Professional Documents

Culture Documents

Dust Emission Measurement in Quarries With The FW 56D/T 10

Dust Emission Measurement in Quarries With The FW 56D/T 10

Uploaded by

Naser JahangiriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dust Emission Measurement in Quarries With The FW 56D/T 10

Dust Emission Measurement in Quarries With The FW 56D/T 10

Uploaded by

Naser JahangiriCopyright:

Available Formats

Dust Emission Measurement in

quarries with the FW 56D/T 10

FW 56

Market segment

The market segment referred In Europe exist (1997) more factured from large stones,

to is the determination of than 5000 quarries of this stone blocks or boulders. The

L I CAT I O N

dust concentration in size. Crushers are used in granulates are used for

quarries using granulate applications, where mineral processing mortar, concrete

crushers with an annual granulates with a grain size or macadam for road and

capacity of > 500.000 t. of up to 80 mm are manu- railway construction.

APP

Process

The crushers are usually

mounted under a roof in open

halls.Dust emission resulting

from the crushing process is

extreme. Sprinkler systems

Results are often used to reduce the

dust content in the immediate

n Accurate measuring

vicinity. The amount of water

values even for extre-

passing the sprinkler system

me dust concentrati- Dust measuring equipment in a quarry

however must be controlled as the

on

water content of the product is

n Parameter for sprink-

restricted for quality reasons. The water

ler control

quantity can be controlled directly by

n Product quality control mesuring the dust content above the

n Limitation of enviro- sprinkler system.

mental pollution

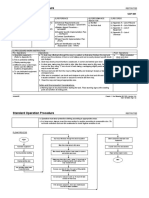

Measuring task ( Performance test )

The task was to measure in system of the sprinkler

a quarry site the dust equipment.

concentration above 6 This installation was

crushers with extreme dust considered as performance

emission in open path and test for the dust measuring

to feed the measured device FW 56 D/T10 for this

values into the control ambitious application.

Measuring solution between measuring head

and test results and reflector was 6m. The

The FW 56 D/T 10 equipped measuring range was set

with long dust-protection from 0 to 100% opacity. Zero

tubes to minimize point (4 mA) was defined by

contamination on the optical the lowest dust level, i.e. with

boundary surfaces was no crusher in operation.

installed above the crushers The dust burden with all 6

in an open bay. The distance crushers in operation was so

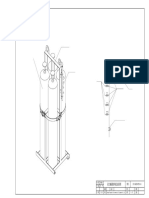

FW 56 D/T10 with mounting brackets

extreme that it was difficult to

see the reflector from the of dust and the device

measuring head position. conse-quently full

operational, see diagramm.

After 2 weeks of operation After further one week of

with 3 crushers the dust build operation with all 6 crushers

up in the protective tubes of a dust deposit of 20 mm was

the FW 56 was extremely low measured in the tubes, but

(only 4 mm at the tube outlet. only in the front half of the

The optical boundary sur- tube. The optical boundary

faces were completely free surfaces again were clean

and with that the device full

operational.

Plotter signal with 3 crushers

in operation

Advantages and benefits

The installation of the FW 56D/T 10D in quarries provides the

advantage to keep the dust burden automatically within given

limits even under extreme operating conditions. This is

achieved by controlling the water flow through the sprinkler

system by the measured dust concentration value.

The benefits – together with very low maintenance needs –

are:

• The sprinkler system output is automatically adapted to

the dust burden

• The product quality regarding water content is secured

• The dust emission into the enviroment is controlled and

reduced.

SICK AG • Environmental Monitoring • Nimburger Str. 11 • D-79276 Reute • Germany

Tel. (+49) 76 41/4 69 0 • Fax. (+49) 76 41/4 69 11 49 • www.sick.de

You might also like

- Caterpillar 910 Wheel LoaderDocument4 pagesCaterpillar 910 Wheel LoaderAya Mariati100% (1)

- Lab 2Document30 pagesLab 2jianneNo ratings yet

- SOP 001 Dust MoppingDocument2 pagesSOP 001 Dust MoppingMade GileeNo ratings yet

- Leaflet English ILMEG Products ABDocument4 pagesLeaflet English ILMEG Products ABVelina MilevaNo ratings yet

- Bihar Cement Plant Environment Compliance April Sep 2020Document26 pagesBihar Cement Plant Environment Compliance April Sep 2020Kumar Saurabh SinghNo ratings yet

- Give Your Plant A Dust Control Tune-Up: Burning PRB CoalDocument4 pagesGive Your Plant A Dust Control Tune-Up: Burning PRB CoalD Gopala Krishnam RajuNo ratings yet

- ES 200 - S2 - Air - L6 - 18oct 2021Document36 pagesES 200 - S2 - Air - L6 - 18oct 2021vishal kumarNo ratings yet

- Welcome To The Presentation: Dust Survey and Free Silica AnalysisDocument21 pagesWelcome To The Presentation: Dust Survey and Free Silica AnalysisMS RajuNo ratings yet

- Fogmaster Products BrochureDocument11 pagesFogmaster Products BrochureAnotec Pty Ltd0% (1)

- Sampling of Dust DUST in MINES - 5Document74 pagesSampling of Dust DUST in MINES - 5Mahesh KhicherNo ratings yet

- HoseDocument4 pagesHoseBhayu Senoaji Dwi PrimasanjoyoNo ratings yet

- Coal Handling and Processing Apc 1 800 PDFDocument8 pagesCoal Handling and Processing Apc 1 800 PDFswapnilpilareNo ratings yet

- 25 Gas Cleanup 2Document23 pages25 Gas Cleanup 2revolvevijaya123No ratings yet

- Over ViewDocument19 pagesOver ViewAlek Al HadiNo ratings yet

- Fdocuments - in - Mesh Vane Mist EliminatorsDocument16 pagesFdocuments - in - Mesh Vane Mist EliminatorsDũng LêNo ratings yet

- Brink Mist Eliminators BrochureDocument12 pagesBrink Mist Eliminators BrochureamolbagadeNo ratings yet

- MeasurIT Flexim ADM7407 Application Lignite Surface Mining 0809Document1 pageMeasurIT Flexim ADM7407 Application Lignite Surface Mining 0809cwiejkowskaNo ratings yet

- Kunal - Dry Fog PaperDocument17 pagesKunal - Dry Fog PaperSK ChaulyaNo ratings yet

- CS Semi-Automated Cleaning of Gas KO Drum 2017 (THIS)Document2 pagesCS Semi-Automated Cleaning of Gas KO Drum 2017 (THIS)Lee Hunter JrNo ratings yet

- Air Pollution: CE1400 Environment and Safety Engineering Lecture-19Document27 pagesAir Pollution: CE1400 Environment and Safety Engineering Lecture-19Dinesh Kumar SahuNo ratings yet

- User Notes and Drawing of Directional Dust Deposit Gauges: W. Volsoo 36-WG11/Stafford/108Document4 pagesUser Notes and Drawing of Directional Dust Deposit Gauges: W. Volsoo 36-WG11/Stafford/108pacoNo ratings yet

- Osha Control of Silica Dust in ConstructionDocument3 pagesOsha Control of Silica Dust in Constructiondhan suNo ratings yet

- Project Proposal Dust Elimination For How MineDocument5 pagesProject Proposal Dust Elimination For How Minetkubvos0% (1)

- EnviroMist Bulk Handling 2017Document3 pagesEnviroMist Bulk Handling 2017RicardoNo ratings yet

- B3636-1 PDS Vacuload-1 AUDocument1 pageB3636-1 PDS Vacuload-1 AUwanfaroukNo ratings yet

- Worksafe Bulletin: Wood Dust Collection System Design and InspectionDocument4 pagesWorksafe Bulletin: Wood Dust Collection System Design and InspectionPaul Miranda GuzmanNo ratings yet

- Fan Motor Noise, Fan Impeller Turning: Source of Noise How/Why Noise ArisesDocument1 pageFan Motor Noise, Fan Impeller Turning: Source of Noise How/Why Noise ArisestoodNo ratings yet

- 1.1 Live Line Dry Cleaning in Electrical Installations FPDocument3 pages1.1 Live Line Dry Cleaning in Electrical Installations FPWalter PossoNo ratings yet

- Filtru Cu Saci - Exhibitor - 19718Document18 pagesFiltru Cu Saci - Exhibitor - 19718Nicoleta UngureanuNo ratings yet

- Young FBD PbeDocument6 pagesYoung FBD PbeAnonymous gzC9adeNo ratings yet

- Dust Extraction SystemDocument13 pagesDust Extraction SystemEng Tennyson SigaukeNo ratings yet

- Fisa Tehnica Senzori Nivel - DBR RadarDocument4 pagesFisa Tehnica Senzori Nivel - DBR RadarjicamihaiNo ratings yet

- 5795 F 69808 Ae 33 e 89 Fad 6 FBBDocument7 pages5795 F 69808 Ae 33 e 89 Fad 6 FBBWilliam ValenciaNo ratings yet

- 14 002 PDFDocument7 pages14 002 PDFRudy Q.VargasNo ratings yet

- Case Study - HK Disneyland Reclamation - IntraforDocument51 pagesCase Study - HK Disneyland Reclamation - IntraforAlvinNo ratings yet

- Kit de Montagem de Detectores em Dutos de Ar para Detectores Ópticos de Fumaça MDP201Document1 pageKit de Montagem de Detectores em Dutos de Ar para Detectores Ópticos de Fumaça MDP201Renan Fernando LopesNo ratings yet

- Tailings Filtration Using Viper Filtration TechnolDocument7 pagesTailings Filtration Using Viper Filtration TechnolNicoViljoenNo ratings yet

- Wet Scrubber: We Make Air Work For YouDocument14 pagesWet Scrubber: We Make Air Work For YouvanyoNo ratings yet

- Flyer Rotaflex SystemDocument2 pagesFlyer Rotaflex Systemم.حسين العامريNo ratings yet

- Design EngineeringDocument28 pagesDesign Engineeringyanuardi2790No ratings yet

- 14 DBlatt05 2011 E - AirDocument1 page14 DBlatt05 2011 E - AirAntonioNo ratings yet

- The Mebradrain System: Vertical DrainageDocument32 pagesThe Mebradrain System: Vertical DrainageГригорий ЛевашовNo ratings yet

- Cte ComplianceDocument31 pagesCte Complianceavln sharmaNo ratings yet

- Suc DrumsDocument6 pagesSuc DrumsrkoGear100% (1)

- Amistco - KO Drum Demister Options (Mist Eliminator Spacing What To Do For Liquid Carryover)Document6 pagesAmistco - KO Drum Demister Options (Mist Eliminator Spacing What To Do For Liquid Carryover)Mubarik AliNo ratings yet

- A.1 Site Development Including Minor Excavation: Batching and Crushing PlantDocument4 pagesA.1 Site Development Including Minor Excavation: Batching and Crushing PlantJaja BarredoNo ratings yet

- Las Mejores Prácticas para El Control de Polvo en La Minería de CarbónDocument58 pagesLas Mejores Prácticas para El Control de Polvo en La Minería de CarbónmilagrosNo ratings yet

- Wet Scrubbers - Design of Spray Tower To Control Air PollutantsDocument7 pagesWet Scrubbers - Design of Spray Tower To Control Air Pollutantsngabang51No ratings yet

- Mine Dressing MCQDocument8 pagesMine Dressing MCQPRAVEEN YADAWNo ratings yet

- Duct TypesDocument4 pagesDuct Typeschathura buddhikaNo ratings yet

- Cleancut CCB PDFDocument2 pagesCleancut CCB PDFbruce lian100% (1)

- Clean Room Technology: The Concept of Total Environmental Control For Advanced IndustriesDocument7 pagesClean Room Technology: The Concept of Total Environmental Control For Advanced Industriesks aksNo ratings yet

- Gas Filtration IntroDocument11 pagesGas Filtration IntroRavi Kumar VermaNo ratings yet

- 3 Kurnia2014 PDFDocument6 pages3 Kurnia2014 PDFSpeciaL ONENo ratings yet

- Atex - Explosive ProofDocument20 pagesAtex - Explosive ProofrubysultanaNo ratings yet

- Dust Control Tissue Making Mill-Primeline-Dust-Mill-Hall-Ventilation-Tissue-En-DataDocument3 pagesDust Control Tissue Making Mill-Primeline-Dust-Mill-Hall-Ventilation-Tissue-En-DataMahbuburRahmanAzadNo ratings yet

- TR-1 Single Separator For MQL and Dry ProcessesDocument12 pagesTR-1 Single Separator For MQL and Dry ProcessesYing Kei ChanNo ratings yet

- Dust Control in Hard Rock Mines: What You Can't See Can Kill YouDocument27 pagesDust Control in Hard Rock Mines: What You Can't See Can Kill YouDinesh KumarNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Gas and Dust Concentration and Flow Measurements For Emission Control in Cement PlantsDocument2 pagesGas and Dust Concentration and Flow Measurements For Emission Control in Cement PlantsNaser JahangiriNo ratings yet

- A Comprehensive Review On Water-Emulsified Diesel Fuel: Chemistry, Engine Performance and Exhaust EmissionsDocument18 pagesA Comprehensive Review On Water-Emulsified Diesel Fuel: Chemistry, Engine Performance and Exhaust EmissionsNaser JahangiriNo ratings yet

- Viscosity Blending Equations (PDF Download Available)Document4 pagesViscosity Blending Equations (PDF Download Available)Naser JahangiriNo ratings yet

- PRC 1733 Crudeoilandpetroleumproductspumpingstationsv 1Document4 pagesPRC 1733 Crudeoilandpetroleumproductspumpingstationsv 1Naser JahangiriNo ratings yet

- Gas Velocity Measurement For Process Air Volume Flow Control in Coating EquipmentDocument2 pagesGas Velocity Measurement For Process Air Volume Flow Control in Coating EquipmentNaser JahangiriNo ratings yet

- Freeze Protection: Heat TracingDocument4 pagesFreeze Protection: Heat TracingNaser JahangiriNo ratings yet

- AB - Flow Condit. Cement - eDocument2 pagesAB - Flow Condit. Cement - eNaser JahangiriNo ratings yet

- Emr SWT Ot 00016Document1 pageEmr SWT Ot 00016Naser JahangiriNo ratings yet

- P230 Ilf DT 0170Document1 pageP230 Ilf DT 0170Naser JahangiriNo ratings yet

- P230 Ilf DT 0145Document1 pageP230 Ilf DT 0145Naser JahangiriNo ratings yet

- Nitrogen Bottles Assembly Bracket SchematicDocument1 pageNitrogen Bottles Assembly Bracket SchematicNaser JahangiriNo ratings yet

- 24.02 Safety InstructionsDocument18 pages24.02 Safety InstructionsNaser JahangiriNo ratings yet

- ST10600 Cylinder StrapDocument1 pageST10600 Cylinder StrapNaser JahangiriNo ratings yet

- Exampel Quotation GM302Document3 pagesExampel Quotation GM302Naser JahangiriNo ratings yet

- Yemen Yadav FINALvDocument12 pagesYemen Yadav FINALvNaser JahangiriNo ratings yet

- GM 302 - Update - 10-2004Document26 pagesGM 302 - Update - 10-2004Naser JahangiriNo ratings yet

- Man - 6020 Photometric AnalyzerDocument92 pagesMan - 6020 Photometric AnalyzerNaser JahangiriNo ratings yet

- Man lxt-280Document57 pagesMan lxt-280Naser JahangiriNo ratings yet

- Gmail - On Campus Recruitment Drive of 'MGH Infrastructures' On 15.09.2023 - Diploma - 2024Document2 pagesGmail - On Campus Recruitment Drive of 'MGH Infrastructures' On 15.09.2023 - Diploma - 2024Raj vardhan PrasadNo ratings yet

- DKT 373 - 2022.11.10 - Google Chat DeletionsDocument14 pagesDKT 373 - 2022.11.10 - Google Chat DeletionsTechCrunchNo ratings yet

- Us Deloitte For Development BrochureDocument4 pagesUs Deloitte For Development BrochuremichekaNo ratings yet

- Consequences For Not Doing Homework in High SchoolDocument5 pagesConsequences For Not Doing Homework in High Schoolafeusgqqj100% (1)

- Chapter-2 Plant Asset and Intangible AssetDocument2 pagesChapter-2 Plant Asset and Intangible AssetHayelom Tadesse GebreNo ratings yet

- Vip in MathematicsDocument170 pagesVip in MathematicsJerome Jeremias100% (1)

- Husqvarna TC 142T - 96051014600 (2016-08) Parts Diagram For CHASSIS - FRAMEDocument7 pagesHusqvarna TC 142T - 96051014600 (2016-08) Parts Diagram For CHASSIS - FRAMEmarcos garciaNo ratings yet

- VALIX - Chapter 5Document28 pagesVALIX - Chapter 5glenn langcuyan100% (1)

- 6 PDFDocument100 pages6 PDFKory JenoNo ratings yet

- Case Study in Textile PrintingDocument33 pagesCase Study in Textile PrintingAun Na-DonNo ratings yet

- Financial Status and Academic AchievementDocument20 pagesFinancial Status and Academic AchievementkalbokalapatoNo ratings yet

- Rudolf Elmer's Complaint To The ECHR v. Jersey (Standard Bank)Document13 pagesRudolf Elmer's Complaint To The ECHR v. Jersey (Standard Bank)David LeloupNo ratings yet

- 10T SRAM Computing-in-Memory Macros For Binary andDocument15 pages10T SRAM Computing-in-Memory Macros For Binary and그랬구나No ratings yet

- Long Tube Vertical EvaporatorDocument6 pagesLong Tube Vertical EvaporatorKyle HartlerNo ratings yet

- INNCOM E7w USER GUIDE - INSTALLATION INSTRUCTIONSDocument83 pagesINNCOM E7w USER GUIDE - INSTALLATION INSTRUCTIONSGustavo angel lopez gomezNo ratings yet

- C4+ Maintenance ManualDocument28 pagesC4+ Maintenance Manualnorizam77100% (1)

- TS-NCIR-SW-0023 Cancelling Stuck NCIR Alarms Manually in NetActDocument22 pagesTS-NCIR-SW-0023 Cancelling Stuck NCIR Alarms Manually in NetActRicardo QueirosNo ratings yet

- One UI Samsung USDocument1 pageOne UI Samsung USRomsamBlaNo ratings yet

- Barco Vs CADocument5 pagesBarco Vs CAdjango69No ratings yet

- MetaSwitch MG3510Document2 pagesMetaSwitch MG3510MC BklynNo ratings yet

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- ALMM For Solar PV ModuleDocument53 pagesALMM For Solar PV Modulemandar kattiNo ratings yet

- Organization & Management: First Semester - First Quarter Week - 4Document4 pagesOrganization & Management: First Semester - First Quarter Week - 4Mira Joey AradoNo ratings yet

- China S Soft Power in East Asia: A Quest For Status and Influence?Document24 pagesChina S Soft Power in East Asia: A Quest For Status and Influence?Kibirango PaddyNo ratings yet

- Common Effluent Treatment Plants: Technical Eia Guidance ManualDocument183 pagesCommon Effluent Treatment Plants: Technical Eia Guidance ManualGOWTHAM GUPTHANo ratings yet

- Transmission Hydraulic SystemDocument4 pagesTransmission Hydraulic SystemA Ramos Gaby100% (5)

- Use To Show An Exact Time: - Two O'clock - Midnight / Noon - The Moment, EtcDocument3 pagesUse To Show An Exact Time: - Two O'clock - Midnight / Noon - The Moment, EtcKasira PammpersNo ratings yet

- DXM AgfaDocument8 pagesDXM AgfaAmilcar BureloNo ratings yet