Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

515 viewsHybrid Roubo - Nicholson Workbench

Hybrid Roubo - Nicholson Workbench

Uploaded by

Elisif DeFairThis document provides instructions for building a hybrid Roubo/Nicholson workbench. It begins by listing the materials needed and providing cutting instructions. It then details the process of gluing up boards to form the two halves of the thick workbench top. The halves are joined together with dowels and the base is constructed with mortise and tenon joints. The top is attached to the base with through-tenons. A gap stop is fitted and accessories like vises are added to complete the workbench.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 1.5l Duratorq-Tdci Timing BeltDocument62 pages1.5l Duratorq-Tdci Timing Beltsuysuy00100% (3)

- Thermo 2 Problem SetDocument3 pagesThermo 2 Problem SetElisif DeFairNo ratings yet

- A Heavy Duty WorkbenchDocument16 pagesA Heavy Duty Workbenchjohnflory123445100% (1)

- Lock Rabbet Drawer JointsDocument3 pagesLock Rabbet Drawer JointsSANTI90900% (1)

- Fondant PDFDocument16 pagesFondant PDFRohmah Fitri Utami75% (12)

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Creating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesFrom EverandCreating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesNo ratings yet

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopFrom EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopNo ratings yet

- How to Build A Laminate Square Edge CountertopFrom EverandHow to Build A Laminate Square Edge CountertopRating: 2 out of 5 stars2/5 (1)

- More of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideFrom EverandMore of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideNo ratings yet

- Wood Working Plans - Portable Router Station PDFDocument8 pagesWood Working Plans - Portable Router Station PDFBen GerezNo ratings yet

- Shooting Board, How To Build.Document21 pagesShooting Board, How To Build.eduelocoNo ratings yet

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 pagesLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNo ratings yet

- Whatnot Dish: The Ideal Gift BowlDocument5 pagesWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.No ratings yet

- Wood ThreadDocument23 pagesWood Threadroberto_belyz100% (1)

- Box Joinery 4.25ver8Document5 pagesBox Joinery 4.25ver8cajemarNo ratings yet

- FinishDocument4 pagesFinishGsmHelpNo ratings yet

- Creating A Ring HolderDocument3 pagesCreating A Ring Holderapi-522254901No ratings yet

- Hand Cut DovetailsFINALDocument6 pagesHand Cut DovetailsFINALMuhammet OfluoğluNo ratings yet

- Traditional WorkbenchDocument7 pagesTraditional Workbenchaguinaldo6690100% (1)

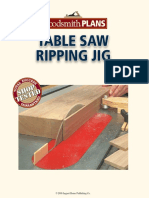

- Table Saw Ripping JigDocument5 pagesTable Saw Ripping JigFranciscoCoto100% (1)

- Bowl Basics 2Document5 pagesBowl Basics 2api-522254901No ratings yet

- Cutting A Bridle JointDocument6 pagesCutting A Bridle JointMario BerronesNo ratings yet

- Sash PlanesDocument5 pagesSash PlanesBlakdawg15100% (1)

- Milling Table: Illustration by James ProvostDocument4 pagesMilling Table: Illustration by James Provostrhinorod100% (1)

- Add A Router Table To A Table Saw: Step 1: Tools and MaterialsDocument8 pagesAdd A Router Table To A Table Saw: Step 1: Tools and Materialsafrica schoolNo ratings yet

- Invocation Et DanseDocument7 pagesInvocation Et Danseimoon63No ratings yet

- 2 - Woodworking Plans - OakplateDocument6 pages2 - Woodworking Plans - OakplatemacpatorNo ratings yet

- Coffe TableDocument15 pagesCoffe TableJun Vargas100% (1)

- 111 - Router Table PlanDocument18 pages111 - Router Table PlanFrans SadieNo ratings yet

- Cove CalculationsDocument1 pageCove Calculationsflerzi100% (1)

- Sanding BlockDocument3 pagesSanding BlockOlavo Pastore100% (1)

- Toolbox Tours de ForceDocument5 pagesToolbox Tours de Forceartust0% (1)

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableVia CreazionemxNo ratings yet

- Router Table - Projects - American WoodworkerDocument12 pagesRouter Table - Projects - American Woodworkermarcoskelpen100% (1)

- Wood Working Plans - Toys - Rocking Horse PDFDocument6 pagesWood Working Plans - Toys - Rocking Horse PDFBen GerezNo ratings yet

- Portable Sandpaper StorageDocument3 pagesPortable Sandpaper Storagegmand68100% (1)

- Rool AroundDocument6 pagesRool AroundMiguel Oyarzabal100% (1)

- Bench - Mendocino BenchDocument5 pagesBench - Mendocino BenchvdbrogerNo ratings yet

- Stanley Number 5 and Up Plane Tote C 06 eDocument3 pagesStanley Number 5 and Up Plane Tote C 06 eArturo Isaak Gonzalez Palazuelos50% (2)

- Easy Resawing: The Fence. The FenceDocument2 pagesEasy Resawing: The Fence. The FenceBilAndersenNo ratings yet

- Measuring and MarkingWDocument40 pagesMeasuring and MarkingWThabiso MmesoNo ratings yet

- Wooden JointsDocument14 pagesWooden JointsAparna KulshresthaNo ratings yet

- EZPine Wall ShelfDocument3 pagesEZPine Wall ShelfBSulliNo ratings yet

- Types of Joints in Carpentry With DescriptionDocument5 pagesTypes of Joints in Carpentry With DescriptionYuuki ChanNo ratings yet

- How To Make A Jack Plane: Overcoming PrejudiceDocument10 pagesHow To Make A Jack Plane: Overcoming Prejudicebollería PebeNo ratings yet

- Portable WorkshopDocument7 pagesPortable WorkshopJose PichardoNo ratings yet

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- Handwork Issue 1Document79 pagesHandwork Issue 1andrew_phelps100% (1)

- Chisel CabinetDocument3 pagesChisel CabinetErika Ramirez100% (4)

- 011130080Document6 pages011130080roose1100% (2)

- ShopNotes #08 - Box Joint JigDocument32 pagesShopNotes #08 - Box Joint Jigrumbo norteNo ratings yet

- Deluxe Router TableDocument27 pagesDeluxe Router Tableiacob_gilberto6473100% (1)

- 8A Thickness SanderDocument15 pages8A Thickness SanderAulia Haq Aqoby100% (1)

- ParquetDocument4 pagesParquetFernando FrayreNo ratings yet

- 5 Router PlaneDocument4 pages5 Router PlaneAngel R Rodriguez100% (1)

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68No ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Table Saw Ripping JigDocument5 pagesTable Saw Ripping Jiggmand68100% (1)

- Five Cut Method To Square Table SawDocument9 pagesFive Cut Method To Square Table Sawhankgurdjieff100% (1)

- Chisel CaseDocument4 pagesChisel CasePeter WestNo ratings yet

- Clamping & AssemblyDocument8 pagesClamping & AssemblyGsmHelp100% (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Machine Foundation Heat Transfer Problem SetDocument3 pagesMachine Foundation Heat Transfer Problem SetElisif DeFairNo ratings yet

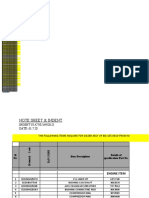

- Name: - Date Started / First Enrolled: - ID Number: - Expected Date of GraduationDocument2 pagesName: - Date Started / First Enrolled: - ID Number: - Expected Date of GraduationElisif DeFairNo ratings yet

- Thermo1-Problem Set Part 1Document4 pagesThermo1-Problem Set Part 1Elisif DeFairNo ratings yet

- Thermo 1-Problem Set Part 2Document5 pagesThermo 1-Problem Set Part 2Elisif DeFairNo ratings yet

- Ppe Problem Set - Variable LoadsDocument5 pagesPpe Problem Set - Variable LoadsElisif DeFairNo ratings yet

- (Ab) - English-2019 (No Filipino)Document2 pages(Ab) - English-2019 (No Filipino)Elisif DeFairNo ratings yet

- ME 424 B Quiz 1Document2 pagesME 424 B Quiz 1Elisif DeFairNo ratings yet

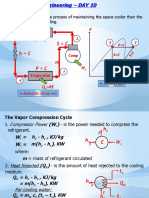

- P C H C S C: RefrigerationDocument23 pagesP C H C S C: RefrigerationElisif DeFairNo ratings yet

- "The Computer Enthusiasts' Resource Center": NEW NEWDocument2 pages"The Computer Enthusiasts' Resource Center": NEW NEWElisif DeFairNo ratings yet

- (Bsme) Em2020Document2 pages(Bsme) Em2020Elisif DeFairNo ratings yet

- DC Generator Short Questions With AnswerDocument5 pagesDC Generator Short Questions With AnswerElisif DeFairNo ratings yet

- DC Motor Hand-OutsDocument35 pagesDC Motor Hand-OutsElisif DeFairNo ratings yet

- Simoun 445: Sailboat SpecificationsDocument1 pageSimoun 445: Sailboat SpecificationsElisif DeFairNo ratings yet

- DC Circuit Short QuizDocument1 pageDC Circuit Short QuizElisif DeFairNo ratings yet

- FormulasDocument18 pagesFormulasElisif DeFairNo ratings yet

- Power On The Move: Portable GeneratorsDocument12 pagesPower On The Move: Portable GeneratorsElisif DeFairNo ratings yet

- Sample Problems: Material (-CM/FT) T (C) at 20 CDocument6 pagesSample Problems: Material (-CM/FT) T (C) at 20 CElisif DeFairNo ratings yet

- Compact Air Conditioner Series - PC-KMADocument18 pagesCompact Air Conditioner Series - PC-KMAElisif DeFairNo ratings yet

- Honda Ca95Document42 pagesHonda Ca95Hoang HungNo ratings yet

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Document9 pagesRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- Popular Woodworking - 054 - 1990 PDFDocument92 pagesPopular Woodworking - 054 - 1990 PDFejeroth1991100% (2)

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleDocument4 pagesOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODRENo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- 1993 Yamaha XVZ13D - E - EC Parts CatalogDocument108 pages1993 Yamaha XVZ13D - E - EC Parts CatalogKevin M. CampbellNo ratings yet

- ShopNotes Issue 42 PDFDocument32 pagesShopNotes Issue 42 PDFbenigno100% (1)

- Speed Dowel Brochure 0811 Reduced PDFDocument8 pagesSpeed Dowel Brochure 0811 Reduced PDFDivyanshu Singh JaatNo ratings yet

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- 5PS 04 Parts ListDocument48 pages5PS 04 Parts Listkari6uskaliNo ratings yet

- Indent No-149 For Dozer BD-155Document26 pagesIndent No-149 For Dozer BD-155Sandeep NikhilNo ratings yet

- Design of Drill JigDocument26 pagesDesign of Drill JigDIPAK VINAYAK SHIRBHATE100% (1)

- Dodec Spinning Wheel Brochure PDFDocument5 pagesDodec Spinning Wheel Brochure PDFamanda grovesNo ratings yet

- MAST CalculationDocument20 pagesMAST Calculationshamir_ahmedabad100% (3)

- Build Your Own Doug Coil Machine Part 2Document70 pagesBuild Your Own Doug Coil Machine Part 2Jason Verbelli100% (5)

- Henri 3 Hurdy GurdyDocument40 pagesHenri 3 Hurdy GurdyMariana Pavan100% (2)

- Popular Woodworking - 001 - 1981 PDFDocument16 pagesPopular Woodworking - 001 - 1981 PDFKawchhar Ahammed100% (1)

- Road Works PDFDocument13 pagesRoad Works PDFSasidhar ReddyNo ratings yet

- How To Make A Bamboo Bed - Guadua BambooDocument21 pagesHow To Make A Bamboo Bed - Guadua Bambooupendar reddy MalluNo ratings yet

- Shear Friction & Dowel ActionDocument15 pagesShear Friction & Dowel ActionLordM00nNo ratings yet

- Ludeca Thoughts On Dowel Pins in Machine FeetDocument4 pagesLudeca Thoughts On Dowel Pins in Machine Feetskaker100% (1)

- Wire WrappingDocument8 pagesWire WrappingInterweave69% (35)

- Yamaha Xjr1300 Parts CatalogueDocument75 pagesYamaha Xjr1300 Parts Cataloguesumeemtariq100% (1)

- TDM850Document70 pagesTDM850Oana Ludmila PopescuNo ratings yet

- Welding Jig Assessment SheetDocument2 pagesWelding Jig Assessment SheetRahul Anand100% (1)

- Rubber Band BullroarerDocument6 pagesRubber Band BullroarerSimone B.No ratings yet

- B+V-Manual - Tongs BV & WRT Models PDFDocument58 pagesB+V-Manual - Tongs BV & WRT Models PDFYina Useche100% (2)

- Arboform 050509Document19 pagesArboform 050509Mas TriNo ratings yet

Hybrid Roubo - Nicholson Workbench

Hybrid Roubo - Nicholson Workbench

Uploaded by

Elisif DeFair100%(1)100% found this document useful (1 vote)

515 views22 pagesThis document provides instructions for building a hybrid Roubo/Nicholson workbench. It begins by listing the materials needed and providing cutting instructions. It then details the process of gluing up boards to form the two halves of the thick workbench top. The halves are joined together with dowels and the base is constructed with mortise and tenon joints. The top is attached to the base with through-tenons. A gap stop is fitted and accessories like vises are added to complete the workbench.

Original Description:

Original Title

Hybrid Roubo_Nicholson Workbench

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides instructions for building a hybrid Roubo/Nicholson workbench. It begins by listing the materials needed and providing cutting instructions. It then details the process of gluing up boards to form the two halves of the thick workbench top. The halves are joined together with dowels and the base is constructed with mortise and tenon joints. The top is attached to the base with through-tenons. A gap stop is fitted and accessories like vises are added to complete the workbench.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

515 views22 pagesHybrid Roubo - Nicholson Workbench

Hybrid Roubo - Nicholson Workbench

Uploaded by

Elisif DeFairThis document provides instructions for building a hybrid Roubo/Nicholson workbench. It begins by listing the materials needed and providing cutting instructions. It then details the process of gluing up boards to form the two halves of the thick workbench top. The halves are joined together with dowels and the base is constructed with mortise and tenon joints. The top is attached to the base with through-tenons. A gap stop is fitted and accessories like vises are added to complete the workbench.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 22

Hybrid Roubo/Nicholson Workbench

Best Workbench Ever?

For this Project you will need.

6= 4x4 , 8ft untreated pine (one will be used for gap stop)

16= 2x6, 6ft untreated pine

1= 2x12 6ft untreated pine

2= 2x4 8ft untreated pine

2= 1x8 8ft untreated pine

The cutlist is as follows:

To get started

First joint one edge of all 2x6 material, then rip the other edge at the table saw

to ensure a flat, square board. Glue 8 of the 2x6s on edge together to create

one half of your bench top. The resulting half should be about 5” thick and

about 65” long You will want to leave extra length and thickness to be

trimmed . Allow the glue to cure overnight.

Clean up the two halves

There will almost certainly be movement in your glue up. This is why we left

that extra material so we can get the bench top half to our actual desired

finished size. Plane and cut the two halves to the final dimensions. Ensure that

both halves are identical.

Join the two Halves

Use the small 4x4 blocks cut at 5” (3) and drill 4 holes on each side for dowels.

Use doweling jig to mark the opposite hole to drill in the bench top half. Glue

all dowels into place and clamp. Allow to dry overnight.

Start on the base

Mill all your 4x4 material so there are no bows, cups or twists. In my process

this netted a final dimension of 3.25” for my lumber. Begin layout of the

mortise and tenon joints that will bring the base together. Cut all joints and

glue components together, allow glue to dry overnight. Make sure to leave the

tenons that will go through the top LONGER THAN NEEDED by about an inch

or so, so you can trim it flush once the two are joined.

Join the top to the base

I personally used the base itself on top of the assembled workbench top to

layout the through mortises that joint the top and base. If you are more

confident in your measurements and that your material has not moved at all

due to humidity you may use layout tools to find where to cut the large

mortise for the tenon on top of the leg. Proceed to cut the mortise and set the

top on the base. Unless you are superman, you WILL NEED HELP!

True up the workbench top

Cut the tops of the through tenons flush with the top of the workbench top.

Then proceed to make the gap stop from the last remaining 4x4. You will need

to align the gap stop with the smaller 4x4 blocks that are joining the two

halves and notch them out appropriately so that the gap stop sits flush with

the rest of the bench top. I chose to add a couple notches on either side of the

main dado so that i could shift the gap stop to one side or the other and it

would sit proud of the benchtop surface either a half inch or an inch and a

half to accommodate different stock thicknesses. What you’ve accomplished

by doing this is essentially a planing stop that is the length of your bench.

Plane and or sand the entire top flat again.

Build up Nicholson Apron

Now it is time to build up the Nicholson side of the hybrid. Add the 1, 1x12’

with the top edge flush with the bottom of the top and the edges of the top

and screw into place. Then add the 2x4s along the face of the legs and the

long stretcher in the base to create an even plane all along the Nicholson side

of the bench. Mark where you want the dog holes and drill halfway from the

face and halfway from the back to reduce tearout.

Add all Accesories

Now its time to add all vises and i added a sliding deadman as well. The

workbench casters are awesome in a small shop to make the bench mobile.

Add whatever you like and remember you don't have to do it all at once.

GO BUILD YOUR BENCH!!!

Now that you’ve seen my process get out and build your own! It can

incorporate some, all or none of the features i used. Find what works for you

in your shop and get to building! Thanks for checking out my Workbench

build and stay tuned for all the accessories i'll add in the future.

You might also like

- 1.5l Duratorq-Tdci Timing BeltDocument62 pages1.5l Duratorq-Tdci Timing Beltsuysuy00100% (3)

- Thermo 2 Problem SetDocument3 pagesThermo 2 Problem SetElisif DeFairNo ratings yet

- A Heavy Duty WorkbenchDocument16 pagesA Heavy Duty Workbenchjohnflory123445100% (1)

- Lock Rabbet Drawer JointsDocument3 pagesLock Rabbet Drawer JointsSANTI90900% (1)

- Fondant PDFDocument16 pagesFondant PDFRohmah Fitri Utami75% (12)

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Creating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesFrom EverandCreating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesNo ratings yet

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopFrom EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopNo ratings yet

- How to Build A Laminate Square Edge CountertopFrom EverandHow to Build A Laminate Square Edge CountertopRating: 2 out of 5 stars2/5 (1)

- More of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideFrom EverandMore of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideNo ratings yet

- Wood Working Plans - Portable Router Station PDFDocument8 pagesWood Working Plans - Portable Router Station PDFBen GerezNo ratings yet

- Shooting Board, How To Build.Document21 pagesShooting Board, How To Build.eduelocoNo ratings yet

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 pagesLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNo ratings yet

- Whatnot Dish: The Ideal Gift BowlDocument5 pagesWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.No ratings yet

- Wood ThreadDocument23 pagesWood Threadroberto_belyz100% (1)

- Box Joinery 4.25ver8Document5 pagesBox Joinery 4.25ver8cajemarNo ratings yet

- FinishDocument4 pagesFinishGsmHelpNo ratings yet

- Creating A Ring HolderDocument3 pagesCreating A Ring Holderapi-522254901No ratings yet

- Hand Cut DovetailsFINALDocument6 pagesHand Cut DovetailsFINALMuhammet OfluoğluNo ratings yet

- Traditional WorkbenchDocument7 pagesTraditional Workbenchaguinaldo6690100% (1)

- Table Saw Ripping JigDocument5 pagesTable Saw Ripping JigFranciscoCoto100% (1)

- Bowl Basics 2Document5 pagesBowl Basics 2api-522254901No ratings yet

- Cutting A Bridle JointDocument6 pagesCutting A Bridle JointMario BerronesNo ratings yet

- Sash PlanesDocument5 pagesSash PlanesBlakdawg15100% (1)

- Milling Table: Illustration by James ProvostDocument4 pagesMilling Table: Illustration by James Provostrhinorod100% (1)

- Add A Router Table To A Table Saw: Step 1: Tools and MaterialsDocument8 pagesAdd A Router Table To A Table Saw: Step 1: Tools and Materialsafrica schoolNo ratings yet

- Invocation Et DanseDocument7 pagesInvocation Et Danseimoon63No ratings yet

- 2 - Woodworking Plans - OakplateDocument6 pages2 - Woodworking Plans - OakplatemacpatorNo ratings yet

- Coffe TableDocument15 pagesCoffe TableJun Vargas100% (1)

- 111 - Router Table PlanDocument18 pages111 - Router Table PlanFrans SadieNo ratings yet

- Cove CalculationsDocument1 pageCove Calculationsflerzi100% (1)

- Sanding BlockDocument3 pagesSanding BlockOlavo Pastore100% (1)

- Toolbox Tours de ForceDocument5 pagesToolbox Tours de Forceartust0% (1)

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableVia CreazionemxNo ratings yet

- Router Table - Projects - American WoodworkerDocument12 pagesRouter Table - Projects - American Woodworkermarcoskelpen100% (1)

- Wood Working Plans - Toys - Rocking Horse PDFDocument6 pagesWood Working Plans - Toys - Rocking Horse PDFBen GerezNo ratings yet

- Portable Sandpaper StorageDocument3 pagesPortable Sandpaper Storagegmand68100% (1)

- Rool AroundDocument6 pagesRool AroundMiguel Oyarzabal100% (1)

- Bench - Mendocino BenchDocument5 pagesBench - Mendocino BenchvdbrogerNo ratings yet

- Stanley Number 5 and Up Plane Tote C 06 eDocument3 pagesStanley Number 5 and Up Plane Tote C 06 eArturo Isaak Gonzalez Palazuelos50% (2)

- Easy Resawing: The Fence. The FenceDocument2 pagesEasy Resawing: The Fence. The FenceBilAndersenNo ratings yet

- Measuring and MarkingWDocument40 pagesMeasuring and MarkingWThabiso MmesoNo ratings yet

- Wooden JointsDocument14 pagesWooden JointsAparna KulshresthaNo ratings yet

- EZPine Wall ShelfDocument3 pagesEZPine Wall ShelfBSulliNo ratings yet

- Types of Joints in Carpentry With DescriptionDocument5 pagesTypes of Joints in Carpentry With DescriptionYuuki ChanNo ratings yet

- How To Make A Jack Plane: Overcoming PrejudiceDocument10 pagesHow To Make A Jack Plane: Overcoming Prejudicebollería PebeNo ratings yet

- Portable WorkshopDocument7 pagesPortable WorkshopJose PichardoNo ratings yet

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- Handwork Issue 1Document79 pagesHandwork Issue 1andrew_phelps100% (1)

- Chisel CabinetDocument3 pagesChisel CabinetErika Ramirez100% (4)

- 011130080Document6 pages011130080roose1100% (2)

- ShopNotes #08 - Box Joint JigDocument32 pagesShopNotes #08 - Box Joint Jigrumbo norteNo ratings yet

- Deluxe Router TableDocument27 pagesDeluxe Router Tableiacob_gilberto6473100% (1)

- 8A Thickness SanderDocument15 pages8A Thickness SanderAulia Haq Aqoby100% (1)

- ParquetDocument4 pagesParquetFernando FrayreNo ratings yet

- 5 Router PlaneDocument4 pages5 Router PlaneAngel R Rodriguez100% (1)

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68No ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Table Saw Ripping JigDocument5 pagesTable Saw Ripping Jiggmand68100% (1)

- Five Cut Method To Square Table SawDocument9 pagesFive Cut Method To Square Table Sawhankgurdjieff100% (1)

- Chisel CaseDocument4 pagesChisel CasePeter WestNo ratings yet

- Clamping & AssemblyDocument8 pagesClamping & AssemblyGsmHelp100% (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Machine Foundation Heat Transfer Problem SetDocument3 pagesMachine Foundation Heat Transfer Problem SetElisif DeFairNo ratings yet

- Name: - Date Started / First Enrolled: - ID Number: - Expected Date of GraduationDocument2 pagesName: - Date Started / First Enrolled: - ID Number: - Expected Date of GraduationElisif DeFairNo ratings yet

- Thermo1-Problem Set Part 1Document4 pagesThermo1-Problem Set Part 1Elisif DeFairNo ratings yet

- Thermo 1-Problem Set Part 2Document5 pagesThermo 1-Problem Set Part 2Elisif DeFairNo ratings yet

- Ppe Problem Set - Variable LoadsDocument5 pagesPpe Problem Set - Variable LoadsElisif DeFairNo ratings yet

- (Ab) - English-2019 (No Filipino)Document2 pages(Ab) - English-2019 (No Filipino)Elisif DeFairNo ratings yet

- ME 424 B Quiz 1Document2 pagesME 424 B Quiz 1Elisif DeFairNo ratings yet

- P C H C S C: RefrigerationDocument23 pagesP C H C S C: RefrigerationElisif DeFairNo ratings yet

- "The Computer Enthusiasts' Resource Center": NEW NEWDocument2 pages"The Computer Enthusiasts' Resource Center": NEW NEWElisif DeFairNo ratings yet

- (Bsme) Em2020Document2 pages(Bsme) Em2020Elisif DeFairNo ratings yet

- DC Generator Short Questions With AnswerDocument5 pagesDC Generator Short Questions With AnswerElisif DeFairNo ratings yet

- DC Motor Hand-OutsDocument35 pagesDC Motor Hand-OutsElisif DeFairNo ratings yet

- Simoun 445: Sailboat SpecificationsDocument1 pageSimoun 445: Sailboat SpecificationsElisif DeFairNo ratings yet

- DC Circuit Short QuizDocument1 pageDC Circuit Short QuizElisif DeFairNo ratings yet

- FormulasDocument18 pagesFormulasElisif DeFairNo ratings yet

- Power On The Move: Portable GeneratorsDocument12 pagesPower On The Move: Portable GeneratorsElisif DeFairNo ratings yet

- Sample Problems: Material (-CM/FT) T (C) at 20 CDocument6 pagesSample Problems: Material (-CM/FT) T (C) at 20 CElisif DeFairNo ratings yet

- Compact Air Conditioner Series - PC-KMADocument18 pagesCompact Air Conditioner Series - PC-KMAElisif DeFairNo ratings yet

- Honda Ca95Document42 pagesHonda Ca95Hoang HungNo ratings yet

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Document9 pagesRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- Popular Woodworking - 054 - 1990 PDFDocument92 pagesPopular Woodworking - 054 - 1990 PDFejeroth1991100% (2)

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleDocument4 pagesOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODRENo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- 1993 Yamaha XVZ13D - E - EC Parts CatalogDocument108 pages1993 Yamaha XVZ13D - E - EC Parts CatalogKevin M. CampbellNo ratings yet

- ShopNotes Issue 42 PDFDocument32 pagesShopNotes Issue 42 PDFbenigno100% (1)

- Speed Dowel Brochure 0811 Reduced PDFDocument8 pagesSpeed Dowel Brochure 0811 Reduced PDFDivyanshu Singh JaatNo ratings yet

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- 5PS 04 Parts ListDocument48 pages5PS 04 Parts Listkari6uskaliNo ratings yet

- Indent No-149 For Dozer BD-155Document26 pagesIndent No-149 For Dozer BD-155Sandeep NikhilNo ratings yet

- Design of Drill JigDocument26 pagesDesign of Drill JigDIPAK VINAYAK SHIRBHATE100% (1)

- Dodec Spinning Wheel Brochure PDFDocument5 pagesDodec Spinning Wheel Brochure PDFamanda grovesNo ratings yet

- MAST CalculationDocument20 pagesMAST Calculationshamir_ahmedabad100% (3)

- Build Your Own Doug Coil Machine Part 2Document70 pagesBuild Your Own Doug Coil Machine Part 2Jason Verbelli100% (5)

- Henri 3 Hurdy GurdyDocument40 pagesHenri 3 Hurdy GurdyMariana Pavan100% (2)

- Popular Woodworking - 001 - 1981 PDFDocument16 pagesPopular Woodworking - 001 - 1981 PDFKawchhar Ahammed100% (1)

- Road Works PDFDocument13 pagesRoad Works PDFSasidhar ReddyNo ratings yet

- How To Make A Bamboo Bed - Guadua BambooDocument21 pagesHow To Make A Bamboo Bed - Guadua Bambooupendar reddy MalluNo ratings yet

- Shear Friction & Dowel ActionDocument15 pagesShear Friction & Dowel ActionLordM00nNo ratings yet

- Ludeca Thoughts On Dowel Pins in Machine FeetDocument4 pagesLudeca Thoughts On Dowel Pins in Machine Feetskaker100% (1)

- Wire WrappingDocument8 pagesWire WrappingInterweave69% (35)

- Yamaha Xjr1300 Parts CatalogueDocument75 pagesYamaha Xjr1300 Parts Cataloguesumeemtariq100% (1)

- TDM850Document70 pagesTDM850Oana Ludmila PopescuNo ratings yet

- Welding Jig Assessment SheetDocument2 pagesWelding Jig Assessment SheetRahul Anand100% (1)

- Rubber Band BullroarerDocument6 pagesRubber Band BullroarerSimone B.No ratings yet

- B+V-Manual - Tongs BV & WRT Models PDFDocument58 pagesB+V-Manual - Tongs BV & WRT Models PDFYina Useche100% (2)

- Arboform 050509Document19 pagesArboform 050509Mas TriNo ratings yet