Professional Documents

Culture Documents

Pressure Vessel Steel Equivalents

Pressure Vessel Steel Equivalents

Uploaded by

Masteel_UK_LtdCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MSS SP 97 PDFDocument15 pagesMSS SP 97 PDFgowtham_venkat_4100% (1)

- Injection MouldingDocument8 pagesInjection MouldingKarthick N50% (2)

- Computer Integrated Manufacturing SystemDocument12 pagesComputer Integrated Manufacturing Systemabemat100% (1)

- Memoria Estabilidad Del Talud IxiamasDocument5 pagesMemoria Estabilidad Del Talud IxiamasMarco Antonio TorrezNo ratings yet

- As-4 Fact SheetDocument2 pagesAs-4 Fact Sheetasswad1No ratings yet

- Contrat - Technip - Sanofi - Algérie 2 PDFDocument8 pagesContrat - Technip - Sanofi - Algérie 2 PDFnadjib62No ratings yet

- Glass Construction ManualDocument350 pagesGlass Construction ManualAdina Serban100% (1)

- Cement Industry - Group19Document28 pagesCement Industry - Group19swati100% (1)

- Electric Railways 1880 1990Document476 pagesElectric Railways 1880 1990Shashidhar Kasthala100% (4)

- @conferencepaperisopei 16183Document5 pages@conferencepaperisopei 16183Mohammed100% (1)

- Injection Molding TechnologyDocument11 pagesInjection Molding TechnologyManeet Kohli100% (7)

- PLC Based Star - Delta Starter For Three Phase Squirrel Cage Induction MotorDocument10 pagesPLC Based Star - Delta Starter For Three Phase Squirrel Cage Induction MotorTana AzeezNo ratings yet

- SSL 38 SreskyDocument1 pageSSL 38 SreskyAlicia AltamiranoNo ratings yet

- How To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesDocument9 pagesHow To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesjoreliNo ratings yet

- Caterpillar 980H Wheel LoaderDocument2 pagesCaterpillar 980H Wheel LoaderYudi Afsyah100% (2)

- Cornell BR Mine DewateringDocument8 pagesCornell BR Mine Dewateringtan_dat2003No ratings yet

- Fire Investigation ReportDocument7 pagesFire Investigation ReportTenson ChikumbaNo ratings yet

- ASME V Art 27 LT PDFDocument12 pagesASME V Art 27 LT PDFAgniva DuttaNo ratings yet

- Airman Generator SpecsDocument12 pagesAirman Generator SpecsDave Wallace100% (1)

- W201 Wiring Diagram PDFDocument290 pagesW201 Wiring Diagram PDFNadeem Mohd100% (2)

- Acoustics and Auditoriums - 30 Sections To Guide Your Design - ArchDailyDocument24 pagesAcoustics and Auditoriums - 30 Sections To Guide Your Design - ArchDailynishakrajan1347No ratings yet

- Design Construction and Maintenance of A Biogas Generator PDFDocument23 pagesDesign Construction and Maintenance of A Biogas Generator PDFBiswa Jyoti GuptaNo ratings yet

- Inventory Management in Supply ChainDocument3 pagesInventory Management in Supply ChainInternational Journal of Innovative Science and Research Technology67% (3)

- LinearDocument8 pagesLinearclonzzNo ratings yet

- Tendering Process PresentationDocument16 pagesTendering Process PresentationArvind NagriNo ratings yet

- Econ Gland and Plug Cocks Cast Iron: Valves & FittingsDocument1 pageEcon Gland and Plug Cocks Cast Iron: Valves & FittingsChristianGuerreroNo ratings yet

- Api 653 Preparatory Important Open Book Questions: Professional Training and ConsultationDocument1 pageApi 653 Preparatory Important Open Book Questions: Professional Training and ConsultationShaalan AliNo ratings yet

- Properties of AlluminiumDocument3 pagesProperties of Alluminiumtapan456No ratings yet

- Unit12chipcarving PDFDocument22 pagesUnit12chipcarving PDFMartinNo ratings yet

- Manual de Partes FRLO-15410CDocument31 pagesManual de Partes FRLO-15410CJorge Castillo HdzNo ratings yet

Pressure Vessel Steel Equivalents

Pressure Vessel Steel Equivalents

Uploaded by

Masteel_UK_LtdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Vessel Steel Equivalents

Pressure Vessel Steel Equivalents

Uploaded by

Masteel_UK_LtdCopyright:

Available Formats

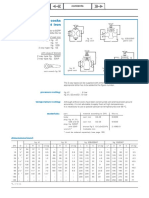

Boiler and Pressure Vessel

Comparisons & Equivalents

Equivalent Specifications & Standards

Chemical & mechanical property comparisons between pressure vessel grade material. For more information about pressure vessel steel visit our website at www.masteel.co.uk/index.htm

Mechanical Properties

Plates Chemical Composition Maximum (unless stated) Tensile Yield Flanges Pipe

ASTM Grade Grade

BS EN DIN C Si Mn P S Al Cr Cu Ni Mo Nb Ti V N/mm² N/mm²

ASME A182 A335

161-360A P235GH A285-C H1 0.16 0.35 0.4/ 1.2 0.03 0.03 0.02 0.3 0.3 0.3 0.08 0.01 0.03 0.02 360/ 480 235

161-430A P265GH A516-60 H11 0.2 0.4 0.5/ 1.40 0.03 0.03 0.02 0.3 0.3 0.3 0.08 0.01 0.03 0.02 410/ 530 265

223-490A/B - - - 0.2 0.4 0.5/ 1.40 0.03 0.03 0.02 0.3 0.3 0.3 0.08 0.01 0.03 0.02 410/ 530 265

224-460A/B P295GH A516-65 17Mn4 0.08/ 0.20 0.4 0.9 / 1.5 0.03 0.03 0.02 0.3 0.3 0.3 0.08 0.01 0.03 0.02 460/ 580 295

224-490A/B P355GH A516-70 - 0.10/ 0.22 0.6 1 / 1.7 0.03 0.03 0.02 0.3 0.3 0.3 0.08 0.01 0.03 0.02 510/ 650 355

225-490A/B P355N/NH - 19Mn6 0.2 0.5 0.9 / 1.7 0.03 0.03 0.02 0.3 0.3 0.5 0.08 0.05 0.03 0.1 430/ 630 355

243 16Mo3 A204-A 15Mo3 0.12/ 0.20 0.35 0.4/ 0.90 0.03 0.03 - 0.3 0.3 0.3 0.25/ 0.35 - - - 440/ 590 275 F1 P1

620 B 13CrMo45 A387-12-2 13CrMo44 0.08/ 0.18 0.35 0.4/ 1.00 0.03 0.03 - 0.7/ 1.15 0.3 - 0.4/ 0.60 - - - 450/ 600 300 F12-2 P12

621 B - A387-11-2 - 0.09/ 0.17 0.5 0.40 / 0.65 0.03 0.02 0.02 1/ 1.50 0.3 0.3 0.45/ 0.60 - - - 515/ 690 340 F11-2 P11

622-515B 10CrMo910 A387-22-2 10CrMo910 0.08/ 0.14 0.5 0.4/ 0.80 0.03 0.03 - 2/ 2.50 0.3 - 0.3/ 1.10 - - - 520/ 630 310 F22 P22

- - A387-5-2 - 0.15 0.5 0.3/ 0.60 0.04 0.03 - 4/ 6.00 0.3 - 0.45/ 0.65 - - - 515/ 690 310 F5 P5

- - A387-9-2 - 0.15 1 0.3/ 0.60 0.03 0.03 - 8/ 10.0 - - 0.9/ 1.10 - - - 515/ 690 310 F9 P9

Please note: the above chart is for guidance only – for exact specifications please check with our sales team

Material Testing

All plates are supplied fully certified to EN10204 3.1 or 3.2 as required, with full traceability usually by hard stamping. Additional client or third party inspection is available at the request of the client. Where specific applications require

materials complete with additional testing, Masteel can provide a complete testing service using independent NAMAS approved test houses. If testing requires EN10204 3.2 certification, tests would be witnessed by your nominated third

party inspection agency.

Additional testing available includes: Charpy V Notch Impact Testing | Through Thickness Testing (TTT) | Ultrasonic Testing | Hardness Testing | Mechanical Testing after Simulated PWHT | Micro-structural Examination

HIC testing according to NACE | SSCC testing according to NACE

Masteel UK Limited, The Cedars, Coton Road, Nether Whitacre, Coleshill, Birmingham, B46 2HH. Tel: +44(0)1675 437733 Fax: +44(0) 1675 437734 email: enquiries@masteel.co.uk website: www.masteel.co.uk

© Masteel UK Limited 2010

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MSS SP 97 PDFDocument15 pagesMSS SP 97 PDFgowtham_venkat_4100% (1)

- Injection MouldingDocument8 pagesInjection MouldingKarthick N50% (2)

- Computer Integrated Manufacturing SystemDocument12 pagesComputer Integrated Manufacturing Systemabemat100% (1)

- Memoria Estabilidad Del Talud IxiamasDocument5 pagesMemoria Estabilidad Del Talud IxiamasMarco Antonio TorrezNo ratings yet

- As-4 Fact SheetDocument2 pagesAs-4 Fact Sheetasswad1No ratings yet

- Contrat - Technip - Sanofi - Algérie 2 PDFDocument8 pagesContrat - Technip - Sanofi - Algérie 2 PDFnadjib62No ratings yet

- Glass Construction ManualDocument350 pagesGlass Construction ManualAdina Serban100% (1)

- Cement Industry - Group19Document28 pagesCement Industry - Group19swati100% (1)

- Electric Railways 1880 1990Document476 pagesElectric Railways 1880 1990Shashidhar Kasthala100% (4)

- @conferencepaperisopei 16183Document5 pages@conferencepaperisopei 16183Mohammed100% (1)

- Injection Molding TechnologyDocument11 pagesInjection Molding TechnologyManeet Kohli100% (7)

- PLC Based Star - Delta Starter For Three Phase Squirrel Cage Induction MotorDocument10 pagesPLC Based Star - Delta Starter For Three Phase Squirrel Cage Induction MotorTana AzeezNo ratings yet

- SSL 38 SreskyDocument1 pageSSL 38 SreskyAlicia AltamiranoNo ratings yet

- How To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesDocument9 pagesHow To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesjoreliNo ratings yet

- Caterpillar 980H Wheel LoaderDocument2 pagesCaterpillar 980H Wheel LoaderYudi Afsyah100% (2)

- Cornell BR Mine DewateringDocument8 pagesCornell BR Mine Dewateringtan_dat2003No ratings yet

- Fire Investigation ReportDocument7 pagesFire Investigation ReportTenson ChikumbaNo ratings yet

- ASME V Art 27 LT PDFDocument12 pagesASME V Art 27 LT PDFAgniva DuttaNo ratings yet

- Airman Generator SpecsDocument12 pagesAirman Generator SpecsDave Wallace100% (1)

- W201 Wiring Diagram PDFDocument290 pagesW201 Wiring Diagram PDFNadeem Mohd100% (2)

- Acoustics and Auditoriums - 30 Sections To Guide Your Design - ArchDailyDocument24 pagesAcoustics and Auditoriums - 30 Sections To Guide Your Design - ArchDailynishakrajan1347No ratings yet

- Design Construction and Maintenance of A Biogas Generator PDFDocument23 pagesDesign Construction and Maintenance of A Biogas Generator PDFBiswa Jyoti GuptaNo ratings yet

- Inventory Management in Supply ChainDocument3 pagesInventory Management in Supply ChainInternational Journal of Innovative Science and Research Technology67% (3)

- LinearDocument8 pagesLinearclonzzNo ratings yet

- Tendering Process PresentationDocument16 pagesTendering Process PresentationArvind NagriNo ratings yet

- Econ Gland and Plug Cocks Cast Iron: Valves & FittingsDocument1 pageEcon Gland and Plug Cocks Cast Iron: Valves & FittingsChristianGuerreroNo ratings yet

- Api 653 Preparatory Important Open Book Questions: Professional Training and ConsultationDocument1 pageApi 653 Preparatory Important Open Book Questions: Professional Training and ConsultationShaalan AliNo ratings yet

- Properties of AlluminiumDocument3 pagesProperties of Alluminiumtapan456No ratings yet

- Unit12chipcarving PDFDocument22 pagesUnit12chipcarving PDFMartinNo ratings yet

- Manual de Partes FRLO-15410CDocument31 pagesManual de Partes FRLO-15410CJorge Castillo HdzNo ratings yet