Professional Documents

Culture Documents

Alia ADP D Diaphragm Seal

Alia ADP D Diaphragm Seal

Uploaded by

RexCrazyMindCopyright:

Available Formats

You might also like

- Plano Hidráulico Retroexcavadora 420fDocument13 pagesPlano Hidráulico Retroexcavadora 420fgerardo92% (13)

- RCU - RCUP AUZ SM Service ManualDocument36 pagesRCU - RCUP AUZ SM Service ManualRexCrazyMind100% (3)

- Ingersoll Rand - T30: Electric-Driven Single Stage & Two Stage Dry Type Vacuum PumpsDocument2 pagesIngersoll Rand - T30: Electric-Driven Single Stage & Two Stage Dry Type Vacuum PumpsstkmNo ratings yet

- Concession Map 16.01.2019Document1 pageConcession Map 16.01.2019Sathish100% (4)

- Medidor de Nivel PDFDocument4 pagesMedidor de Nivel PDFGarcia FranciscoNo ratings yet

- 8017031Document4 pages8017031alisuseNo ratings yet

- Transmisor de PresionDocument4 pagesTransmisor de PresionGarcia FranciscoNo ratings yet

- Man Sse Nae 8Document8 pagesMan Sse Nae 8Jorge Gustavo GoyecheaNo ratings yet

- Electromagnetic FlowmeterDocument5 pagesElectromagnetic FlowmeterEllen ShengNo ratings yet

- Electromagnetic Flow Meter: DN3-DN3000mm / Flange Connection / Integrated TypeDocument9 pagesElectromagnetic Flow Meter: DN3-DN3000mm / Flange Connection / Integrated TypeMPNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- Spirax Sarco Clean Steam FilterDocument6 pagesSpirax Sarco Clean Steam FilterMuhammad Ahsan KhanNo ratings yet

- 1.1.certificacion de Producto Macro 24 PulgadasDocument37 pages1.1.certificacion de Producto Macro 24 PulgadasNatalia RengifoNo ratings yet

- LUNNIMAG - Magnetic Level Gauge PDFDocument3 pagesLUNNIMAG - Magnetic Level Gauge PDFachmad arifNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterJane Umali CastilloNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterMohammad HosseinNo ratings yet

- Application: Nominal Dia (MM) DN 15 DN 3000Document3 pagesApplication: Nominal Dia (MM) DN 15 DN 3000guillermoNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- ALFAGOMMA Catalogue - HoseDocument35 pagesALFAGOMMA Catalogue - HoseGilles BrunengoNo ratings yet

- D3010 HSV600 ReducedDocument28 pagesD3010 HSV600 ReducedY.EbadiNo ratings yet

- Robust Pressure Transmitters T.3: 1.4404 / AISI 316LDocument4 pagesRobust Pressure Transmitters T.3: 1.4404 / AISI 316LRodica PuscauNo ratings yet

- Alfa Laval SPC 2 Regulating Valve Product LeafletDocument4 pagesAlfa Laval SPC 2 Regulating Valve Product LeafletNIO NIETONo ratings yet

- SHM Sewage FlowmeterDocument5 pagesSHM Sewage FlowmeterSaifudin ZuhriNo ratings yet

- Alia AUF790 Ultrasonic Open Channel FlowmeterDocument4 pagesAlia AUF790 Ultrasonic Open Channel FlowmeterRexCrazyMindNo ratings yet

- 1377 Duragauge Pressure Gauge: Data SheetDocument4 pages1377 Duragauge Pressure Gauge: Data SheetkarthikNo ratings yet

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezNo ratings yet

- FD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Document2 pagesFD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Guilherme ZanotelliNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Spring Push Pneumatic Push: Standard Series Standard Series DP/S DP/P Dimensions (MM)Document2 pagesSpring Push Pneumatic Push: Standard Series Standard Series DP/S DP/P Dimensions (MM)Arturo Garza SantosNo ratings yet

- Rev1 - 154-AC-YTKI-V-22-DH - PT. YTK INDONESIA - Rev.1Document2 pagesRev1 - 154-AC-YTKI-V-22-DH - PT. YTK INDONESIA - Rev.1sales-admin.bdgNo ratings yet

- Product Range - Tomoe ValvesDocument4 pagesProduct Range - Tomoe Valvesheru hsNo ratings yet

- Cmo Knife Gate ValvesDocument14 pagesCmo Knife Gate ValvesBruno PatracaNo ratings yet

- Norma Pipe Connections DIN-11864Document17 pagesNorma Pipe Connections DIN-11864bioNo ratings yet

- Nichicon CS Pencil CapacitorsDocument2 pagesNichicon CS Pencil CapacitorsVaslejeanNo ratings yet

- Datasheet n5500 Low Pressure Capsule GaugeDocument5 pagesDatasheet n5500 Low Pressure Capsule GaugeLuis AliagaNo ratings yet

- Water Flow MeterDocument6 pagesWater Flow Meterrommel5No ratings yet

- Ficha Mang Oxiacetileno BalflexDocument1 pageFicha Mang Oxiacetileno BalflexJUANPANIAGUANo ratings yet

- Walvoil Comando SD6DLS7 2019Document101 pagesWalvoil Comando SD6DLS7 2019Istenio Cassiano NetoNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- Folleto 75Document4 pagesFolleto 75ricardoNo ratings yet

- PressedDocument46 pagesPressedsameh aboulsoudNo ratings yet

- Vc-90200.01.03-En Ecoline DJDocument6 pagesVc-90200.01.03-En Ecoline DJGary IrawanNo ratings yet

- DS BDH Series ENDocument13 pagesDS BDH Series EN9033301054No ratings yet

- CATALOG - Final - Low ResulotionDocument66 pagesCATALOG - Final - Low ResulotionKadiri El MoustaphaNo ratings yet

- TA-Modulator EN LowDocument16 pagesTA-Modulator EN Lowkap4enijNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Differential Pr. Gauges Diaphragm TypeDocument4 pagesDifferential Pr. Gauges Diaphragm TypeVara PrasadNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- ISOBUS Flyer Amphenol ConnectorDocument4 pagesISOBUS Flyer Amphenol ConnectorGustavo ParlantiNo ratings yet

- Diaphragm Sensing Pressure Gauges 1Document2 pagesDiaphragm Sensing Pressure Gauges 1Wency JavateNo ratings yet

- ManometreDocument6 pagesManometreAbdo KouNo ratings yet

- Stainless Steel Pressure Filters - BrochureDocument20 pagesStainless Steel Pressure Filters - Brochureviktor_gligorovNo ratings yet

- APT8000V1 2 3 r4 LT enDocument4 pagesAPT8000V1 2 3 r4 LT enThanh Tung NguyenNo ratings yet

- General Pressure Gauge (GP Series) PG1111Document1 pageGeneral Pressure Gauge (GP Series) PG1111Tran Quoc Thinh - M&ENo ratings yet

- General Pressure Gauge (GP Series) PG1111Document1 pageGeneral Pressure Gauge (GP Series) PG1111Jf OngNo ratings yet

- Alia AVF250 Variable Area FlowmeterDocument4 pagesAlia AVF250 Variable Area FlowmeterRexCrazyMindNo ratings yet

- General Specifications: Y/17B6 Pneumatic Buoyancy TransmitterDocument3 pagesGeneral Specifications: Y/17B6 Pneumatic Buoyancy Transmitterمحمد امين التشغيل الآليNo ratings yet

- Technical Datasheet Knife Gate Valve Stainless Steel Epdm pn10 SgateDocument14 pagesTechnical Datasheet Knife Gate Valve Stainless Steel Epdm pn10 Sgateruiz sumarNo ratings yet

- Industrial Pressure Gauge Model: P52: Standard SpecificationDocument2 pagesIndustrial Pressure Gauge Model: P52: Standard SpecificationPort VideoNo ratings yet

- FME800 - Compressed MagnaticoDocument5 pagesFME800 - Compressed MagnaticocalymosqueraNo ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Dao 2000-98 PDFDocument179 pagesDao 2000-98 PDFJohnKevinVillarNo ratings yet

- CNC CIP Flow Diagram Rev0Document1 pageCNC CIP Flow Diagram Rev0RexCrazyMindNo ratings yet

- Rcu - Rcup-Auz - SC2-P02QDocument56 pagesRcu - Rcup-Auz - SC2-P02QRexCrazyMind50% (2)

- Vortex TrainingDocument17 pagesVortex TrainingRexCrazyMindNo ratings yet

- Variable Area TrainingDocument12 pagesVariable Area TrainingRexCrazyMindNo ratings yet

- Paperless Recorder TrainingDocument9 pagesPaperless Recorder TrainingRexCrazyMindNo ratings yet

- Variable Area TrainingDocument12 pagesVariable Area TrainingRexCrazyMindNo ratings yet

- Training For ALIA Ultrasonic FlowmeterDocument20 pagesTraining For ALIA Ultrasonic FlowmeterRexCrazyMind100% (1)

- Vortex TrainingDocument17 pagesVortex TrainingRexCrazyMindNo ratings yet

- VTX TrainingDocument9 pagesVTX TrainingRexCrazyMindNo ratings yet

- Alia APF810 Oval Gear FlowmeterDocument4 pagesAlia APF810 Oval Gear FlowmeterRexCrazyMindNo ratings yet

- Alia AMC3100 ConverterDocument4 pagesAlia AMC3100 ConverterRexCrazyMindNo ratings yet

- Training For ALIA MAG: Specifications About Electromagnetic FlowmeterDocument18 pagesTraining For ALIA MAG: Specifications About Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Mag TrainingDocument17 pagesMag TrainingRexCrazyMindNo ratings yet

- Paperless Recorder TrainingDocument9 pagesPaperless Recorder TrainingRexCrazyMindNo ratings yet

- Mag TrainingDocument17 pagesMag TrainingRexCrazyMindNo ratings yet

- Alia AMC4000 ConverterDocument4 pagesAlia AMC4000 ConverterRexCrazyMindNo ratings yet

- DP PT TrainingDocument19 pagesDP PT TrainingRexCrazyMindNo ratings yet

- Alia Technology LLC: Electromagnetic FlowmeterDocument11 pagesAlia Technology LLC: Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Alia APT3000 Pressure TransmitterDocument2 pagesAlia APT3000 Pressure TransmitterRexCrazyMindNo ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Alia AMF601 Electromagnetic FlowmeterDocument4 pagesAlia AMF601 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Alia ARC1000 Paperless RecorderDocument4 pagesAlia ARC1000 Paperless RecorderRexCrazyMindNo ratings yet

- Alia Apf850 Oval GearDocument4 pagesAlia Apf850 Oval GearRexCrazyMindNo ratings yet

- Alia ARC900 Paperless RecordersDocument4 pagesAlia ARC900 Paperless RecordersRexCrazyMindNo ratings yet

- Alia ARH950 Relative Humidity TransmitterDocument2 pagesAlia ARH950 Relative Humidity TransmitterRexCrazyMindNo ratings yet

- r5310302 Hydraulic Machinery and SystemsDocument4 pagesr5310302 Hydraulic Machinery and SystemswirelessandlessNo ratings yet

- Capillary Flow PorosimetryDocument3 pagesCapillary Flow PorosimetryAlokaNo ratings yet

- DistillationDocument8 pagesDistillationsahil khandelwalNo ratings yet

- Koppel Wall Mounted Split Type Super Inverter Aria SeriesDocument1 pageKoppel Wall Mounted Split Type Super Inverter Aria SeriesJohn Rodolfo BultronNo ratings yet

- Course - ASAP 2020 Laboratory Practical Exercise GuideDocument39 pagesCourse - ASAP 2020 Laboratory Practical Exercise GuideHassan DMNo ratings yet

- Schedule Install Compressor CentrifugalDocument2 pagesSchedule Install Compressor CentrifugalredharereNo ratings yet

- JamnagarPresentation Thomas MathewDocument70 pagesJamnagarPresentation Thomas MathewsthegNo ratings yet

- Basic Hydrocyclone OperationDocument23 pagesBasic Hydrocyclone OperationGeorgi SavovNo ratings yet

- Chi tiết main servo DRU450Document1 pageChi tiết main servo DRU450Nguyễn Văn HùngNo ratings yet

- Universal Gas ConstantDocument2 pagesUniversal Gas ConstantArdhendu SamantaNo ratings yet

- Group5 PDFDocument11 pagesGroup5 PDFvzimak2355No ratings yet

- Gas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821-1!60!41-60Document20 pagesGas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821-1!60!41-60Karen VlNo ratings yet

- B50EL - S2 - 2018 - 19 GasDynamicsDesignExercise PDFDocument1 pageB50EL - S2 - 2018 - 19 GasDynamicsDesignExercise PDFWaqas NasirNo ratings yet

- 4 Vacuum PumpDocument4 pages4 Vacuum PumpMithun Singh Rajput100% (1)

- Air Conditioning System TheoryDocument3 pagesAir Conditioning System Theorymeenakshinathan100% (1)

- 3 Pipe Sizing 2013 3Document34 pages3 Pipe Sizing 2013 3siva anand100% (1)

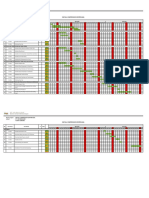

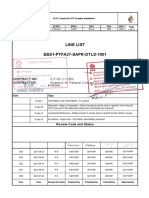

- Ebs1 Ptfa27 Sapr Dtls 1001 d04 Line List NapalmDocument5 pagesEbs1 Ptfa27 Sapr Dtls 1001 d04 Line List NapalmAhmedNo ratings yet

- What An Exhaust Does: MufflerDocument3 pagesWhat An Exhaust Does: Mufflermj recillaNo ratings yet

- ME FR Elec Quiz 004Document3 pagesME FR Elec Quiz 004Adrian Ray AyamNo ratings yet

- DENSODocument5 pagesDENSOItalo Riccelli100% (1)

- Blackmer - Specification InformationDocument2 pagesBlackmer - Specification InformationYlm PtanaNo ratings yet

- Flow Element: Base Maximum Flow Min Flow Property MethodDocument4 pagesFlow Element: Base Maximum Flow Min Flow Property Methodscploperation.2x50 CommonNo ratings yet

- A New Approach For Sizing Finger-Type (Multiple-Pipe) Slug CatchersDocument9 pagesA New Approach For Sizing Finger-Type (Multiple-Pipe) Slug CatchersnicolasNo ratings yet

- Life Cycle Assessment of Hydrogen Production Via Natural Gas Steam ReformingDocument33 pagesLife Cycle Assessment of Hydrogen Production Via Natural Gas Steam ReformingJosiph BukairNo ratings yet

- Levin NatVentTheoryDocument40 pagesLevin NatVentTheoryeimrehNo ratings yet

- Agar Multiphase Flow Meter For Wet-Gas MeasurementDocument17 pagesAgar Multiphase Flow Meter For Wet-Gas MeasurementmaylabinotiNo ratings yet

- Parker - H.cylinder Test ProcedureDocument1 pageParker - H.cylinder Test Procedureqrmjm67qkjNo ratings yet

Alia ADP D Diaphragm Seal

Alia ADP D Diaphragm Seal

Uploaded by

RexCrazyMindCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alia ADP D Diaphragm Seal

Alia ADP D Diaphragm Seal

Uploaded by

RexCrazyMindCopyright:

Available Formats

®

ALIADP

Direct-Mount / Remote diaphragm seal

Model D Series

GENERAL

ALIADP D series is a diaphragm seal product combining

APT8000 / ADP9000 / ADP9000L transmitter, which designed for the

high-viscosity/ granular/ high-temp./ high-corrosivity situation.

D series diaphragm seal assembles Alia pressure/DP transmitter

to form direct-mount / capillary-connections style.

FEATURES

The maximum temperature comes up to 280 °C

Multiple connection modes- Flange style / Tri-Clamp style

Multiple diaphragms/alternative connection material

Vegetable oil can be used to fill fluid for food industry

Extreme hot and cold temperature

Stainless Steel with PPC coating capillary

IDF Tri-Clamp or union screw connection for food industry

Oil free treatment & water free treatment

Fast and dynamic response

Improved performance, increased accuracy, great stability

SPECIFICATION

Process Fluid : Liquid, Gas or Vapor Installation Style

Application : Liquid Level, Differential Pressure, Direct-mount : APT8000 only

Gauge Pressure, Absolute Pressure One-sided capillary : APT8000 / ADP9000 / ADP9000L

Material Two-sided capillaries : ADP9000 only

Flange : Carbon steel Capillary Length : 1.0 M ~ 10 M

: Stainless Steel 304 Max. Temperature

: Stainless Steel 316 Direct-Mount : -20 to 80 °C

Diaphragms : Stainless Steel 316L Remote Diaphragm : -40 to 280 °C

: Hastelloy B Max. Pressure : 6.8 Mpa

: Hastelloy C Fill Fluid and Maximum : Silicone (Max. Temperature 130 °C)

: Tantalum Temperature : HT Silicone (Max. Temperature 280 °C)

: Stainless Steel with PTFE diaphragm : Fluorine (Max. Temperature 160 °C)

Capillary : Stainless Steel with PPC coating : Vegetable Oil (Max. Temperature 130 °C)

Flange Size : 40mm, 50mm, 80mm, 100mm Ambient Temperature : +/-0.18% of span per 20 °C

: 1-1/2", 2", 3", 4" Effect

Process connections : Flange Time Response : Less then 1.12 Seconds

Flanges rating : JIS 10K / JIS 20K / JIS 40K Options

: ANSI 150# / ANSI 300# / ANSI 600# Water Free Treatment : Transmitter shipping with water-free

: DIN PN10 / PN16 / PN25 / PN40 wetted parts

: Tri Clamp ( DIN32676 / ISO2852 ) Oil Free Treatment : Transmitter shipping with oil-free wetted

Extension Length : 2" , 3" , 4" parts

Accuracy : +/-0.075% of Span

Stability : +/-0.15% of URL for 2 years

ALIA GROUP INC. URL : www.alia-inc.com

113 Barksdale Professional Center, Newark, DE 19711, USA E-mail : alia@alia-inc.com

TEL : + 1 - 302 - 213 - 0106 FAX : + 1 - 302 - 213 - 0107 ADP_D_V1.1.5en

ALIADP Direct-Mount / Remote diaphragm seal Model D Series

MEASURE RANGE AND MAX. STATIC PRESSURE

Direct-Mount Diaphragm Min. Range Max. Range Min. Range Max. Range Max. Static Pressure

0 - 10 Kpa 0 - 100 Mpa 0 - 1019.7 mmH20 0 - 10197 MH2O

Pressure Transmitter

0 - 100 mbar 0 - 1000 bar 0 - 2.95 InH2O 0 - 401463 InH2O 100 Mpa

APT8000 with DD Series

0 - 1.45 psi 0 - 14504 psi 0 - 0.1 Kg/cm2 0 - 1020 kg/cm2

Remote Diaphragm Seal Min. Range Max. Range Min. Range Max. Range Max. Static Pressure

0 - 6.2 Kpa 0 - 6.8 Mpa 0 - 632 mmH20 0 - 693 MH2O

Pressure Transmitter

0 - 62 mbar 0 - 68 Bar 0 - 24.9 InH2O 0 - 27299 InH2O 6.8 Mpa

APT8000 with D1 Series

0 - 0.9 psi 0 - 986 psi 0 - 0.06 Kg/cm2 0 - 69.3 Kg/cm2

Differential Pressure 0 - 6.2 Kpa 0 - 6.8 Mpa 0 - 632 mmH20 0 - 693 MH2O

Transmitter 0 - 62 mbar 0 - 68 Bar 0 - 24.9 InH2O 0 - 27299 InH2O 6.8 Mpa

ADP9000 with D1 / D2 Series 0 - 0.9 psi 0 - 986 psi 0 - 0.06 Kg/cm2 0 - 69.3 Kg/cm2

0 - 6.2 Kpa 0 - 6.8 Mpa 0 - 632 mmH20 0 - 693 MH2O

Level Transmitter

0 - 62 mbar 0 - 68 Bar 0 - 24.9 InH2O 0 - 27299 InH2O 6.8 Mpa

ADP9000L with D1 Series

0 - 0.9 psi 0 - 986 psi 0 - 0.06 Kg/cm2 0 - 69.3 Kg/cm2

L H L H

ADP9000 with D1 Series ADP9000 with D2 Series

ALIA GROUP INC. ADP_D_V1.1.5en Page 2

ALIADP Direct-Mount / Remote diaphragm seal Model D Series

DIMENSIONS

APT8000 with DD Series

ADP9000L with D1 Series APT8000 with D1 Series

FLANGE TABLES

Dimension of Flange Bolt Dimension of Flange Bolt

Flange style Flange style

C D T H NO C D T H NO

1-1/2" JIS 10K 105 140 16 19 4 DN40 PN10 110 150 18 18 4

2" JIS 10K 120 155 16 19 4 DN50 PN10 125 165 20 18 4

3" JIS 10K 150 185 18 19 8 DN80 PN10 160 200 24 18 8

4" JIS 10K 175 210 18 19 8 DN100 PN 10 180 220 20 18 8

1-1/2" JIS 20K 105 140 16 19 4 DN40 PN16 110 150 18 18 4

2" JIS 20K 120 155 16 19 4 DN50 PN16 125 165 20 18 4

3" JIS 20K 160 200 20 23 8 DN80 PN16 160 200 24 18 8

4" JIS 20K 185 225 22 23 8 DN100 PN16 180 220 24 18 8

1-1/2" JIS 40K 120 160 24 23 4 DN40 PN25 110 150 18 18 4

2" JIS 40K 130 165 26 19 8 DN50 PN25 125 165 20 18 4

3" JIS 40K 170 210 32 23 8 DN80 PN25 160 200 24 18 8

4" JIS 40K 205 250 36 25 8 DN100 PN25 190 235 24 22 8

1-1/2" ANSI 150# 98.6 127 18 15.7 4 DN40 PN40 110 150 22 18 4

2" ANSI 150# 120.7 152.4 19 19.1 4 DN50 PN40 125 165 24 18 4

3" ANSI 150# 152.4 190.5 24 19.1 4 DN80 PN40 160 200 24 18 8

4" ANSI 150# 190.5 228.6 24 19.1 8 DN100 PN40 190 235 24 22 8

1-1/2" ANSI 300# 114.3 155.4 24.6 22.4 4 H

2" ANSI 300# 127 165.1 26.4 19.1 8

3" ANSI 300# 168.1 209.6 32.4 22.4 8 T

4" ANSI 300# 200.2 254 35.8 22.4 8 A

C

D

ALIA GROUP INC. ADP_D_V1.1.5en Page 3

ALIADP Direct-Mount / Remote diaphragm seal Model D Series

Model SELECTION GUIDE

D Series

Example: D2-A22B4-N05-W

D X- X X X X X -X XX -X Description

D- Direct-mount (APT8000 only)

Installation

1- One-sided capillary connects remote diaphragm seal

Style

2- Two-sided capillaries connect remote diaphragm seal (ADP9000 only)

1 PN10

2 PN16

3 PN25

4 PN40

A ANSI 150#

Process

B ANSI 300#

Connection

J JIS 10K

K JIS 20K

L JIS 40K

T Tri-clamp (DIN32676 / ISO2852)

Z Other

1 1-1/2" (If Include Extended Diaphragm, Diameter=32mm)

2 2" (If Include Extended Diaphragm, Diameter=49mm)

Flange Size

3 3" (If Include Extended Diaphragm, Diameter=64mm)

4 4" (If Include Extended Diaphragm, Diameter=89mm)

0 Flush Diaphragm

2 2" (50mm)

Diaphragm Extension Length

4 4" (100mm)

6 6" (150mm)

N Stainless Steel 316L

B Hastelloy B

C Hastelloy C

Diaphragm Material

T Tantalum

P Stainless Steel with PTFE diaphragm

Z Other

N Carbon Steel

4 Stainless Steel 304

Flange Material

6 Stainless Steel 316

Z Other

-N Silicone (Max. Temperature 130 °C)

-S HT Silicone (Max. Temperature 280 °C)

Fill Fluid

-F Fluorine (Max. Temperature 160 °C)

-V Vegetable Oil (Max. Temperature 130 °C)

NN Direct-Mount

Capillary Length

01-10 1 M ~ 10 M

- N None

Options

- W Oil Free and Water Free Treatment

ALIA GROUP INC. ADP_D_V1.1.5en Page 4

You might also like

- Plano Hidráulico Retroexcavadora 420fDocument13 pagesPlano Hidráulico Retroexcavadora 420fgerardo92% (13)

- RCU - RCUP AUZ SM Service ManualDocument36 pagesRCU - RCUP AUZ SM Service ManualRexCrazyMind100% (3)

- Ingersoll Rand - T30: Electric-Driven Single Stage & Two Stage Dry Type Vacuum PumpsDocument2 pagesIngersoll Rand - T30: Electric-Driven Single Stage & Two Stage Dry Type Vacuum PumpsstkmNo ratings yet

- Concession Map 16.01.2019Document1 pageConcession Map 16.01.2019Sathish100% (4)

- Medidor de Nivel PDFDocument4 pagesMedidor de Nivel PDFGarcia FranciscoNo ratings yet

- 8017031Document4 pages8017031alisuseNo ratings yet

- Transmisor de PresionDocument4 pagesTransmisor de PresionGarcia FranciscoNo ratings yet

- Man Sse Nae 8Document8 pagesMan Sse Nae 8Jorge Gustavo GoyecheaNo ratings yet

- Electromagnetic FlowmeterDocument5 pagesElectromagnetic FlowmeterEllen ShengNo ratings yet

- Electromagnetic Flow Meter: DN3-DN3000mm / Flange Connection / Integrated TypeDocument9 pagesElectromagnetic Flow Meter: DN3-DN3000mm / Flange Connection / Integrated TypeMPNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- Spirax Sarco Clean Steam FilterDocument6 pagesSpirax Sarco Clean Steam FilterMuhammad Ahsan KhanNo ratings yet

- 1.1.certificacion de Producto Macro 24 PulgadasDocument37 pages1.1.certificacion de Producto Macro 24 PulgadasNatalia RengifoNo ratings yet

- LUNNIMAG - Magnetic Level Gauge PDFDocument3 pagesLUNNIMAG - Magnetic Level Gauge PDFachmad arifNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterJane Umali CastilloNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterMohammad HosseinNo ratings yet

- Application: Nominal Dia (MM) DN 15 DN 3000Document3 pagesApplication: Nominal Dia (MM) DN 15 DN 3000guillermoNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- ALFAGOMMA Catalogue - HoseDocument35 pagesALFAGOMMA Catalogue - HoseGilles BrunengoNo ratings yet

- D3010 HSV600 ReducedDocument28 pagesD3010 HSV600 ReducedY.EbadiNo ratings yet

- Robust Pressure Transmitters T.3: 1.4404 / AISI 316LDocument4 pagesRobust Pressure Transmitters T.3: 1.4404 / AISI 316LRodica PuscauNo ratings yet

- Alfa Laval SPC 2 Regulating Valve Product LeafletDocument4 pagesAlfa Laval SPC 2 Regulating Valve Product LeafletNIO NIETONo ratings yet

- SHM Sewage FlowmeterDocument5 pagesSHM Sewage FlowmeterSaifudin ZuhriNo ratings yet

- Alia AUF790 Ultrasonic Open Channel FlowmeterDocument4 pagesAlia AUF790 Ultrasonic Open Channel FlowmeterRexCrazyMindNo ratings yet

- 1377 Duragauge Pressure Gauge: Data SheetDocument4 pages1377 Duragauge Pressure Gauge: Data SheetkarthikNo ratings yet

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezNo ratings yet

- FD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Document2 pagesFD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Guilherme ZanotelliNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Spring Push Pneumatic Push: Standard Series Standard Series DP/S DP/P Dimensions (MM)Document2 pagesSpring Push Pneumatic Push: Standard Series Standard Series DP/S DP/P Dimensions (MM)Arturo Garza SantosNo ratings yet

- Rev1 - 154-AC-YTKI-V-22-DH - PT. YTK INDONESIA - Rev.1Document2 pagesRev1 - 154-AC-YTKI-V-22-DH - PT. YTK INDONESIA - Rev.1sales-admin.bdgNo ratings yet

- Product Range - Tomoe ValvesDocument4 pagesProduct Range - Tomoe Valvesheru hsNo ratings yet

- Cmo Knife Gate ValvesDocument14 pagesCmo Knife Gate ValvesBruno PatracaNo ratings yet

- Norma Pipe Connections DIN-11864Document17 pagesNorma Pipe Connections DIN-11864bioNo ratings yet

- Nichicon CS Pencil CapacitorsDocument2 pagesNichicon CS Pencil CapacitorsVaslejeanNo ratings yet

- Datasheet n5500 Low Pressure Capsule GaugeDocument5 pagesDatasheet n5500 Low Pressure Capsule GaugeLuis AliagaNo ratings yet

- Water Flow MeterDocument6 pagesWater Flow Meterrommel5No ratings yet

- Ficha Mang Oxiacetileno BalflexDocument1 pageFicha Mang Oxiacetileno BalflexJUANPANIAGUANo ratings yet

- Walvoil Comando SD6DLS7 2019Document101 pagesWalvoil Comando SD6DLS7 2019Istenio Cassiano NetoNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- Folleto 75Document4 pagesFolleto 75ricardoNo ratings yet

- PressedDocument46 pagesPressedsameh aboulsoudNo ratings yet

- Vc-90200.01.03-En Ecoline DJDocument6 pagesVc-90200.01.03-En Ecoline DJGary IrawanNo ratings yet

- DS BDH Series ENDocument13 pagesDS BDH Series EN9033301054No ratings yet

- CATALOG - Final - Low ResulotionDocument66 pagesCATALOG - Final - Low ResulotionKadiri El MoustaphaNo ratings yet

- TA-Modulator EN LowDocument16 pagesTA-Modulator EN Lowkap4enijNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Differential Pr. Gauges Diaphragm TypeDocument4 pagesDifferential Pr. Gauges Diaphragm TypeVara PrasadNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- ISOBUS Flyer Amphenol ConnectorDocument4 pagesISOBUS Flyer Amphenol ConnectorGustavo ParlantiNo ratings yet

- Diaphragm Sensing Pressure Gauges 1Document2 pagesDiaphragm Sensing Pressure Gauges 1Wency JavateNo ratings yet

- ManometreDocument6 pagesManometreAbdo KouNo ratings yet

- Stainless Steel Pressure Filters - BrochureDocument20 pagesStainless Steel Pressure Filters - Brochureviktor_gligorovNo ratings yet

- APT8000V1 2 3 r4 LT enDocument4 pagesAPT8000V1 2 3 r4 LT enThanh Tung NguyenNo ratings yet

- General Pressure Gauge (GP Series) PG1111Document1 pageGeneral Pressure Gauge (GP Series) PG1111Tran Quoc Thinh - M&ENo ratings yet

- General Pressure Gauge (GP Series) PG1111Document1 pageGeneral Pressure Gauge (GP Series) PG1111Jf OngNo ratings yet

- Alia AVF250 Variable Area FlowmeterDocument4 pagesAlia AVF250 Variable Area FlowmeterRexCrazyMindNo ratings yet

- General Specifications: Y/17B6 Pneumatic Buoyancy TransmitterDocument3 pagesGeneral Specifications: Y/17B6 Pneumatic Buoyancy Transmitterمحمد امين التشغيل الآليNo ratings yet

- Technical Datasheet Knife Gate Valve Stainless Steel Epdm pn10 SgateDocument14 pagesTechnical Datasheet Knife Gate Valve Stainless Steel Epdm pn10 Sgateruiz sumarNo ratings yet

- Industrial Pressure Gauge Model: P52: Standard SpecificationDocument2 pagesIndustrial Pressure Gauge Model: P52: Standard SpecificationPort VideoNo ratings yet

- FME800 - Compressed MagnaticoDocument5 pagesFME800 - Compressed MagnaticocalymosqueraNo ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Dao 2000-98 PDFDocument179 pagesDao 2000-98 PDFJohnKevinVillarNo ratings yet

- CNC CIP Flow Diagram Rev0Document1 pageCNC CIP Flow Diagram Rev0RexCrazyMindNo ratings yet

- Rcu - Rcup-Auz - SC2-P02QDocument56 pagesRcu - Rcup-Auz - SC2-P02QRexCrazyMind50% (2)

- Vortex TrainingDocument17 pagesVortex TrainingRexCrazyMindNo ratings yet

- Variable Area TrainingDocument12 pagesVariable Area TrainingRexCrazyMindNo ratings yet

- Paperless Recorder TrainingDocument9 pagesPaperless Recorder TrainingRexCrazyMindNo ratings yet

- Variable Area TrainingDocument12 pagesVariable Area TrainingRexCrazyMindNo ratings yet

- Training For ALIA Ultrasonic FlowmeterDocument20 pagesTraining For ALIA Ultrasonic FlowmeterRexCrazyMind100% (1)

- Vortex TrainingDocument17 pagesVortex TrainingRexCrazyMindNo ratings yet

- VTX TrainingDocument9 pagesVTX TrainingRexCrazyMindNo ratings yet

- Alia APF810 Oval Gear FlowmeterDocument4 pagesAlia APF810 Oval Gear FlowmeterRexCrazyMindNo ratings yet

- Alia AMC3100 ConverterDocument4 pagesAlia AMC3100 ConverterRexCrazyMindNo ratings yet

- Training For ALIA MAG: Specifications About Electromagnetic FlowmeterDocument18 pagesTraining For ALIA MAG: Specifications About Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Mag TrainingDocument17 pagesMag TrainingRexCrazyMindNo ratings yet

- Paperless Recorder TrainingDocument9 pagesPaperless Recorder TrainingRexCrazyMindNo ratings yet

- Mag TrainingDocument17 pagesMag TrainingRexCrazyMindNo ratings yet

- Alia AMC4000 ConverterDocument4 pagesAlia AMC4000 ConverterRexCrazyMindNo ratings yet

- DP PT TrainingDocument19 pagesDP PT TrainingRexCrazyMindNo ratings yet

- Alia Technology LLC: Electromagnetic FlowmeterDocument11 pagesAlia Technology LLC: Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Alia APT3000 Pressure TransmitterDocument2 pagesAlia APT3000 Pressure TransmitterRexCrazyMindNo ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Alia AMF601 Electromagnetic FlowmeterDocument4 pagesAlia AMF601 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Alia ARC1000 Paperless RecorderDocument4 pagesAlia ARC1000 Paperless RecorderRexCrazyMindNo ratings yet

- Alia Apf850 Oval GearDocument4 pagesAlia Apf850 Oval GearRexCrazyMindNo ratings yet

- Alia ARC900 Paperless RecordersDocument4 pagesAlia ARC900 Paperless RecordersRexCrazyMindNo ratings yet

- Alia ARH950 Relative Humidity TransmitterDocument2 pagesAlia ARH950 Relative Humidity TransmitterRexCrazyMindNo ratings yet

- r5310302 Hydraulic Machinery and SystemsDocument4 pagesr5310302 Hydraulic Machinery and SystemswirelessandlessNo ratings yet

- Capillary Flow PorosimetryDocument3 pagesCapillary Flow PorosimetryAlokaNo ratings yet

- DistillationDocument8 pagesDistillationsahil khandelwalNo ratings yet

- Koppel Wall Mounted Split Type Super Inverter Aria SeriesDocument1 pageKoppel Wall Mounted Split Type Super Inverter Aria SeriesJohn Rodolfo BultronNo ratings yet

- Course - ASAP 2020 Laboratory Practical Exercise GuideDocument39 pagesCourse - ASAP 2020 Laboratory Practical Exercise GuideHassan DMNo ratings yet

- Schedule Install Compressor CentrifugalDocument2 pagesSchedule Install Compressor CentrifugalredharereNo ratings yet

- JamnagarPresentation Thomas MathewDocument70 pagesJamnagarPresentation Thomas MathewsthegNo ratings yet

- Basic Hydrocyclone OperationDocument23 pagesBasic Hydrocyclone OperationGeorgi SavovNo ratings yet

- Chi tiết main servo DRU450Document1 pageChi tiết main servo DRU450Nguyễn Văn HùngNo ratings yet

- Universal Gas ConstantDocument2 pagesUniversal Gas ConstantArdhendu SamantaNo ratings yet

- Group5 PDFDocument11 pagesGroup5 PDFvzimak2355No ratings yet

- Gas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821-1!60!41-60Document20 pagesGas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821-1!60!41-60Karen VlNo ratings yet

- B50EL - S2 - 2018 - 19 GasDynamicsDesignExercise PDFDocument1 pageB50EL - S2 - 2018 - 19 GasDynamicsDesignExercise PDFWaqas NasirNo ratings yet

- 4 Vacuum PumpDocument4 pages4 Vacuum PumpMithun Singh Rajput100% (1)

- Air Conditioning System TheoryDocument3 pagesAir Conditioning System Theorymeenakshinathan100% (1)

- 3 Pipe Sizing 2013 3Document34 pages3 Pipe Sizing 2013 3siva anand100% (1)

- Ebs1 Ptfa27 Sapr Dtls 1001 d04 Line List NapalmDocument5 pagesEbs1 Ptfa27 Sapr Dtls 1001 d04 Line List NapalmAhmedNo ratings yet

- What An Exhaust Does: MufflerDocument3 pagesWhat An Exhaust Does: Mufflermj recillaNo ratings yet

- ME FR Elec Quiz 004Document3 pagesME FR Elec Quiz 004Adrian Ray AyamNo ratings yet

- DENSODocument5 pagesDENSOItalo Riccelli100% (1)

- Blackmer - Specification InformationDocument2 pagesBlackmer - Specification InformationYlm PtanaNo ratings yet

- Flow Element: Base Maximum Flow Min Flow Property MethodDocument4 pagesFlow Element: Base Maximum Flow Min Flow Property Methodscploperation.2x50 CommonNo ratings yet

- A New Approach For Sizing Finger-Type (Multiple-Pipe) Slug CatchersDocument9 pagesA New Approach For Sizing Finger-Type (Multiple-Pipe) Slug CatchersnicolasNo ratings yet

- Life Cycle Assessment of Hydrogen Production Via Natural Gas Steam ReformingDocument33 pagesLife Cycle Assessment of Hydrogen Production Via Natural Gas Steam ReformingJosiph BukairNo ratings yet

- Levin NatVentTheoryDocument40 pagesLevin NatVentTheoryeimrehNo ratings yet

- Agar Multiphase Flow Meter For Wet-Gas MeasurementDocument17 pagesAgar Multiphase Flow Meter For Wet-Gas MeasurementmaylabinotiNo ratings yet

- Parker - H.cylinder Test ProcedureDocument1 pageParker - H.cylinder Test Procedureqrmjm67qkjNo ratings yet