Professional Documents

Culture Documents

SGS Audit Plan

SGS Audit Plan

Uploaded by

fransiskaCopyright:

Available Formats

You might also like

- Participant Workbook-ISO 9001 - 2015-Issue 02 Rev 03 Nov 2022-3Document52 pagesParticipant Workbook-ISO 9001 - 2015-Issue 02 Rev 03 Nov 2022-3Jadesh ChandranNo ratings yet

- Iso TS - 22003-1-2022-1Document37 pagesIso TS - 22003-1-2022-1Ahmed HatemNo ratings yet

- ISO 9001 Lead Auditor PDFDocument1 pageISO 9001 Lead Auditor PDFmdasifkhan201350% (2)

- Audit Plan ISO 9001Document2 pagesAudit Plan ISO 9001Mokhamad83% (6)

- QUIZ For ISO 14001 Internal AuditorDocument2 pagesQUIZ For ISO 14001 Internal AuditorSharani Kamaludin80% (15)

- NEW UPDATE! FSSC 22000 Version 6.0Document36 pagesNEW UPDATE! FSSC 22000 Version 6.0afriani_rachman100% (1)

- (Ver21.00) ISO 9001 QMS Internal Audit Training (New)Document177 pages(Ver21.00) ISO 9001 QMS Internal Audit Training (New)RSA ChannelNo ratings yet

- 15 Workbook 1.Document56 pages15 Workbook 1.Gokul G0% (1)

- Sample Quality Objectives TemplateDocument2 pagesSample Quality Objectives Templatesamebc100% (3)

- Turtle Diagram ExampleDocument1 pageTurtle Diagram ExampleMuhammad Abdul Hakim Faqih100% (1)

- F13-QMS Stage 1 (5) AqcDocument5 pagesF13-QMS Stage 1 (5) AqcPriyank SuranaNo ratings yet

- Procedure For Internal AuditingDocument4 pagesProcedure For Internal AuditingQuality Unit 1 Ajay Pandey67% (3)

- QHSE Awareness Training: - Madankumar PalaniDocument28 pagesQHSE Awareness Training: - Madankumar Palanimadan19810% (1)

- Annex A - NON CONFORMITY RESOLUTION REPORT-BridsiteDocument8 pagesAnnex A - NON CONFORMITY RESOLUTION REPORT-BridsiteGodwin A.udo-akanNo ratings yet

- Proyect Sheduling Iso 9001 2015Document1 pageProyect Sheduling Iso 9001 2015roellyNo ratings yet

- List of Documents ISO 9001Document3 pagesList of Documents ISO 9001xenophontosxenNo ratings yet

- Project Proposal For Iso 9001:2015 Implementation: (Organization Name)Document5 pagesProject Proposal For Iso 9001:2015 Implementation: (Organization Name)RajasekharChimiralaNo ratings yet

- List of Internal Auditors With Skill MatrixDocument2 pagesList of Internal Auditors With Skill MatrixSachin Ramdurg50% (2)

- List of Mandatory Documents Required by ISO 9001Document2 pagesList of Mandatory Documents Required by ISO 9001Rieneke KusmawaningtyasNo ratings yet

- Two 2 Page Quality ManualDocument2 pagesTwo 2 Page Quality Manualtony s100% (1)

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- ISO 9001 2008 Awareness Training QuestionnaireDocument2 pagesISO 9001 2008 Awareness Training Questionnaireezal2100% (3)

- 3 3 3-OHSMS-LAC - Delelgate Activity Manual-20-JULY-2020Document33 pages3 3 3-OHSMS-LAC - Delelgate Activity Manual-20-JULY-2020walidNo ratings yet

- FSSC 22000 V6 0Document83 pagesFSSC 22000 V6 0Ahmed HatemNo ratings yet

- Participant Workbook - SDocument48 pagesParticipant Workbook - SSugashiniNo ratings yet

- Checklist - Iso 17021Document41 pagesChecklist - Iso 17021Rui Madureira100% (1)

- Group Work Booklet: Hazard Analysis Fundamentals of Food Safety As Per ISO 22000 / FSSC 22000 V 5Document14 pagesGroup Work Booklet: Hazard Analysis Fundamentals of Food Safety As Per ISO 22000 / FSSC 22000 V 5Vineeth Kumar MishraNo ratings yet

- Participant Handout - Audit Report - Stage 1Document10 pagesParticipant Handout - Audit Report - Stage 1francisNo ratings yet

- Compliance Obligation Register: ISO 9001:2015 & ISO 14001:2015Document1 pageCompliance Obligation Register: ISO 9001:2015 & ISO 14001:2015ALEX B100% (1)

- Audit Checkpoint For ISO 9001 2015 & 14001 2015Document2 pagesAudit Checkpoint For ISO 9001 2015 & 14001 2015suresh kumar100% (1)

- Irca 14153 Ems La-Pre Course Quiz-Sep 2015 2015Document3 pagesIrca 14153 Ems La-Pre Course Quiz-Sep 2015 2015fahady05a09ce27470% (1)

- Audit Plan: Order No. Customer NoDocument2 pagesAudit Plan: Order No. Customer NofaradayNo ratings yet

- List of Documents For SEDEX PDFDocument3 pagesList of Documents For SEDEX PDFSunilNo ratings yet

- Correspondence: ISO 9001:2015/ ISO 14001:2015/ ISO 45001:2018Document3 pagesCorrespondence: ISO 9001:2015/ ISO 14001:2015/ ISO 45001:2018AnkurNo ratings yet

- Case Studies'Document71 pagesCase Studies'Harbaaz Singh100% (1)

- EN ISO 14064-3 (2019) (E) CodifiedDocument9 pagesEN ISO 14064-3 (2019) (E) Codifiedcabinet xerisNo ratings yet

- Mandatory Documents and Records Required by ISODocument3 pagesMandatory Documents and Records Required by ISOAli AliNo ratings yet

- 0.checklist, GP3113 ISO 14001 2015 EvaluationDocument29 pages0.checklist, GP3113 ISO 14001 2015 EvaluationAshraf SeragNo ratings yet

- 9k 14k 22k 45k SLComparisonDocument4 pages9k 14k 22k 45k SLComparisonEyong EpondulanNo ratings yet

- Closing MeetingDocument8 pagesClosing MeetingScarlet Sudipra100% (1)

- Ems 14001Document57 pagesEms 14001Sarmad Hussain0% (1)

- FSSC 22000 V5.1 Training Matrix 2021 TOOLDocument5 pagesFSSC 22000 V5.1 Training Matrix 2021 TOOLdiana ungureanuNo ratings yet

- Exercise For IMS INTERNAL AUDITINGDocument12 pagesExercise For IMS INTERNAL AUDITINGdhir.ankur100% (2)

- EMS ISO 14001:2015 & OH&S MS ISO 45001:2018: Section Marks Maximum Book RefDocument13 pagesEMS ISO 14001:2015 & OH&S MS ISO 45001:2018: Section Marks Maximum Book RefBharath K GNo ratings yet

- ISO9001-2015 Standard Audit Documents Checklist PDFDocument4 pagesISO9001-2015 Standard Audit Documents Checklist PDFmerrwon100% (1)

- Certified ISO 9001 Lead Auditor - Two Page BrochureDocument2 pagesCertified ISO 9001 Lead Auditor - Two Page BrochurePECBCERTIFICATIONNo ratings yet

- Iso 22003 1 and Iso 22003 2 Presentation GeneralDocument25 pagesIso 22003 1 and Iso 22003 2 Presentation Generaldenisenko.marina2017No ratings yet

- Sample - Management Review MeetingDocument9 pagesSample - Management Review MeetingClaire TanNo ratings yet

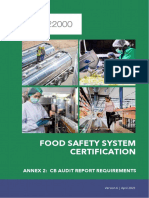

- Audit Report Requirements FSSC 22000 Version 6 1685175466Document48 pagesAudit Report Requirements FSSC 22000 Version 6 1685175466Ruben VenturaNo ratings yet

- QMSP-19 Procedure To Address Risks and OpportunitiesDocument8 pagesQMSP-19 Procedure To Address Risks and OpportunitiesAniruddha ChatterjeeNo ratings yet

- ISO 22000 Audit Check ListDocument18 pagesISO 22000 Audit Check ListMohamed ShabirNo ratings yet

- EMS-LAC-Delegate Activity Manual - VILT - CR - 08 - 2021Document32 pagesEMS-LAC-Delegate Activity Manual - VILT - CR - 08 - 2021Muthazhagan Saravanan100% (2)

- Ea Codes UkasDocument1 pageEa Codes UkasvavvavNo ratings yet

- Iso 22001 Efresh IndiaDocument13 pagesIso 22001 Efresh IndiaMahmoud KhalifaNo ratings yet

- Documentation Plan - IsO 9001Document4 pagesDocumentation Plan - IsO 9001Ahmed Elsayed100% (1)

- ISO 21001 Vs ISO 9001 Readiness AnalysisDocument137 pagesISO 21001 Vs ISO 9001 Readiness AnalysisAnnie Wong100% (1)

- Annex II: Audit Time Calculation: 1.1 Auditor DayDocument3 pagesAnnex II: Audit Time Calculation: 1.1 Auditor DayVineeth Kumar MishraNo ratings yet

- BSCIC PresentationDocument60 pagesBSCIC PresentationVuppala SrinivasNo ratings yet

- 003 - 20190401 - Awareness ISO 9001 2015 Training Material Rev.2Document119 pages003 - 20190401 - Awareness ISO 9001 2015 Training Material Rev.2Dio AghniaurrizqiNo ratings yet

- Kada Network Action PlanDocument2 pagesKada Network Action Planjesica MantacNo ratings yet

- Academic Censorship in China The Case of The China QuarterlyDocument6 pagesAcademic Censorship in China The Case of The China QuarterlyManuelNo ratings yet

- 3 Solas Isps CodeDocument40 pages3 Solas Isps CodeZoltan NagyNo ratings yet

- Samplemeetingminutes 2020Document2 pagesSamplemeetingminutes 2020Jay-Jay BordeosNo ratings yet

- Iso 527-3Document8 pagesIso 527-3Pal SinghNo ratings yet

- APPLICATIONS FOR A DRIVING LICENCE AND ADDITION OF A NEW CLASS OF VEHICLE TO A DRIVING LICENCE (For Indian Citizen) PART - I.ÂDocument12 pagesAPPLICATIONS FOR A DRIVING LICENCE AND ADDITION OF A NEW CLASS OF VEHICLE TO A DRIVING LICENCE (For Indian Citizen) PART - I.ÂRahul UnnikrishnanNo ratings yet

- Tutorial 2 - Question 1Document6 pagesTutorial 2 - Question 1Shaaru ThiagarajanNo ratings yet

- EF4e Uppint Filetest 03a Answer SheetDocument1 pageEF4e Uppint Filetest 03a Answer SheetNik GerNo ratings yet

- Right To Compensation For Wrongful Prosecution Incarceration and Conviction A Necessity of The Contemporary Indian Socio Legal FrameworkDocument12 pagesRight To Compensation For Wrongful Prosecution Incarceration and Conviction A Necessity of The Contemporary Indian Socio Legal FrameworkAliveNo ratings yet

- Report RPHDocument4 pagesReport RPHDela Cruz, Carlie Belle, F.No ratings yet

- Motion To Set Hearing Via Video9.7Document4 pagesMotion To Set Hearing Via Video9.7Illie M. GemanilNo ratings yet

- Honda City Car - ACKO General InsuranceDocument2 pagesHonda City Car - ACKO General InsurancepsvsridharNo ratings yet

- My Own BoswellDocument15 pagesMy Own BoswellJai SoniNo ratings yet

- MIL First Quarter ReviewerDocument19 pagesMIL First Quarter ReviewerPaupau CapitleNo ratings yet

- Project IBF Submitted To: DR. Sabeen Khurram KhanDocument7 pagesProject IBF Submitted To: DR. Sabeen Khurram KhanSheikh AbdullahNo ratings yet

- Republic Act No. 4136 - Official Gazette of The Republic of The PhilippinesDocument35 pagesRepublic Act No. 4136 - Official Gazette of The Republic of The PhilippinesJose Leonard RayosNo ratings yet

- Term Paper About Political Dynasty in The PhilippinesDocument8 pagesTerm Paper About Political Dynasty in The PhilippinesdelhwlwgfNo ratings yet

- Icsi-Ccgrt: Charges (Sec 77) - Definition and Some Basic ConceptsDocument5 pagesIcsi-Ccgrt: Charges (Sec 77) - Definition and Some Basic ConceptsMuthu KumaranNo ratings yet

- Subsidy of Rs. 2 To 3 Lacs by The Government of Sindh For Purchasing Locally Assembled/ Manufactured TractorsDocument2 pagesSubsidy of Rs. 2 To 3 Lacs by The Government of Sindh For Purchasing Locally Assembled/ Manufactured TractorsdraqbhattiNo ratings yet

- Văn Hóa Anh 1Document3 pagesVăn Hóa Anh 1phamanhthi90No ratings yet

- Indian-Constitution GTU Study Material Presentations ALL 23102019061527AMDocument12 pagesIndian-Constitution GTU Study Material Presentations ALL 23102019061527AMHarsh GajjarNo ratings yet

- State Fiscal RankingsDocument117 pagesState Fiscal RankingsRithvickNo ratings yet

- Sample Registry ExtractDocument2 pagesSample Registry ExtractsignulitraNo ratings yet

- Chapter 3 StatConDocument7 pagesChapter 3 StatConDenver OliverosNo ratings yet

- UPDATED BROCHURE - 10th Intra Bail Argument Competition 2023Document13 pagesUPDATED BROCHURE - 10th Intra Bail Argument Competition 2023shailja singhNo ratings yet

- It FileDocument16 pagesIt Filedishu kumarNo ratings yet

- Pretest in TCWDocument18 pagesPretest in TCWRosie ToszieNo ratings yet

- Sushila Lohiya CW Education For Reinstatment - Removal of ServiceDocument28 pagesSushila Lohiya CW Education For Reinstatment - Removal of ServiceLaw OfficeNo ratings yet

- Complainant Vs Vs Respondent: First DivisionDocument7 pagesComplainant Vs Vs Respondent: First DivisionMaureen AntallanNo ratings yet

- In Every Filipino The Time-Honored Tradition of Bayanihan To Foster Social Justice, Solidarity and Sustainable DevelopmentDocument6 pagesIn Every Filipino The Time-Honored Tradition of Bayanihan To Foster Social Justice, Solidarity and Sustainable DevelopmentRexson TagubaNo ratings yet

SGS Audit Plan

SGS Audit Plan

Uploaded by

fransiskaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SGS Audit Plan

SGS Audit Plan

Uploaded by

fransiskaCopyright:

Available Formats

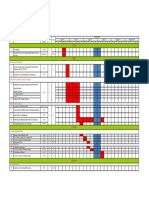

SGS Audit Plan

PT. SMART Tbk. (PT. Sinar Mas Agro Resources and Technology Tbk.) –

Company:

Belawan Refinery

Address: Jl. Belmera Baru III, Belawan II, Medan 20412, North Sumatera, Indonesia

Site Contact Person: Ms. Theresia Sitepu Site PCQI (FSMA only): -

ISO 9001:2015

Manufacturing of Fats (Shortening and Cocoa Butter Substitute) and Cooking

Audit Scope: Oils (Palm Based Liquid and Semisolid and Palm Kernel Oils), and Palm

Incl. Exclusions Kernel Expeller

Incl. FDA Product codes

(FSMA only) ISO 22000:2005

Manufacturing of Fats (Shortening and Cocoa Butter Substitute) and Cooking

Oils (Palm Based Liquid and Semisolid and Palm Kernel Oils)

Standard(s): ISO 22000:2005 & ISO 9001:2015

Start Date: 09 June 2020 End Date: 12 June 2020

Surveillance 22000,

Calculated Audit 7 MD (Full remote audit ID/JKT – 1234

Visit Type / Contract No:

Duration: by MS Team) Recertification ISO

9001:2015, ID/JKT-1386

Tech Scope (IFS only):

Product Categories: C4d : Oil and Fats -

Regulatory Scope:

-

(FSMA only)

Lead Auditor: A – Agustinus Budiharto

Team Member(s): B – Risto Manik

Additional Attendees

-

and Roles:

Audit Language: Indonesia

Audit objectives:

To confirm that the site has established and implemented the requirements of the Standard

Day One

Auditor Standard(s)

Area / Department / Process / Key Site Contact

Time (for Audit (for combined

Function Person

Teams) Audits)

08.30 Audit Preparation via MS Team A, B

09.00 Opening Meeting A, B

09.30 Discussion with Top Management ISO

(Vision, mission, strategic planning, 9001:2015

commitment, company policy, objective) + ISO

22000:2005

10.00 Food Safety Team

ISO

- Revoew changes

9001:2015

- Closed out previous ISO 22000 + ISO

& ISO 9001 Minor CAR(s) and 22000:2005

verify observation(s)

12.00 Working lunch

13.00 Production Refinery & Fractionation A ISO

9001:2015

+ ISO

22000:2005

Issue n°: 2

Document: GF0103 Audit Plan Food Safety Page n°: 1 of 4

15.00 Production Kernel oil-Expeller ISO

(KCP): 9001:2015

+ ISO

22000:2005

17.00 End of Day 1

13.00 PPIC B ISO

9001:2015

14.00 Commercial ISO

- Industrial 9001:2015

- Trading + ISO

- Admin 22000:2005

15.00 Logistics- Incoming and Storage Bulk ISO

Oil in Tank Farm, Delivery Bulk Finished 9001:2015

Product & Pump House + ISO

22000:2005

17.00 End of Day 1

Day Two

Auditor Standard(s)

Area / Department / Process / Key Site Contact

Time (for Audit (for combined

Function Person

Teams) Audits)

09.00 Production Cooking Oil in Consumer ISO

Pack 9001:2015

A

+ ISO

22000:2005

12.00 Working lunch

13.00 Engineering Utility ISO

9001:2015

+ ISO

22000:2005

15.00 Engineering Maintenance ISO

9001:2015

+ ISO

22000:2005

17.00 End of day 2

09.00 Bulk Storage Belawan : B ISO

- OTD 9001:2015

- Installation + ISO

22000:2005

10.30 Production CBS ISO

9001:2015

+ ISO

22000:2005

12.00 Working lunch

13.00 Production Texturizing ISO

9001:2015

+ ISO

22000:2005

15.00 Storage of ingredients/food additive and ISO

packaging material 9001:2015

+ ISO

22000:2005

Issue n°: 2

Document: GF0103 Audit Plan Food Safety Page n°: 2 of 4

17.00 End of day 2

Day Three

Auditor Standard(s)

Area / Department / Process / Key Site Contact

Time (for Audit (for combined

Function Person

Teams) Audits)

09.00 Finished goods storage – shortening ISO

and cooking oil 9001:2015

A

+ ISO

22000:2005

10.30 Pest Control ISO

9001:2015

+ ISO

22000:2005

12.00 Working lunch

13.00 Calibration ISO

9001:2015

+ ISO

22000:2005

15.00 QC: raw material inspection, in-process ISO

and Finished Good Refinery and 9001:2015

Fractionation, KCP, Utility + ISO

22000:2005

17.00 End of day 3

Day Four

Auditor Standard(s)

Area / Department / Process / Key Site Contact

Time (for Audit (for combined

Function Person

Teams) Audits)

09.00 HRD: recruitment and training and ISO

medical check up 9001:2015

A

+ ISO

22000:2005

12.00 Working lunch

13.00 Food Safety Team:

- Management review

- Internal audit

- FSMS Verification and Validation

- Customer complaint,

- Correction and corrective action ISO

- Continual improvement 9001:2015

- Mock recall and Traceability system + ISO

- Withdrawal 22000:2005

- Emergency preparedness and

response

- Management of purchased material

- Certification claims and use of

certification marks

09.00 QC-Incoming bulk oil, CBS, Texturing, ISO

delivery bulk oil, utility 9001:2015

B

+ ISO

22000:2005

10.00 Procurement ISO

9001:2015

Issue n°: 2

Document: GF0103 Audit Plan Food Safety Page n°: 3 of 4

+ ISO

22000:2005

12.00 Working Lunch

13.00 IT ISO

9001:2015

14.00 Summarizing and audit report

A, B

preparation

15.00 Closing Meeting

18.00 End of recertification ISO 9001 and

Surveillance ISO 22000

Notes to Client:

• If applicable, Quality objectives, internal communication, analysis of data will be audited at all relevant functions.

• A management representative should be available during audit period and all key staff (or deputies) should be

readily available to ensure that the plan can be followed.

• It is essential that SGS are informed of any changes to the process or the facilities since the quotation or previous

audit that could affect timings on this audit plan. This must be done prior to the audit.

• It is essential that all operations applicable to the scope are seen during the audit please advise if any of these

cannot be seen within these timeframes (For IFS; Production lines/ products which cannot be assessed on site

during the audit, cannot be included in the certificate scope).

• It is essential that appropriate protective clothing is provided for visiting facilities.

• Times are approximate and will be confirmed at the opening meeting prior to commencement of the audit.

• SGS auditors reserve the right to change or add to the elements listed before or during the audit depending on

the results of on-site investigation.

• A private place for preparation, review and conferencing is requested for the auditor’s use.

• Please provide a light working lunch on-site each audit day.

• Your contract with SGS is an integral part of this audit plan and details confidentiality arrangements, audit scope,

information on follow up activities and any special reporting requirements.

Issue n°: 2

Document: GF0103 Audit Plan Food Safety Page n°: 4 of 4

You might also like

- Participant Workbook-ISO 9001 - 2015-Issue 02 Rev 03 Nov 2022-3Document52 pagesParticipant Workbook-ISO 9001 - 2015-Issue 02 Rev 03 Nov 2022-3Jadesh ChandranNo ratings yet

- Iso TS - 22003-1-2022-1Document37 pagesIso TS - 22003-1-2022-1Ahmed HatemNo ratings yet

- ISO 9001 Lead Auditor PDFDocument1 pageISO 9001 Lead Auditor PDFmdasifkhan201350% (2)

- Audit Plan ISO 9001Document2 pagesAudit Plan ISO 9001Mokhamad83% (6)

- QUIZ For ISO 14001 Internal AuditorDocument2 pagesQUIZ For ISO 14001 Internal AuditorSharani Kamaludin80% (15)

- NEW UPDATE! FSSC 22000 Version 6.0Document36 pagesNEW UPDATE! FSSC 22000 Version 6.0afriani_rachman100% (1)

- (Ver21.00) ISO 9001 QMS Internal Audit Training (New)Document177 pages(Ver21.00) ISO 9001 QMS Internal Audit Training (New)RSA ChannelNo ratings yet

- 15 Workbook 1.Document56 pages15 Workbook 1.Gokul G0% (1)

- Sample Quality Objectives TemplateDocument2 pagesSample Quality Objectives Templatesamebc100% (3)

- Turtle Diagram ExampleDocument1 pageTurtle Diagram ExampleMuhammad Abdul Hakim Faqih100% (1)

- F13-QMS Stage 1 (5) AqcDocument5 pagesF13-QMS Stage 1 (5) AqcPriyank SuranaNo ratings yet

- Procedure For Internal AuditingDocument4 pagesProcedure For Internal AuditingQuality Unit 1 Ajay Pandey67% (3)

- QHSE Awareness Training: - Madankumar PalaniDocument28 pagesQHSE Awareness Training: - Madankumar Palanimadan19810% (1)

- Annex A - NON CONFORMITY RESOLUTION REPORT-BridsiteDocument8 pagesAnnex A - NON CONFORMITY RESOLUTION REPORT-BridsiteGodwin A.udo-akanNo ratings yet

- Proyect Sheduling Iso 9001 2015Document1 pageProyect Sheduling Iso 9001 2015roellyNo ratings yet

- List of Documents ISO 9001Document3 pagesList of Documents ISO 9001xenophontosxenNo ratings yet

- Project Proposal For Iso 9001:2015 Implementation: (Organization Name)Document5 pagesProject Proposal For Iso 9001:2015 Implementation: (Organization Name)RajasekharChimiralaNo ratings yet

- List of Internal Auditors With Skill MatrixDocument2 pagesList of Internal Auditors With Skill MatrixSachin Ramdurg50% (2)

- List of Mandatory Documents Required by ISO 9001Document2 pagesList of Mandatory Documents Required by ISO 9001Rieneke KusmawaningtyasNo ratings yet

- Two 2 Page Quality ManualDocument2 pagesTwo 2 Page Quality Manualtony s100% (1)

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- ISO 9001 2008 Awareness Training QuestionnaireDocument2 pagesISO 9001 2008 Awareness Training Questionnaireezal2100% (3)

- 3 3 3-OHSMS-LAC - Delelgate Activity Manual-20-JULY-2020Document33 pages3 3 3-OHSMS-LAC - Delelgate Activity Manual-20-JULY-2020walidNo ratings yet

- FSSC 22000 V6 0Document83 pagesFSSC 22000 V6 0Ahmed HatemNo ratings yet

- Participant Workbook - SDocument48 pagesParticipant Workbook - SSugashiniNo ratings yet

- Checklist - Iso 17021Document41 pagesChecklist - Iso 17021Rui Madureira100% (1)

- Group Work Booklet: Hazard Analysis Fundamentals of Food Safety As Per ISO 22000 / FSSC 22000 V 5Document14 pagesGroup Work Booklet: Hazard Analysis Fundamentals of Food Safety As Per ISO 22000 / FSSC 22000 V 5Vineeth Kumar MishraNo ratings yet

- Participant Handout - Audit Report - Stage 1Document10 pagesParticipant Handout - Audit Report - Stage 1francisNo ratings yet

- Compliance Obligation Register: ISO 9001:2015 & ISO 14001:2015Document1 pageCompliance Obligation Register: ISO 9001:2015 & ISO 14001:2015ALEX B100% (1)

- Audit Checkpoint For ISO 9001 2015 & 14001 2015Document2 pagesAudit Checkpoint For ISO 9001 2015 & 14001 2015suresh kumar100% (1)

- Irca 14153 Ems La-Pre Course Quiz-Sep 2015 2015Document3 pagesIrca 14153 Ems La-Pre Course Quiz-Sep 2015 2015fahady05a09ce27470% (1)

- Audit Plan: Order No. Customer NoDocument2 pagesAudit Plan: Order No. Customer NofaradayNo ratings yet

- List of Documents For SEDEX PDFDocument3 pagesList of Documents For SEDEX PDFSunilNo ratings yet

- Correspondence: ISO 9001:2015/ ISO 14001:2015/ ISO 45001:2018Document3 pagesCorrespondence: ISO 9001:2015/ ISO 14001:2015/ ISO 45001:2018AnkurNo ratings yet

- Case Studies'Document71 pagesCase Studies'Harbaaz Singh100% (1)

- EN ISO 14064-3 (2019) (E) CodifiedDocument9 pagesEN ISO 14064-3 (2019) (E) Codifiedcabinet xerisNo ratings yet

- Mandatory Documents and Records Required by ISODocument3 pagesMandatory Documents and Records Required by ISOAli AliNo ratings yet

- 0.checklist, GP3113 ISO 14001 2015 EvaluationDocument29 pages0.checklist, GP3113 ISO 14001 2015 EvaluationAshraf SeragNo ratings yet

- 9k 14k 22k 45k SLComparisonDocument4 pages9k 14k 22k 45k SLComparisonEyong EpondulanNo ratings yet

- Closing MeetingDocument8 pagesClosing MeetingScarlet Sudipra100% (1)

- Ems 14001Document57 pagesEms 14001Sarmad Hussain0% (1)

- FSSC 22000 V5.1 Training Matrix 2021 TOOLDocument5 pagesFSSC 22000 V5.1 Training Matrix 2021 TOOLdiana ungureanuNo ratings yet

- Exercise For IMS INTERNAL AUDITINGDocument12 pagesExercise For IMS INTERNAL AUDITINGdhir.ankur100% (2)

- EMS ISO 14001:2015 & OH&S MS ISO 45001:2018: Section Marks Maximum Book RefDocument13 pagesEMS ISO 14001:2015 & OH&S MS ISO 45001:2018: Section Marks Maximum Book RefBharath K GNo ratings yet

- ISO9001-2015 Standard Audit Documents Checklist PDFDocument4 pagesISO9001-2015 Standard Audit Documents Checklist PDFmerrwon100% (1)

- Certified ISO 9001 Lead Auditor - Two Page BrochureDocument2 pagesCertified ISO 9001 Lead Auditor - Two Page BrochurePECBCERTIFICATIONNo ratings yet

- Iso 22003 1 and Iso 22003 2 Presentation GeneralDocument25 pagesIso 22003 1 and Iso 22003 2 Presentation Generaldenisenko.marina2017No ratings yet

- Sample - Management Review MeetingDocument9 pagesSample - Management Review MeetingClaire TanNo ratings yet

- Audit Report Requirements FSSC 22000 Version 6 1685175466Document48 pagesAudit Report Requirements FSSC 22000 Version 6 1685175466Ruben VenturaNo ratings yet

- QMSP-19 Procedure To Address Risks and OpportunitiesDocument8 pagesQMSP-19 Procedure To Address Risks and OpportunitiesAniruddha ChatterjeeNo ratings yet

- ISO 22000 Audit Check ListDocument18 pagesISO 22000 Audit Check ListMohamed ShabirNo ratings yet

- EMS-LAC-Delegate Activity Manual - VILT - CR - 08 - 2021Document32 pagesEMS-LAC-Delegate Activity Manual - VILT - CR - 08 - 2021Muthazhagan Saravanan100% (2)

- Ea Codes UkasDocument1 pageEa Codes UkasvavvavNo ratings yet

- Iso 22001 Efresh IndiaDocument13 pagesIso 22001 Efresh IndiaMahmoud KhalifaNo ratings yet

- Documentation Plan - IsO 9001Document4 pagesDocumentation Plan - IsO 9001Ahmed Elsayed100% (1)

- ISO 21001 Vs ISO 9001 Readiness AnalysisDocument137 pagesISO 21001 Vs ISO 9001 Readiness AnalysisAnnie Wong100% (1)

- Annex II: Audit Time Calculation: 1.1 Auditor DayDocument3 pagesAnnex II: Audit Time Calculation: 1.1 Auditor DayVineeth Kumar MishraNo ratings yet

- BSCIC PresentationDocument60 pagesBSCIC PresentationVuppala SrinivasNo ratings yet

- 003 - 20190401 - Awareness ISO 9001 2015 Training Material Rev.2Document119 pages003 - 20190401 - Awareness ISO 9001 2015 Training Material Rev.2Dio AghniaurrizqiNo ratings yet

- Kada Network Action PlanDocument2 pagesKada Network Action Planjesica MantacNo ratings yet

- Academic Censorship in China The Case of The China QuarterlyDocument6 pagesAcademic Censorship in China The Case of The China QuarterlyManuelNo ratings yet

- 3 Solas Isps CodeDocument40 pages3 Solas Isps CodeZoltan NagyNo ratings yet

- Samplemeetingminutes 2020Document2 pagesSamplemeetingminutes 2020Jay-Jay BordeosNo ratings yet

- Iso 527-3Document8 pagesIso 527-3Pal SinghNo ratings yet

- APPLICATIONS FOR A DRIVING LICENCE AND ADDITION OF A NEW CLASS OF VEHICLE TO A DRIVING LICENCE (For Indian Citizen) PART - I.ÂDocument12 pagesAPPLICATIONS FOR A DRIVING LICENCE AND ADDITION OF A NEW CLASS OF VEHICLE TO A DRIVING LICENCE (For Indian Citizen) PART - I.ÂRahul UnnikrishnanNo ratings yet

- Tutorial 2 - Question 1Document6 pagesTutorial 2 - Question 1Shaaru ThiagarajanNo ratings yet

- EF4e Uppint Filetest 03a Answer SheetDocument1 pageEF4e Uppint Filetest 03a Answer SheetNik GerNo ratings yet

- Right To Compensation For Wrongful Prosecution Incarceration and Conviction A Necessity of The Contemporary Indian Socio Legal FrameworkDocument12 pagesRight To Compensation For Wrongful Prosecution Incarceration and Conviction A Necessity of The Contemporary Indian Socio Legal FrameworkAliveNo ratings yet

- Report RPHDocument4 pagesReport RPHDela Cruz, Carlie Belle, F.No ratings yet

- Motion To Set Hearing Via Video9.7Document4 pagesMotion To Set Hearing Via Video9.7Illie M. GemanilNo ratings yet

- Honda City Car - ACKO General InsuranceDocument2 pagesHonda City Car - ACKO General InsurancepsvsridharNo ratings yet

- My Own BoswellDocument15 pagesMy Own BoswellJai SoniNo ratings yet

- MIL First Quarter ReviewerDocument19 pagesMIL First Quarter ReviewerPaupau CapitleNo ratings yet

- Project IBF Submitted To: DR. Sabeen Khurram KhanDocument7 pagesProject IBF Submitted To: DR. Sabeen Khurram KhanSheikh AbdullahNo ratings yet

- Republic Act No. 4136 - Official Gazette of The Republic of The PhilippinesDocument35 pagesRepublic Act No. 4136 - Official Gazette of The Republic of The PhilippinesJose Leonard RayosNo ratings yet

- Term Paper About Political Dynasty in The PhilippinesDocument8 pagesTerm Paper About Political Dynasty in The PhilippinesdelhwlwgfNo ratings yet

- Icsi-Ccgrt: Charges (Sec 77) - Definition and Some Basic ConceptsDocument5 pagesIcsi-Ccgrt: Charges (Sec 77) - Definition and Some Basic ConceptsMuthu KumaranNo ratings yet

- Subsidy of Rs. 2 To 3 Lacs by The Government of Sindh For Purchasing Locally Assembled/ Manufactured TractorsDocument2 pagesSubsidy of Rs. 2 To 3 Lacs by The Government of Sindh For Purchasing Locally Assembled/ Manufactured TractorsdraqbhattiNo ratings yet

- Văn Hóa Anh 1Document3 pagesVăn Hóa Anh 1phamanhthi90No ratings yet

- Indian-Constitution GTU Study Material Presentations ALL 23102019061527AMDocument12 pagesIndian-Constitution GTU Study Material Presentations ALL 23102019061527AMHarsh GajjarNo ratings yet

- State Fiscal RankingsDocument117 pagesState Fiscal RankingsRithvickNo ratings yet

- Sample Registry ExtractDocument2 pagesSample Registry ExtractsignulitraNo ratings yet

- Chapter 3 StatConDocument7 pagesChapter 3 StatConDenver OliverosNo ratings yet

- UPDATED BROCHURE - 10th Intra Bail Argument Competition 2023Document13 pagesUPDATED BROCHURE - 10th Intra Bail Argument Competition 2023shailja singhNo ratings yet

- It FileDocument16 pagesIt Filedishu kumarNo ratings yet

- Pretest in TCWDocument18 pagesPretest in TCWRosie ToszieNo ratings yet

- Sushila Lohiya CW Education For Reinstatment - Removal of ServiceDocument28 pagesSushila Lohiya CW Education For Reinstatment - Removal of ServiceLaw OfficeNo ratings yet

- Complainant Vs Vs Respondent: First DivisionDocument7 pagesComplainant Vs Vs Respondent: First DivisionMaureen AntallanNo ratings yet

- In Every Filipino The Time-Honored Tradition of Bayanihan To Foster Social Justice, Solidarity and Sustainable DevelopmentDocument6 pagesIn Every Filipino The Time-Honored Tradition of Bayanihan To Foster Social Justice, Solidarity and Sustainable DevelopmentRexson TagubaNo ratings yet