Professional Documents

Culture Documents

5s Audit Summary Score Sheet

5s Audit Summary Score Sheet

Uploaded by

ubraghuCopyright:

Available Formats

You might also like

- 6s AuditchecklistDocument7 pages6s Auditchecklistpremrrs50% (2)

- Feasibility Study - Muntinlupa - PupDocument134 pagesFeasibility Study - Muntinlupa - PupCamille Grace Gonzales Datay100% (4)

- 5S Warehouse ChecklistDocument3 pages5S Warehouse ChecklistAudit Department100% (1)

- Lear 145 5S ChecklistsDocument10 pagesLear 145 5S ChecklistsEfrain PerezNo ratings yet

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5S Safety AuditDocument9 pages5S Safety Auditmuthuswamy77No ratings yet

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (2)

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFTJOSNo ratings yet

- Job Startup Checklist Format No: P3/00 Part Name: Date Part Number: Shift Check Points: Yes No NADocument1 pageJob Startup Checklist Format No: P3/00 Part Name: Date Part Number: Shift Check Points: Yes No NAubraghuNo ratings yet

- Haleeb Foods Limited PresentationDocument25 pagesHaleeb Foods Limited PresentationUmair AbdullahNo ratings yet

- Textile Internship ReportDocument134 pagesTextile Internship Reportmeezan_alam91% (23)

- Proposal For The Supply of Fresh Tomato PasteDocument2 pagesProposal For The Supply of Fresh Tomato PasteJob IshayaNo ratings yet

- PMPlan Cafe FinalDocument27 pagesPMPlan Cafe FinalFarhat Ali KhanNo ratings yet

- 5S Score Sheet: Auditor: Nikesha Clarence Area: Shop Floor Date: 10-Feb-2012Document1 page5S Score Sheet: Auditor: Nikesha Clarence Area: Shop Floor Date: 10-Feb-2012Faith26No ratings yet

- 1S2S3S - Check SheetDocument1 page1S2S3S - Check SheetManoj KaushikNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- Audit 5 SDocument6 pagesAudit 5 SGleone KaiserinNo ratings yet

- 1S, 2S & 3S Check List: DepartmentDocument4 pages1S, 2S & 3S Check List: DepartmentBharathNo ratings yet

- Weekly 5S Audit ChecklistDocument1 pageWeekly 5S Audit ChecklistRandloneNo ratings yet

- 5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Document6 pages5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Dian PeshevNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormNavnath Tamhane100% (2)

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- 5S Audit Scorecard Instructions: Step 1Document4 pages5S Audit Scorecard Instructions: Step 1commonthinksNo ratings yet

- 6s Audit Workshop FormDocument22 pages6s Audit Workshop FormGman0% (1)

- 5s ChecklistDocument8 pages5s ChecklistMohini MaratheNo ratings yet

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- 03 5S Audit Spider-Chart 4 PgsDocument4 pages03 5S Audit Spider-Chart 4 PgsAnonymous eumALlINo ratings yet

- 5S Audit Check SheetDocument1 page5S Audit Check SheetSiva Subramanian ( Ebauche )No ratings yet

- 5s ChecklistDocument4 pages5s ChecklistedeceNo ratings yet

- 5S Audit SheetDocument1 page5S Audit SheetSiddharth GuptaNo ratings yet

- 5S ChecklistDocument2 pages5S Checklisteidlberto casedoNo ratings yet

- Propec® 5S Audit Checklist: Work Area Completed by DateDocument1 pagePropec® 5S Audit Checklist: Work Area Completed by DatePratik SharmaNo ratings yet

- 5s Check List MakeDocument27 pages5s Check List MakeAmor ELHAJAHMEDNo ratings yet

- 6S Scan Diagnostic Sheet-Print For ExerciseDocument2 pages6S Scan Diagnostic Sheet-Print For ExerciseHardi BanuareaNo ratings yet

- 5S Audit Final VersionDocument13 pages5S Audit Final VersionMuqeet KazmiNo ratings yet

- 5S AuditDocument7 pages5S Auditjorge.kemelNo ratings yet

- 5s - Office ChecklistDocument1 page5s - Office ChecklistChokri AouinaNo ratings yet

- 5S LEAN Office Scorecard: Work Area Assessed: - DateDocument1 page5S LEAN Office Scorecard: Work Area Assessed: - DateumeshjmangroliyaNo ratings yet

- Simple 5s Scorecard PDFDocument1 pageSimple 5s Scorecard PDFumeshjmangroliyaNo ratings yet

- Simple 5s Scorecard PDFDocument1 pageSimple 5s Scorecard PDFumeshjmangroliyaNo ratings yet

- Lear 145 5S - ChecklistsDocument10 pagesLear 145 5S - ChecklistsCarlos HernandezNo ratings yet

- PP 3) . - Aud's S's OficinasDocument2 pagesPP 3) . - Aud's S's OficinasJose OrtegaNo ratings yet

- 5S Audit Check Sheet: 1 Very Little ComplianceDocument2 pages5S Audit Check Sheet: 1 Very Little ComplianceVirendra KumarNo ratings yet

- 5 S Check ListDocument6 pages5 S Check ListWaqar LatifNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFradhajaladiNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistIan MardiansyahNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistAtul Sharma100% (1)

- 5s Workplace Scan ChecklistDocument1 page5s Workplace Scan ChecklistEbrahim HanashNo ratings yet

- 145 5S ChecklistsDocument10 pages145 5S Checklistsyogesh prajapatiNo ratings yet

- Lean Overview For OrientationDocument14 pagesLean Overview For OrientationFabio GonzalezNo ratings yet

- Sort - SEIRI: Checklist Item Criteria Exist? Rating CommentsDocument2 pagesSort - SEIRI: Checklist Item Criteria Exist? Rating CommentsFaysalNo ratings yet

- 5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not NeededDocument2 pages5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not Neededsaeed ahmedNo ratings yet

- 5s AuditchecklistDocument15 pages5s AuditchecklistChristian PaulsenNo ratings yet

- 5's TemplateDocument5 pages5's TemplatealamtareqNo ratings yet

- 6S Assessment Sheet: Necessary Information Is Not VisibleDocument1 page6S Assessment Sheet: Necessary Information Is Not VisibleMmstevens00No ratings yet

- 5S ChecklistsDocument5 pages5S ChecklistsRheneir MoraNo ratings yet

- 5s Workstation AuditchecklistDocument10 pages5s Workstation AuditchecklistJamal AbdullahNo ratings yet

- 5S Audits Check Sheet and Comments Sheet - Issue2Document2 pages5S Audits Check Sheet and Comments Sheet - Issue2vipindixit78100% (1)

- Sort - SEIRI: Checklist Item Criteria Exist? Rating CommentsDocument2 pagesSort - SEIRI: Checklist Item Criteria Exist? Rating CommentsmmmmNo ratings yet

- Checklist For Audit 5SDocument2 pagesChecklist For Audit 5SSouhail ChabatNo ratings yet

- 5s Audit ChecklistDocument2 pages5s Audit Checklistabdelhadi smahiNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 1537 Minutes of MeetingDocument2 pages1537 Minutes of MeetingubraghuNo ratings yet

- RunOutRawData2023 08 02T10 21 07Document128 pagesRunOutRawData2023 08 02T10 21 07ubraghuNo ratings yet

- Apqp - Layered Process Audit-1594636097 SAMPLE 4Document9 pagesApqp - Layered Process Audit-1594636097 SAMPLE 4ubraghuNo ratings yet

- Iso/Ts 16949 WorkshopDocument115 pagesIso/Ts 16949 WorkshopubraghuNo ratings yet

- P Gen 11Document4 pagesP Gen 11ubraghuNo ratings yet

- Apqp 2017Document124 pagesApqp 2017ubraghuNo ratings yet

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 pagesNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNo ratings yet

- Resume - BALARAGHAVAN UDocument2 pagesResume - BALARAGHAVAN UubraghuNo ratings yet

- B515 TempDocument4 pagesB515 TempubraghuNo ratings yet

- Questionnaire For Quotation Preparation: ISO/TS 16949Document2 pagesQuestionnaire For Quotation Preparation: ISO/TS 16949ubraghuNo ratings yet

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YDocument2 pagesHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuNo ratings yet

- SU2I Ins STDDocument10 pagesSU2I Ins STDubraghuNo ratings yet

- Save 1. Water 2. Tree To Save Earth and NatureDocument2 pagesSave 1. Water 2. Tree To Save Earth and NatureubraghuNo ratings yet

- Grinding Machine ParametterDocument19 pagesGrinding Machine ParametterubraghuNo ratings yet

- Balaraghavanudayasankar: PR Ofi L EsummaryDocument4 pagesBalaraghavanudayasankar: PR Ofi L EsummaryubraghuNo ratings yet

- This Document Has Been Prepared By: Parthasarathi Desikan and Sunder KidambiDocument38 pagesThis Document Has Been Prepared By: Parthasarathi Desikan and Sunder KidambiubraghuNo ratings yet

- Without This Message by Purchasing Novapdf : Print To PDFDocument48 pagesWithout This Message by Purchasing Novapdf : Print To PDFubraghuNo ratings yet

- Mahalakshmi Stotram Vishnu PuranaDocument13 pagesMahalakshmi Stotram Vishnu PuranaubraghuNo ratings yet

- Krishna AshtothramDocument1 pageKrishna AshtothramubraghuNo ratings yet

- MERCHANDISER: Resume CV Jobs in India, Current Careers, Latest Vacancies, Openings / OpportunitiesDocument8 pagesMERCHANDISER: Resume CV Jobs in India, Current Careers, Latest Vacancies, Openings / OpportunitiesAsad ZamanNo ratings yet

- Pawla Knitwear PVT Ltd.Document12 pagesPawla Knitwear PVT Ltd.FoyjurRazzakTuhinNo ratings yet

- Fruit Logistica Trend Report 2019 PDFDocument19 pagesFruit Logistica Trend Report 2019 PDFKEVIN VENTURANo ratings yet

- Title - PROJECT PROPOSAL ON EDIBLE OIL PR PDFDocument28 pagesTitle - PROJECT PROPOSAL ON EDIBLE OIL PR PDFlijyonas80% (5)

- SAG - Food and Beverage Services NC IIDocument9 pagesSAG - Food and Beverage Services NC IIMhel DemabogteNo ratings yet

- Pvivate Limited Companies Database SampleDocument10 pagesPvivate Limited Companies Database SampleBinduPrakashBhattNo ratings yet

- Paper Sector in Bangladesh PDFDocument6 pagesPaper Sector in Bangladesh PDFsonumonu23No ratings yet

- Apes ProjectDocument13 pagesApes Projectapi-464363462No ratings yet

- Jaybird Sports Medicine CatalogDocument10 pagesJaybird Sports Medicine CatalogdavorribicicNo ratings yet

- A Detailed Project Report ON Handmade Paper Manufacturing & Conversion UnitDocument38 pagesA Detailed Project Report ON Handmade Paper Manufacturing & Conversion UnitNaga PrabhasNo ratings yet

- Body PartDocument73 pagesBody PartRekha RamannavarNo ratings yet

- Kraft FoodDocument9 pagesKraft FoodCristy Jean LuminariasNo ratings yet

- Logistic ManagementDocument35 pagesLogistic Managementvk_love100% (1)

- Architectural Company ProfileDocument14 pagesArchitectural Company ProfileAli D ViVasNo ratings yet

- CSM For RollDocument14 pagesCSM For RollThanhNhựtNo ratings yet

- Shelf LifeDocument1 pageShelf Lifeluis hernandezNo ratings yet

- Milk For The NationDocument59 pagesMilk For The Nationmihin.wimalasena100% (2)

- Tata Tea DistributionDocument38 pagesTata Tea DistributionYogesh Kende74% (19)

- DESIGN and TYPOGRAPHY PDFDocument25 pagesDESIGN and TYPOGRAPHY PDFGustavo RosadasNo ratings yet

- WSB - Itc Limited PresentationDocument22 pagesWSB - Itc Limited PresentationvamshiNo ratings yet

- XyzDocument6 pagesXyzdangerous sanjuNo ratings yet

- Kraton 101 What Is SBS?Document2 pagesKraton 101 What Is SBS?Alvaro CPNo ratings yet

- UT5 OH SensorDocument4 pagesUT5 OH Sensortanuj_dewan0% (1)

- Suma Bac Sanitization (BoxC) SOPDocument2 pagesSuma Bac Sanitization (BoxC) SOPsuyogonhisownNo ratings yet

- Grasim Training ReportDocument32 pagesGrasim Training ReportAshutosh Pandey100% (1)

5s Audit Summary Score Sheet

5s Audit Summary Score Sheet

Uploaded by

ubraghuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5s Audit Summary Score Sheet

5s Audit Summary Score Sheet

Uploaded by

ubraghuCopyright:

Available Formats

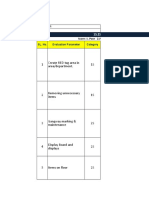

A 5S Score Sheet

Auditor: Area: Date:

5S Evaluation & Scoring Criteria

Score

Item Description 0 = 5+ problems 2 = 3 problems 4 = 1 problem Notes for next level of improvement

(0-5)

1 = 4 problems 3 = 2 problems 5 = 0 problems

All items not necessary for performing work are removed from the

No unnecessary items workplace; only tools and products are present at work stations. No items

are on top of machines, cabinets, or equipment.

Only binders containing documentation necessary for operations (such as

Documentation binders MSDS and SOP binders) are stored at the work stations

Boxes, containers, and materials are necessary and stored neatly in

clearly - labelled shelves or cabinets. WIP and other small items arre not

Material storage stored on the floor. Large items are stored on the floor in coreectly colour-

coded areas. Stacked items are not crooked or in danger of toppling over.

Tools, fixtures, and gauges are stored neatly in designated locations;

Tools & Gauges storeage is designed to ensure cleanliness and prevent damage.

All cleaning equipment and materials are easily accessible and stored

Cleaning equipment & materials neatly in a clearly-labelled location (colour coded, if hazardous materials

involved).

Fire-fighting and other emergency/first aid equipment is unobstructed and

Emergency equipment correctly stored in a correctly colour-coded area. Emergency stop

switches/breakers are colour-coded, easily accessible.

Aisles are clearly marked with the correct colour code; lines are straight,

Aisles clean, continuous, and at right angles. Aisles and operator exits to the

aisles are free of obstructions; objects are at right angles to the aisle.

All floors are clean and free of debris, oil, and dirt. Floors are cleaned

Equipment (Cleanliness) daily, at a minimum.

Machines and equipment are neatly painted. Safety guards and signs are

Equipment (maintenance) correctly installed. No fluid leaks, frayed electrical cords, or worn air lines.

Standard ops documentation and the QCDS board are up-to-date, in good

Visual management systems condition, easily visible, and neatly displayed in the designated location(s).

5S control (posted) Weekly audits completed, results graphed, countermeasures implemented.

Total / 12 =

You might also like

- 6s AuditchecklistDocument7 pages6s Auditchecklistpremrrs50% (2)

- Feasibility Study - Muntinlupa - PupDocument134 pagesFeasibility Study - Muntinlupa - PupCamille Grace Gonzales Datay100% (4)

- 5S Warehouse ChecklistDocument3 pages5S Warehouse ChecklistAudit Department100% (1)

- Lear 145 5S ChecklistsDocument10 pagesLear 145 5S ChecklistsEfrain PerezNo ratings yet

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5S Safety AuditDocument9 pages5S Safety Auditmuthuswamy77No ratings yet

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (2)

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFTJOSNo ratings yet

- Job Startup Checklist Format No: P3/00 Part Name: Date Part Number: Shift Check Points: Yes No NADocument1 pageJob Startup Checklist Format No: P3/00 Part Name: Date Part Number: Shift Check Points: Yes No NAubraghuNo ratings yet

- Haleeb Foods Limited PresentationDocument25 pagesHaleeb Foods Limited PresentationUmair AbdullahNo ratings yet

- Textile Internship ReportDocument134 pagesTextile Internship Reportmeezan_alam91% (23)

- Proposal For The Supply of Fresh Tomato PasteDocument2 pagesProposal For The Supply of Fresh Tomato PasteJob IshayaNo ratings yet

- PMPlan Cafe FinalDocument27 pagesPMPlan Cafe FinalFarhat Ali KhanNo ratings yet

- 5S Score Sheet: Auditor: Nikesha Clarence Area: Shop Floor Date: 10-Feb-2012Document1 page5S Score Sheet: Auditor: Nikesha Clarence Area: Shop Floor Date: 10-Feb-2012Faith26No ratings yet

- 1S2S3S - Check SheetDocument1 page1S2S3S - Check SheetManoj KaushikNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- Audit 5 SDocument6 pagesAudit 5 SGleone KaiserinNo ratings yet

- 1S, 2S & 3S Check List: DepartmentDocument4 pages1S, 2S & 3S Check List: DepartmentBharathNo ratings yet

- Weekly 5S Audit ChecklistDocument1 pageWeekly 5S Audit ChecklistRandloneNo ratings yet

- 5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Document6 pages5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Dian PeshevNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormNavnath Tamhane100% (2)

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- 5S Audit Scorecard Instructions: Step 1Document4 pages5S Audit Scorecard Instructions: Step 1commonthinksNo ratings yet

- 6s Audit Workshop FormDocument22 pages6s Audit Workshop FormGman0% (1)

- 5s ChecklistDocument8 pages5s ChecklistMohini MaratheNo ratings yet

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- 03 5S Audit Spider-Chart 4 PgsDocument4 pages03 5S Audit Spider-Chart 4 PgsAnonymous eumALlINo ratings yet

- 5S Audit Check SheetDocument1 page5S Audit Check SheetSiva Subramanian ( Ebauche )No ratings yet

- 5s ChecklistDocument4 pages5s ChecklistedeceNo ratings yet

- 5S Audit SheetDocument1 page5S Audit SheetSiddharth GuptaNo ratings yet

- 5S ChecklistDocument2 pages5S Checklisteidlberto casedoNo ratings yet

- Propec® 5S Audit Checklist: Work Area Completed by DateDocument1 pagePropec® 5S Audit Checklist: Work Area Completed by DatePratik SharmaNo ratings yet

- 5s Check List MakeDocument27 pages5s Check List MakeAmor ELHAJAHMEDNo ratings yet

- 6S Scan Diagnostic Sheet-Print For ExerciseDocument2 pages6S Scan Diagnostic Sheet-Print For ExerciseHardi BanuareaNo ratings yet

- 5S Audit Final VersionDocument13 pages5S Audit Final VersionMuqeet KazmiNo ratings yet

- 5S AuditDocument7 pages5S Auditjorge.kemelNo ratings yet

- 5s - Office ChecklistDocument1 page5s - Office ChecklistChokri AouinaNo ratings yet

- 5S LEAN Office Scorecard: Work Area Assessed: - DateDocument1 page5S LEAN Office Scorecard: Work Area Assessed: - DateumeshjmangroliyaNo ratings yet

- Simple 5s Scorecard PDFDocument1 pageSimple 5s Scorecard PDFumeshjmangroliyaNo ratings yet

- Simple 5s Scorecard PDFDocument1 pageSimple 5s Scorecard PDFumeshjmangroliyaNo ratings yet

- Lear 145 5S - ChecklistsDocument10 pagesLear 145 5S - ChecklistsCarlos HernandezNo ratings yet

- PP 3) . - Aud's S's OficinasDocument2 pagesPP 3) . - Aud's S's OficinasJose OrtegaNo ratings yet

- 5S Audit Check Sheet: 1 Very Little ComplianceDocument2 pages5S Audit Check Sheet: 1 Very Little ComplianceVirendra KumarNo ratings yet

- 5 S Check ListDocument6 pages5 S Check ListWaqar LatifNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFradhajaladiNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistIan MardiansyahNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistAtul Sharma100% (1)

- 5s Workplace Scan ChecklistDocument1 page5s Workplace Scan ChecklistEbrahim HanashNo ratings yet

- 145 5S ChecklistsDocument10 pages145 5S Checklistsyogesh prajapatiNo ratings yet

- Lean Overview For OrientationDocument14 pagesLean Overview For OrientationFabio GonzalezNo ratings yet

- Sort - SEIRI: Checklist Item Criteria Exist? Rating CommentsDocument2 pagesSort - SEIRI: Checklist Item Criteria Exist? Rating CommentsFaysalNo ratings yet

- 5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not NeededDocument2 pages5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not Neededsaeed ahmedNo ratings yet

- 5s AuditchecklistDocument15 pages5s AuditchecklistChristian PaulsenNo ratings yet

- 5's TemplateDocument5 pages5's TemplatealamtareqNo ratings yet

- 6S Assessment Sheet: Necessary Information Is Not VisibleDocument1 page6S Assessment Sheet: Necessary Information Is Not VisibleMmstevens00No ratings yet

- 5S ChecklistsDocument5 pages5S ChecklistsRheneir MoraNo ratings yet

- 5s Workstation AuditchecklistDocument10 pages5s Workstation AuditchecklistJamal AbdullahNo ratings yet

- 5S Audits Check Sheet and Comments Sheet - Issue2Document2 pages5S Audits Check Sheet and Comments Sheet - Issue2vipindixit78100% (1)

- Sort - SEIRI: Checklist Item Criteria Exist? Rating CommentsDocument2 pagesSort - SEIRI: Checklist Item Criteria Exist? Rating CommentsmmmmNo ratings yet

- Checklist For Audit 5SDocument2 pagesChecklist For Audit 5SSouhail ChabatNo ratings yet

- 5s Audit ChecklistDocument2 pages5s Audit Checklistabdelhadi smahiNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 1537 Minutes of MeetingDocument2 pages1537 Minutes of MeetingubraghuNo ratings yet

- RunOutRawData2023 08 02T10 21 07Document128 pagesRunOutRawData2023 08 02T10 21 07ubraghuNo ratings yet

- Apqp - Layered Process Audit-1594636097 SAMPLE 4Document9 pagesApqp - Layered Process Audit-1594636097 SAMPLE 4ubraghuNo ratings yet

- Iso/Ts 16949 WorkshopDocument115 pagesIso/Ts 16949 WorkshopubraghuNo ratings yet

- P Gen 11Document4 pagesP Gen 11ubraghuNo ratings yet

- Apqp 2017Document124 pagesApqp 2017ubraghuNo ratings yet

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 pagesNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNo ratings yet

- Resume - BALARAGHAVAN UDocument2 pagesResume - BALARAGHAVAN UubraghuNo ratings yet

- B515 TempDocument4 pagesB515 TempubraghuNo ratings yet

- Questionnaire For Quotation Preparation: ISO/TS 16949Document2 pagesQuestionnaire For Quotation Preparation: ISO/TS 16949ubraghuNo ratings yet

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YDocument2 pagesHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuNo ratings yet

- SU2I Ins STDDocument10 pagesSU2I Ins STDubraghuNo ratings yet

- Save 1. Water 2. Tree To Save Earth and NatureDocument2 pagesSave 1. Water 2. Tree To Save Earth and NatureubraghuNo ratings yet

- Grinding Machine ParametterDocument19 pagesGrinding Machine ParametterubraghuNo ratings yet

- Balaraghavanudayasankar: PR Ofi L EsummaryDocument4 pagesBalaraghavanudayasankar: PR Ofi L EsummaryubraghuNo ratings yet

- This Document Has Been Prepared By: Parthasarathi Desikan and Sunder KidambiDocument38 pagesThis Document Has Been Prepared By: Parthasarathi Desikan and Sunder KidambiubraghuNo ratings yet

- Without This Message by Purchasing Novapdf : Print To PDFDocument48 pagesWithout This Message by Purchasing Novapdf : Print To PDFubraghuNo ratings yet

- Mahalakshmi Stotram Vishnu PuranaDocument13 pagesMahalakshmi Stotram Vishnu PuranaubraghuNo ratings yet

- Krishna AshtothramDocument1 pageKrishna AshtothramubraghuNo ratings yet

- MERCHANDISER: Resume CV Jobs in India, Current Careers, Latest Vacancies, Openings / OpportunitiesDocument8 pagesMERCHANDISER: Resume CV Jobs in India, Current Careers, Latest Vacancies, Openings / OpportunitiesAsad ZamanNo ratings yet

- Pawla Knitwear PVT Ltd.Document12 pagesPawla Knitwear PVT Ltd.FoyjurRazzakTuhinNo ratings yet

- Fruit Logistica Trend Report 2019 PDFDocument19 pagesFruit Logistica Trend Report 2019 PDFKEVIN VENTURANo ratings yet

- Title - PROJECT PROPOSAL ON EDIBLE OIL PR PDFDocument28 pagesTitle - PROJECT PROPOSAL ON EDIBLE OIL PR PDFlijyonas80% (5)

- SAG - Food and Beverage Services NC IIDocument9 pagesSAG - Food and Beverage Services NC IIMhel DemabogteNo ratings yet

- Pvivate Limited Companies Database SampleDocument10 pagesPvivate Limited Companies Database SampleBinduPrakashBhattNo ratings yet

- Paper Sector in Bangladesh PDFDocument6 pagesPaper Sector in Bangladesh PDFsonumonu23No ratings yet

- Apes ProjectDocument13 pagesApes Projectapi-464363462No ratings yet

- Jaybird Sports Medicine CatalogDocument10 pagesJaybird Sports Medicine CatalogdavorribicicNo ratings yet

- A Detailed Project Report ON Handmade Paper Manufacturing & Conversion UnitDocument38 pagesA Detailed Project Report ON Handmade Paper Manufacturing & Conversion UnitNaga PrabhasNo ratings yet

- Body PartDocument73 pagesBody PartRekha RamannavarNo ratings yet

- Kraft FoodDocument9 pagesKraft FoodCristy Jean LuminariasNo ratings yet

- Logistic ManagementDocument35 pagesLogistic Managementvk_love100% (1)

- Architectural Company ProfileDocument14 pagesArchitectural Company ProfileAli D ViVasNo ratings yet

- CSM For RollDocument14 pagesCSM For RollThanhNhựtNo ratings yet

- Shelf LifeDocument1 pageShelf Lifeluis hernandezNo ratings yet

- Milk For The NationDocument59 pagesMilk For The Nationmihin.wimalasena100% (2)

- Tata Tea DistributionDocument38 pagesTata Tea DistributionYogesh Kende74% (19)

- DESIGN and TYPOGRAPHY PDFDocument25 pagesDESIGN and TYPOGRAPHY PDFGustavo RosadasNo ratings yet

- WSB - Itc Limited PresentationDocument22 pagesWSB - Itc Limited PresentationvamshiNo ratings yet

- XyzDocument6 pagesXyzdangerous sanjuNo ratings yet

- Kraton 101 What Is SBS?Document2 pagesKraton 101 What Is SBS?Alvaro CPNo ratings yet

- UT5 OH SensorDocument4 pagesUT5 OH Sensortanuj_dewan0% (1)

- Suma Bac Sanitization (BoxC) SOPDocument2 pagesSuma Bac Sanitization (BoxC) SOPsuyogonhisownNo ratings yet

- Grasim Training ReportDocument32 pagesGrasim Training ReportAshutosh Pandey100% (1)