Professional Documents

Culture Documents

STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFET

STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFET

Uploaded by

Raja RajaCopyright:

Available Formats

You might also like

- Price List 2021 (GLOBAL - USD) Process Instruments - Modular Control SolutionsDocument36 pagesPrice List 2021 (GLOBAL - USD) Process Instruments - Modular Control Solutionsatikah100% (2)

- Cobra 1046Document7 pagesCobra 1046cockybundooNo ratings yet

- STR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument28 pagesSTR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETAnonymous uEOZ7raPkzNo ratings yet

- Str-A606xh Ds en PDFDocument27 pagesStr-A606xh Ds en PDFDylan Gonzalez Villalobos100% (1)

- STR3A100 Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument25 pagesSTR3A100 Series: Off-Line PWM Controllers With Integrated Power MOSFETMiguel Angel GullonNo ratings yet

- For New Designs: STR-W6000S SeriesDocument26 pagesFor New Designs: STR-W6000S SeriesGedealdo TorresNo ratings yet

- STR-W6000S Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument26 pagesSTR-W6000S Series: Off-Line PWM Controllers With Integrated Power MOSFETJulian Andres RozoNo ratings yet

- STR 6XXX SeriesDocument2 pagesSTR 6XXX SeriesGabriel LatiuNo ratings yet

- Str-W625xseries An enDocument17 pagesStr-W625xseries An enFederico GiordanoNo ratings yet

- STR A6252 Allegro MicroSystemsDocument7 pagesSTR A6252 Allegro MicroSystemsSergio ReyesNo ratings yet

- STR A6159 MosfetDocument26 pagesSTR A6159 MosfetAngel CallejebrioNo ratings yet

- Str-Y6700 SeriesDocument2 pagesStr-Y6700 SeriesDaniel MestresNo ratings yet

- For New Designs: STR-A6131MDocument26 pagesFor New Designs: STR-A6131Misdi antoroNo ratings yet

- Diag. STR-y6763 PDFDocument33 pagesDiag. STR-y6763 PDFJAPHET JAIME AYALA ACUÑANo ratings yet

- Str-X67xxseries An en PDFDocument19 pagesStr-X67xxseries An en PDFRenn PaculanangNo ratings yet

- Str-Y6700 Ds enDocument33 pagesStr-Y6700 Ds enUbernel NavarroNo ratings yet

- STR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching RegulatorDocument8 pagesSTR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching RegulatorEmmanuel ZambranoNo ratings yet

- STR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching RegulatorDocument8 pagesSTR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching Regulatorlewis gonzalezNo ratings yet

- STR-W6754: Universal-Input/100 W Off-Line Quasi-Resonant Flyback Switching RegulatorDocument8 pagesSTR-W6754: Universal-Input/100 W Off-Line Quasi-Resonant Flyback Switching RegulatorTecnico GenioNo ratings yet

- Str-A6251 Str-A6252 PDFDocument7 pagesStr-A6251 Str-A6252 PDFrafalero1No ratings yet

- STRW6756 PDFDocument8 pagesSTRW6756 PDFAntWonxxxNo ratings yet

- STR-W6754 - DataDocument8 pagesSTR-W6754 - DataRosyid AsmawiNo ratings yet

- STR W6754 AllegroMicrosystemsDocument8 pagesSTR W6754 AllegroMicrosystemsDelta PratamaNo ratings yet

- EM8635 ExcellianceMOSDocument13 pagesEM8635 ExcellianceMOSBruno MartinsNo ratings yet

- Not Recommended For New Designs: STR-Y6700 SeriesDocument33 pagesNot Recommended For New Designs: STR-Y6700 SeriesmaxNo ratings yet

- AABIDocument63 pagesAABIsureshkurumaNo ratings yet

- Str-W625xseries An enDocument17 pagesStr-W625xseries An encjtrybiec0% (1)

- AP3101 Application Note V1.3 080107Document5 pagesAP3101 Application Note V1.3 080107Carlos Marinho SilvaNo ratings yet

- STR-A6252M: Switching RegulatorsDocument13 pagesSTR-A6252M: Switching RegulatorsAntonioPeriniNo ratings yet

- BM1513 EtcDocument7 pagesBM1513 EtcDimas BarretoNo ratings yet

- Str-A6251M: Universal-Input/15 W 67 KHZ Flyback Switching RegulatorDocument7 pagesStr-A6251M: Universal-Input/15 W 67 KHZ Flyback Switching RegulatorAlexisNo ratings yet

- DM311Document16 pagesDM311Hernan Ortiz EnamoradoNo ratings yet

- Ast965-U12 IgbtDocument6 pagesAst965-U12 IgbtBhethhoNo ratings yet

- Stra6252m SKDocument13 pagesStra6252m SKLeonildo CostaNo ratings yet

- STR W6000S Series Application NoteDocument20 pagesSTR W6000S Series Application NoteSutrisno OkNo ratings yet

- Off-Line Current Mode PWM Control Circuit With Very Low Start Up CurrentDocument7 pagesOff-Line Current Mode PWM Control Circuit With Very Low Start Up CurrentSero StivNo ratings yet

- W6053S SankenDocument12 pagesW6053S SankenTorikul HabibNo ratings yet

- Datasheeta6259h PDFDocument13 pagesDatasheeta6259h PDFEsteban MaryoryNo ratings yet

- STR x6750 PDFDocument19 pagesSTR x6750 PDFJose Domingo Maltez VallecilloNo ratings yet

- Description Features: APU3037 / APU3037ADocument18 pagesDescription Features: APU3037 / APU3037ALeonardoNo ratings yet

- STR-A6100: SeriesDocument2 pagesSTR-A6100: SeriesY. Leonel MolinaNo ratings yet

- Off-Line Current Mode PWM Control Circuit With Undervoltage LockoutDocument7 pagesOff-Line Current Mode PWM Control Circuit With Undervoltage LockoutSero StivNo ratings yet

- STR-W6252D SankenElectric PDFDocument15 pagesSTR-W6252D SankenElectric PDFAriel dajaoNo ratings yet

- STR-W6750F: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeDocument11 pagesSTR-W6750F: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeJonhny PhamNo ratings yet

- 1SFA896106R7000 psr12 600 70Document5 pages1SFA896106R7000 psr12 600 70degaizaorellanaNo ratings yet

- Lava DoraDocument13 pagesLava DoraRay Zander FebresNo ratings yet

- STR A6200eDocument3 pagesSTR A6200eLuis HumNo ratings yet

- Features: ISL8033, ISL8033ADocument18 pagesFeatures: ISL8033, ISL8033Achangiz2220No ratings yet

- MAX77533 14V Input, 1.5A High-Efficiency Buck Converter with 9μA IDocument32 pagesMAX77533 14V Input, 1.5A High-Efficiency Buck Converter with 9μA Ijohn doewrNo ratings yet

- Stra 6251Document9 pagesStra 6251Anonymous 56f2Wl2No ratings yet

- FSDM0565R: Green Mode Fairchild Power Switch (FPS)Document20 pagesFSDM0565R: Green Mode Fairchild Power Switch (FPS)Najam Ul HassanNo ratings yet

- STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDDocument18 pagesSTR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDBertrand Soppo YokiNo ratings yet

- Arrancador Suave-PSRDocument8 pagesArrancador Suave-PSRsofiNo ratings yet

- Str3a150 Str3a150d Str3a160hd Application NoteDocument17 pagesStr3a150 Str3a150d Str3a160hd Application Notecristian González sarmientoNo ratings yet

- Arduino Nano 3 User ManualDocument20 pagesArduino Nano 3 User ManualDj PopNo ratings yet

- Bd7682fj LB eDocument30 pagesBd7682fj LB eKartik ShuklaNo ratings yet

- SD6835 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetDocument9 pagesSD6835 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetАлександр КачеишвилиNo ratings yet

- VS-6CWQ06FN-M3: Vishay SemiconductorsDocument7 pagesVS-6CWQ06FN-M3: Vishay SemiconductorsSolihin iingNo ratings yet

- MS116-6.3 Manual Motor Starter: Product-DetailsDocument7 pagesMS116-6.3 Manual Motor Starter: Product-DetailsLuis Carlos Sandoval BlancoNo ratings yet

- 1SAM350000R1011 ms132 16Document8 pages1SAM350000R1011 ms132 16kikokiko KarimNo ratings yet

- Digital T-Rms Auto-Ranging Multimeter Metrasafe-10: The Quality LeaderDocument5 pagesDigital T-Rms Auto-Ranging Multimeter Metrasafe-10: The Quality LeaderRaja RajaNo ratings yet

- TDA7491P: 10 W + 10 W Dual BTL Class-D Audio AmplifierDocument40 pagesTDA7491P: 10 W + 10 W Dual BTL Class-D Audio AmplifierRaja RajaNo ratings yet

- Unisonic Technologies Co., LTD: BTL 4.0W X 1Ch Power AmplifierDocument4 pagesUnisonic Technologies Co., LTD: BTL 4.0W X 1Ch Power AmplifierRaja RajaNo ratings yet

- St3151a05 5 CsotDocument22 pagesSt3151a05 5 CsotRaja RajaNo ratings yet

- Impex Induction Cooker Error CodesDocument4 pagesImpex Induction Cooker Error CodesRaja RajaNo ratings yet

- Charger Ripple Current Effect v2Document4 pagesCharger Ripple Current Effect v2diyitNo ratings yet

- Electrical Principles (EET0113) : Direct Current (DC)Document10 pagesElectrical Principles (EET0113) : Direct Current (DC)Amirah MohdNo ratings yet

- A PH Meter Has A Membrane That Allows Acidic IonsDocument4 pagesA PH Meter Has A Membrane That Allows Acidic IonsWaltas KariukiNo ratings yet

- Thin-Film Structuring: Holger BartolfDocument7 pagesThin-Film Structuring: Holger BartolfMichelle CedNo ratings yet

- LTC6655 6655LNDocument30 pagesLTC6655 6655LNpravin jadavNo ratings yet

- Chapter 6 PDFDocument58 pagesChapter 6 PDFAdel AtawiNo ratings yet

- Genset Honda EU65isDocument78 pagesGenset Honda EU65isdoddyNo ratings yet

- Silver Engineering Co Solar PanelDocument1 pageSilver Engineering Co Solar PanelPankaj JaiswalNo ratings yet

- Solenoid Valve - Float ValveDocument4 pagesSolenoid Valve - Float ValveHJNo ratings yet

- Sic Schottky Barrier Diodes: Semiconductor Storage ProductsDocument4 pagesSic Schottky Barrier Diodes: Semiconductor Storage ProductsKrishna KumarNo ratings yet

- 142 Siemens Energy Sector Power Engineering Guide Edition 7.0Document90 pages142 Siemens Energy Sector Power Engineering Guide Edition 7.0Feodor RadilovNo ratings yet

- BAtch 5 - Automatic Washroom Light SwitchDocument2 pagesBAtch 5 - Automatic Washroom Light Switchrajapandiya50% (2)

- Battery Autonomy Test For Makongo Songas Dar543Document11 pagesBattery Autonomy Test For Makongo Songas Dar543Paul Lazaro Lalah SulleNo ratings yet

- 4 X 45W Quad Bridge Car Radio Amplifier Plus HSD: Multipower BCD TechnologyDocument11 pages4 X 45W Quad Bridge Car Radio Amplifier Plus HSD: Multipower BCD TechnologyРамиль НевмяновNo ratings yet

- Short Circuit Page PG PDFDocument6 pagesShort Circuit Page PG PDFcarlik09No ratings yet

- EPP-2410-1015 Marine AnalogueDocument24 pagesEPP-2410-1015 Marine AnalogueFernando TamayoNo ratings yet

- RCPschneider PDFDocument2 pagesRCPschneider PDFFirman Jufri YasinNo ratings yet

- Scanner RP 6150 Owner Operation ManualDocument24 pagesScanner RP 6150 Owner Operation ManualBruce JollyNo ratings yet

- Auto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3Document4 pagesAuto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3sharawany 20No ratings yet

- Systemair Prio 250E2 Circular Duct FanDocument6 pagesSystemair Prio 250E2 Circular Duct FanYvanNo ratings yet

- MJA36600Document1 pageMJA36600Ronny Rodriguez SandovalNo ratings yet

- 1212200-00 Installation Instructions 01Document8 pages1212200-00 Installation Instructions 01tetioNo ratings yet

- Lecture 4a.transmission Line Parameters and EffectsDocument19 pagesLecture 4a.transmission Line Parameters and Effectswakolesha TadeoNo ratings yet

- Bill of Supply For Electricity: Area Details Connection Details Supply and Meter DetailsDocument2 pagesBill of Supply For Electricity: Area Details Connection Details Supply and Meter DetailsvamsiNo ratings yet

- Vector Group of Transformer - Electrical Notes & ArticlesDocument24 pagesVector Group of Transformer - Electrical Notes & ArticlesNavneet SinghNo ratings yet

- Series 858, Relay Sockets With Industrial RelayDocument6 pagesSeries 858, Relay Sockets With Industrial RelayAhmedNo ratings yet

- A Dynamic Approach For Distribution System Planning Considering Distributed GenerationDocument10 pagesA Dynamic Approach For Distribution System Planning Considering Distributed GenerationJohan ParradoNo ratings yet

- Inversor - PV35 PRO - 6KDocument1 pageInversor - PV35 PRO - 6KPaolo Cesar Castro DiazNo ratings yet

STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFET

STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFET

Uploaded by

Raja RajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFET

STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFET

Uploaded by

Raja RajaCopyright:

Available Formats

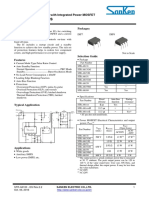

Off-Line PRC Controllers with Integrated Power MOSFET

STR-A6100 Series Data Sheet

Description Package

The STR-A6100 series are power ICs for switching

power supplies, incorporating a MOSFET and a current DIP7

mode PRC controller IC.

PRC (Pulse Ratio Control) controls on-time with

fixed off-time.

The IC includes a startup circuit and a standby

function to achieve the low standby power. The rich set

of protection features helps to realize low component

counts, and high performance-to-cost power supply. Not to scale

Selection Guide

Features

Specifications

Current Mode Type Pulse Ratio Control Fixed Automatic Bias Startup

Part Number

Auto-standby Function Off-time Function Resistance

Normal Operation ------------------------------ PRC Mode STR-A61×× 8 μs Yes ―

Standby ---------------------------- Burst Oscillation Mode STR-A61××M 11.5 μs ― ―

No Load Power Consumption < 40 mW STR-A61××E 11.5 μs ― Yes*

Leading Edge Blanking Function * ST pin does not need diode.

Automatic Bias Function

Protections Power MOSFET electrical characteristics and output

Overcurrent Protection (OCP): Pulse-by-pulse power, POUT*

Overload Protection (OLP): Auto-restart POUT

Overvoltage Protection (OVP): Latched Shutdown VDSS RDS(ON) (Open Frame)

Part Number

Thermal Shutdown Protection (TSD): Latched (min.) (max.) AC85

AC220V ~265V

Shutdown

STR-A6153E 1.9 Ω 22 W 18 W

STR-A6151

3.95 Ω 15 W 13 W

Typical Application STR-A6151M 650 V

STR-A6159

6Ω 13 W 10 W

BR1

L51 STR-A6159M

D51 VOUT

19.2 Ω

T1

VAC (+) STR-A6169 800 V 8W 5W

R54

C1 C5 R1

PC1 R51

* The output power is actual continues power that is measured

P

C51 R55 at 50 °C ambient. The peak output power can be 120 to

DST D1 S R52 C53 140 % of the value stated here. Core size, ON Duty, and

C52 R53 thermal design affect the output power. It may be less than

8 7 5 U2

R56

the value stated here.

D2 R2

D D NC ST (-)

C6 U1

STR-A6100 D

C2

S/OCP VCC GND FB/OLP

1 2 3 4

Applications

ROCP

DZ1 White Goods

C4 C3

PC1 CY

Auxiliary SMPS

Low Power SMPS, etc.

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 1

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Contents

Description ------------------------------------------------------------------------------------------------------ 1

1. Absolute Maximum Ratings --------------------------------------------------------------------------- 3

2. Electrical Characteristics ------------------------------------------------------------------------------ 4

3. Performance Curves ------------------------------------------------------------------------------------ 5

3.1 Derating Curves ------------------------------------------------------------------------------- 5

3.2 Power MOSFET Safe Operating Area Curves ------------------------------------------ 6

3.3 Ambient Temperature versus Power Dissipation, PD1 Curves------------------------ 7

3.4 Internal Frame Temperature versus Power Dissipation, PD2 Curves --------------- 7

3.5 Transient Thermal Resistance Curves ---------------------------------------------------- 8

4. Block Diagrams ------------------------------------------------------------------------------------------ 9

5. Pin Configuration Definitions ----------------------------------------------------------------------- 10

6. Typical Applications ---------------------------------------------------------------------------------- 11

7. Physical Dimensions ----------------------------------------------------------------------------------- 12

8. Marking Diagrams ------------------------------------------------------------------------------------ 13

9. Operational Description ------------------------------------------------------------------------------ 14

9.1 Startup Operation --------------------------------------------------------------------------- 14

9.2 Undervoltage Lockout (UVLO)----------------------------------------------------------- 14

9.3 Constant Output Voltage Control -------------------------------------------------------- 15

9.4 Leading Edge Blanking Function -------------------------------------------------------- 15

9.5 Auto-standby Function --------------------------------------------------------------------- 16

9.6 Automatic Bias Function (STR-A61xx) ------------------------------------------------- 16

9.7 Overcurrent Protection Function (OCP) ----------------------------------------------- 16

9.8 Overload Protection (OLP) ---------------------------------------------------------------- 16

9.9 Overvoltage Protection (OVP) ------------------------------------------------------------ 17

9.10 Thermal Shutdown Function (TSD) ----------------------------------------------------- 18

10. Design Notes -------------------------------------------------------------------------------------------- 18

10.1 External Components----------------------------------------------------------------------- 18

10.2 PCB Trace Layout and Component Placement --------------------------------------- 20

11. Pattern Layout Example ----------------------------------------------------------------------------- 22

12. Reference Design of Power Supply ----------------------------------------------------------------- 23

Important Notes ---------------------------------------------------------------------------------------------- 25

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 2

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

1. Absolute Maximum Ratings

The polarity value for current specifies a sink as "+," and a source as "−," referencing the IC.

Unless otherwise specified, TA is 25 °C, 7 pin = 8 pin

Parameter Symbol Test Conditions Pins Rating Units Remarks

2.5 A6151/51M

3.4 A6153E

Drain Peak Current(1) IDPEAK Single pulse 8–1 A

1.8 A6159/59M

1.2 A6169

3.2 A6131/31M

2.5 A6151/51M

Maximum Switching (3) 3.4 A6153E

IDMAX 8–1 A

Current(2) 1.8 A6159/59M

1.2 A6169

ILPEAK = 2.5 A 72 A6151/51M

ILPEAK = 3.4 A 136 A6153E

Avalanche Energy(4)(5) EAS 8–1 mJ

ILPEAK = 1.8 A 24 A6159/59M

ILPEAK = 1.2 A 7 A6169

S/OCP Pin Voltage VOCP 1–3 −0.5 to 6 V

VCC Pin Voltage VCC 2–3 35 V

FB/OLP Pin Voltage VFB/OLP 4–3 −0.5 to 10 V

ST Pin Voltage VST 5−3 −0.3 to 600 V

Power MOSFET Power (7)

PD1 8–1 1.35 W

Dissipation (6)

A61××

Control Part Power 0.15

PD2 VCC × ICC 2–3 W A61××M

Dissipation(8) 0.46 A6153E

Recommended

Frame Temperature in operation

TF −20 to 125 °C temperature

Operation

TF = 115 °C (max.)

Operating Ambient

TOP ― −20 to 125 °C

Temperature

Storage Temperature Tstg ― −40 to 125 °C

Junction Temperature Tch ― 150 °C

(1)

See Figure 3-1. SOA Temperature Derating

Coefficient Curve

(2)

Maximum Switching Current is Drain current that is limited by the VGS(th) of internal power MOSFET and the gate

drive voltage of internal control IC setting. TA = −20 to 125 °C

(3)

STR-A61×× : V1-3 = 0.86 V, STR-A61××M/E : V1-3 = 1.28 V

(4)

See Figure 3-2. Avalanche Energy Derating

Coefficient Curve

(5)

Single pulse, VDD = 99 V, L = 20 mH

(6)

See Section 3.3 Ta-PD1 curve

(7)

When embedding this hybrid IC onto the printed circuit board (cupper area in a 15 mm × 15 mm)

(8)

See Section 3.4 Ta-PD2 curve

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 3

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

2. Electrical Characteristics

The polarity value for current specifies a sink as "+," and a source as "−," referencing the IC.

Unless otherwise specified, TA = 25 °C, VCC = 20 V, 7 pin = 8 pin

Test

Parameter Symbol Pins Min. Typ. Max. Units Remarks

Conditions

Power Supply Startup Operation

Operation Start Voltage VCC(ON) 2−3 16 17.5 19.2 V

(1)

Operation Stop Voltage VCC(OFF) 2−3 9 10 11 V

Circuit Current in Operation ICC(ON) 2−3 ― ― 4 mA

Circuit Current in Non

ICC(OFF) VCC = 14 V 2−3 ― ― 50 µA

Operation

Automatic Bias Threshold

VCC(BIAS) 2−3 9.6 10.6 11.6 V A61××

Voltage(1)(2)

VCC(BIAS)-VCC(OFF)(2) ― ― 0.2 ― ― V A61××

Startup Current ISTARTUP VCC = 15 V 2−3 −1230 −790 −340 µA

ST Pin Leakage Current ISTART(leak) 5−3 ― ― 30 µA

PRC Operation

7.3 8 8.7 A61××

Maximum Off Time tOFF(MAX) 8−3 µs A61××M

10.5 11.5 12.5 A6153E

Standby Operation

0.70 0.79 0.88 A61××

Burst Threshold Voltage VBURST 4−3 V A61××M

0.66 0.75 0.84 A6153E

Protection Operation

Leading Edge Blanking Time tBW ― 200 320 480 ns

0.69 0.77 0.86 A61××

OCP Threshold Voltage VOCP(TH) 1−3 V A61××M

0.96 1.13 1.28 A6153E

OLP Threshold Voltage VOLP 4−3 6.5 7.2 7.9 V

FB/OLP Pin Source Current −35 −26 −18 A61××

IOLP 4−3 µA A61××M

in OLP Operation −34.1 −26 −18.2 A6153E

FB/OLP Pin Maximum −388 −300 −227 A61××

IFB(MAX) 4−3 µA A61××M

Source Current −390 −300 −220 A6153E

VCC Pin OVP Threshold

VCC(OVP) 2−3 28.7 31.2 34.1 V

Voltage

Latched Shutdown Keep

ICC(H) 2−3 ― ― 200 μA

Current

Latched Shutdown Release

VCC(La.OFF) 2−3 6.6 7.3 8.0 V

Threshold Voltage

Thermal Shutdown Operating

Tj(TSD) ― 135 ― ― °C

Temperature

(1)

VCC(BIAS) > VCC(OFF) always.

(2)

STR-A61××M and STR-A6153E do not have the Automatic Bias Threshold voltage because the automatic bias

function is not included.

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 4

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Test

Parameter Symbol Pins Min. Typ. Max. Units Remarks

Conditions

Power MOSFET

A6151/51M

Drain-to-Source Breakdown 650 ― ― A6159/59M

VDSS ID = 300 μA 8–1 V A6153E

Voltage

800 ― ― A6169

Drain Leakage Current IDSS VD = VDSS 8–1 ― ― 300 μA

― ― 1.9 A6153E

― ― 3.95 A6151/51M

On Resistance RDS(ON) ID = 0.4 A 8–1 Ω

― ― 6 A6159/59M

― ― 19.2 A6169

Switching Time tf VD = 10V 8–1 ― ― 250 ns

Thermal Characteristics

Thermal Resistance(3) θch-F ― ― ― 52 °C/W

(3)

θch-F is thermal resistance between channel and frame. Frame temperature (T F) is measured at the base of pin 3.

3. Performance Curves

3.1 Derating Curves

100 100

EAS Temperature Derating Coefficient (%)

Temperature Derating Coefficient (%)

80 80

Safe Operating Area

60 60

40 40

20 20

0 0

0 25 50 75 100 125 150 25 50 75 100 125 150

Channel Temperature, Tch (°C) Channel Temperature, Tch (°C)

Figure 3-1. SOA Temperature Derating

Figure 3-2. Avalanche Energy Derating

Coefficient Curve

Coefficient Curve

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 5

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

3.2 Power MOSFET Safe Operating Area Curves

When the IC is used, the safe operating area curve should be multiplied by the temperature derating coefficient

derived from Figure 3-1.

The broken line in the safe operating area curve is the drain current curve limited by on-resistance.

Unless otherwise specified, TA = 25 °C, Single pulse

STR-A6151 / 51M STR-A6159 / 59M

10 10

0.1ms

0.1ms

Drain Current, ID (A)

Drain Current, ID (A)

1 1

1ms 1ms

0.1 0.1

0.01 0.01

1 10 100 1000 1 10 100 1000

Drain-to-Source Voltage (V) Drain-to-Source Voltage (V)

STR-A6169 STR-A6153E

10 10

0.1ms

0.1ms

Drain Current, ID (A)

Drain Current, ID (A)

1 1

1ms

1ms

0.1 0.1

0.01 0.01

1 10 100 1000 1 10 100 1000

Drain-to-Source Voltage (V) Drain-to-Source Voltage (V)

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 6

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

3.3 Ambient Temperature versus Power Dissipation, PD1 Curve

● ●

1.6

1.4

Power Dissipation, PD1 (W)

1.2

0.8

0.6

0.4

0.2

0

0 25 50 75 100 125 150

Ambient Temperature, TA (°C )

3.4 Internal Frame Temperature versus Power Dissipation, PD2 Curves

STR-A61×× STR-A6153E

STR-A61××M

0.16 0.50

0.45

0.14 PD2 = 0.15 W PD2 = 0.46 W

Power Dissipation, PD2 (W)

Power Dissipation, PD2 (W)

0.40

0.12

0.35

0.10 0.30

0.08 0.25

0.06 0.20

0.15

0.04

0.10

0.02

0.05

0.00 0.00

0 20 40 60 80 100 120 140 0 25 50 75 100 125 150

Internal Frame Temperature, TF (°C) Internal Frame Temperature, TF (°C)

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 7

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

3.5 Transient Thermal Resistance Curves

STR-A6151 / 51M

100

Resistance θch-c (°C/W)

Transient Thermal

10

0.1

0.01

1µ 10µ 100µ 1m 10m 100m 1 10

Time (s)

STR-A6159 / 59M

10

Transient Thermal Resistance

1

θch-c (°C/W)

0.1

0.01

1µ 10µ 100µ 1m 10m 100m

Time (s)

STR-A6169

10

Transient Thermal Resistance

1

θch-c (°C/W)

0.1

0.01 1µ 10µ 100µ 1m 10m 100m

Time (s)

STR-A6153E

10

Transient Thermal Resistance

1

θch-c (°C/W)

0.1

0.01

0.001

1µ 10µ 100µ 1m 10m 100m

Time (s)

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 8

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

4. Block Diagrams

STR-A61××

2 VCC

ST

5

OVP

UVLO +

-

+ Internal

- Bias Latch Delay

TSD

7,8

Power D

MOS FET

OFF Timer Drive

PWM Latch

+

S Q OLP

- Bias +

R -

-

+

Burst

+ Blanking

-

FB

-

Discharge

+ OCP

+

- 1

S/OCP

Buffer

3

FB/OLP GND

STR-A61××M

2 VCC

ST

5 OVP

UVLO +

-

+ Internal

- Bias Latch Delay

TSD

7,8

Power

MOS FET

D

OFF Timer Drive

PWM Latch

+

S Q OLP

- +

R -

Burst

Blanking

+

FB -

Discharge

+ OCP

+

- 1

S/OCP

Buffer

3

FB/OLP GND

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 9

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

STR-A6153E

2 VCC

ST

5 OVP

UVLO +

-

+ Internal

- Bias Latch Delay

TSD

7,8

Power

MOS FET

D

OFF Timer Drive

PWM Latch

+

S Q OLP

- +

R -

Burst

Blanking

+

FB

-

Discharge

+ OCP

+

- 1

S/OCP

Buffer

3

FB/OLP GND

4

5. Pin Configuration Definitions

Pin Name Descriptions

Power MOSFET source and input of

S/OCP 1 S/OCP

1 8 D overcurrent protection (OCP) signal

Power supply voltage input for control part and

2 VCC

VCC 2 7 D input of overvoltage protection (OVP) signal

3 GND Ground

GND 3 6

Input of constant voltage control signal and

4 FB /OLP

input of over load protection (OLP) signal

FB/OLP 4 5 ST

5 ST Startup current input

6 − (Pin removed)

7

D Power MOSFET drain

8

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 10

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

6. Typical Applications

The PCB traces of D pins should be as wide as possible, in order to enhance thermal dissipation.

In applications having a power supply specified such that V DS has large transient surge voltages, a clamp snubber

circuit of a capacitor-resistor-diode (CRD) combination should be added on the primary winding P, or a damper

snubber circuit of a capacitor (C) or a resistor-capacitor (RC) combination should be added between the D pin and

the S/OCP pin.

As shown in Figure 6-2, STR-A6153E does not need diode connected to ST pin.

CRD clamp snubber

L1

BR1 D51 VOUT

T1

VAC (+)

R54

C6 R1

C1 R51

P PC1

DST R55

C51

D1 S R52 C53

C52 R53

D2 R2

8 7 5 U51

R56

D D NC ST D

C2 (-)

C5 U1

STR-A61×× GND

STR-A61××M

S/OCP VCC GND FB/OLP

C(RC)

Damper snubber 1 2 3 4

CY

DZ1

ROCP C3 PC1

C4

Figure 6-1. Typical Application (STR-A61××/ STR-A61××M)

CRD clamp snubber

L1

BR1 D51 VOUT

T1

VAC (+)

R54

C6 R1

C1 R51

P PC1

R55

C51

D1 S R52 C53

C52 R53

D2 R2

8 7 5 U51

R56

D D NC ST D

C2 (-)

C5 U1

GND

STR-A6153E

S/OCP VCC GND FB/OLP

C(RC)

Damper snubber 1 2 3 4

CY

DZ1

ROCP C3 PC1

C4

Figure 6-2. Typical Application (STR-A6153E)

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 11

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

7. Physical Dimensions

DIP7 (Type A)

NOTES:

- Dimensions in millimeters

- Bare lead frame: Pb-free (RoHS compliant)

DIP7 (Type B)

NOTES:

- Dimensions in millimeters

- Bare lead frame: Pb-free (RoHS compliant)

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 12

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

8. Marking Diagram

8

Specific Device Code (See Table 8-1)

S KY MD

Lot Number:

1 Y is the last digit of the year of manufacture (0 to 9)

M is the month of the year (1 to 9, O, N, or D)

D is a period of days:

1: the first 10 days of the month (1st to 10th)

2: the second 10 days of the month (11th to 20th)

3: the last 10–11 days of the month (21st to 31st)

Control Number

Table 8-1. Specific Device Code

Specific Device Code Part Number

A6153E STR-A6153E

A6151 STR-A6151

A6151M STR-A6151M

A6159 STR-A6159

A6159M STR-A6159M

A6169 STR-A6169

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 13

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

9. Operational Description the auxiliary winding D in Figure 9-1 becomes a power

source to the control circuit in operation.

All of the parameter values used in these descriptions The approximate value of auxiliary winding voltage is

are typical values of STR-A6151, unless they are about 15 V to 20 V, taking account of the winding turns

specified as minimum or maximum. of D winding so that VCC pin voltage becomes

With regard to current direction, "+" indicates sink Equation (2) within the specification of input and output

current (toward the IC) and "–" indicates source voltage variation of power supply.

current (from the IC).

VCC( BIAS) (max .) VCC VCC(OVP ) (min .)

9.1 Startup Operation

⇒ 11.6(V) VCC 28.7(V)

(1)

Figure 9-1 shows the circuit around VCC pin. Figure

9-2 shows VCC pin voltage behavior during the startup

The startup time of IC is determined by C2 capacitor

period.

value. The approximate startup time tSTART is

calculated as follows:

BR1 T1

VCC( ON )-VCC( INT )

VAC t START C2 × (2)

C1 P I STRATUP

DST

5 Where:

ST

tSTART: Startup time of IC (s)

U1 D2 R2 VCC(INT): Initial voltage on VCC pin (V)

2

VCC

C2 VD 9.2 Undervoltage Lockout (UVLO)

3 D

GND Figure 9-3 shows the relationship of VCC pin voltage

and circuit current ICC. When VCC pin voltage

increases to VCC(ON) = 17.5 V, the control circuit starts

Figure 9-1. VCC Pin Peripheral Circuit

switching operation and the circuit current ICC increases.

When VCC pin voltage decreases to VCC(OFF) = 10 V, the

VCC pin voltage IC starts operation Startup success control circuit stops operation by UVLO (Undervoltage

Lockout) circuit, and reverts to the state before startup.

Target operating

voltage

VCC(ON) Circuit current, ICC

Increase with rising of

output voltage ICC(ON)

VCC(OFF)

Startup failure

Stop Start

Time

Figure 9-2. VCC Pin Voltage during Startup Period

The IC incorporates the startup circuit. The circuit is VCC(OFF) VCC(ON) VCC pin

voltage

connected to ST pin. During the startup process, the

constant current, ISTARTUP = − 790 µA, charges C2 at

VCC pin. When VCC pin voltage increases to Figure 9-3. Relationship between

VCC(ON) = 17.5 V, the IC starts the operation. Then VCC Pin Voltage and ICC

circuit current increases and VCC pin voltage decreases.

Since the Operation Stop Voltage VCC(OFF) = 10 V is low,

the auxiliary winding voltage reaches to setting value

before VCC pin voltage decreases to VCC(OFF). Thus

control circuit continues the operation. The voltage from

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 14

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

9.3 Constant Output Voltage Control Turn-on

After the period of tOFF, OFF signal output becomes

Figure 9-4 shows FB/OLP pin peripheral circuit,

Figure 9-5 shows the waveform of ID and FB High, Q of PRC latch circuit is latched to Low. As a

comparator input. result, turn-on signal is input to the gate control circuit,

The IC achieves the constant voltage control of the and power MOSFET turns on.

power supply output by PRC (Pulse Ratio Control). PRC

controls on-time with fixed off-time. In addition, the IC Tuen-off

uses the peak-current-mode control method, which When the OCP comparator or the FB comparator

enhances the response speed and provides the stable resets the PRC latch circuit, Q of PRC latch circuit

operation. is latched to High. As a result, turn-off signal is input

to the gate control circuit, and power MOSFET turns

D off.

Timer reset

7,8

The IC controls the peak value of VOCPM voltage to be

OFF signal Drive

OFF output Gate

close to target voltage (VSC), comparing VOCPM with VSC

Timer S Q control by internal FB comparator.

Circuit

R VOCPM is amplified VROCP voltage that is a detection

ON/OFF PRC latch circuit voltage by current detection resistor, ROCP.

Light load Conditions

VSC When load conditions become lighter, the output

-V voltage, VOUT, increases. Thus, the feedback current

OCPM

+

FB Comp.

from the error amplifier on the secondary-side also

Buffer increases. The feedback current is sunk at the FB/OLP

S/OCP pin, transferred through a photo-coupler, PC1, and the

+ FB/OLP pin voltage decreases. Thus, VSC decreases,

- 1 ID

OCP Comp. VOCP(TH) and the peak value of VOCPM is controlled to be low,

U1 and the peak drain current of I D decreases.

3 GND 4 FB/OLP This control prevents the output voltage from

VROCP increasing.

IFB

DZ1

ROCP

Heavy Load Conditions

When load conditions become greater, the IC

C3 PC1

performs the inverse operation to that described above.

C4 Thus, VSC increases and the peak drain current of ID

increases.

This control prevents the output voltage from

Figure 9-4. FB/OLP Pin Peripheral Circuit decreasing.

FB comparator 9.4 Leading Edge Blanking Function

- VSC

The constant voltage control of output of the IC uses

the peak-current-mode control method.

+ VOCPM

In peak-current-mode control method, there is a case

that the power MOSFET turns off due to unexpected

response of FB comparator or overcurrent protection

Drain current, ID circuit (OCP) to the steep surge current in turning on a

power MOSFET.

In order to prevent this operation, Leading Edge

Figure 9-5. Drain Current and FB Comparator Input Blanking Time, tBW = 320 ns is built-in.

Voltage Waveforms In the period of tBW, the IC does not respond to the

surge voltage in turning on the power MOSFET.

The internal fixed off-time, tOFF is made from internal

off timer circuit, the turn-on timing of power MOSFET

depends on tOFF.

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 15

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

9.5 Auto-standby Function the current level reaches to OCP threshold voltage,

VOCP(TH) = 0.77 V (1.13 V for STR-A61××M and

Auto-standby mode is activated automatically when STR-A6153E).

the drain current, ID, reduces under light load conditions, Figure 9-7 shows the output characteristics. When

at which ID is less than 25% of the maximum drain OCP becomes active, the output voltage decreases and

current (it is in the Overcurrent Protection state). The the auxiliary winding voltage, VD decreases in

operation mode becomes burst oscillation, as shown in proportion to the output voltage.

Figure 9-6. The 25% of the maximum drain current When VCC pin voltage decreases to VCC(OFF) = 10 V,

corresponds to the Burst Threshold Voltage of FB/OLP the control circuit stops operation by UVLO circuit, and

pin, VBURST = 0.79 V (0.75 V for STR-A61××M and reverts to the state before startup. After that, VCC pin

STR-A6153E). voltage is increased by Startup Current, ISTARTUP. When

Burst oscillation mode reduces switching losses and VCC pin voltage increases to VCC(ON) = 17.5 V, the IC

improves power supply efficiency because of periodic restarts the operation. Thus the intermittent operation by

non-switching intervals. UVLO is repeated in OCP operation.

Generally, to improve efficiency under light load The IC usually has some propagation delay time. The

conditions, the frequency of the burst mode becomes steeper the slope of the actual drain current at a high AC

just a few kilohertz. Because the IC suppresses the peak input voltage is, the larger the actual peak of drain

drain current well during burst mode, audible noises can current is. As a result, the detection voltage becomes

be reduced. higher than VOCP(TH). Thus, the output current depends

on the AC input voltage in OCP operation (see Figure

Output current, Burst oscillation 9-7).

IOUT

Output voltage, VOUT(V)

High AC

input voltage

Below several kHz Low AC

input voltage

Drain current,

ID

Normal Standby Normal

operation operation operation

Figure 9-6. Auto-standby Mode Timing Output current, IOUT(A)

Figure 9-7. Output Characteristic Curves

9.6 Automatic Bias Function (STR-A61xx)

STR-A61xx includes the automatic bias function. The When the multi outputs transformer is used, there is the

function becomes active during burst oscillation mode. case that the auxiliary winding voltage, VD does not

When VCC pin voltage decreases to the Automatic Bias decrease and the intermittent operation is not started,

Threshold Voltage, VCC(BIAS) = 10.6 V, during burst even if output voltage decreases in OCP operation. This

oscillation mode, the IC shifts to PRC operation so that is due to the poor coupling of transformer. In this case,

VCC pin voltage does not decrease. As a result, the IC the overload protection (OLP) becomes active. (see

achieves stable standby operation. Section 9.8.)

However, if the Bias Assist function is always

activated during steady-state operation including

standby mode, the power loss increases. Therefore, the

VCC pin voltage should be more than VCC(BIAS), for 9.8 Overload Protection (OLP)

example, by adjusting the turns ratio of the auxiliary Figure 9-8 shows the FB/OLP pin peripheral circuit.

winding and secondary winding and/or reducing the Figure 9-9 shows the OLP operational waveforms.

value of R2 in Figure 10-2 (see Section 10.1 Peripheral When the peak drain current of ID is limited by OCP

Components for a detail of R2). operation, the output voltage, VOUT, decreases and the

feedback current from the secondary photo-coupler

becomes zero. Thus, the feedback current, IFB, charges

9.7 Overcurrent Protection Function (OCP) C3 connected to the FB/OLP pin and the FB/OLP pin

voltage increases. When the FB/OLP pin voltage

Overcurrent Protection Function (OCP) detects each increases to VFB(OLP) = 7.2 V or more for the OLP delay

drain peak current level of a power MOSFET on time, tDLY or more, the OLP function is activated and the

pulse-by-pulse basis, and limits the output power when IC stops switching operation. tDLY is calculated using

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 16

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Equation (3). 9.9 Overvoltage Protection (OVP)

Figure 9-10 shows the OVP operational waveforms.

(VOLP VZ )

t DLY C4 × (3) When a voltage between VCC pin and GND terminal

I OLP increases to VCC(OVP) = 31.2 V or more, OVP function is

activated. When the OVP function is activated, the IC

Where: stops switching operation at the latched state.

tDLY: OLP delay time After that, VCC pin voltage is decreased by circuit

VZ: zener voltage of zener diode, DZ1 current of IC. When VCC pin voltage becomes

IOLP: FB/OLP Pin Source Current in OLP Operation is VCC(OFF) = 10 V or less, VCC pin voltage is increased by

−26 µA Startup Current. When VCC pin voltage increases to

VCC(ON) = 17.5 V, the circuit current increases and VCC

After the switching operation stops, VCC pin voltage pin voltage decreases. In this way, VCC pin voltage

decreases to Operation Stop Voltage VCC(OFF) = 10 V and goes up and down between VCC(OFF) and VCC(ON) during

the intermittent operation by UVLO is repeated. the latched state, excessive increase of VCC pin voltage

This intermittent operation reduces the stress of parts is prevented.

such as power MOSFET and secondary side rectifier Releasing the latched state is done by turning off the

diode. In addition, this operation reduces power input voltage and by dropping the VCC pin voltage

consumption because the switching period in this below VCC(La.OFF) = 7.3 V.

intermittent operation is short compared with oscillation

stop period. When the abnormal condition is removed,

the IC returns to normal operation automatically. VCC pin voltage Latched state

As shown in Figure 9-9, tDLY should be longer than VCC(OVP)=31.2V

tSTART which is the period until the output voltage

becomes constant. If tDLY is shorter than tSTART, the

power supply may not start due to OLP operation. VCC(ON)=17.5V

VCC(OFF)=10V

U1

S/OCP GND FB/OLP

1 3 4 Drain current,

ID

DZ1 PC1

VROCP ROCP IFB

C4

C3

Figure 9-10. OVP Operational Waveforms

If output voltage detection circuit becomes open, the

Figure 9-8. FB/OLP Pin Peripheral Circuit

output voltage of secondary side increases. In case the

VCC pin voltage is provided by using auxiliary winding

of transformer, the overvoltage conditions can be

tSTART tSTART

VCC pin voltage detected because the VCC pin voltage is proportional to

VCC(ON) output voltage. The approximate value of output voltage

VOUT(OVP) in OVP condition is calculated by using

VCC(OFF)

Equation (4).

FB/OLP pin voltage VOUT ( NORMAL )

tDLY tDLY VOUT(OVP) × 31.2 (4)

VCC( NORMAL )

VOLP

Where:

Drain current, Non-switching interval VOUT(NORMAL): Output voltage in normal operation

ID

VCC(NORMAL): VCC pin voltage in normal operation

Figure 9-9. OLP Operational Waveforms

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 17

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

9.10 Thermal Shutdown Function (TSD) which is caused by the transient surge voltage coupled

from the primary winding when the power MOSFET

When the temperature of control circuit increases to turns off. For alleviating C2 peak charging, it is

Tj(TSD) = 135 °C or more, Thermal Shutdown function effective to add some value R2, of several tenths of

is activated. When the TSD function is activated, the IC ohms to several ohms, in series with D2 (see Figure

stops switching operation at the latched state (see the 10-1). The optimal value of R2 should be determined

Section 9.9). Releasing the latched state is done by using a transformer matching what will be used in the

turning off the input voltage and by dropping the VCC actual application, because the variation of the

pin voltage below VCC(La.OFF) = 7.3 V. auxiliary winding voltage is affected by the

transformer structural design.

VCC pin voltage Without R2

10.Design Notes

10.1 External Components

Take care to use properly rated, including derating as With R2

necessary and proper type of components.

Output current, IOUT

BR1 CRD clamp snubber

T1

VAC

Figure 10-2. Variation of VCC Pin Voltage and Power

(

C6 R1

RST DST

C1 P

D1

FB/OLP Pin Peripheral Circuit

)

8 7 5 D2 R2 Figure 10-1 performs high frequency noise rejection

D D NC ST and phase compensation, and should be connected

C5 U1

STRA6100 C2 D close to these pins. The value of C3 is recommended

to be about 2200p to 0.01µF.

S/OCP VCC GND FB/OLP

C(RC)

In order to make the value of C3 low and make the

damper snubber 1 2 3 4

output response fast, DZ1 and C4 are connected.

DZ1 DZ1 prevents C4 charging in normal operation. The

ROCP C3 PC1

zener voltage of DZ1, VZ should be set higher than

C4

FB/OLP pin voltage in normal operation. Usually, the

value of VZ is about 4.7 V to 5.6 V.

C4 is for OLP delay time, tDLY setting. If C4 is too

Figure 10-1. Peripheral Circuit of IC small, the power supply may not start due to OLP

operation (see Section 9.8). The value of C4 is about

Electrolytic Capacitor 4.7 μF to 22 μF.

Apply proper derating to ripple current, voltage, and C3, C4 and DZ1 should be selected based on actual

temperature rise. Use of high ripple current and low operation in the application.

impedance types, designed for switch mode power

supplies, is recommended. ST Pin Peripheral Circuit

When STR-A61×× and STR-A61××M are used, DST

S/OCP Pin Peripheral Circuit or RST should be connected to ST pin as shown in

Choose a type of low internal inductance because a Figure 10-1. DST and RST prevent negative voltage

high frequency switching current flows to ROCP in from applying to ST pin. If ST pin voltage becomes

Figure 10-1, and of properly allowable dissipation. under −0.3 V, the power supply may not start. The

value of DST and RST should be selected based on

VCC Pin Peripheral Circuit actual operation in the application.

The value of C2 in Figure 10-1 is generally Recommended value of RST is 33 kΩ,

recommended to be 10µ to 47μF (see Section 9.1, Recommended characteristics of DST is as follows:

because the startup time is determined by the value of Characteristics Recommended Range

C2). In actual power supply circuits, there are cases in

which the VCC pin voltage fluctuates in proportion to Peak Reverse Voltage, VRM > 35 V

the output current, IOUT (see Figure 10-2), and the Forward current, IF > 1.5 mA

Overvoltage Protection function (OVP) on the VCC Reverse Recovery Time, trr < 27 μs

pin may be activated. This happens because C2 is Reverse Leakage Current, IR < 100 μA

charged to a peak voltage on the auxiliary winding D,

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 18

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Snubber Circuit In the following cases, the surge of VCC pin

In case the serge voltage of VDS is large, the circuit voltage becomes high.

should be added as follows (see Figure 10-1); ▫ The surge voltage of primary main winding, P, is

・ A clamp snubber circuit of a capacitor-resistor- high (low output voltage and high output current

diode (CRD) combination should be added on the power supply designs)

primary winding P. ▫ The winding structure of auxiliary winding, D, is

・ A damper snubber circuit of a capacitor (C) or a susceptible to the noise of winding P.

resistor-capacitor (RC) combination should be

added between the D pin and the GND pin. When the surge voltage of winding D is high, the

In case the damper snubber circuit is added, this VCC pin voltage increases and the Overvoltage

components should be connected near D pin and Protection function (OVP) may be activated. In

S/OCP pin. transformer design, the following should be

considered;

Phase Compensation ▫ The coupling of the winding P and the secondary

A typical phase compensation circuit with a output winding S should be maximized to reduce the

secondary shunt regulator (U51) is shown in Figure leakage inductance.

10-3. ▫ The coupling of the winding D and the winding S

C52 and R53 are for phase compensation. The value should be maximized.

of C52 and R53 are recommended to be around 0.047 ▫ The coupling of the winding D and the winding P

μF to 0.47 μF and 4.7 kΩ to 470 kΩ, respectively. should be minimized.

They should be selected based on actual operation in

the application. In the case of multi-output power supply, the

coupling of the secondary-side stabilized output

winding, S1, and the others (S2, S3…) should be

L51 maximized to improve the line-regulation of those

T1 D51 VOUT

outputs.

(+)

R54 Figure 10-4 shows the winding structural examples

of two outputs.

PC1 R51

C51 R55

S R52 C53

Margin tape

Bobbin

C52 R53 P1 S1 P2 S2 D

Margin tape

U51

R56

Winding structural example (a)

(-)

Margin tape

Figure 10-3. Peripheral Circuit Around Secondary

Shunt Regulator (U51)

Bobbin

P1 S1 D S2 S1 P2

Transformer Margin tape

Apply proper design margin to core temperature rise

Winding structural example (b)

by core loss and copper loss.

Because the switching currents contain high

frequency currents, the skin effect may become a Figure 10-4. Winding Structural Examples

consideration.

Choose a suitable wire gauge in consideration of the Winding structural example (a):

RMS current and a current density of 4 to 6 A/mm2. S1 is sandwiched between P1 and P2 to

If measures to further reduce temperature are still maximize the coupling of them for surge

necessary, the following should be considered to reduction of P1 and P2.

increase the total surface area of the wiring: D is placed far from P1 and P2 to minimize the

▫ Increase the number of wires in parallel. coupling to the primary for the surge reduction of

▫ Use litz wires. D.

▫ Thicken the wire gauge.

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 19

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Winding structural example (b)

P1 and P2 are placed close to S1 to maximize the (5) FB/OLP Trace Layout

coupling of S1 for surge reduction of P1 and P2. The components connected to FB/OLP pin should be

D and S2 are sandwiched by S1 to maximize the as close to FB/OLP pin as possible. The trace

coupling of D and S1, and that of S1 and S2. between the components and FB/OLP pin should be

This structure reduces the surge of D, and as short as possible.

improves the line-regulation of outputs.

(6) Secondary Rectifier Smoothing Circuit Trace

Layout: T1 (winding S) to D51 to C51

10.2 PCB Trace Layout and Component This is the trace of the rectifier smoothing loop,

Placement carrying the switching current, and thus it should be

as wide trace and small loop as possible. If this trace

Since the PCB circuit trace design and the component is thin and long, inductance resulting from the loop

layout significantly affects operation, EMI noise, and may increase surge voltage at turning off the power

power dissipation, the high frequency PCB trace should MOSFET. Proper rectifier smoothing trace layout

be low impedance with small loop and wide trace. helps to increase margin against the power MOSFET

In addition, the ground traces affect radiated EMI breakdown voltage, and reduces stress on the clamp

noise, and wide, short traces should be taken into snubber circuit and losses in it.

account.

Figure 10-5 shows the circuit design example. (7) Thermal Considerations

Because the power MOSFET has a positive thermal

(1) Main Circuit Trace Layout: S/OCP pin to ROCP to C1 coefficient of RDS(ON), consider it in thermal design.

to T1 (winding P) to D pin Since the copper area under the IC and the D pin

This is the main trace containing switching currents, trace act as a heatsink, its traces should be as wide as

and thus it should be as wide trace and small loop as possible.

possible. If C1 and the IC are distant from each other,

placing a capacitor such as film capacitor (about 0.1

μF and with proper voltage rating) close to the

transformer or the IC is recommended to reduce

impedance of the high frequency current loop.

(2) Control Ground Trace Layout

Since the operation of IC may be affected from the

large current of the main trace that flows in control

ground trace, the control ground trace should be

separated from main trace and connected at a single

point grounding of point A in Figure 10-5 as close

to the ROCP pin as possible.

(3) VCC Trace Layout: GND pin to C2 (negative) to T1

(winding D) to R2 to D2 to C2 (positive) to VCC pin

This is the trace for supplying power to the IC, and

thus it should be as small loop as possible. If C2 and

the IC are distant from each other, placing a

capacitor such as film capacitor Cf (about 0.1 μF to

1.0 μF) close to the VCC pin and the GND pin is

recommended.

(4) ROCP Trace Layout

ROCP should be placed as close as possible to the

S/OCP pin. The connection between the power

ground of the main trace and the IC ground should

be at a single point ground (point A in Figure

10-5) which is close to the base of ROCP.

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 20

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

(1) Main trace should be wide (6) Main trace of secondary side should

trace and small loop be wide trace and small loop

D51

T1

C6 R1

C1

P

DST

(7)Trace of D pin should be wide C51

for heat release

D1 S

8 7 5

D2 R2

D D NC ST

C5 U1

STR-A6100

C2 D

S/OCP VCC GND FB/OLP

1 2 3 4

(3) Loop of the power

supply should be small

ROCP DZ1 PC1

(5)The components connected to

C3 FB/OLP pin should be as close

C4 to FB/OLP pin as possible

A CY

(4)ROCP should be as close to S/OCP pin as (2) Control GND trace should be connected at a

possible. single point as close to the ROCP as possible

Figure 10-5. Peripheral Circuit Example of IC

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 21

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

11.Pattern Layout Example

The following show the PCB pattern layout example and the circuit schematic with STR-A6100 series.

Top View

Bottom View

Figure 11-1. PCB Layout Example

J1

F1 L1

L2 J2

R1 D1 T1 D11

ZNR1 R2 C1 C91 R11

C2 R13

R91 R92 R93 PC1

D4 R12

D91 P C11 R14

S C12

D2 R9

C13 R16

8 7 5

C14

D D NC ST D

C4 IC2

U1 R15

STR-A61××

STR-A61××M

S/OCP VCC GND FB/OLP

1 2 3 4

C99

D3

C3 PC1

C5

C8

R3 R4 R5 R6

Figure 11-2. Circuit of the PCB Layout Example

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 22

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

The above circuit symbols correspond to these of Figure 11-1.

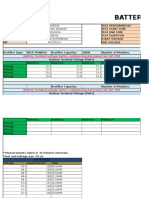

12.Reference Design of Power Supply

As an example, the following show the power supply specification, the circuit schematic, the bill of materials, and

the transformer specification.

Power Supply Specifications

IC STR-A6159

Input Voltage AC 85 V to AC 265 V

Maximum Output Power 5W

Output 5V/1A

Circuit Schematic

See Figure 11-2

Bill of Materials

Recommended Recommended

Symbol Part type Ratings(1) Symbol Part type Ratings(1)

Sanken Parts Sanken Parts

AC 250 V,

F1 Fuse R6 General, chip 10 Ω, 1/4 W

500 mA

L1 (2)

CM inductor 16.5 mH R9 (2)

General, chip 0 Ω, 1/4 W

ZNR1 (2)

Varistor Open R91 Metal oxide, chip 270 kΩ, 1/4 W

D1 General 600 V, 1 A AM01A (Axial) R92 Metal oxide, chip 270 kΩ, 1/4 W

D2 Fast recovery 200 V, 1 A AL01Z R93 Metal oxide, chip 270 kΩ, 1/4 W

D3 Zener, chip 5.1 V PC1 Photo-coupler PC123 or equiv

D4 General, chip 200 V, 1 A IC1 IC - STR-A6159

See

D91 Fast recovery 1000 V, 0.2 A EG01C T1 Transformer

the specification

C1 (2)

Film 0.15 μF, 270 V L2 (2)

Inductor 2.2 μF

C2 Electrolytic 22 μF, 450 V D11 Schottky, chip 60 V, 2 A SJPB-H6

C3 Ceramic, chip 4700 pF, 50 V C11 Electrolytic 680 μF, 10 V

C4 Electrolytic 22 μF, 50 V C12 Electrolytic 220 μF, 10 V

C5 Electrolytic 2.2 μF, 50 V C13 Ceramic, chip 0.1 μF, 50 V

C8 (2)

Ceramic, chip 0.33 μF, 50 V C14 (2)

Ceramic, chip Open

C91 Ceramic, chip 1000 pF, 630 V R11 General, chip 220 Ω, 1/8 W

2200 μF,

C99 (2)

Ceramic, Y1 R12 General, chip 1.5 kΩ, 1/8 W

AC 250 V

R1 (2)

General, chip Open R13 (2)

General, chip, 1% 0 Ω, 1/8 W

R2 (2)

General, chip Open R14 General, chip, 1% 10 kΩ, 1/8 W

R3 General, chip 10 Ω, 1/4 W R15 General, chip, 1% 10 kΩ, 1/8 W

R4 General, chip 10 Ω, 1/4 W R16 General, chip 47kΩ, 1/8 W

VREF = 2.5 V

R5 General, chip 10 Ω, 1/4 W IC2 Shunt regulator

TL431 or equiv

(1)

Unless otherwise specified, the voltage rating of capacitor is 50 V or less and the power rating of resistor is 1/8 W or less.

(2)

It is necessary to be adjusted based on actual operation in the application.

(3)

Resistors applied high DC voltage and of high resistance are recommended to select resistors designed against electromigration or use

combinations of resistors in series for that to reduce each applied voltage, according to the requirement of the application.

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 23

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Transformer Specifications

▫ Primary Inductance, LP: 3.1 mH

▫ Core Size: EI-16

▫ Al-value: 114 nH/N2 (Center gap of about 0.188 mm)

▫ Winding Specification

Number of

Winding Symbol Wire Diameter (mm) Construction

Turns (T)

Double-layer,

Primary winding P1 66 φ 0.18 UEW

solenoid winding

Triple-layer,

Primary winding P2 99 φ 0.18 UEW

solenoid winding

Auxiliary winding D 29 φ 0.18 UEW Solenoid winding

Output S1 11 φ 0.4 × 3 TIW Solenoid winding

5V

VDC VOUT(+)

P1

P2 S1

P2 VOUT(-)

D

S1 D

P1 VCC

Bobbin D

GND

Cross-section view : Start at this pin

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 24

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

STR-A6100 Series

Important Notes

● All data, illustrations, graphs, tables and any other information included in this document (the “Information”) as to Sanken’s

products listed herein (the “Sanken Products”) are current as of the date this document is issued. The Information is subject to any

change without notice due to improvement of the Sanken Products, etc. Please make sure to confirm with a Sanken sales

representative that the contents set forth in this document reflect the latest revisions before use.

● The Sanken Products are intended for use as components of general purpose electronic equipment or apparatus (such as home

appliances, office equipment, telecommunication equipment, measuring equipment, etc.). Prior to use of the Sanken Products,

please put your signature, or affix your name and seal, on the specification documents of the Sanken Products and return them to

Sanken. When considering use of the Sanken Products for any applications that require higher reliability (such as transportation

equipment and its control systems, traffic signal control systems or equipment, disaster/crime alarm systems, various safety

devices, etc.), you must contact a Sanken sales representative to discuss the suitability of such use and put your signature, or affix

your name and seal, on the specification documents of the Sanken Products and return them to Sanken, prior to the use of the

Sanken Products. The Sanken Products are not intended for use in any applications that require extremely high reliability such as:

aerospace equipment; nuclear power control systems; and medical equipment or systems, whose failure or malfunction may result

in death or serious injury to people, i.e., medical devices in Class III or a higher class as defined by relevant laws of Japan

(collectively, the “Specific Applications”). Sanken assumes no liability or responsibility whatsoever for any and all damages and

losses that may be suffered by you, users or any third party, resulting from the use of the Sanken Products in the Specific

Applications or in manner not in compliance with the instructions set forth herein.

● In the event of using the Sanken Products by either (i) combining other products or materials or both therewith or (ii) physically,

chemically or otherwise processing or treating or both the same, you must duly consider all possible risks that may result from all

such uses in advance and proceed therewith at your own responsibility.

● Although Sanken is making efforts to enhance the quality and reliability of its products, it is impossible to completely avoid the

occurrence of any failure or defect or both in semiconductor products at a certain rate. You must take, at your own responsibility,

preventative measures including using a sufficient safety design and confirming safety of any equipment or systems in/for which

the Sanken Products are used, upon due consideration of a failure occurrence rate and derating, etc., in order not to cause any

human injury or death, fire accident or social harm which may result from any failure or malfunction of the Sanken Products.

Please refer to the relevant specification documents and Sanken’s official website in relation to derating.

● No anti-radioactive ray design has been adopted for the Sanken Products.

● The circuit constant, operation examples, circuit examples, pattern layout examples, design examples, recommended examples, all

information and evaluation results based thereon, etc., described in this document are presented for the sole purpose of reference of

use of the Sanken Products.

● Sanken assumes no responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third

party, or any possible infringement of any and all property rights including intellectual property rights and any other rights of you,

users or any third party, resulting from the Information.

● No information in this document can be transcribed or copied or both without Sanken’s prior written consent.

● Regarding the Information, no license, express, implied or otherwise, is granted hereby under any intellectual property rights and

any other rights of Sanken.

● Unless otherwise agreed in writing between Sanken and you, Sanken makes no warranty of any kind, whether express or implied,

including, without limitation, any warranty (i) as to the quality or performance of the Sanken Products (such as implied warranty

of merchantability, and implied warranty of fitness for a particular purpose or special environment), (ii) that any Sanken Product is

delivered free of claims of third parties by way of infringement or the like, (iii) that may arise from course of performance, course

of dealing or usage of trade, and (iv) as to the Information (including its accuracy, usefulness, and reliability).

● In the event of using the Sanken Products, you must use the same after carefully examining all applicable environmental laws and

regulations that regulate the inclusion or use or both of any particular controlled substances, including, but not limited to, the EU

RoHS Directive, so as to be in strict compliance with such applicable laws and regulations.

● You must not use the Sanken Products or the Information for the purpose of any military applications or use, including but not

limited to the development of weapons of mass destruction. In the event of exporting the Sanken Products or the Information, or

providing them for non-residents, you must comply with all applicable export control laws and regulations in each country

including the U.S. Export Administration Regulations (EAR) and the Foreign Exchange and Foreign Trade Act of Japan, and

follow the procedures required by such applicable laws and regulations.

● Sanken assumes no responsibility for any troubles, which may occur during the transportation of the Sanken Products including

the falling thereof, out of Sanken’s distribution network.

● Although Sanken has prepared this document with its due care to pursue the accuracy thereof, Sanken does not warrant that it is

error free and Sanken assumes no liability whatsoever for any and all damages and losses which may be suffered by you resulting

from any possible errors or omissions in connection with the Information.

● Please refer to our official website in relation to general instructions and directions for using the Sanken Products, and refer to the

relevant specification documents in relation to particular precautions when using the Sanken Products.

● All rights and title in and to any specific trademark or tradename belong to Sanken and such original right holder(s).

DSGN-CEZ-16003

STR-A6100-DSE rev.3.0 SANKEN ELECTRIC CO., LTD 25

Dec. 13, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2006

You might also like

- Price List 2021 (GLOBAL - USD) Process Instruments - Modular Control SolutionsDocument36 pagesPrice List 2021 (GLOBAL - USD) Process Instruments - Modular Control Solutionsatikah100% (2)

- Cobra 1046Document7 pagesCobra 1046cockybundooNo ratings yet

- STR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument28 pagesSTR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETAnonymous uEOZ7raPkzNo ratings yet

- Str-A606xh Ds en PDFDocument27 pagesStr-A606xh Ds en PDFDylan Gonzalez Villalobos100% (1)

- STR3A100 Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument25 pagesSTR3A100 Series: Off-Line PWM Controllers With Integrated Power MOSFETMiguel Angel GullonNo ratings yet

- For New Designs: STR-W6000S SeriesDocument26 pagesFor New Designs: STR-W6000S SeriesGedealdo TorresNo ratings yet

- STR-W6000S Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument26 pagesSTR-W6000S Series: Off-Line PWM Controllers With Integrated Power MOSFETJulian Andres RozoNo ratings yet

- STR 6XXX SeriesDocument2 pagesSTR 6XXX SeriesGabriel LatiuNo ratings yet

- Str-W625xseries An enDocument17 pagesStr-W625xseries An enFederico GiordanoNo ratings yet

- STR A6252 Allegro MicroSystemsDocument7 pagesSTR A6252 Allegro MicroSystemsSergio ReyesNo ratings yet

- STR A6159 MosfetDocument26 pagesSTR A6159 MosfetAngel CallejebrioNo ratings yet

- Str-Y6700 SeriesDocument2 pagesStr-Y6700 SeriesDaniel MestresNo ratings yet

- For New Designs: STR-A6131MDocument26 pagesFor New Designs: STR-A6131Misdi antoroNo ratings yet

- Diag. STR-y6763 PDFDocument33 pagesDiag. STR-y6763 PDFJAPHET JAIME AYALA ACUÑANo ratings yet

- Str-X67xxseries An en PDFDocument19 pagesStr-X67xxseries An en PDFRenn PaculanangNo ratings yet

- Str-Y6700 Ds enDocument33 pagesStr-Y6700 Ds enUbernel NavarroNo ratings yet

- STR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching RegulatorDocument8 pagesSTR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching RegulatorEmmanuel ZambranoNo ratings yet

- STR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching RegulatorDocument8 pagesSTR-W6753: Universal-Input/58 W Off-Line Quasi-Resonant Flyback Switching Regulatorlewis gonzalezNo ratings yet

- STR-W6754: Universal-Input/100 W Off-Line Quasi-Resonant Flyback Switching RegulatorDocument8 pagesSTR-W6754: Universal-Input/100 W Off-Line Quasi-Resonant Flyback Switching RegulatorTecnico GenioNo ratings yet

- Str-A6251 Str-A6252 PDFDocument7 pagesStr-A6251 Str-A6252 PDFrafalero1No ratings yet

- STRW6756 PDFDocument8 pagesSTRW6756 PDFAntWonxxxNo ratings yet

- STR-W6754 - DataDocument8 pagesSTR-W6754 - DataRosyid AsmawiNo ratings yet

- STR W6754 AllegroMicrosystemsDocument8 pagesSTR W6754 AllegroMicrosystemsDelta PratamaNo ratings yet

- EM8635 ExcellianceMOSDocument13 pagesEM8635 ExcellianceMOSBruno MartinsNo ratings yet

- Not Recommended For New Designs: STR-Y6700 SeriesDocument33 pagesNot Recommended For New Designs: STR-Y6700 SeriesmaxNo ratings yet

- AABIDocument63 pagesAABIsureshkurumaNo ratings yet

- Str-W625xseries An enDocument17 pagesStr-W625xseries An encjtrybiec0% (1)

- AP3101 Application Note V1.3 080107Document5 pagesAP3101 Application Note V1.3 080107Carlos Marinho SilvaNo ratings yet

- STR-A6252M: Switching RegulatorsDocument13 pagesSTR-A6252M: Switching RegulatorsAntonioPeriniNo ratings yet

- BM1513 EtcDocument7 pagesBM1513 EtcDimas BarretoNo ratings yet

- Str-A6251M: Universal-Input/15 W 67 KHZ Flyback Switching RegulatorDocument7 pagesStr-A6251M: Universal-Input/15 W 67 KHZ Flyback Switching RegulatorAlexisNo ratings yet

- DM311Document16 pagesDM311Hernan Ortiz EnamoradoNo ratings yet

- Ast965-U12 IgbtDocument6 pagesAst965-U12 IgbtBhethhoNo ratings yet

- Stra6252m SKDocument13 pagesStra6252m SKLeonildo CostaNo ratings yet

- STR W6000S Series Application NoteDocument20 pagesSTR W6000S Series Application NoteSutrisno OkNo ratings yet

- Off-Line Current Mode PWM Control Circuit With Very Low Start Up CurrentDocument7 pagesOff-Line Current Mode PWM Control Circuit With Very Low Start Up CurrentSero StivNo ratings yet

- W6053S SankenDocument12 pagesW6053S SankenTorikul HabibNo ratings yet

- Datasheeta6259h PDFDocument13 pagesDatasheeta6259h PDFEsteban MaryoryNo ratings yet

- STR x6750 PDFDocument19 pagesSTR x6750 PDFJose Domingo Maltez VallecilloNo ratings yet

- Description Features: APU3037 / APU3037ADocument18 pagesDescription Features: APU3037 / APU3037ALeonardoNo ratings yet

- STR-A6100: SeriesDocument2 pagesSTR-A6100: SeriesY. Leonel MolinaNo ratings yet

- Off-Line Current Mode PWM Control Circuit With Undervoltage LockoutDocument7 pagesOff-Line Current Mode PWM Control Circuit With Undervoltage LockoutSero StivNo ratings yet

- STR-W6252D SankenElectric PDFDocument15 pagesSTR-W6252D SankenElectric PDFAriel dajaoNo ratings yet

- STR-W6750F: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeDocument11 pagesSTR-W6750F: Power IC For Quasi-Resonant Type Switching Power Supply With High Efficiency and Low Noise in Full Load RangeJonhny PhamNo ratings yet

- 1SFA896106R7000 psr12 600 70Document5 pages1SFA896106R7000 psr12 600 70degaizaorellanaNo ratings yet

- Lava DoraDocument13 pagesLava DoraRay Zander FebresNo ratings yet

- STR A6200eDocument3 pagesSTR A6200eLuis HumNo ratings yet

- Features: ISL8033, ISL8033ADocument18 pagesFeatures: ISL8033, ISL8033Achangiz2220No ratings yet

- MAX77533 14V Input, 1.5A High-Efficiency Buck Converter with 9μA IDocument32 pagesMAX77533 14V Input, 1.5A High-Efficiency Buck Converter with 9μA Ijohn doewrNo ratings yet

- Stra 6251Document9 pagesStra 6251Anonymous 56f2Wl2No ratings yet

- FSDM0565R: Green Mode Fairchild Power Switch (FPS)Document20 pagesFSDM0565R: Green Mode Fairchild Power Switch (FPS)Najam Ul HassanNo ratings yet

- STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDDocument18 pagesSTR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDBertrand Soppo YokiNo ratings yet

- Arrancador Suave-PSRDocument8 pagesArrancador Suave-PSRsofiNo ratings yet

- Str3a150 Str3a150d Str3a160hd Application NoteDocument17 pagesStr3a150 Str3a150d Str3a160hd Application Notecristian González sarmientoNo ratings yet

- Arduino Nano 3 User ManualDocument20 pagesArduino Nano 3 User ManualDj PopNo ratings yet

- Bd7682fj LB eDocument30 pagesBd7682fj LB eKartik ShuklaNo ratings yet

- SD6835 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetDocument9 pagesSD6835 - Datasheet: Current Mode PWM+PFM Controller With Built-In High Voltage MosfetАлександр КачеишвилиNo ratings yet

- VS-6CWQ06FN-M3: Vishay SemiconductorsDocument7 pagesVS-6CWQ06FN-M3: Vishay SemiconductorsSolihin iingNo ratings yet

- MS116-6.3 Manual Motor Starter: Product-DetailsDocument7 pagesMS116-6.3 Manual Motor Starter: Product-DetailsLuis Carlos Sandoval BlancoNo ratings yet

- 1SAM350000R1011 ms132 16Document8 pages1SAM350000R1011 ms132 16kikokiko KarimNo ratings yet

- Digital T-Rms Auto-Ranging Multimeter Metrasafe-10: The Quality LeaderDocument5 pagesDigital T-Rms Auto-Ranging Multimeter Metrasafe-10: The Quality LeaderRaja RajaNo ratings yet

- TDA7491P: 10 W + 10 W Dual BTL Class-D Audio AmplifierDocument40 pagesTDA7491P: 10 W + 10 W Dual BTL Class-D Audio AmplifierRaja RajaNo ratings yet

- Unisonic Technologies Co., LTD: BTL 4.0W X 1Ch Power AmplifierDocument4 pagesUnisonic Technologies Co., LTD: BTL 4.0W X 1Ch Power AmplifierRaja RajaNo ratings yet

- St3151a05 5 CsotDocument22 pagesSt3151a05 5 CsotRaja RajaNo ratings yet

- Impex Induction Cooker Error CodesDocument4 pagesImpex Induction Cooker Error CodesRaja RajaNo ratings yet

- Charger Ripple Current Effect v2Document4 pagesCharger Ripple Current Effect v2diyitNo ratings yet

- Electrical Principles (EET0113) : Direct Current (DC)Document10 pagesElectrical Principles (EET0113) : Direct Current (DC)Amirah MohdNo ratings yet

- A PH Meter Has A Membrane That Allows Acidic IonsDocument4 pagesA PH Meter Has A Membrane That Allows Acidic IonsWaltas KariukiNo ratings yet

- Thin-Film Structuring: Holger BartolfDocument7 pagesThin-Film Structuring: Holger BartolfMichelle CedNo ratings yet

- LTC6655 6655LNDocument30 pagesLTC6655 6655LNpravin jadavNo ratings yet

- Chapter 6 PDFDocument58 pagesChapter 6 PDFAdel AtawiNo ratings yet

- Genset Honda EU65isDocument78 pagesGenset Honda EU65isdoddyNo ratings yet