Professional Documents

Culture Documents

GR - WRDSP - Tech Literature

GR - WRDSP - Tech Literature

Uploaded by

Digger Downhole ToolsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GR - WRDSP - Tech Literature

GR - WRDSP - Tech Literature

Uploaded by

Digger Downhole ToolsCopyright:

Available Formats

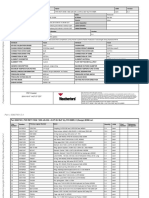

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

DESCRIPTION:- SETTING PROCEDURE: -

Model “GR-WRDSP” Retrievable Wireline

Double Seal Bore Packer is a Retrievable Packer • The Packer is run in the model “GR-W” wire

which is Hydraulically set by pressure in the line adapter kit. Attached to the model

production tubing. It is particularly suitable for “GR-HST” Hydraulic Setting Tool on the drill

Extended Reach Drilling ( ERD ) Wells. It is pipe and lower to setting depth.

run with GR Running Tool and the retrieving of

this packer is done independently from the tubing • The tubing fits automatically as it is run in,

by means of though a ported top sub in the setting assembly.

Retrieving Tool , manipulated on a work string.

• The port also permits circulation at any time.

APPLICATIONS: -

Model “GR-WRDSP” Retrievable Wireline • A 1-7/16 “Brass Ball is pumped down to seat in

Double Seal Bore Packer can be used as a simple the hydraulic setting tool.

Single or oil production wells or in water or gas

injection wells. The stresses created on the tubing • Approximately 1500 psi is applied to set the

are contained by it and therefore upper joint of the packer slips. Following which the pressure is

tubing must be checked to see that it can stand released and / or tension applied to shear the

these stresses. Release stud of the Wire line Adapter Kit.

The Hydraulic setting Tool along with Wire line

OPERATION RUNNING: - adapter kit can then be retrieved leaving the

packer set in hole.

• Check that the outside diameter corresponds to

the weight of the tubing. RETRIEVING PROCEDURE:-

1. Run the “GR-RT” Retrieving Tool on the

• Lubricate the polished bore. Work string or the tubing

• Install the test pins in the corresponding holes 2 Put Set down weight 7,500-10,000 Lbs on

keep them in place with a heavy duty elastic band The Packer, may be slickly rotated to the

or adhesive strip. right to engage the collet of the Retrieving

Tool under the supporting sleeve of the

• Pressurize the assembly Make sure that all air is Packer.

eliminated. Remove test plugs and all test pins. 3. PULL! In principle the packer should

Release with a pull of 5-10tons. In order

• Lower the packer slowly to the required to fully retrieve the Packer up-Ward and

position. Be careful when entering liners. down ward motion of retrieving string will

help.

• Install and land tubing Hanger. Once the screws have sheared the support

sleeve moves upwards freeing the support

• Test the tubing by running (remaining attached beneath the finger of the collet .The latter can

to) a Standing valve in a nipple above the Packer. then flex and detach itself from the thread

linking it to the base of the Housing . On

• Install the well head. upward movement of the body of the packer

the compression of the packing element is

• Displace the mud with a “completion” fluid in released and the slips retracted. The Setting

the annulus by introducing a lighter fluid Sleeve is supported by the Ring witch rests

(diesel/gas oil) for example into the tubing. on the top of the piston above the o-ring

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 1 of 7

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

.NOTE: The ‘GR-RT’ has a limited resistance

to tensile load –e.g. the 3.900” size has a rating 14. Screw the Lower connection sleeve (11) onto

of 50 000 Lbs. collet (120 until bottom sub (15) contacts the

collet (12) back off the lower connection sleeve

DISENGAGING THE ‘GR-RT’ Until the tapped holes in the collet line up with

slots in the lower connection sleeve.

A safety release feature is also provided in

Retrieving Tool for emergency release. Six nos. of 15. Install cap screw (16) into the collet (12)

brass screw are provided in Shear Ring having

value 3565 lbs. per screw. For emergency release 16. Screw lower gauge ring (5) and upper cone (7)

of tool give 10-15 right hand rotation followed by

a straight pull of 22,000 lbs. 17. Slide Packing element (6) on to the mandrel.

ASSEMBLY: 18. Screw Lock ring (18) into lock ring housing

1. Assembly O-Ring (20) & (21) in the bottom (4) .

sub.

19. Install screw (22) thru lock ring housing (4)

2. Slide upper cone (7) in to the slip cage (8).

20. Slide Lock ring housing /Lock ring onto the

3. Install slip spring (25) into inside of slip cage mandrel (1)

(8)

21. Screw Top sub (2) onto Mandrel (1) and

4. Install Slip (9) into Slip Cage (8) install screws (17)

5. Slide slip and slip cage assembly into the 22. Screw setting sleeve (3) into lock ring housing

mandrel (1). (4), Holding backup on the lock ring housing.

6. Install pick-up ring (19) onto Mandrel. 23. Install cap screws (160 thru slots in the setting

sleeve.(3)into the top sub.

7. Slide lower cone (10) onto the mandrel (1) 24. Install Cap screw (23) and shear screws (24)

thru slip cage (8) into upper cone (7) and lower

8. Install Support Ring (13) in to the collet cone (10).

(12).Line up tapped holes in the collet fingers will

flat bottom drill in support ring (13) DISSASSEMBLY:-

9. Install Shear Screw (14) thru collet fingers into 1. Place Setting Sleeve (3) in vice.

flat bottom holes until screws bottom out. Then

back off slightly. 2. Remove set Screw (17) from bottom of lower

Connection (11).

10. Assembly collet (12) onto the mandrel (1)

3. Remove bottom sub (15) and o-Rings.(20)

11. Install set screw (12) into the Collet (12)

4. Remove hex. Soc. Cap screws (16) and set

12. Assembly bottom sub (150 into Lower Screws (170 from lower connection.

connection sleeve (11) and install set screw (17).

5. Remove set screws (17) from collet (12).

13. Slide lower connection sleeve onto lower cone Remove collet and o-rings (20) and (21)

(10) and install set screw (17)

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 2 of 7

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

6. Remove cap screws (23) and shear

Screws (24) from lower cone (10) and slip

cage (80. Remove lower cone (10)

7. Reposition Tool with lower portion of the

Mandrel (1) in vice.

8. Remove hex. Soc, cap screws (16)

From top sub (2) . Remove setting sleeve (3).

9. Remove set screws (17) from Top sub and

Remove Top sub.

10. Remove shear screw (22) from ratchet

Housing (4) Unscrew Ratchet ring housing

and lock nut (18) from mandrel(1).Note:-

Right hand Thread. Remove lock nut from

Ratchet ring housing.

11. Slide Packing Element (6) off the mandrel.

12. Remove Gage ring (5) from upper cone (7)

And remove upper cone and slip assembly.

13. Remove slip (9) and slip spring (250) from

slip cage.

14. Remove shear screws (24) from slip

Cage (8) and remove upper cone (7)

15. Remove pick-up ring (190 from mandrel.

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 3 of 7

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

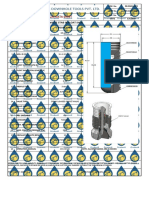

Wire Line Set Retrievable Packer

(Dual Bore):

GRADWELL Model GR-WRDSP is a double Bore

Retrievable Seal Bore Packer designed for use in

applications where a long tailpipe assembly is

required. It is set hydraulically using a Hydraulic

Setting Tool (GR-HST) with appropriate Wireline

Adapter Kit and once set does not require string

weight or tension to remain anchored. All the load

bearing parts are designed to withstand high

tensile loads and the bidirectional slips prevent

any movement of the tool. The packer is retrieved

by a straight pull shear release mechanism.

Features/Benefits

➢ Designed for use in vertical, deviated or

horizontal well completions.

➢ Bi-directional slips which prevent

movement after setting.

➢ An internal locking system maintains

pack-off.

➢ Full bore ID matches tubing and extended

tailpipe.

➢ Both setting pressure and shear release

are field adjustable.

➢ Ideal for anchoring a liner in the multi-

zone stimulation system.

SPECIFICATION GUIDE FOR “GR-WRDSP”

CASING PACKER DIMENSION

LOWER ACCESS.

UPPER PACKER

OD WEIGHT PACKER SIZE SEAL BORE SIZES

SEAL BORE OD

In LBS/FT In In in

9-5/8” 36 194-73 X 60 7.350 8.670 6.000 190-73

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 4 of 7

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

PART LIST

S. NO. QTY. PART NAME

1 1 SETTING SLEEVE

2 1 TOP BOX

3 1 RATCHET HOUSING

4 1 LOCK NUT

5 1 PACKING ELEMENT

6 1 GAGE RING

7 1 UPPER CONE

8 4 SLIPS

9 1 SLIP CAGE

10 1 PICK UP RING

11 1 LOWER CONE

12 1 MANDREL

LOWER CONNECTOR

13 1

SLEEVE

14 1 COLLET

15 1 SUPPORT RING

16 1 BOTTOM SUB

17 4 BRASS SHEAR SCREW

HEX. SOC. HEAD CAP

18 4

SCREW

19 10 HEX. SOC. SET SCREW

20 2 O-RING

21 1 O-RING

22 7 BRASS SHEAR SCREW

HEX. SOC. HEAD CAP

23 4

SCREW

24 8 BRASS SHEAR SCREW

25 4 SLIP SPRING

26 6 HEX. SOC. SET SCREW

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 5 of 7

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

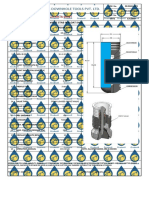

MODEL “GR-WAK-RSP” WIRE LINE ADAPTER KIT FOR

ITEM No.

Part Name

NO. Req’d

1 Adapter Sleeve 1

Hex. Soc. Set.

2 Ref.+

Screw

Adapter Sleeve 1

3

Bushing

Hex. Soc. Set.

4 Ref.+

Screw

5 Adjusting Nut 1

Hex. Soc. Set.

6 Ref.+

Screw

7 Adapter Bushing 1

8 Stud Bushing 1

Hex. Soc. Set.

9 Ref.+

Screw

10 Release Stud 1

11 Body 1

12 Mandrel 1

13 Split Ring Ret. 1

14 Split Ring Seg. 2 Seg

15 Release Sleeve 1

16 Mandrel Guide 1

17 Lock Bushing 1

Hex. Soc. Set.

18 Ref.+

Screw

19 Gage Ring 1

Tension Mandrel

20 1

Lock Spring

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 6 of 7

GRADWELL OILFIELD PRIVATE LIMITED

TECHNICAL LITERATURE

GR-OM-148 , MODEL : “GR-WRDSP” DOC. No: GR-DD-03-R00

WIRELINE SET RETRIEVBLE DOUBLE SEAL BORE PACKER

FOR USE WITH #20 WIRELINE PRESSURE SETTING ASSEMBLY

Prepared by NK Date 10.01.2018 Rev. No. 00 Page No.

Approved by RS Date 10.01.2018 Date 12.02.2018 Page 7 of 7

You might also like

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHH100% (1)

- 50 Strategies For Differentiated InstructionDocument19 pages50 Strategies For Differentiated InstructionMisael AmoraNo ratings yet

- Parveen PRHP Packer: Downhole Completion EquipmentDocument5 pagesParveen PRHP Packer: Downhole Completion EquipmentsambhajiNo ratings yet

- Baker A-5 SemidisassenblyDocument7 pagesBaker A-5 SemidisassenblyabodolkuhaaNo ratings yet

- Sect 08 Plug CatchersDocument14 pagesSect 08 Plug CatcherspaimanNo ratings yet

- 9.625x4 Arrow-Pak (265-94)Document3 pages9.625x4 Arrow-Pak (265-94)Tech AlfaNo ratings yet

- Polar RB (Regular Bore) Seal Bore PackerDocument3 pagesPolar RB (Regular Bore) Seal Bore PackerAlexander KlmNo ratings yet

- ELDER IX 5 5 X 2 375Document8 pagesELDER IX 5 5 X 2 375crni rokoNo ratings yet

- Assy Vol IDocument4 pagesAssy Vol IFernando CastelblancoNo ratings yet

- DDocument26 pagesDBalkis FatihaNo ratings yet

- Arrow-Pak RT 266-45Document3 pagesArrow-Pak RT 266-45Tech AlfaNo ratings yet

- Sect 06 Full-Opening EquipmentDocument44 pagesSect 06 Full-Opening EquipmentpaimanNo ratings yet

- BJ S C, USA: Doug LehrDocument12 pagesBJ S C, USA: Doug LehrBalkis FatihaNo ratings yet

- MANDRILDocument2 pagesMANDRILFernando CastelblancoNo ratings yet

- TU-045 - AS-RBP - 9-5.8 inDocument4 pagesTU-045 - AS-RBP - 9-5.8 inAtom InsideNo ratings yet

- Arrow-Pak Retrievingtool: Specification GuideDocument7 pagesArrow-Pak Retrievingtool: Specification GuideTech AlfaNo ratings yet

- WH6 2005Document19 pagesWH6 2005annNo ratings yet

- New BDMI L 4.5 HE0Document6 pagesNew BDMI L 4.5 HE0Natanael SaputraNo ratings yet

- Model NEFU-2 Non-Elastomeric Sliding Sleeve: DescriptioDocument6 pagesModel NEFU-2 Non-Elastomeric Sliding Sleeve: DescriptiofelipeNo ratings yet

- Design Overview: Basic Design and Maintenance InstructionsDocument3 pagesDesign Overview: Basic Design and Maintenance Instructionsazze bouzNo ratings yet

- 2023 10.75 TST-2 Service PackerDocument15 pages2023 10.75 TST-2 Service PackerDhenny FarialNo ratings yet

- Ah Hydraulic Setting ToolDocument12 pagesAh Hydraulic Setting ToolCarlos HolguinNo ratings yet

- Baker PDFDocument6 pagesBaker PDFanthony silvaNo ratings yet

- Descriptio: Model GXA Sliding SleeveDocument4 pagesDescriptio: Model GXA Sliding SleevefelipeNo ratings yet

- 9.625'' Seal NippleDocument1 page9.625'' Seal NippleMohamed Mahmoud Rezk DimoNo ratings yet

- Sur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitDocument3 pagesSur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitTamer Hesham AhmedNo ratings yet

- 7 000 X 2 875 Stradasnap 645-7000-020 2008-04-01Document5 pages7 000 X 2 875 Stradasnap 645-7000-020 2008-04-01Roberto Andres Sizas ReyNo ratings yet

- Model A (O) V-40 Sur-Set™ Check Valve: Flow Control Systems Technical UnitDocument16 pagesModel A (O) V-40 Sur-Set™ Check Valve: Flow Control Systems Technical UnitTamer Hesham AhmedNo ratings yet

- Two-Way Swivel Redress Kit Assembly InstructionsDocument10 pagesTwo-Way Swivel Redress Kit Assembly InstructionsEvolution Oil ToolsNo ratings yet

- Permanent PKR Eline/Hydraulic Setting Tool Signature: AdvantagesDocument18 pagesPermanent PKR Eline/Hydraulic Setting Tool Signature: Advantagesjulio RDLRNo ratings yet

- 2021 16.0 TST-2 Service PackerDocument15 pages2021 16.0 TST-2 Service PackerDhenny FarialNo ratings yet

- Ps 0412 0612obh WDocument1 pagePs 0412 0612obh WHunterNo ratings yet

- Packer HP 6 Technical LiteratureDocument7 pagesPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- Champ IV Packers With Parts ListsDocument82 pagesChamp IV Packers With Parts ListsMohamed ShafieNo ratings yet

- BTU Retreivable PlugDocument1 pageBTU Retreivable Plugbrunolb1No ratings yet

- 8023Document10 pages8023Tamer Hesham AhmedNo ratings yet

- 15 800 7040 00 00 PLDocument1 page15 800 7040 00 00 PLJhonathan MirandaNo ratings yet

- 4.000 Locator Seal Assembly Product: 15-802-0400-00-00: Item Description QTY Part Number 1 2 A B C D 3 Parts ListDocument1 page4.000 Locator Seal Assembly Product: 15-802-0400-00-00: Item Description QTY Part Number 1 2 A B C D 3 Parts ListJhonathan MirandaNo ratings yet

- 9.625'' Inspection SheetDocument3 pages9.625'' Inspection SheetMohamed Mahmoud Rezk DimoNo ratings yet

- Bimbar Inflatable PDFDocument36 pagesBimbar Inflatable PDFcarlosdh_03No ratings yet

- Checkvalve PDFDocument10 pagesCheckvalve PDFCARLOS MORENONo ratings yet

- DESCRIPTION: Map Hydro-Mech Bridge Plug Is Hydraulically ActuatedDocument7 pagesDESCRIPTION: Map Hydro-Mech Bridge Plug Is Hydraulically ActuatedKeshav PujeriNo ratings yet

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 pagesC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Sliding SleveDocument4 pagesSliding SleveMarceloNo ratings yet

- Cementing Plugs AND Ancillary EquipmentDocument16 pagesCementing Plugs AND Ancillary EquipmentTeguh Akbar HarahapNo ratings yet

- Lock-Set, J-LokDocument3 pagesLock-Set, J-LokYaqoob IbrahimNo ratings yet

- Technical Unit: Landing Nipple MODEL "MX", "MXN", "MF" & "MR" 0700000601 C Landing Nipple JUL 07 2020Document11 pagesTechnical Unit: Landing Nipple MODEL "MX", "MXN", "MF" & "MR" 0700000601 C Landing Nipple JUL 07 2020scignoniNo ratings yet

- Tubing Punch ADocument22 pagesTubing Punch AOrtiz Rivera SergioNo ratings yet

- Act Asi X PackerDocument8 pagesAct Asi X PackersambhajiNo ratings yet

- Technical: BTR-1.0 Tubing Retrievable MandrelDocument3 pagesTechnical: BTR-1.0 Tubing Retrievable MandrelRebeca RodriguezNo ratings yet

- PCK para Limpiar PunzadosDocument19 pagesPCK para Limpiar PunzadosRodolfo RiderNo ratings yet

- Bdmi SM-6013 1 PDFDocument27 pagesBdmi SM-6013 1 PDFFatoni Gea AirlanggaNo ratings yet

- AFT-2 Equalizing Check ValvesDocument25 pagesAFT-2 Equalizing Check ValvesHassane AmadouNo ratings yet

- G.V. Manual (FC Type)Document20 pagesG.V. Manual (FC Type)sambhajiNo ratings yet

- Separation Sleeve For X-Flow Injection and Production SystemDocument9 pagesSeparation Sleeve For X-Flow Injection and Production SystemTamer Hesham AhmedNo ratings yet

- Schlumbergerblue Pack PBR & PBR PKR Ret Tool: 33/8" 5 3/4" 4 1/2" Left Hand Thread 3 15/16"Document1 pageSchlumbergerblue Pack PBR & PBR PKR Ret Tool: 33/8" 5 3/4" 4 1/2" Left Hand Thread 3 15/16"yasirismNo ratings yet

- Liner PackersDocument1 pageLiner PackersMohamed ElabbasyNo ratings yet

- RB and RS Pulling Tool - Rev.E0 - 11-Oct-11Document2 pagesRB and RS Pulling Tool - Rev.E0 - 11-Oct-11Cristian Camilo Saenz LizarazoNo ratings yet

- Arrow-Pak 7.0 X 4Document9 pagesArrow-Pak 7.0 X 4Tech AlfaNo ratings yet

- Instructions For Champ III Packers: SectionDocument18 pagesInstructions For Champ III Packers: SectionMohamed ShafieNo ratings yet

- Fork Rebound Gold Valve Installation: 1501 Pomona RD, Corona, CA 92880 951.279.6655Document2 pagesFork Rebound Gold Valve Installation: 1501 Pomona RD, Corona, CA 92880 951.279.6655Tiyok HidrolikNo ratings yet

- Ip FRGV 200602wDocument2 pagesIp FRGV 200602wbslitvin1No ratings yet

- Casing AccessoriesDocument48 pagesCasing AccessoriesDigger Downhole ToolsNo ratings yet

- 4.2.1. Dr-Nr-Svfc-2000-133ppf-Mat-X56-Butt Weld Thd.Document1 page4.2.1. Dr-Nr-Svfc-2000-133ppf-Mat-X56-Butt Weld Thd.Digger Downhole ToolsNo ratings yet

- Technical Data Sheet: Product Descriptions: Double Valve Stab in Float ShoeDocument1 pageTechnical Data Sheet: Product Descriptions: Double Valve Stab in Float ShoeDigger Downhole ToolsNo ratings yet

- 0500 Wireline Bridge PlugsDocument1 page0500 Wireline Bridge PlugsDigger Downhole ToolsNo ratings yet

- Technical Data Sheet: Product Descriptions: Double Valve Stab in Float ShoeDocument1 pageTechnical Data Sheet: Product Descriptions: Double Valve Stab in Float ShoeDigger Downhole ToolsNo ratings yet

- Technical Data Sheet: Product Descriptions: Thermoplastic Spiral Right Vane Solid Rigid Centarlizer (Dr-45)Document1 pageTechnical Data Sheet: Product Descriptions: Thermoplastic Spiral Right Vane Solid Rigid Centarlizer (Dr-45)Digger Downhole ToolsNo ratings yet

- Burst & Collapse Presure FormulaDocument4 pagesBurst & Collapse Presure FormulaDigger Downhole ToolsNo ratings yet

- Product Catalog - Digger Downhole ToolsDocument70 pagesProduct Catalog - Digger Downhole ToolsDigger Downhole ToolsNo ratings yet

- 0500 Wireline Bridge PlugsDocument1 page0500 Wireline Bridge PlugsDigger Downhole ToolsNo ratings yet

- Digger Downhole Tools - Production CapacityDocument26 pagesDigger Downhole Tools - Production CapacityDigger Downhole ToolsNo ratings yet

- 0412 Wireline Bridge PlugsDocument1 page0412 Wireline Bridge PlugsDigger Downhole ToolsNo ratings yet

- Digger Downhole ToolsDocument1 pageDigger Downhole ToolsDigger Downhole ToolsNo ratings yet

- Aisi 1040Document1 pageAisi 1040Digger Downhole ToolsNo ratings yet

- Document 337737.1Document3 pagesDocument 337737.1elcaso34No ratings yet

- DBEBEE601Document4 pagesDBEBEE601bariNo ratings yet

- Weather Forecast: by Vass Tunde Juen, 1 Verbal and Non-Verbal CommunicationDocument5 pagesWeather Forecast: by Vass Tunde Juen, 1 Verbal and Non-Verbal CommunicationAlina-Cristina CotoiNo ratings yet

- Riko Technical Brochure PDFDocument29 pagesRiko Technical Brochure PDFGrigoreOzonNo ratings yet

- Services Procurement Data SheetDocument5 pagesServices Procurement Data Sheetrollingstone3mNo ratings yet

- Dissertation Topic MailDocument57 pagesDissertation Topic MailANUPNo ratings yet

- Mark Scheme (Results) : Summer 2018 Pearson Edexcel International GCSE in Further Pure Mathematics (4PM0) Paper 01Document26 pagesMark Scheme (Results) : Summer 2018 Pearson Edexcel International GCSE in Further Pure Mathematics (4PM0) Paper 01Newton JohnNo ratings yet

- A Project Report On TaxationDocument68 pagesA Project Report On TaxationDinesh ChahalNo ratings yet

- Dont Be Fuuld by JuuLDocument3 pagesDont Be Fuuld by JuuLGabriel ParksNo ratings yet

- Kyrgyzstan. ReportDocument27 pagesKyrgyzstan. Report200211555No ratings yet

- Members Members Shohanur Rahman Rahnuma Nur Elma Adnan Sami Khan Fatema Tuz Zohora Hasan UZ Zaman Safika Mashiat Sunjana Alam SamaDocument11 pagesMembers Members Shohanur Rahman Rahnuma Nur Elma Adnan Sami Khan Fatema Tuz Zohora Hasan UZ Zaman Safika Mashiat Sunjana Alam SamaShohanur RahmanNo ratings yet

- Group 2 (Money Market)Document28 pagesGroup 2 (Money Market)Abdullah Al NomanNo ratings yet

- Draft of The Newsletter: Trends in LeadershipDocument3 pagesDraft of The Newsletter: Trends in LeadershipAgus BudionoNo ratings yet

- Soal Kalimat Prohibition SMP Kelas 7Document3 pagesSoal Kalimat Prohibition SMP Kelas 7yura chanNo ratings yet

- Elephant Elephants Are Large Mammals of The Family: TerminologyDocument13 pagesElephant Elephants Are Large Mammals of The Family: TerminologyMukesh ManwaniNo ratings yet

- Laurie Baker: (The Brick Master of Kerala)Document8 pagesLaurie Baker: (The Brick Master of Kerala)Malik MussaNo ratings yet

- Accomplishment Report On 2019 SchoolDocument10 pagesAccomplishment Report On 2019 SchoolJuliet AlanNo ratings yet

- A Handbook of English Literature by Faizal Risdianto: P Oetr YDocument24 pagesA Handbook of English Literature by Faizal Risdianto: P Oetr YaYu pradhitiyanNo ratings yet

- A Project Report ON A Study On Consumer Satisfaction of PlywoodDocument7 pagesA Project Report ON A Study On Consumer Satisfaction of Plywoodjassi nishadNo ratings yet

- Ball On Plate Balancing SystemDocument27 pagesBall On Plate Balancing SystemChandan NykNo ratings yet

- Crochet Bikini AdriaDocument5 pagesCrochet Bikini AdriaSera Le-Jimmne100% (2)

- Insulation Rfi Control RecordDocument1,353 pagesInsulation Rfi Control RecordJoseph DarwinNo ratings yet

- Lesson 1-SSP 113Document10 pagesLesson 1-SSP 113Jan Lester DemaalaNo ratings yet

- POSTMODERN, 253s '12Document270 pagesPOSTMODERN, 253s '12Raluca Gîlcă100% (1)

- IDC POS Lab Project Plan 2 2Document471 pagesIDC POS Lab Project Plan 2 2shiramkkNo ratings yet

- Motor Claim Form THE ORIENTAL INSURANCE CO. LTD.Document4 pagesMotor Claim Form THE ORIENTAL INSURANCE CO. LTD.rajiv.surveyor7145No ratings yet

- Clone 123C3: Monoclonal Mouse Anti-Human CD56 Code M7304Document3 pagesClone 123C3: Monoclonal Mouse Anti-Human CD56 Code M7304Jaimier CajandabNo ratings yet

- Rodriguez Vs GellaDocument33 pagesRodriguez Vs GellaRozaiineNo ratings yet