Professional Documents

Culture Documents

Nitomortar PE PDF

Nitomortar PE PDF

Uploaded by

JoeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitomortar PE PDF

Nitomortar PE PDF

Uploaded by

JoeCopyright:

Available Formats

Nitomortar® PE constructive solutions

Resin jointing and repair compound

Uses

Technical support

For fast and emergency resinstatement of concrete.

The company provides a technical advisory service supported

For bedding, jointing, profiling of concrete, repair of damaged by a team of specialists in the field.

concrete in precast units, jointing between precast units,

repair of stair treads, fixing tiles, cladding, repairs to kerbs,

Properties

man hole covers, door and window frames etc.

The mixing of resin and hardener starts a polymerisation

Advantages process resulting in excellent mechanical properties like high

compressive strength ( Table 1), high flexural and tensile

Durable - Stronger than concrete. Highly chemical and oil strength ( Table 2), chemical resistance of the cured material

resistant. Excellent bond strength. to chemicals like acids, mild alkalis, oil and petrol.

Ease of application - Mix resin and hardener in any

proportion as required. No primer is required.

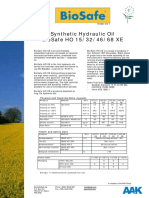

Shrinkage Volume Linear

Quick - Finish job operation in 2 - 3 hours.

Nitomortar PE

Versatile- Can be poured, trowelled, filled with coarse

mortar (1:3.2 by vol) 3.5% 0.8%

aggregates. Will cure in dry, wet, damp, and under water

Nitomortar PE concrete 2.7% 0.8%

conditions. Can be used at down to 00C or upto 600C.

Specification clauses

Description

Jointing and multi-purpose polyester repair mortar

Nitomortar PE is based on polyester resin system. Product

is supplied as resin and hardener for varied applications viz. The high strength jointing and repair mortar shall be Nitomortar

jointing, patching and repairing. It is available in two grades. PE, a two component polyester resin. The mortar shall be

capable of use at a wide range of consistencies without

significantly affecting setting times or strengths. When applied

Nitomortar PE : For general repairs ( resin and

at a flowable consistency, the cured product shall exhibit a

hardener only)

compressive strength of 75N/mm2, a flexural strength of 25N/

Nitomortar PE : To fill larger volumes allowing mm2 and tensile strength of 12N/mm2 at 7 days.

concrete users to add aggregates and

thereby substantially reducing the

cost.

Table 1 Typical compressive strength results

Product Temp. Gel Time Compressive Strength N/mm2

3 Hours 24 Hours 7 days

Nitomortar PE 25 0C 30 min. 45 72 78

Nitomortar PE Concrete 25 0C 30 min. 27 65 76

Table 2 Typical Flexural and tensile strength results

Product Consistency Resin and Hardener Ratio Approx. Young’s Flexural Tensile

By Vol. By wt. Density Modulus Strength Strength

Kg/m3 N/mm2 N/mm 2 N/mm2

Nitomortar® PE

@ 7 days @ 7 days

Nitomortar PE Trowellable 1:3:2 1:4:2 1920 20x103

Pourable 1:2:5 1:3:5 1840 16x103 25 12

Flowable 1:1:6 1:2 1680 10x103

Nitomortar® PE

Multi-purpose polyester repair concrete Nitomortar PE Concrete

The high strength repair concrete shall be Nitomortar PE The following proportions may be used as a guideline for

Concrete, a two component polyester mortar capable of site making Nitomotar PE Concrete :

modification with suitable aggregates. The repair concrete

Resin Hardener Sand Coarse

shall be capable of use at a range of consistencies without

Zone II aggre. 10mm

significantly affecting setting times or strengths. The cured

product shall exhibit a compressive strength of 76N/mm2, a By volume 1 0.8 3.2 --

flexural strength of 25N/mm2 and a tensile strength of 12N/

mm2 at 7 days. By volume 1 0.8 1.45 2.5

with coarse

Application instructions aggregate

By weight 1 1.0 1.6 1.6

Preparation

For making Nitomortar PE concrete, the resin and hardener

All surfaces must be preferably dry and free from oil, loose

shall be mixed in the proportion recommended above and

particles and laitance.

sand and coarse aggregate shall be added and mixed

Mixing thoroughly on a clean board to obtain resin concrete.

The required quantity of resin shall be poured into a plastic Maximum thickness in one layer : 40mm

bucket and the powder hardener shall be added slowly with

Limit plan area to 0.75m for each application. Linear strips

stirring thoroughly until uniform consistency is obtained. It is

should be placed in 1m maximum run at each application.

recommended that small quantities be mixed at a time and

used since pot life of the mixed material decreases at elevated Cleaning

temperatures.

All tools and equipment must be cleaned with Nitoflor Sol,

The Table 2 may be used as a guideline for mixing. solvent immediately after use.

Placing Nitomortar PE - Typical applications

Ensure that resin mortar is trowelled firmly into place to obtain

good adhesion. In the case of dense substrates, priming with Repairing broken, worn or spalled concrete re-profiling arises

resin only or resin and hardener in flowable consistency should of slabs, mullions, columns, beams, posts, sills and precast

be carried out to ensure surface is completely wetted out. units.

Maximum thickness of mortar in one layer permissible is For small/local repairs : Wire brush, clean

12mm. ( If thickness more than 12mm is required the same is off dust and loose material.

achieved in two or more layers with a gap of atleast 4 hours Use : Nitomortar PE - Trowellable mix (or

between each layer). Nitomortar PE is not recommended for pourable mix for deep vertical cracks or

repairs of large areas where Nitomortar S is more suited. holes).

Limit plan area to 0.3m x 0.3m and linear strips should be For more extensive repairs : Cut back

placed in 1m maximum run at each application. concrete to firm sound material. Treat any

exposed steel with Nitozinc Primer ( see

separate datasheet for details).

Use Nitomortar PE - Trowellable mix. Build

up to original profile.

Nitomortar® PE

Filling day work joints and setting expansion strips Brackets, support bars, dowel plugs, air bricks, ventilator

frames, etc.,

Brush, clean off loose material. Set

expansion joint material if applicable. Use Nitomortar PE - Trowellable mix. Exactly

as with cement mortar.

Use Nitomortar PE - Trowellable or

flowable mix. Contouring and Profiling

Filling depression in worn steps or slabs Fairing walls for tiling, plastering or painting. Rendering vertical

faces for improvement, protection or additional cover to

Chip or peck hammer surface to ensure a

reinforcement in exposed positions.

key. Set greased or oiled shuttering if

necessary. Surface must be firm and free from loose

material and laitance. Abrade and

Use Nitomortar PE - Pourable mix.

roughen very smooth surfaces.

Location and Fixing

Use Nitomortar S. (See separate datasheet).

Coping and kerb stones onto concrete, brickwork or asphalt.

Forming gullies, run-offs, channels, ramp, edges, etc. for

Remove dust and loose material and ensure substrate is

stormwater or foul water.

dry.

Hack or key surface and wire brush free of

Use Nitomortar PE - Trowellable mix. Apply

dust.

a mortar bed as usual. Set and level stone

immediately. Use Nitomortar S. ( See separate data

sheet). Form to a finish as required. Fair

Leave to set.

finish curbed gullies can be formed with half

The same Nitomortar PE material may be round metal-guttering section.

used to butter ends to form mortar joints.

Bedding, Jointing and Sealing

Paving slabs, grano or quarry tiles

Bedding and jointing precast units, slabs, lintels, steps,

Use Nitomortar PE - Trowellable mix. partitions and bearer plates.

Paving slabs Bedding base :

Use spot Nitomortar PE pads. Set and level Ensure substrate is clean and free from dust

each slab immediately. and loose material.

Use Nitomortar PE - Trowellable mix. Align

and support unit immediately. Leave to set.

Tiles

Vertical Joints :

Spread Nitomortar PE in an even bed using

a notched trowel. Press tiles gently to Ensure surfaces are clean and free from

finished level. Wipe off any surplus dust and loose material.

material from face. Leave to set grout with

Use Nitomortar PE - Trowellable mix. Joint

cement slurry as usual.

and align panels immediately. Leave to set.

Posts, railings and balustrading in concrete

Bedding and sealing manhole and drain cover frames, door

Cut or, preferably, drill holes with rotary and window frames and pipe unions.

percussive air drill and flush clear off dust.

Manhole/drain covers and brickwork linings. Ensure Corbel is

Keep holes small, i.e., 1 - 2mm ( 1/2") space

clean and surface damp/dry.

all round post.

For small jobs.

Use Nitomortar PE - Flowable mix. Pour in

hole, insert post, top uphole if necessary. Use Nitomortar PE - Trowellable mix.

Prop vertical unit to set.

Nitomortar® PE

For large jobs. Nitomortar PE concrete will Storage

show considerable cost saving -

consult Fosroc for details. Shelf life

For vertical brickwork repair 6 months shelf life when stored below 25 deg.C in original

unopened containers. Storage at low temperatures extends

Use Nitomortar PE. shelf life. High storage temperatures will shorten the shelf

life significantly.

1. Pipe unions of stormwater or

foulwater.

Precautions

2. Bedding window or door frames.

Health & Safety instructions

Use Nitomortar PE - Trowellable mix.

It is recommended that gloves should be worn while handling

resin products. If contact with skin occurs, skin should be

Bedding and fixing slip bricks, stone slips and facing tiles.

washed immediately with soap and water. Solvents should

Use Nitomortar PE - Trowellable mix. First not be used for cleaning hands.

coat brick and concrete faces with resin rich

Fire

mix. Apply Nitomortar PE to bricks or

tiles lightly on back and one end with Confined areas must be well ventilated and no naked flames

trowellable mix. Press gently into position or smoking must be allowed during use.

to develop suction. Avoid excess Nitomortar PE being forced

out onto face. Leave to set. Point with cement mortar to

Additional information

match main facing work.

The Fosroc range of repair mortars includes epoxy resin

Estimating bedding, jointing, grouting and repair compounds, rapid

hardeners for cement and filled epoxy resin mortars for

Packing underwater repairs.

Nitomortar PE - supplied in 5 litre packs. Separate datasheets are available on these products.

Nitomortar PE Concrete : Supplied in 5 litre packs. When

mixed with appropriate amount of aggregate, the the volume

will vary between 9 litres and 19 litres.

® Denotes the trademark of Fosroc International Limited

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold subject

to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst

Fosroc endeavours to ensure that any advice, recommendation specification or information it may

give is accurate and correct, it cannot, because it has no direct or continuous control over where

or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products whether or not in accordance with any advice, specification, recommendation

Fosroc Chemicals (India) Pvt. Ltd. or information given by it.

Head Office telephone fax e-mail

111/3, Hafeeza Chamber II Floor,

++91 80-22240018/120 ++91 80-22233474 india@fosroc.com

K H Road, PBNo. 2744, Bangalore 560027

www.fosroc.com

Regional Offices

Bangalore Mumbai Delhi Kolkata

Shankar House, IV Floor 208/209, Persepolis First floor,1/2 East Patel Nagar 30/B Jodhpur Park

1 & 18, RMV Extension Sector 17, Vashi Opp: Vivek Cinema, Main Patel Rd Ground Floor

Bangalore 560 080 Navi Mumbai 400 703 New Delhi 110 008 Kolkata 700 068

Ph:080-2361 3161/2361 2004 Ph:022-2789 6412/14 Ph:011-25884903/4 Ph: 033 2472 5482

Fax : 080-2361 7454 Fax: 022 - 2789 6413 Fax: 011- 25884422 Fax: 033-2472 9921

email: Bangalore@fosroc.com email:Mumbai@fosroc.com email:Delhi@fosroc.com email:Kolkata@fosroc.com

Ahmedabad : (079) 26762799 Ankleshwar :(02646) 220704/224687 Bhubaneshwar : (0674) 2521176 Chennai (044) 24899949/24853383

Chandigarh : (0172) 2639360 Cochin : (0484) 2356668 Coimbatore : (0422) 2472966 Goa : (0832) 2542465 Guwahati (0361) 2548793

Hyderabad : (040) 27662324/27662425 Hubli (0836) 3402597 Indore : (0731) 504339/5061477 Jaipur : (0141) 2235349 Lucknow :(0522)

22239044 Nagercoil (04652) 2224849 Mangalore: (0824) 22272234 Visakhapatnam : (0891) 2564850 INDIA/2004/0410/E

You might also like

- Nitomortar TC2000 PDFDocument3 pagesNitomortar TC2000 PDFtalatzahoor100% (2)

- TDS Conbextra GP3 IndiaDocument4 pagesTDS Conbextra GP3 IndiaashishroshanNo ratings yet

- The Diagram Shows Electrolysis of Sodium ChlorideDocument17 pagesThe Diagram Shows Electrolysis of Sodium Chlorideapi-25909541No ratings yet

- Fosroc Nitomortar PEDocument5 pagesFosroc Nitomortar PEShahril ZainulNo ratings yet

- TDS Renderoc RG India PDFDocument3 pagesTDS Renderoc RG India PDFrajiv_quantumNo ratings yet

- TDS Renderoc RG IndiaDocument3 pagesTDS Renderoc RG IndiaPrad RNo ratings yet

- Conbextra GP PremixDocument3 pagesConbextra GP Premixtabah sentosaNo ratings yet

- Renderoc RGDocument3 pagesRenderoc RGR.ThangarajNo ratings yet

- Fosroc Renderoc Tgxtra: Constructive SolutionsDocument2 pagesFosroc Renderoc Tgxtra: Constructive SolutionsVincent JavateNo ratings yet

- Nitomortar FCFSDocument2 pagesNitomortar FCFSMansoor AliNo ratings yet

- TDS Renderoc RG SPL IndiaDocument3 pagesTDS Renderoc RG SPL IndiaKumar SundaramNo ratings yet

- Renderoc TGXTRADocument2 pagesRenderoc TGXTRAMansoor AliNo ratings yet

- TDS Renderoc RG IndiaDocument3 pagesTDS Renderoc RG IndiaBijaya RaulaNo ratings yet

- DR - Fixit Micro ConcreteDocument3 pagesDR - Fixit Micro ConcreteKiran KumarNo ratings yet

- Polymer Modified MortarDocument4 pagesPolymer Modified MortarstelogoNo ratings yet

- TDS Renderoc TG Saudi ArabiaDocument4 pagesTDS Renderoc TG Saudi Arabiaumn_mlkNo ratings yet

- Masteremaco® N 900Document3 pagesMasteremaco® N 900Ahmed aalatbeeyNo ratings yet

- Nitomortar S: Constructive SolutionsDocument4 pagesNitomortar S: Constructive SolutionsjitendraNo ratings yet

- Nitomortar TC2000Document3 pagesNitomortar TC2000Ahmed Imad Al-BdairiNo ratings yet

- Pro Mastic Ste 87Document4 pagesPro Mastic Ste 87ahmedyahea181No ratings yet

- TDS - Nitomortar SDocument4 pagesTDS - Nitomortar SDipNo ratings yet

- Nitomortar GP, BC & UA: Two-Part Epoxy Resin MortarsDocument3 pagesNitomortar GP, BC & UA: Two-Part Epoxy Resin MortarssiranepNo ratings yet

- Nitomortar FC PDFDocument2 pagesNitomortar FC PDFganmosesNo ratings yet

- Fosroc Nitomortar EL: Constructive SolutionsDocument4 pagesFosroc Nitomortar EL: Constructive SolutionsVincent JavateNo ratings yet

- Renderoc GPDocument4 pagesRenderoc GPRohan PersaudNo ratings yet

- TDS Renderoc RG SPL IndiaDocument3 pagesTDS Renderoc RG SPL IndialavekushNo ratings yet

- Pf-2211.en 10143Document2 pagesPf-2211.en 10143Dandi ZulkarnainNo ratings yet

- Conbextra GP Premix: General Purpose Non-Shrink Cementitous GroutDocument3 pagesConbextra GP Premix: General Purpose Non-Shrink Cementitous GroutDuta M PuteraNo ratings yet

- CFRP PropertiesDocument2 pagesCFRP Propertiesswapnil gandhiNo ratings yet

- Fosroc Nitomortar FC (FS) : Constructive SolutionsDocument2 pagesFosroc Nitomortar FC (FS) : Constructive SolutionsVincent JavateNo ratings yet

- Nitobond SBR Latex: Constructive SolutionsDocument3 pagesNitobond SBR Latex: Constructive SolutionsKamal RaoNo ratings yet

- Sikacrete® 114 4Document2 pagesSikacrete® 114 4aslam baigNo ratings yet

- Nitobond ArDocument2 pagesNitobond Aradilabad newsNo ratings yet

- TDS Renderoc RGM IndiaDocument4 pagesTDS Renderoc RGM IndiaKishore Nayak kNo ratings yet

- Fosroc Nitomortar MH: Solvent Free Epoxy Lining and Benching MortarDocument4 pagesFosroc Nitomortar MH: Solvent Free Epoxy Lining and Benching MortarVincent JavateNo ratings yet

- TDS Nitoproof Damp Protect India3Document2 pagesTDS Nitoproof Damp Protect India3reshmitapallaNo ratings yet

- Pre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDocument2 pagesPre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDaniel PratamaNo ratings yet

- TDS Renderoc RG SPL India2Document3 pagesTDS Renderoc RG SPL India2Sam WitwickyNo ratings yet

- MasterEmaco SBR 2Document3 pagesMasterEmaco SBR 2Radja NurNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELMansoor AliNo ratings yet

- Renderoc LAXtraDocument2 pagesRenderoc LAXtraMansoor Ali100% (1)

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315No ratings yet

- Nitomortar HBDocument4 pagesNitomortar HBAhmed Imad Al-BdairiNo ratings yet

- Fosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveDocument2 pagesFosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveVincent JavateNo ratings yet

- SikaWrap 231 C PDS PDFDocument4 pagesSikaWrap 231 C PDS PDFMohit KohliNo ratings yet

- MasterEmaco 2525 ASEAN V1.4 0713Document2 pagesMasterEmaco 2525 ASEAN V1.4 0713Muhammad Fadhil ImansyahNo ratings yet

- Renderoc TgxtraDocument2 pagesRenderoc TgxtratalatzahoorNo ratings yet

- Impact of Petroleum Products On Strength of Concrete IJERTV8IS050352Document4 pagesImpact of Petroleum Products On Strength of Concrete IJERTV8IS050352Farsin SignupsNo ratings yet

- Conbextra EP10 (M)Document2 pagesConbextra EP10 (M)abhay_joshi2002No ratings yet

- Polydek: Elastomeric, Single Component Water-Based Waterproofing MembraneDocument4 pagesPolydek: Elastomeric, Single Component Water-Based Waterproofing MembraneprasadNo ratings yet

- Emaco Nanocrete R3 - PDS - ASEAN - 241110Document3 pagesEmaco Nanocrete R3 - PDS - ASEAN - 241110Andri AjaNo ratings yet

- Nitomortar MHDocument4 pagesNitomortar MHMansoor AliNo ratings yet

- Fosroc Nitofix: Constructive SolutionsDocument2 pagesFosroc Nitofix: Constructive SolutionsVincent JavateNo ratings yet

- Sikadur - 31: 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur - 31: 2-Part Thixotropic Epoxy AdhesiveKesto BhaktaNo ratings yet

- Repair Materials IntroductionDocument13 pagesRepair Materials IntroductionSiti Rohani IsdrisNo ratings yet

- Method Statement For Rectifying Cracks by Injection Method On Floor Slab - Wall - Ceiling of Precast Components - RfaDocument50 pagesMethod Statement For Rectifying Cracks by Injection Method On Floor Slab - Wall - Ceiling of Precast Components - Rfakomt qaqcNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Sikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarDocument2 pagesSikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarJoana Marie Perciano100% (1)

- Guncrete: High Strength, Low Shrinkage, High Build Spray Applied Repair MortarDocument4 pagesGuncrete: High Strength, Low Shrinkage, High Build Spray Applied Repair MortarZac Francis DaymondNo ratings yet

- Guncrete: High Strength, Low Shrinkage, High Build Spray Applied Repair MortarDocument4 pagesGuncrete: High Strength, Low Shrinkage, High Build Spray Applied Repair MortarZac Francis DaymondNo ratings yet

- S 70 Eurofins Leed Conformation Eq 4 1 20101015 e 1Document2 pagesS 70 Eurofins Leed Conformation Eq 4 1 20101015 e 1JoeNo ratings yet

- S 10 Eurofins Leed Confirmation Eq 4 1 20101019 e 1Document2 pagesS 10 Eurofins Leed Confirmation Eq 4 1 20101019 e 1JoeNo ratings yet

- Ottocoll® P83: The PU Adhesive/sealantDocument3 pagesOttocoll® P83: The PU Adhesive/sealantJoeNo ratings yet

- Ottoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsDocument3 pagesOttoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsJoeNo ratings yet

- Ottoseal® S70: The Premium Natural Stone SiliconeDocument5 pagesOttoseal® S70: The Premium Natural Stone SiliconeJoeNo ratings yet

- Ottoseal® S94: Technical DatasheetDocument3 pagesOttoseal® S94: Technical DatasheetJoeNo ratings yet

- Ottoseal® S 120: The Premium Alkoxy Window SiliconeDocument5 pagesOttoseal® S 120: The Premium Alkoxy Window SiliconeJoeNo ratings yet

- Ottocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantDocument4 pagesOttocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantJoeNo ratings yet

- Ottocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingDocument3 pagesOttocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingJoeNo ratings yet

- Tds OTTOCOLL M 500 42 - 28gb PDFDocument4 pagesTds OTTOCOLL M 500 42 - 28gb PDFJoeNo ratings yet

- Ottocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionDocument4 pagesOttocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionJoeNo ratings yet

- Otto Primer 1216: The Primer For Natural Stone and MetalDocument2 pagesOtto Primer 1216: The Primer For Natural Stone and MetalJoeNo ratings yet

- Otto Cleanprimer 1101: The Adhesion ImproverDocument2 pagesOtto Cleanprimer 1101: The Adhesion ImproverJoeNo ratings yet

- Sika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairDocument3 pagesSika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairJoeNo ratings yet

- The ASTM D4263 Concrete Moisture TestDocument4 pagesThe ASTM D4263 Concrete Moisture TestJoe100% (1)

- Sikadur - 52: Low Viscosity Injection ResinDocument3 pagesSikadur - 52: Low Viscosity Injection ResinJoeNo ratings yet

- Sikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveJoeNo ratings yet

- Gen Chem 2 ExamDocument2 pagesGen Chem 2 ExamChristian Lloyd ReandinoNo ratings yet

- R Satish Kumar: Rgmcet-NandyalDocument21 pagesR Satish Kumar: Rgmcet-NandyalGopi RamNo ratings yet

- Brosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaDocument13 pagesBrosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaAlvindo Catur SentosaNo ratings yet

- Sandvik - Technical Guide - Materials ISODocument41 pagesSandvik - Technical Guide - Materials ISOznovak77100% (1)

- BSR 2016-Renovation PDFDocument141 pagesBSR 2016-Renovation PDFthareendaNo ratings yet

- MIL-H-6875H Heat Treatment of Steel, Process For (SS by SAE-AMS-H-6875)Document29 pagesMIL-H-6875H Heat Treatment of Steel, Process For (SS by SAE-AMS-H-6875)320338100% (7)

- Lubrication and Piston Rings AmoserDocument44 pagesLubrication and Piston Rings AmoserrafaelNo ratings yet

- Hardnes TestDocument25 pagesHardnes TestSagun AlmarioNo ratings yet

- Asme Sa193 Grade b16Document8 pagesAsme Sa193 Grade b16q alexNo ratings yet

- Detailed DrawingsDocument1 pageDetailed DrawingsTAFADZWA K CHIDUMANo ratings yet

- Astm D2688 23Document4 pagesAstm D2688 23henryaan12No ratings yet

- D977 13e1.pdf (EngPedia - Ir)Document4 pagesD977 13e1.pdf (EngPedia - Ir)Baba Mountain Gem ServicesNo ratings yet

- Banlaw Sales Brochures Flush Face CouplingsDocument2 pagesBanlaw Sales Brochures Flush Face Couplingsapi-3752216100% (2)

- Child and Adolescent Labour (Prohibition and Regulation) Act, 1986Document26 pagesChild and Adolescent Labour (Prohibition and Regulation) Act, 1986sajal sanatanNo ratings yet

- Raychem DS H56870 XMIA EN - tcm432 37895Document9 pagesRaychem DS H56870 XMIA EN - tcm432 37895Sachin SehgalNo ratings yet

- Module 1 PDFDocument8 pagesModule 1 PDFANGELICA GARCIANo ratings yet

- HO OilDocument1 pageHO OilFahrul Rezi AdzaniNo ratings yet

- P2620 CPD SheetDocument1 pageP2620 CPD SheetAlejandra Rodriguez NocuaNo ratings yet

- Method Statement of Refrigran Pipe Insulation and Cladding InstallationDocument16 pagesMethod Statement of Refrigran Pipe Insulation and Cladding InstallationOdot Al GivaryNo ratings yet

- Glassware Cleaning Standard Operating ProcedureDocument5 pagesGlassware Cleaning Standard Operating ProceduretriNo ratings yet

- Presentation 1Document19 pagesPresentation 1Ika ChasaNo ratings yet

- Forensic 2 Week 14Document20 pagesForensic 2 Week 14mindy sansanNo ratings yet

- Nyfgby: Twin Cores, Armoured Cable Low Voltage Armoured CableDocument6 pagesNyfgby: Twin Cores, Armoured Cable Low Voltage Armoured CableOffice ccNo ratings yet

- Br09 Tds Bladerep Lep 9Document2 pagesBr09 Tds Bladerep Lep 9Swarf DwarfNo ratings yet

- MD - IMO - 269 - EU of ACS2 Sys. Cont.Document1 pageMD - IMO - 269 - EU of ACS2 Sys. Cont.remakermaritime.cgpNo ratings yet

- PART 142 What Is Corrosion - Definition and PreventionDocument3 pagesPART 142 What Is Corrosion - Definition and Preventionravindra_jivaniNo ratings yet

- Weldability Testing For Advanced MaterialsDocument8 pagesWeldability Testing For Advanced MaterialsJim BetsingerNo ratings yet

- Analisis Spot TestDocument19 pagesAnalisis Spot TestAnggun Yulfiastanti MalakaNo ratings yet

- 10-DSRF-N 10K Ductile Cast Iron Gate Valve (Flange Type) TOYO VALVE 37700451 - MonotaRO PhilippinesDocument2 pages10-DSRF-N 10K Ductile Cast Iron Gate Valve (Flange Type) TOYO VALVE 37700451 - MonotaRO PhilippinesFredie LabradorNo ratings yet