yet

- ASSIGNMENT On Building ComponentsDocument3 pagesASSIGNMENT On Building Componentsoladipo GraceNo ratings yet

- Characteristics of Ground Movements Induced by ExcavationsDocument4 pagesCharacteristics of Ground Movements Induced by ExcavationsNaveen BansalNo ratings yet

- Structural Concept DesignDocument8 pagesStructural Concept DesignaahtagoNo ratings yet

- GEO Report No. 135 Long-Term Durability of Steel Soil NailsDocument66 pagesGEO Report No. 135 Long-Term Durability of Steel Soil NailsHuy Le QuangNo ratings yet

- Estandares Geotecnicos en Hogn KongDocument9 pagesEstandares Geotecnicos en Hogn KongMerlly GarzonNo ratings yet

- Information Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Document37 pagesInformation Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Leung LiangNo ratings yet

- Guidelines On Structural Survey and Appraisal of Historical Buildings Part I - Materials and Structural FormsDocument100 pagesGuidelines On Structural Survey and Appraisal of Historical Buildings Part I - Materials and Structural FormsLeung Liang100% (1)

- Guideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFDocument92 pagesGuideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFLeung LiangNo ratings yet

- Foundation Design and Construction in Cavernous Karst: A Local ExperienceDocument6 pagesFoundation Design and Construction in Cavernous Karst: A Local ExperienceLeung LiangNo ratings yet

- Highlights of The Code of Practice For Fire Safety in Buildings 2011 PDFDocument12 pagesHighlights of The Code of Practice For Fire Safety in Buildings 2011 PDFLeung LiangNo ratings yet

- Landfill After UseDocument10 pagesLandfill After UseLeung LiangNo ratings yet

- Highlights of The Code of Practice For Fire Safety in Buildings 2011Document12 pagesHighlights of The Code of Practice For Fire Safety in Buildings 2011Leung LiangNo ratings yet

- The Application of PDA and CAPWAP To Ensure Quality and Capacity in Driving Long Steel H-PilesDocument6 pagesThe Application of PDA and CAPWAP To Ensure Quality and Capacity in Driving Long Steel H-PilesLeung LiangNo ratings yet

- Determination of Elastic Critical Load Factor For Steel StructuresDocument16 pagesDetermination of Elastic Critical Load Factor For Steel StructuresLeung Liang100% (1)

- Observations On Using The Energy Obtained From Stress-Wave Measurements in The Hiley FormulaDocument4 pagesObservations On Using The Energy Obtained From Stress-Wave Measurements in The Hiley FormulaLeung LiangNo ratings yet

- Housing Policy For The Sandwich ClassDocument23 pagesHousing Policy For The Sandwich ClassLeung LiangNo ratings yet

- Floor Vibration Induced by Human Rhythmic Activities: Design and Post-Construction Validation at Tin Shui Wai Public Library Cum Indoor Recreation CentreDocument10 pagesFloor Vibration Induced by Human Rhythmic Activities: Design and Post-Construction Validation at Tin Shui Wai Public Library Cum Indoor Recreation CentreLeung LiangNo ratings yet

- Guidelines On The Design of Floor For Vibration Due To Walking LoadsDocument39 pagesGuidelines On The Design of Floor For Vibration Due To Walking LoadsLeung LiangNo ratings yet

- Delhi Public School Chemistry Investigatory Project Academic Session: 2019-20Document11 pagesDelhi Public School Chemistry Investigatory Project Academic Session: 2019-20abhishek pandeyNo ratings yet

- Emulgante CO-55 - MSDSDocument4 pagesEmulgante CO-55 - MSDSMohamed HalemNo ratings yet

- International Standard: Second Edition 2018-07Document18 pagesInternational Standard: Second Edition 2018-07HafiziAhmadNo ratings yet

- 7 Stream Gauging-2Document54 pages7 Stream Gauging-2ChampNo ratings yet

- Gravimetric AnalysisDocument56 pagesGravimetric AnalysisvasantiNo ratings yet

- Informes de LaboratorioDocument17 pagesInformes de Laboratoriojessica vanessaNo ratings yet

- Alkohol Absolut FixDocument14 pagesAlkohol Absolut FixSylvina HerdiantiNo ratings yet

- Circular Expansion Cement Curing Kit Instruction Manual: Manual No. 101443617, Revision C Instrument No. 205814Document19 pagesCircular Expansion Cement Curing Kit Instruction Manual: Manual No. 101443617, Revision C Instrument No. 205814Lê CôngNo ratings yet

- Final Aac PDFDocument7 pagesFinal Aac PDFindrajit sodhaNo ratings yet

- New Lahore Science Academy: Q1. Choose The Correct Answer. 1X6 6Document1 pageNew Lahore Science Academy: Q1. Choose The Correct Answer. 1X6 6AmaezaNo ratings yet

- Is 1528 Part 2 2011Document10 pagesIs 1528 Part 2 2011Caspian DattaNo ratings yet

- Chem213LabManual Feb1st 2024Document22 pagesChem213LabManual Feb1st 2024EyNo ratings yet

- Objectives of HydrometallurgyDocument14 pagesObjectives of HydrometallurgyAnubhav ChandilNo ratings yet

- General Chemistry 2Document39 pagesGeneral Chemistry 2Lhor MaceroNo ratings yet

- Multiple Choices Questions: K K K K (CO)Document14 pagesMultiple Choices Questions: K K K K (CO)MutasimNo ratings yet

- Wet CO2 CorrosionDocument14 pagesWet CO2 CorrosionMedina EldesNo ratings yet

- FP5011 P1069 11HL Lintec BlancoDocument2 pagesFP5011 P1069 11HL Lintec BlancoCamilo ObandoNo ratings yet

- The Open Chemical Engineering Journal: Production of Citric Acid From The Fermentation of Pineapple Waste byDocument9 pagesThe Open Chemical Engineering Journal: Production of Citric Acid From The Fermentation of Pineapple Waste byWindy NainggolanNo ratings yet

- Organic ChemistryDocument1 pageOrganic ChemistryGuruKPONo ratings yet

- Anterior Composite Dr. WalaaDocument4 pagesAnterior Composite Dr. Walaabasel alogilyNo ratings yet

- Synthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidDocument6 pagesSynthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidRoberta VasquesNo ratings yet

- 002 Ac Yoke B100-ParkerDocument2 pages002 Ac Yoke B100-ParkerNubia BarreraNo ratings yet

- Li2020 Article WaterSplittingFromElectrodeToGDocument29 pagesLi2020 Article WaterSplittingFromElectrodeToGAbroo KhattakNo ratings yet

- Method Statement: Chilled Water TreatmentDocument10 pagesMethod Statement: Chilled Water TreatmentNIDHILNo ratings yet

- Expt No. 2-CarbohydratesDocument17 pagesExpt No. 2-CarbohydratesNathaniel PulidoNo ratings yet

- Mathematical Modeling of Ethane Cracking PDFDocument14 pagesMathematical Modeling of Ethane Cracking PDFAlfonso BlancoNo ratings yet

- Hartati 2021Document20 pagesHartati 2021Isabella Leite FerrazNo ratings yet

- Smear LayerDocument114 pagesSmear LayerAME DENTAL COLLEGE RAICHUR, KARNATAKANo ratings yet

- Chemistry SheetDocument10 pagesChemistry Sheetbakr ferasNo ratings yet

Information Paper On Long-Term Durability of Soil Nail (2012)

Information Paper On Long-Term Durability of Soil Nail (2012)

Uploaded by

Leung LiangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Information Paper On Long-Term Durability of Soil Nail (2012)

Information Paper On Long-Term Durability of Soil Nail (2012)

Uploaded by

Leung LiangCopyright:

Available Formats

Information Paper

Long-Term Durability of Soil Nail

STRUCTURAL ENGINEERING BRANCH

ARCHITECTURAL SERVICES DEPARTMENT

July 2012

Structural Engineering Branch, ArchSD Page 1 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

1. Introduction

1.1 GEO (2008) issued Geoguide 7: Guide to Soil Nail Design and Construction

(“Geoguide 7”), which specifies the method to assess the degrees of corrosion potential

of soil nails by considering the soil aggressivity in a site. Based on a marking system, a

site can be classified into: non-aggressive, mildly aggressive, aggressive, and highly

aggressive. Geoguide 7 then recommends the appropriate corrosion protection measure

for each type of site.

1.2 The following paragraphs will:

a) review the literature on the background of the assessment method in Geoguide 7;

b) compare it with international practices, especially the method recently included in

EN 14490:2010: Execution of Special Geotechnical Works - Soil Nailing (BSI

2010).

2. Background on Geoguide 7

2.1 Steel soil nails are used extensively for slope improvement works in Hong Kong.

However, corrosion of steel reinforcement reduces the durability of a soil-nailed system.

Geoguide 7 gives the following two steps in choosing the appropriate corrosion

protection measure for the soil nails to suit the soil conditions of each site:

a) classification of soil aggressivity; and

b) choosing the appropriate corrosion protection measure.

2.2 Classification of soil aggressivity

2.2.1 In order to study the long-term durability of soil nails, GEO in the late 1990s and early

2000s reviewed relevant literature on corrosion protection for steel soil nails, and then

tested and/or collected the relevant properties of the Hong Kong soils. Their findings

were summarized in GEO Report No. 135: Long-Term Durability of Steel Soil Nails

(2003) (Shui and Cheung 2003) and Shui and Cheung (2008). The soil aggressivity

assessment scheme was then devised, which had been based on similar methods in

France, the UK and the US. The soil aggressivity is affected by the physical and

chemical characteristics of the soil, and Geoguide 7 lists out eight parameters to be

considered, which include: soil composition; resistivity; moisture content; groundwater

level; pH; soluble sulphate; made ground; and chloride ion content. Each parameter is

then assigned a mark under the soil aggressivity assessment scheme (Table 1), and will

summated to give a total mark for the soil in a site (Table 2).

Structural Engineering Branch, ArchSD Page 2 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 1: Soil Aggressivity Assessment Scheme in Geoguide 7

(Source: Geoguide 7 Table 4.2)

Structural Engineering Branch, ArchSD Page 3 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 2: Classification of Soil Aggressivity in Geoguide 7

(Source: Geoguide 7 Table 4.1)

2.2.2 Soil resistivity

Soil resistivity is a measure of the ability of a soil to conduct a current. The lower the

resistivity of a soil, the better is the soil's electrolytic properties and the higher is the rate

at which the corrosion can proceed. Soil resistivity is related to the soluble salt content,

which form anions and cations in the soil solution. The major dissolved anions in soil

systems are chloride, sulphate, phosphate and bicarbonate, with chloride and sulphate

the most important anionic constituents in corrosion phenomena. The electrolytic

conductivity is thus the sum of all the individual equivalent ionic conductivities times

their concentration. Besides the amount of soluble salts, particular size distribution also

affects the soil resistivity by changing the aeration and moisture content of the soil

(Chaker 1996). Thus, the measured soil resistivity has incorporated the combined effect

of soluble salts content, the particular size, the void ratio, and the moisture content.

A number of methods have been available to measure soil resistivity. BS 1377-3:1990

gives three laboratory methods: disc electrodes test on undisturbed or compacted soil

sample (Test 10.2), Wenner’s four probe electrodes test on undisturbed or disturbed soil

sample (Test 10.3), and open container test (Test 10.4). Instead of using laboratory tests,

in-situ tests are also available, e.g. ASTM G57-06: Standard Test Method for Field

Measurement of Soil Resistivity Using the Wenner Four-Electrode Method.

Although Shui and Cheung (2003) noted that resistivity is an important parameter for

assessing soil aggressivity, the database in GEO did not contain any test results on

resistivity. Hence, they adopted the values of in-situ soil resistivity measured at five

sites in Hong Kong reported in Chan and Chen (1999). Geoguide 7, however, specifies

that the test for soil resistivity shall follow BS 1377-3:1990 Test 10.4, i.e. open

container test on a soil sample in laboratory. BS 1377-3:1990 states that one of the

limitations of such test is that the soil shall consist of “relatively free-draining materials

into which water can percolate easily”, as the test requires the soil sample to be

saturated with water. This requirement implies that the specified method may not be

applicable to clayey soil. Moreover, by applying this test on clayey soil a lower

Structural Engineering Branch, ArchSD Page 4 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

resistivity is expected, and this, coupling with the higher moisture content of such type

of soil, may over-estimate the soil aggressivity.

The procedures of BS 1377-3:1990 Test 10.4 further require the soil sample to be

saturated by pouring water. SGE/NP explained that “[r]esistivity do not stay consist in

field. Therefore, it can be argued that the resistivity should be determined under the

most adverse condition in order to obtain a comparable resistivity that is independent of

seasonal and other variations in soil-moisture content. AASHTO has adopted Method

T-288 for measuring resistivity after review and analysis of a number of available

methodologies. This laboratory test to measure resistivity of a soil at various moisture

contents up to saturation and reports the minimum obtained resistivity” (Elis et al 2009).

SGE/NP further noted that NGG (2004) states that “[t]he resistivity depends on the

water content of the soil. Hence it is recommended that the tests are preformed for the

most severe conditions i.e. the soil is fully saturated. For a field test it is impossible to

choose the conditions but the water content should be accounted for when evaluation

the test. There are a number of different methods to determine the resistivity both in

laboratory and the field.”

It is therefore evident that measuring resistivity under the most adverse condition (i.e.

saturated state) is to obtain a comparable resistivity that is independent of seasonal and

other variations in soil moisture content. This may be understandable if moisture

content and groundwater level were not separately measured and marked. However, in

assessing soil aggressivity, both moisture content and groundwater level are included as

parameters and marked. The corresponding clause in both EN 14490:2010 and EN

1997-2:2007 does not specify the method. However, the National Foreword to EN

1997-2:2007 specifies that the test methods in BS 1377-3:1990 are continued to be

preferred; whilst in the US, the test method is specified to be the in-situ Wenner’s four

probe electrodes test according to ASTM G57-06.

2.2.3 pH

For pH, zinc is vulnerable to corrosion in both strongly acidic and alkaline soils.

Geoguide 7, therefore, considers that the galvanized coating will more easily be

corroded in either acidic or alkaline regimes, although it is well-known that steel is

passivated in alkaline environments (i.e., pH>10).

2.3 Choice of corrosion protection measure

2.3.1 Geoguide 7 classifies the corrosion protection measures used in Hong Kong into the

following three classes:

Structural Engineering Branch, ArchSD Page 5 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

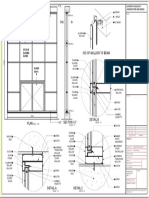

Class 1 - hot-dip galvanising steel nails in corrugated plastic sheathing with in-

filled grout, which are then installed in pre-drilled grout hole

Class 2 - hot-dip galvanising steel nails plus a 2mm sacrificial thickness

allowance in pre-drilled grout hole

Class 3 - hot-dip galvanizing steel nails in pre-drilled grout hole

2.3.2 Once the soil aggressivity has been classified, an appropriate class of corrosion

protection measure (Table 3) can be provided to the soil nails, which are required to

carry transient loads. For a design life exceeding 2 years, Class 1 corrosion protection

measure (i.e. hot-dip galvanizing soil nails in grouted corrugated plastic sheathing with

in-filled grout) is recommended for both highly aggressive and aggressive soil, whilst

Class 2 corrosion protection measure (i.e. hot-dip galvanizing soil nails with a 2mm

sacrificial thickness allowance) can be used for mildly aggressive and non-aggressive

soil. Geoguide 7 further recommends that for potentially aggressive soil where no soil

aggressivity assessment has been carried out, Class 1 corrosion protection measure

should be adopted, irrespective of the actual site condition. Geoguide 7 gives the

following examples for potentially aggressive sites: a site that has the potential of being

affected by the leakage or discharge of fluids from developments, public roads, landfill,

sewage treatment plant, industrial plant, water-carrying services, etc., a site that shows

constant seepage or high groundwater levels, the source of which is uncertain.

Table 3: Recommended Corrosion Protection Measures in Geoguide 7

(Source: Geoguide 7 Table 5.1)

2.3.3 Grout Protection

In Hong Kong, soil nails are mostly installed in pre-drilled grouted holes, and the grout

can prevent corrosion by forming a physical barrier and protecting the steel in an

alkaline environment. Table 3 does not consider the contribution of such grout

Structural Engineering Branch, ArchSD Page 6 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

encapsulation of the soil nails as corrosion protection measure, though in Class 1

corrosion protection measure, the plastic sheathing is filled with grout in order to

protect the nails. Shui and Cheung (2003) noted that the grout is usually assumed to

offer no protection and that the corrosion rate is assumed to be the same as that for the

steel installed directly in the ground, though they noted that this is a rather conservative

approach. The rationale advanced by Shui and Cheung (2003) to support these

conservative assumptions are:

a) the cement grout is subject to tensile stresses when the steel bar is under load, and

micro-cracks will then occur;

b) shrinkage cracks may also form during the setting of the cement grout; and

c) it is very difficult to check the quality of the grout in the ground, e.g. drillhole

collapses.

SGE/NP noted that though international practice does allow the use of grout to provide

corrosion protection, some comes with a qualification. For example, EN 14490:2010

states that “[e]ncapsulation of the steel in grout will reduce the corrosion. If the grout is

evenly distributed along the nail with a thickness of the cover corresponding to the

environment and it can be guaranteed that no cracks larger than 0.1 mm will occur, then

the grout cover itself might be considered as a satisfactory corrosion protection.

However, usually there will be cracks and therefore the grout usually combined with

some type of corrosion protection system.”

In reply to a), our ex-SGE/NP, Dr H Y Wong, once said, “[t]his is a practice adopted in

permanent prestressed anchors”, where the anchors are subjecting to high prestress

tension throughout their whole life span, and he further said, “[a]ny corrosion in the

steel reinforcement will result in a loss in the prestress tension force and hence the

working load of the anchor. On the other hand, soil nails installed in slopes in Hong

Kong are basically unstressed …. unless there is very large slope movement.” This

comment is echoed in NGG (2004), where it is said that “[a] soil nail installed in the

natural slope will be non-tensioned as long as no further movement of the active wedge

of the slope occurs”, i.e. when the FOS of the slope is less than 1.0, active movement of

the slipping surface under service load is expected. Thus, in the majority of cases where

soil nails are installed to upgrade the FOS of slope to the required value of 1.2 or 1.4

from a FOS of not less than 1.0, it is unlikely that the grout in service load will be

subjected to tensile stress and hence cracked.

For shrinkage crack, the steel soil nail itself acts as temperature reinforcement to control

the shrinkage of the cement grout during setting. There may be cases where cracks may

occur due to shrinkage. Such micro-cracks are usually of width less than 0.1mm, and it

has been known (e.g. EN 14490:2010) that they are self-healing. For micro-cracks of

width greater than 0.1mm, it is unlikely that the crack width, similar to other rc

Structural Engineering Branch, ArchSD Page 7 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

structures, will exceed 0.3mm. For fine cracks less than 0.3mm, they will heal

completely under moist conditions. This is called “autogenous healing” (Neville 2002),

and is due to “the hydration of the hitherto unhydrated cement” (Neville 2011). Neville

(2002) noted that opening of cracks exposes the interior of cement paste, including

cement hydrates as well as the hitherto unhydrated remnants of cement powder. As long

as they are exposed to air, no autogenous healing takes place. However, when the air

becomes replaced by water, hydration restarts and calcium hydroxide and calcium

silicate hydrate are formed.

For the quality of grout, Shui and Cheung (2003) quoted a case at a re-development site

on the Hong Kong Island, where the grout cover was found to be only 5mm even

though the drillhole was greater than 100 mm in diameter. However, it should be noted

that the reduction mostly occurs locally, and that soil nails are usually installed at close

spacing, say 1.5m c/c. The risk of such localized areas is therefore averaged out by

other soil nails, and the risk is also within those allowed in the FOS.

3. Comparison with Overseas Studies and Practices

3.1 Before publication of Geoguide 7 (2008), Shui and Cheung (2003, 2008) have surveyed

extensively the literature and overseas experience on this topic. Project officer can

therefore refer to the summary contained in their publication. The following paragraphs

will therefore provide a brief review of their summary together with latest research, and

will then present the provisions on this topic introduced in EN 14490:2010.

3.2 Loss of Thickness of Bare Steel in Soils

3.2.1 The leading authority on the loss of thickness of bare steel (i.e. without any corrosion

protection measure) embedded in soil is Eurocode 3 Part 5: Design of Steel Structures –

Piling (as modified by the UK National Annex), which states that the corrosion rates of

steel piles in soils are affected by the type of soil, the level of the groundwater table, the

presence of oxygen, and the presence of contaminants, and then recommends a

corrosion rate in term of the loss of steel thickness (Table 4(a)) for various design life.

For a design life of 125 years, the losses of thickness of steel piles in aggressive and

non-aggressive soils are respectively 4mm and 2.7mm. This should serve as an upper

bound for corrosion of bare steel embedded in soil, and most bare steel with a 2mm

sacrificial thickness allowance can survive a design life of 120 years, unless embedded

in aggressive or polluted soils.

Structural Engineering Branch, ArchSD Page 8 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 4(a): Loss of Thickness (in mm) due to Corrosion for Piles in Soil

in Eurocode 3

(Source: Eurocode 3 Part 5 Table 4.1 as modified by UK National Annex)

3.2.2 For soil nails, Table 4(b) summarizes the design corrosion rates for bare soil nails with

no surface treatment or grout encapsulation for different soil aggressivity in EN

14490:2010. The values tally with those given in Eurocode 3 Part 5, i.e. most bare

steel soil nails with a 2mm sacrificial thickness allowance can survive a design life of

120 years unless embedded in aggressive or highly aggressive soils.

Table 4(b): Design Corrosion Rates for Bare Steel Soil Nails in EN 14490:2010

Total loss of steel thickness up to

Classification of Soil Aggressivity

100 years (reduction of radius)1

Highly aggressive -

Aggressive -

Slightly aggressive 4.00mm (2.00mm)

Non-aggressive 2.00mm (1.00mm)

Note: 1) The corrosion rate given in EN 14490:2010 is the total reduction of diameter.

(Source: EN 14490:2010 Table B.3)

3.2.3 Limited data are available in Hong Kong. Shui and Cheung (2008) measured two

19mm sacrificial bare soil nails installed in 50mm grouted holes in aggressive soil in

Tai Po, and found that there had been a maximum pitting depth of corrosion of 3mm

after nine years of embedment (Photo 1). They then averaged the result to give a

localized corrosion rate to give about 0.3mm/year, which is much higher than that given

in either Eurocode 3 Part 5 or EN 14490:2010. They also measured a number of

32mm hot-dip galvanized soil nails installed in 100mm grouted holes in aggressive

soil in Ho Man Tin, and found that a maximum pitting depth of corrosion of 0.085mm

after ten years of embedment. They again averaged the result to give a localized

Structural Engineering Branch, ArchSD Page 9 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

corrosion rate of 0.0085mm/year. However, it should be noted that rather than the

maximum pitting corrosion depth, the main concern for the structural design of soil

nails is the percentage reduction of area, which determines the maximum force on the

nails. Moreover, even if the corrosion is assumed to be uniform across the whole

section, it should be noted that the corrosion rate of steel is not linear with time, with

faster rate initially which falls to a steady rate. Hence, simply averaging the total

corrosion depth with time is not an accurate estimate. Even with such average corrosion

rate, the loss of thickness for a hot-dip galvanized soil nail for a design life of 120 years

would be in the range of 2mm (for the diameter), or 1mm (for the radius). Hence, the

current practice of providing a 2mm sacrificial thickness allowance around hot-dip

galvanized soil nails can be enough for a design life of 120 years.

Photo 1: Pitting Corrosion of 3mm Depth

in an Exhumed Bare Soil Nail at Tai Po

(Source: Shui and Cheung 2003 Plate 3)

3.3 Guidance in the US

3.3.1 Classification of soil aggressivity

Geotechnical Engineering Circular No. 7: Soil Nail Walls (2003) issued by the US

Federal Highway Administration (Lazarte et al 2003) categorizes soil aggressivity into

two types: aggressive and non-aggressive. Rather than using eight parameters as in

Geoguide 7, Lazarte et al (2003) use five, which include: resistivity, pH, soluble

sulphate, chloride ion content, and stray current. When one of the parameters falls

within the aggressive category (Table 5), the soil will be categorized as aggressive.

Structural Engineering Branch, ArchSD Page 10 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 5: Classification of Site by Lazarte et al 2003

Parameter Aggressive Non-Aggressive

Resistivity (ohm-cm)

(measured by in-situ Wenner’s 2,000 5,000

four probe electrodes test)

pH pH4.5 or pH10 5.5pH10

Soluble sulphate (ppm) 200 200

Chloride ion (ppm) 100 100

Stray current Present -

(Source: Lazarte et al 2003)

3.3.2 Choice of corrosion protection measure

There are two corresponding classes of corrosion protection measures: Class 1 (epoxy-

coated soil nail with grout encapsulation, or soil nail encapsulated in plastic sheathing

and grout) and Class 2 (soil nail with grout encapsulation). For aggressive soil, Class 1

corrosion protection measure is mandated (Chart 1). Similar to Geoguide 7, where no

soil aggressivity assessment has been carried out, Class 1 corrosion protection measure

is recommended. Moreover, even for non-aggressive soil, Class 1 corrosion protection

measure is recommended when the failure consequence is serious or the cost of

increasing corrosion protection is small.

Although this seems a rather strict categorization, Class 1 corrosion protection measure,

besides using plastic sheathing, can be achieved by epoxy-coating plus grout

encapsulation. Epoxy-coated soil nails are not commonly used in Hong Kong, as “the

coatings have to be impermeable to gases and moisture and free of gaps at the interface

between the steel and the coating” (Shui and Cheung 2008). Hence, although in theory

epoxy-coated soil nails can have a longer life in soil, EN 14490:2010 considers that

epoxy coating is taken as equivalent to hot-dip galvanizing, provided that hot-dip

galvanizing has been performed according to EN ISO 1461. In Hong Kong, nearly all

permanent soil nails installed inside a pre-drilled grout holes are hot-dip galvanized to a

thickness of 85m according to EN 14490:2010, and hence according to the US practice,

they can fulfill Class1 corrosion protection measure.

Moreover, Class1 corrosion protection measure in the US does not consider the 2mm

sacrificial thickness allowance provided to the steel, which is provided for all permanent

soil nails in Hong Kong. Hence, our current practice, with a combination of different

corrosion protection measures, should be enough for a design life of 120 years.

Structural Engineering Branch, ArchSD Page 11 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Chart 1: Criteria for Selection of Corrosion Protection Measure for Soil Nail

(Source: Lazarte et al 2003)

3.4 Guidance in Nordic countries

3.4.1 Nordic countries consist of Denmark, Finland, Iceland, Norway and Sweden. Nordic

Geosynthetics Group of the Geotechnical Societies and the Nordic Industrial Fund

issued Nordic Guidelines for Reinforced Soils and Fill (Revision A) (NGG 2004), which

gives the following procedures to classify the soil aggressivity for a site and to choose

the appropriate corrosion protection measures.

3.4.2 Classification of soil aggressivity

NGG (2004) notes that the major factor affecting soil aggressivity is the soil type, and

hence differs from the practice in Hong Kong, the US and other European countries in

that the classification involves two staged procedures – preliminary and detailed. In the

preliminary estimate, points are summated from the soil type (Table 6(a)) and its

specific site or soil composition (Table 6(b)).

Structural Engineering Branch, ArchSD Page 12 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 6(a): Basic Point for Different Soil Type in NGG (2004)

Soil Type Point

Clay with salt content, organic soil (e.g. gyttja), fibrous 10

peat, fill, industrial waste (cinders, ashes, coal)

Other clay and peat, construction waste (plasters, brick) 6

Silt, dry crust clay, moraine 2

Rock, sand, gravel, sandy and gravely moraine 0

(Source: NGG (2004) Table 7.5)

Table 6(b): Adjustment Point for Specific Site and Soil Composition in NGG (2004)

(Source: NGG (2004) Table 7.6)

Based on the total point, the site is classified to have a low (Class I), normal (Class II)

or high (Class III) potential for corrosion (Table 7). If the total amount of points from

this preliminary estimate is less than 5, no further information is needed to determine

the necessary corrosion protection. Detailed study of the soil aggressivity for a site is

only required when the preliminary estimate gives a total point greater than 5.

Table 7: Classification of Site in NGG (2004)

(Source: NGG (2004) Table 7.8)

Structural Engineering Branch, ArchSD Page 13 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

In the detailed study, eight parameters are used, including: soil type, resistivity,

moisture-salt, pH, vertical layering, and other factors (e.g. presence of industrial waste)

(Table 8). NGG (2004) notes that a higher environmental class may be required in

some situations, e.g. flowing water, soil nails subjected to high stress level or cyclic

loads, site with contaminated soil or high concentration of sulphate, etc.

.

Table 8: Detailed Assessment of Soil Aggressivity by NGG (2004)

(Source: NGG (2004) Table 7.7)

3.3.2 Choice of corrosion protection measure

NGG (2004) lists four corrosion protection measures (no corrosion protection, 2 mm of

sacrificial thickness or grout, 4 mm of sacrificial thickness or grout at least 20 mm thick

combined with plastic barrier or sacrificial thickness, and plastic barrier) depending on

the environmental class and design life. For a design life exceeding 80 years, NGG

(2004) does not specifically recommend the corrosion protection measure for Class II

and III environmental class; but states that special investigation should be carried out,

probably in the form of a combination of the corrosion protection measures. In a

subsequent example, NGG (2004) considers that soil nails with grout combined with

either sacrificial thickness or plastic sheathing could be used for a design life of 100

Structural Engineering Branch, ArchSD Page 14 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

years in Class III environmental class (i.e. high potential for corrosion) for a slope with

serious consequence upon failure.

3.5 Guidance in the Europe

3.5.1 EN 14490:2010 (BSI 2010) is the most recent publication on this topic to standardize

soil nailing works, and is now being used throughout EU countries. That document has

incorporated the various previous European guidance including those used in Germany,

France, the UK, and Switzerland.

3.5.2 Classification of soil aggressivity

3.5.2.1 Similar to Geoguide 7, the soil aggressivity in a site has to be classified by a number

of parameters, which include: soil type; resistivity; moisture content; and pH, and a

weight A will be assigned to each parameter (Table 9). Once the weight A from each

parameter has been assigned, they are summated to give an overall index. The soil

aggressivity can then classified into (Table 10): Class 1 (highly corrosive), Class 2

(corrosive), Class 3 (average corrosive), and Class 4 (slightly corrosive).

3.5.2.2 Differences between Geoguide 7 and EN 14490:2010

Although similar parameters have been chosen in classifying soil aggressivity in

Geoguide 7 and EN 14490:2010, the following are the major differences:

a) The marks for corrosive and highly corrosive are 9-12 and 13 or above

respectively for EN 14490:2010, whereas in Geoguide 7, -5 to -10 for aggressive

and -11 for highly aggressive.

b) In the parameter of soil type, Geoguide 7 includes detailed indices including

Atterberg limits, particle size distribution, organic content, whilst EN 14490:2010

adopts a broad-brush approach similar to NGG (2004). Wong (2009) commented

that as only limited soil test results are available, these detailed indices “are not

contributing a lot to soil corrosivity”, and suggested that reference should be made

to site specific conditions, such as organic matters, leakage of sewers and water

mains. Similarly, as stated above, Chaker (1996) noted that the measured soil

resistivity has incorporated the combined effect of soluble salts content, the

particular size, the void ratio, and the moisture content. It is, therefore, doubted

whether it is necessary for such detailed indices.

c) The parameter of ground water level has been included in the moisture content.

This seems to be more rational, as by assigning two different types of mark for

moisture content and groundwater level as in Geoguide 7, the effect of

Structural Engineering Branch, ArchSD Page 15 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

groundwater will be counted twice, especially in the case that soil nails are

embedded above water table and the moisture content is likely to be high.

d) The parameters of soluble sulphate and chloride ion contents in Geoguide 7 are not

included in EN 14490:2010. Chloride ions are found naturally in soils as a result

of brackish groundwater and in site close to sea. The presence of chloride ions

results in anodic dissolution reactions of metals and also decreases the soil

resistivity. Its effect (and similarly the effect of soluble sulphate) on soil

aggressivity is therefore included in the parameters of soil type and soil resistivity.

e) For pH value, a higher alkaline soil of pH greater than 10 will be classified as

aggressive according to Geoguide 7, in line with the Lazarte et al (2003) and Shui

and Cheung (2003. However, as stated above, a highly alkaline environment will

affect zinc but will passivate steel. Therefore, no such provision has been included

in EN 14490:2010, and soil with pH greater than 6 will get a weight of 0 in this

parameter.

3.5.2.3 Two examples have also been included in Annex A to compare the classification of

two different sites according to Geoguide 7 and EN 14490:2010. These examples

illustrate that the classification according to Geoguide 7 is in general more

conservative than that in EN 14490:2010.

3.5.3 Choice of corrosion protection measure

3.5.3.1 EN 14490:2010 gives the following six corrosion protection measures:

a) sacrificial thickness allowance;

b) encapsulated in grout;

c) surface coating in the forms of hot-dip galvanized or epoxy-coated;

d) encapsulated with plastic sheathing;

e) stainless steel;

f) a combination of the above.

Structural Engineering Branch, ArchSD Page 16 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 9: Assessment of Soil Aggressivity in EN 14490:2010

Note: 2) The value of the weight of criterion for "Types of soil" would be the maximum value

applicable to that soil from subgroups "texture", "peat", "industrial waste" and "liquid". The

maximum weight for each of the four criteria is less than or equal to 8.

(Source: EN 14490:2010 Table B.2)

Structural Engineering Branch, ArchSD Page 17 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table 10: Classification of Site in EN 14490:2010

(Source: EN 14490:2010 Table B.1)

3.5.3.2 The listed measures are similar to those given in Geoguide 7, except that stainless steel

soil nails are introduced. Moreover, unlike those in Geoguide 7, there are no

recommended corrosion protection measures for different classes of soil aggressivity.

The only recommendations on the appropriate corrosion protection measures are:

a) sacrificial thickness allowance alone shall not be used for Class I (highly

corrosive) or Class II (corrosive) sites for a design life exceeding 30 years, and

soil nails with plastic sheathing shall then be used; and

b) soil nails encapsulated with grout alone shall not be used for Class I (high

aggressive) site and shall only be used for Class II (corrosive) site for a design life

of 100 years with special consideration of the grout cover (Table 11).

3.5.3.3 In the earlier paragraph, it has been mentioned that Shui and Cheung (2003) had

reservation on the effectiveness of grout, and that they concluded that the grout is

usually assumed to offer no protection. However, EN 14490:2010, besides stating that

research has indicated that micro-cracks of width of less than 0.1mm are self-healing,

considers that the grout cover is one of the major contributors to corrosion protection.

Table 11 shows the minimum grout cover as corrosion protection measure for

different design life, which shows that a cover of 50mm alone (i.e. without hot-dip

galvanized or sacrificial allowance) can provide effective protection of 50 years in

aggressive soil and 75 years in slightly aggressive soil, and a cover of 75mm alone can

provide effective protection of 75 years in aggressive soil.

Table 11: Grout Cover for Steel Nail for Different Design Life

(Source: EN 14490:2010 Table B.4)

Structural Engineering Branch, ArchSD Page 18 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

4. Discussion and Recommendation

a) Limited data have been available on the long-term loss of thickness of soil nails in

Hong Kong. The corrosion rate is estimated from using the measured depth of

pitting corrosion in limited number of soil nails embedded in soil for about 10

years with no deduction for the faster initial corrosion rate. Moreover, localized

pitting corrosion in the diameter of the steel nails will not result in the

corresponding area reduction in the area of the nails, and hence will not affect the

structural strength of the nails. According to EN 14490:2010, the total loss of bare

steel diameter is only 4mm and 2mm respectively in slightly and non-aggressive

environment.

b) In assessing the environment around soil nails and on the choice of corrosion

protection measures, Geoguide 7 assumes that the grout around soil nails is not

effective to provide both physical and chemical protection. With such assumption,

it is true that the bare steel soil nails will be severely affected by soil parameters,

e.g. pH, soil resistivity, moisture content, and hot-dip galvanized soil nails in

plastic sheathing in-filled with grout is therefore recommended for both

“aggressive” and “highly aggressive” soil. This is, however, a rather conservative

approach. In Hong Kong, all permanent soil nails are installed in pre-drilled grout

holes, and the environment in direct contact with the soil nail is modified by the

cement grout. The pH in contact with soil nail is exceeding 10, and soil resistivity

is of less importance. Even if there are micro-cracks in the grout cover, the cracks

are normally sealed by autogenous healing under moist condition. Study should

therefore be carried out on “cement grouted aggressivity” rather than on “soil

aggressivity”. Though with limited research in this area, it is likely that the

environment can be classified as slightly or non-aggressive. In such cases, 75mm

grout cover, according to EN 14490:2010, is good enough for a service life of 75

years. International practices have not ignored the contribution of grout as a

corrosion protection measure. In the US and European practice, soil nails with

plastic sheathing is only reserved for highly aggressive soil. For other soil

aggressivity, hot-dip galvanized soil nails with 2mm sacrificial thickness

allowance in pre-drilled grouted holes can provide effective corrosion protection

for a design life of 120 years.

c) Geoguide 7 lists out comprehensively the parameters to be considered in

classifying the soil aggressivity of a site. However, some parameters (e.g.

groundwater level, moisture content, soil resistivity, soluble sulphate, chloride

ions content) are not independent on each other. Furthermore, the mark for

classification of aggressive soil is -5, which is much lower than 10 used in other

standards, though the marking system is different.

Structural Engineering Branch, ArchSD Page 19 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

d) From Annex A, it can be seen that classification based on Geoguide 7 is generally

more conservative than that based on EN 14490:2010. Hence, project officer

should exercise judgment on using this classification method, especially when the

total mark falls marginally into the “highly aggressive”. Detailed laboratory tests

may be required for sites with highly polluted soil (such as sites with records of

contaminated soil, organic peat, leakage of sewers), highly acidic soil with pH4,

or high concentration of sulphate soil. For sites with high aggressive soils, the use

of soil nails with double corrosion protection using plastic sheathing warrants.

Project officer should then specify such nail via a particular specification in the

contract. A particular specification is being prepared by SGE/NP.

References:

ASTM (2006), ASTM G57-06 Standard Test Method for Field Measurement of Soil Resistivity Using the Wenner

Four-Electrode Method (West Conshohocken: ASTM International) (available:

www.astm.org/Standards/G57.htm; accessed: 29 February 2012).

BSI (1990), BS 1377-3:1990 Methods of Test for Soils for Civil Engineering Purposes (London: BSI).

BSI (2007), Eurocode 3 Part 5 Design of Steel Structures – Piling (BS EN 1993-5) (London: BSI).

BSI (2010), BS EN 14490:2010 Execution of Special Geotechnical Works - Soil Nailing (London: BSI).

BSI (2007), Eurocode 7 (BS EN 1997-2:2007) Geotechnical Design Part 2 - Ground Investigation and Testing

(London: BSI).

Chan, L S and Chen, Q F (1999), Integrated Geophysical and Radiometric Surveys at Five Sites in Hong Kong

(GEO: Hong Kong).

Elias V, Fishman K L, Christopher B R and Breg R R (2009), Report No. FHWA-NHI-09-087:

Corrosion/Degradation of Soil Reinforcements for Mechanically Stabilized Earth Walls and Reinforced

Soil Slopes (Washington, DC: National Highway Institute, Federal Highway Administration) (available:

www.fhwa.dot.gov; accessed: 20 June 2012).

GEO (2008), Geoguide 7: Guide to Soil Nail Design and Construction (Hong Kong: GEO).

ISO (2009), BS EN ISO 1461: Hot Dip Galvanized Coatings on Fabricated Iron and Steel Articles --

Specifications and Test Methods (Geneva: ISO).

NGG (2004), Nordic Guidelines for Reinforced Soils and Fills (Nordic Geotechnical Societies, Revision A)

(available: www.danskgeotekniskforening.dk/media/nordisk_handbok_armerad_jord-engelsk.pdf;

accessed: 29 February 2012).

Lazarte, C A, Elias, V, Espinoza, D R and Sabatini, P J (2003), Geotechnical Engineering Circular No. 7: Soil

Nail Walls (Washington, DC: Federal Highway Administration) (available:

www.scribd.com/doc/27487989/GEOTECHNICAL-ENGINEERING-CIRCULAR-NO-7-Soil-Nail-

Walls; accessed: 29 February 2012).

Structural Engineering Branch, ArchSD Page 20 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Neville, A M (2011), Properties of Concrete (New York: Pearson, 5th ed).

Neville, A M (2002), “Autogenous Healing — a Concrete Miracle?”, Concrete International 24(11) pp.76–82.

Shui, H Y K and Cheung, R W M (2008), “Long-Term Durability of Steel Soil Nails in Hong Kong”,

Transactions Hong Kong Institution of Engineers, 15(3), pp. 24-32(available:

www.hkie.org.hk/html/publications/transactions/html/2008/v15n3/v15n3_abstract4a.htm; accessed: 29

February 2012).

Shui, H Y K and Cheung, R W M (2003), GEO Report No. 135: Long-Term Durability of Steel Soil Nails (Hong

Kong: GEO).

Wong, H Y (2009), “Discussion on ‘Long-Term Durability of Steel Soil Nails in Hong Kong’”, Transactions

Hong Kong Institution of Engineers, 16(1), pp. 45-7.

Structural Engineering Branch, ArchSD Page 21 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Annex A

Examples of Classification of Sites

Structural Engineering Branch, ArchSD Page 22 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Shui and Cheung (2003) surveyed comprehensively the database in GEO, and summarized the

parameters of the soil in Hong Kong. However, for the data of resistivity, they had adopted

the in-situ measured resistivity reported in Chan and Chen (1999) rather than using the

suggested laboratory open container test. As such, their typical values of resistivity of 30000-

50000 ohm-cm may not be the laboratory values, which require the soil sample to be saturated

by pouring water. In order to model the actual laboratory values, a typical value of resistivity

of 100 ohm-cm will be adopted in the following examples. Other than this, the following two

examples have considered two hypothetic sites with such typical types of soil in Hong Kong -

Site A with CDG and Site B with CDV. Table A.1 lists the soil parameters of two sites.

Table A.2 and Table A.3 compute the soil aggressivity of the sites based on Geoguide 7 and

EN 14490:2010.

Table A.1: Soil Parameters of Sites

Site A (CDG) B (CDV)

Soil composition 10% < fraction passing 63μm 10% < fraction passing 63μm

sieve ≤ 75% sieve ≤ 75%

Fraction passing 2μm sieve ≤ Fraction passing 2μm sieve ≤

10% 10%

PI = 0-5 PI = 0-5

organic content < 1.0% organic content < 1.0%

Resistivity (ohm-cm) 100 100

Moisture content 22.5% 17.5%

Groundwater level groundwater level near groundwater level near

ground level ground level

pH 4.5 5.5

Soluble sulphate < 200 < 200

(ppm)

Made ground none none

Chloride ion (ppm) < 300 < 300

Soil type Permeable, sandy Permeable, sandy

Table A.2: Soil Aggressivity Assessment based on Geoguide 7

Site A B

Soil composition 0 0

Resistivity (ohm-cm) -4 -4

Moisture content -1 0

Groundwater level -4 -4

pH -2 -1

Soluble sulphate (ppm) 0 0

Made ground 0 0

Chloride ion (ppm) -1 -1

Total Mark -12 -10

Structural Engineering Branch, ArchSD Page 23 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

Table A.3: Soil Aggressivity Assessment based on EN 14490:2010

Site A B

Soil composition 0 0

Resistivity (ohm-cm) 5 5

Moisture content 2 0

pH 3 2

Total Mark 10 7

Table A.4 classifies the sites based on Geoguide 7 and EN 14490:2010.

Classification Method Site A (CDG) Site B (CDV)

Geoguide 7 Highly Aggressive Highly Aggressive

EN 14490:2010 Class II Class III

(Corrosive) (Average corrosive)

Structural Engineering Branch, ArchSD Page 24 of 24 File code : SoilNail.doc

Revision No. : 0 CTW/KYT/MKL

First Issue Date : July 2012 Current Issue Date : July 2012

You might also like

- Chapter 1-8 Worksheet SolutionsDocument38 pagesChapter 1-8 Worksheet SolutionsNancyNguyen1675% (4)

- RILEM TC 178 (2013) - Methods For Obtaining Dust Samples by Means of Grinding Concrete in OrderDocument8 pagesRILEM TC 178 (2013) - Methods For Obtaining Dust Samples by Means of Grinding Concrete in OrderJosé GomesNo ratings yet

- Foundations For The Pan Pacific Hotel On Pinnacled and Cavernous Limestone, 1985, 8th SEAGC, MalaysiaDocument16 pagesFoundations For The Pan Pacific Hotel On Pinnacled and Cavernous Limestone, 1985, 8th SEAGC, MalaysiafreezefreezeNo ratings yet

- 3291 SinDocument109 pages3291 SinbansaldhruvNo ratings yet

- Pressuremeter Test Suggested Exam Answers (CSE512 Advanced Geotechnical Engineering)Document3 pagesPressuremeter Test Suggested Exam Answers (CSE512 Advanced Geotechnical Engineering)kiddhoNo ratings yet

- Analysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyDocument4 pagesAnalysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyJohn STCNo ratings yet

- 2016 - 04 - 01 - IES - The Singapore Engineer (PG 16-22)Document8 pages2016 - 04 - 01 - IES - The Singapore Engineer (PG 16-22)ThaungMyintNo ratings yet

- GuidelineOnStructuralFireEngineering (Part2)Document62 pagesGuidelineOnStructuralFireEngineering (Part2)Leung LiangNo ratings yet

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- A Case Study of Using Metal Scaffold System For Demountable Grandstand: The Opening Ceremony of Hong Kong 2009 East Asian GamesDocument57 pagesA Case Study of Using Metal Scaffold System For Demountable Grandstand: The Opening Ceremony of Hong Kong 2009 East Asian GamesLeung Liang100% (1)

- Guidelines On Crack Repair in Concrete StructureDocument17 pagesGuidelines On Crack Repair in Concrete StructureLeung Liang100% (1)

- Marking Scheme Q4Document2 pagesMarking Scheme Q4dexterbox1No ratings yet

- 2625 Deep Foundations For High Rise Buildings in Hong KongDocument11 pages2625 Deep Foundations For High Rise Buildings in Hong KongJulio MzpNo ratings yet

- 11 Bolted Connections Part 2 - Sem 2 AY 2015 - 16 - IVLEDocument27 pages11 Bolted Connections Part 2 - Sem 2 AY 2015 - 16 - IVLESteven KuaNo ratings yet

- ICGE 15 KN 04 Endicott PDFDocument10 pagesICGE 15 KN 04 Endicott PDFDiego SerónNo ratings yet

- Hkie Paper 2021Document29 pagesHkie Paper 2021Sol TianNo ratings yet

- Ir DR James LAU Chi WangDocument6 pagesIr DR James LAU Chi WangkzoneasdfNo ratings yet

- Information Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Document37 pagesInformation Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Leung LiangNo ratings yet

- 建築物基礎構造設計規範Document260 pages建築物基礎構造設計規範wilson.nottingham6435100% (2)

- HKSMM4 DaaDocument220 pagesHKSMM4 DaaEaston Cheung0% (1)

- dc16 14Document24 pagesdc16 14Subramanian SaravananNo ratings yet

- Technical References For Mortar and AssociatedDocument8 pagesTechnical References For Mortar and AssociatedLolaNo ratings yet

- Deflection of Permanent FormworkDocument4 pagesDeflection of Permanent FormworkBogdanBNo ratings yet

- SCEA6747Document7 pagesSCEA6747Rahul KolateNo ratings yet

- Landslide Risk Reduction Through Works 35 Years of LPM Programme and Beyond, HKIE 2011Document215 pagesLandslide Risk Reduction Through Works 35 Years of LPM Programme and Beyond, HKIE 2011lamyuwangNo ratings yet

- Zaha Hadid, Aaron Betsky - Zaha Hadid - The Complete Buildings and Projects (1998, Thames & Hudson LTD) - Libgen - LiDocument144 pagesZaha Hadid, Aaron Betsky - Zaha Hadid - The Complete Buildings and Projects (1998, Thames & Hudson LTD) - Libgen - LiParsa RangiNo ratings yet

- Company Profile HumeDocument36 pagesCompany Profile HumeYudith Bdoel AbdullahNo ratings yet

- (CQHP) Guidelines For Structural & Architectural + Annex PDFDocument43 pages(CQHP) Guidelines For Structural & Architectural + Annex PDFflashtronNo ratings yet

- Betopan Betopanplus Eng KKDocument48 pagesBetopan Betopanplus Eng KKkashmir_sefNo ratings yet

- Shear Modulus Ohsaki JapaneseDocument13 pagesShear Modulus Ohsaki Japaneseyin hoe ong100% (1)

- Study of Relationship Between Fines Content and Cohesion of SoilDocument11 pagesStudy of Relationship Between Fines Content and Cohesion of SoilorgaNo ratings yet

- SS EN 1992-2 - 2012 - PreviewDocument12 pagesSS EN 1992-2 - 2012 - PreviewHS EngineeringNo ratings yet

- Martina (2002) - Punching Behavior of Biaxial Hollow SlabsDocument6 pagesMartina (2002) - Punching Behavior of Biaxial Hollow SlabsWanderley NicacioNo ratings yet

- Diaphragm Wall - Soletanch BachyDocument4 pagesDiaphragm Wall - Soletanch BachymlakkissNo ratings yet

- Tamboli 2008 TallBuildingsSustainable.a6b917db A870 4417 8b86 6b19c01f604bDocument0 pagesTamboli 2008 TallBuildingsSustainable.a6b917db A870 4417 8b86 6b19c01f604bsmaliscribdNo ratings yet

- NA To Sls en 1991-1-1Document12 pagesNA To Sls en 1991-1-1Shan Sandaruwan AbeywardeneNo ratings yet

- ELS Sample Questions For 2010 HKPU T3 Top Up Course PDFDocument2 pagesELS Sample Questions For 2010 HKPU T3 Top Up Course PDFYu chung yinNo ratings yet

- 1407 1f CTR PDFDocument353 pages1407 1f CTR PDFThaungMyintNo ratings yet

- AECOM Construction-Handbook-2018 19 PDFDocument7 pagesAECOM Construction-Handbook-2018 19 PDFDurgaPrasadKrishnaNo ratings yet

- SupertallDocument53 pagesSupertallMajdoline SadeddineNo ratings yet

- B3 Tendering Rules PN6Document27 pagesB3 Tendering Rules PN6Eduardo CappellinaNo ratings yet

- BirdSafeBuildingGuidelines PDFDocument59 pagesBirdSafeBuildingGuidelines PDFamvitaNo ratings yet

- CP84-Entry Into and Safe Working in Confined SpacesDocument20 pagesCP84-Entry Into and Safe Working in Confined SpacesSim Guobin100% (1)

- 1a PDFDocument116 pages1a PDFgkutNo ratings yet

- Modular Buildings in Modern Construction: SciencedirectDocument6 pagesModular Buildings in Modern Construction: SciencedirectBhagyaraj KoppishettyNo ratings yet

- HyD Technical Circular No. 3-90Document5 pagesHyD Technical Circular No. 3-90Gary LoNo ratings yet

- Concrete Pipes: Scib Concrete Manufacturing SDN BHDDocument4 pagesConcrete Pipes: Scib Concrete Manufacturing SDN BHDSoonHan WaiNo ratings yet

- Geosythetic Reinforced Unpaved RoadDocument10 pagesGeosythetic Reinforced Unpaved RoadPalak ShivhareNo ratings yet

- SUOS2011Document270 pagesSUOS2011Wong ChingNo ratings yet

- Nist Ncstar 1-2b, WTC InvestigationDocument208 pagesNist Ncstar 1-2b, WTC InvestigationDavid PetersNo ratings yet

- GGF - StakloDocument24 pagesGGF - StakloJelena ĆukNo ratings yet

- Case Study On Structure Collapse: Jacklin Mary - J 121901040Document12 pagesCase Study On Structure Collapse: Jacklin Mary - J 121901040Crazy MechonsNo ratings yet

- Innovative Design and Construction of Composite Steel-Concrete StructuresDocument12 pagesInnovative Design and Construction of Composite Steel-Concrete Structuressusan87No ratings yet

- Technical Manual Whole 09 - BRICKDocument150 pagesTechnical Manual Whole 09 - BRICKMuhamad Zaid Md ZinNo ratings yet

- Designers' Guide To Eurocode 1: Actions On BuildingsDocument13 pagesDesigners' Guide To Eurocode 1: Actions On BuildingsVrajesh SodagarNo ratings yet

- 1670 Evaluation Techniques of Damping in BuildingsDocument9 pages1670 Evaluation Techniques of Damping in BuildingsApetsi AmpiahNo ratings yet

- Singapore Standards EShopDocument2 pagesSingapore Standards EShoplimegreens0% (1)

- Lateral Suport Systems FHWADocument326 pagesLateral Suport Systems FHWADiego Alejandro Flores OrtízNo ratings yet

- Fardis EC8-3 Member Models - 0Document75 pagesFardis EC8-3 Member Models - 0Wendirad BeshadaNo ratings yet

- Sanchita Blacka ND WhiteDocument1 pageSanchita Blacka ND WhiteSanchita JhaNo ratings yet

- ASSIGNMENT On Building ComponentsDocument3 pagesASSIGNMENT On Building Componentsoladipo GraceNo ratings yet

- Characteristics of Ground Movements Induced by ExcavationsDocument4 pagesCharacteristics of Ground Movements Induced by ExcavationsNaveen BansalNo ratings yet

- Structural Concept DesignDocument8 pagesStructural Concept DesignaahtagoNo ratings yet

- GEO Report No. 135 Long-Term Durability of Steel Soil NailsDocument66 pagesGEO Report No. 135 Long-Term Durability of Steel Soil NailsHuy Le QuangNo ratings yet

- Estandares Geotecnicos en Hogn KongDocument9 pagesEstandares Geotecnicos en Hogn KongMerlly GarzonNo ratings yet

- Information Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Document37 pagesInformation Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Leung LiangNo ratings yet

- Guidelines On Structural Survey and Appraisal of Historical Buildings Part I - Materials and Structural FormsDocument100 pagesGuidelines On Structural Survey and Appraisal of Historical Buildings Part I - Materials and Structural FormsLeung Liang100% (1)

- Guideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFDocument92 pagesGuideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFLeung LiangNo ratings yet

- Foundation Design and Construction in Cavernous Karst: A Local ExperienceDocument6 pagesFoundation Design and Construction in Cavernous Karst: A Local ExperienceLeung LiangNo ratings yet

- Highlights of The Code of Practice For Fire Safety in Buildings 2011 PDFDocument12 pagesHighlights of The Code of Practice For Fire Safety in Buildings 2011 PDFLeung LiangNo ratings yet

- Landfill After UseDocument10 pagesLandfill After UseLeung LiangNo ratings yet

- Highlights of The Code of Practice For Fire Safety in Buildings 2011Document12 pagesHighlights of The Code of Practice For Fire Safety in Buildings 2011Leung LiangNo ratings yet

- The Application of PDA and CAPWAP To Ensure Quality and Capacity in Driving Long Steel H-PilesDocument6 pagesThe Application of PDA and CAPWAP To Ensure Quality and Capacity in Driving Long Steel H-PilesLeung LiangNo ratings yet

- Determination of Elastic Critical Load Factor For Steel StructuresDocument16 pagesDetermination of Elastic Critical Load Factor For Steel StructuresLeung Liang100% (1)

- Observations On Using The Energy Obtained From Stress-Wave Measurements in The Hiley FormulaDocument4 pagesObservations On Using The Energy Obtained From Stress-Wave Measurements in The Hiley FormulaLeung LiangNo ratings yet

- Housing Policy For The Sandwich ClassDocument23 pagesHousing Policy For The Sandwich ClassLeung LiangNo ratings yet

- Floor Vibration Induced by Human Rhythmic Activities: Design and Post-Construction Validation at Tin Shui Wai Public Library Cum Indoor Recreation CentreDocument10 pagesFloor Vibration Induced by Human Rhythmic Activities: Design and Post-Construction Validation at Tin Shui Wai Public Library Cum Indoor Recreation CentreLeung LiangNo ratings yet

- Guidelines On The Design of Floor For Vibration Due To Walking LoadsDocument39 pagesGuidelines On The Design of Floor For Vibration Due To Walking LoadsLeung LiangNo ratings yet

- Delhi Public School Chemistry Investigatory Project Academic Session: 2019-20Document11 pagesDelhi Public School Chemistry Investigatory Project Academic Session: 2019-20abhishek pandeyNo ratings yet

- Emulgante CO-55 - MSDSDocument4 pagesEmulgante CO-55 - MSDSMohamed HalemNo ratings yet

- International Standard: Second Edition 2018-07Document18 pagesInternational Standard: Second Edition 2018-07HafiziAhmadNo ratings yet

- 7 Stream Gauging-2Document54 pages7 Stream Gauging-2ChampNo ratings yet

- Gravimetric AnalysisDocument56 pagesGravimetric AnalysisvasantiNo ratings yet

- Informes de LaboratorioDocument17 pagesInformes de Laboratoriojessica vanessaNo ratings yet

- Alkohol Absolut FixDocument14 pagesAlkohol Absolut FixSylvina HerdiantiNo ratings yet

- Circular Expansion Cement Curing Kit Instruction Manual: Manual No. 101443617, Revision C Instrument No. 205814Document19 pagesCircular Expansion Cement Curing Kit Instruction Manual: Manual No. 101443617, Revision C Instrument No. 205814Lê CôngNo ratings yet

- Final Aac PDFDocument7 pagesFinal Aac PDFindrajit sodhaNo ratings yet

- New Lahore Science Academy: Q1. Choose The Correct Answer. 1X6 6Document1 pageNew Lahore Science Academy: Q1. Choose The Correct Answer. 1X6 6AmaezaNo ratings yet

- Is 1528 Part 2 2011Document10 pagesIs 1528 Part 2 2011Caspian DattaNo ratings yet

- Chem213LabManual Feb1st 2024Document22 pagesChem213LabManual Feb1st 2024EyNo ratings yet

- Objectives of HydrometallurgyDocument14 pagesObjectives of HydrometallurgyAnubhav ChandilNo ratings yet

- General Chemistry 2Document39 pagesGeneral Chemistry 2Lhor MaceroNo ratings yet

- Multiple Choices Questions: K K K K (CO)Document14 pagesMultiple Choices Questions: K K K K (CO)MutasimNo ratings yet

- Wet CO2 CorrosionDocument14 pagesWet CO2 CorrosionMedina EldesNo ratings yet

- FP5011 P1069 11HL Lintec BlancoDocument2 pagesFP5011 P1069 11HL Lintec BlancoCamilo ObandoNo ratings yet

- The Open Chemical Engineering Journal: Production of Citric Acid From The Fermentation of Pineapple Waste byDocument9 pagesThe Open Chemical Engineering Journal: Production of Citric Acid From The Fermentation of Pineapple Waste byWindy NainggolanNo ratings yet

- Organic ChemistryDocument1 pageOrganic ChemistryGuruKPONo ratings yet

- Anterior Composite Dr. WalaaDocument4 pagesAnterior Composite Dr. Walaabasel alogilyNo ratings yet

- Synthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidDocument6 pagesSynthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidRoberta VasquesNo ratings yet

- 002 Ac Yoke B100-ParkerDocument2 pages002 Ac Yoke B100-ParkerNubia BarreraNo ratings yet

- Li2020 Article WaterSplittingFromElectrodeToGDocument29 pagesLi2020 Article WaterSplittingFromElectrodeToGAbroo KhattakNo ratings yet

- Method Statement: Chilled Water TreatmentDocument10 pagesMethod Statement: Chilled Water TreatmentNIDHILNo ratings yet

- Expt No. 2-CarbohydratesDocument17 pagesExpt No. 2-CarbohydratesNathaniel PulidoNo ratings yet

- Mathematical Modeling of Ethane Cracking PDFDocument14 pagesMathematical Modeling of Ethane Cracking PDFAlfonso BlancoNo ratings yet

- Hartati 2021Document20 pagesHartati 2021Isabella Leite FerrazNo ratings yet

- Smear LayerDocument114 pagesSmear LayerAME DENTAL COLLEGE RAICHUR, KARNATAKANo ratings yet

- Chemistry SheetDocument10 pagesChemistry Sheetbakr ferasNo ratings yet