Professional Documents

Culture Documents

Kawasaki Engine Shop Rebuild Manual: 4-Stroke Air-Cooled Gasoline Engine

Kawasaki Engine Shop Rebuild Manual: 4-Stroke Air-Cooled Gasoline Engine

Uploaded by

Raúl TorresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kawasaki Engine Shop Rebuild Manual: 4-Stroke Air-Cooled Gasoline Engine

Kawasaki Engine Shop Rebuild Manual: 4-Stroke Air-Cooled Gasoline Engine

Uploaded by

Raúl TorresCopyright:

Available Formats

608172

11

16

15

13

7 8

18

17 1 - INCLUDES ITEMS 3 - 16

19 3

10

KAWASAKI ENGINE

SHOP REBUILD MANUAL

4-STROKE AIR-COOLED GASOLINE

ENGINE

STARTING MODEL YEAR: 2008

REVISED OCTOBER 2008

NOTES

KAWASAKI ENGINE

SHOP REBUILD MANUAL

4-STROKE AIR-COOLED GASOLINE ENGINE

E-Z-GO Division of Textron, Inc. reserves the right to make design changes without obligation to make these changes on units previously sold and the informa-

tion contained in this manual is subject to change without notice.

E-Z-GO Division of Textron, Inc. is not liable for errors in this manual or for incidental or consequential damages that result from the use of the material in this

manual.

CUSTOMER SERVICE DEPARTMENT IN USA PHONE: 1-800-241-5855 FAX: 1-800-448-8124

OUTSIDE USA PHONE: 010-1-706-798-4311, FAX: 010-1-706-771-4609

E-Z-GO DIVISION OF TEXTRON, INC., 1451 MARVIN GRIFFIN RD., AUGUSTA, GEORGIA USA 30906

Kawasaki Engine Shop Rebuild Manual Page i

NOTES

TO OBTAIN A COPY OF THE LIMITED WARRANTY THAT IS APPLICABLE TO THE VEHICLE,

CALL OR WRITE THE LOCAL DISTRIBUTOR, E-Z-G0 BRANCH OR E-Z-G0 WARRANTY

DEPARTMENT WITH VEHICLE SERIAL NUMBER AND MANUFACTURER’S CODE.

THE USE OF NON E-Z-GO PARTS AND HARDWARE MAY VOID THE WARRANTY.

TAMPERING WITH OR ADJUSTING GOVERNOR TO PERMIT VEHICLE TO OPERATE AT

ABOVE FACTORY SETTINGS WILL VOID THE VEHICLE WARRANTY.

IF APPLICABLE, REFER TO BACK COVER FOR CALIFORNIA AND/OR FEDERAL EMISSIONS

CONTROL WARRANTY STATEMENT.

Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

The exhaust emissions of this vehicle’s engine comply with regulations set forth by the Environmental Protection Agency (EPA) of the

United States of America (USA) at time of manufacture. Significant fines could result from modifications or tampering with the engine,

fuel, ignition or air intake systems.

Page ii Kawasaki Engine Shop Rebuild Manual

TABLE OF CONTENTS

Section Page No.

HOW TO USE THIS MANUAL ............................. ............................................. .......................................... vii

ENGINE TOP END DISASSEMBLY A

ENGINE TOP END

• Tool List................................................ ............................................. ......................................... A-1

CYLINDER HEAD

• Remove Cylinder Head........................ ............................................. ......................................... A-1

VALVES

• Remove Valve Mechanism................... ............................................. ......................................... A-2

SPECIFICATIONS................................................ ............................................. ......................................... A-3

EXPLODED VIEW ............................................... ............................................. ......................................... A-4

ENGINE BOTTOM END DISASSEMBLY B

ENGINE BOTTOM END

• Tool List................................................ ............................................. ......................................... B-1

CRANKCASE

• Remove Crankcase Cover ................... ............................................. ......................................... B-1

CAMSHAFT AND TAPPETS

• Remove Camshaft, Tappet .................. ............................................. ......................................... B-1

CYLINDERS AND PISTONS

• Remove Piston..................................... ............................................. ......................................... B-2

CRANKSHAFT AND CONNECTING RODS

• Remove Connecting Rod..................... ............................................. ......................................... B-3

• Remove Crankshaft ............................. ............................................. ......................................... B-3

BALANCER SHAFT

• Remove Balancer Shaft ....................... ............................................. ......................................... B-3

BREATHER VALVE

• Remove Breather Valve ....................... ............................................. ......................................... B-3

SPECIFICATIONS................................................ ............................................. ......................................... B-4

EXPLODED VIEW ............................................... ............................................. ......................................... B-6

Kawasaki Engine Shop Rebuild Manual Page iii

TABLE OF CONTENTS

Section Page No.

ENGINE MEASUREMENTS AND SPECIFICATIONS C

ENGINE MEASUREMENTS AND SPECIFICATIONS

• Tool List................................................ ............................................. ......................................... C-1

• Using Telescoping Gauges and Hole Gauges ................................... ......................................... C-1

CYLINDER HEAD

• Measure Cylinder Compression .......... ............................................. ......................................... C-1

• Inspect Push Rod ................................ ............................................. ......................................... C-3

• Inspect Rocker Arm ............................. ............................................. ......................................... C-3

• Measure Cylinder Head Warp ............. ............................................. ......................................... C-3

VALVES

• Inspect Valve Clearance ...................... ............................................. ......................................... C-4

• Adjust Valve Clearance........................ ............................................. ......................................... C-4

• Inspect Valve Seat ............................... ............................................. ......................................... C-4

• Repair Valve Seat ................................ ............................................. ......................................... C-4

• Operating Procedures.......................... ............................................. ......................................... C-5

• Measure Valve Spring Free Length ..... ............................................. ......................................... C-8

• Measure Valve Head Thickness .......... ............................................. ......................................... C-8

• Measure Valve Stem Bend ................. ............................................. ......................................... C-8

• Measure Valve Stem Diameter ........... ............................................. ......................................... C-9

• Measure Valve Guide Inside Diameter ............................................. ......................................... C-9

• Measure Valve/Guide Clearance (Wobble Method)........................... ......................................... C-9

CAMSHAFT AND TAPPETS

• Measure Camshaft Bearing/Journal Wear......................................... ........................................ C-10

CYLINDER AND PISTONS

• Clean Piston ........................................ ............................................. ........................................ C-11

• Check Piston Ring and Ring Groove Wear ....................................... ........................................ C-11

• Measure Piston Ring End Gap ............ ............................................. ........................................ C-12

• Measure Piston Pin, Piston Pin Hole, and Connecting Rod Wear..... ........................................ C-13

• Measure Piston Diameter .................... ............................................. ........................................ C-13

• Check Cylinder Inside Diameter .......... ............................................. ........................................ C-14

CRANKSHAFT AND CONNECTING RODS

• Clean/Inspect....................................... ............................................. ........................................ C-14

• Measure Connecting Rod Bend/Twist.. ............................................. ........................................ C-14

• Measure Connecting Rod Big End/Crankpin Width Wear ................. ........................................ C-15

• Measure Connecting Rod Big End Bearing/Crankpin Wear ............. ........................................ C-15

• Measure Crankshaft Runout................ ............................................. ........................................ C-16

• Measure Crankshaft Main Bearing/Journal Wear ............................. ........................................ C-16

BALANCER SHAFT

• Measure Balancer Shaft Bearing/Journal Wear ............................... ........................................ C-17

BREATHER VALVE

• Inspect Breather Valve......................... ............................................. ........................................ C-17

Page iv Kawasaki Engine Shop Rebuild Manual

TABLE OF CONTENTS

Section Page No.

ENGINE BOTTOM END REASSEMBLY D

ENGINE BOTTOM END

• Tool List................................................ ............................................. .........................................D-1

BREATHER VALVE

• Install Breather Valve ........................... ............................................. .........................................D-1

BALANCER SHAFT

• Install Balancer Shaft ........................... ............................................. .........................................D-1

CRANKSHAFT AND CONNECTING RODS

• Install Crankshaft ................................. ............................................. .........................................D-2

• Install Connecting Rod......................... ............................................. .........................................D-2

CYLINDERS AND PISTONS

• Install Piston ........................................ ............................................. .........................................D-2

CAMSHAFT AND PISTONS

• Install Camshaft, Tappet ...................... ............................................. .........................................D-4

CRANKCASE

• Assemble Crankcase Cover ................ ............................................. .........................................D-4

• Install Crankcase Cover ....................... ............................................. .........................................D-4

ENGINE TOP END REASSEMBLY E

ENGINE TOP END

• Tool List................................................ ............................................. ......................................... E-1

VALVES

• Install Valve Mechanism ...................... ............................................. ......................................... E-1

CYLINDER HEAD

• Install Cylinder Head............................ ............................................. ......................................... E-1

Kawasaki Engine Shop Rebuild Manual Page v

TABLE OF CONTENTS

Section Page No.

ILLUSTRATED PARTS BREAKDOWN F

CYLINDER/CRANKCASE ...................................................................................... .................................... F-2

PISTON/CRANKSHAFT ......................................................................................... .................................... F-4

VALVE/CAMSHAFT................................................................................................ .................................... F-6

LUBRICATION........................................................................................................ .................................... F-8

COOLING ............................................................................................................... ................................... F-10

ELECTRICAL.......................................................................................................... ................................... F-12

CARBURETOR/CABLE BRACKETS...................................................................... ................................... F-14

AIR INTAKE/BREATHER - EXHAUST ................................................................... ................................... F-16

LIMITED WARRANTY G

Federal Emissions Component Defect Warranty.................................................... ....................................G-1

California Emission Control Warranty Statement (1995-1999) ............................... ....................................G-5

California Emission Control Warranty Statement (2000) ........................................ ....................................G-8

California Emission Control Warranty Statement (2001) ........................................ ...................................G-11

California Emission Control Warranty Statement (2004) ........................................ ...................................G-14

Page vi Kawasaki Engine Shop Rebuild Manual

HOW TO USE THIS MANUAL

This manual is designed to suit the needs of mechanics at all levels of experience with the E-Z-GO 4-cycle engine. The

outline format allows the mechanic to choose the level of instructional detail needed to completely disassemble, diag-

nose, repair/overhaul and reassemble the engine.

The manual is divided into four major operational sections, which are each divided into smaller operational sections. At

the beginning of each major section is a list of tools that will be required to perform the operations desired in that sec-

tion. Do not use non-specified tools (vise grips®, hammers, adjustable wrenches, etc.). The use of these tools

could cause permanent damage to the engine components.

WE STRONGLY RECOMMEND that, no matter what your experience level, you use this manual as a guide when disas-

sembling, repairing/overhauling and reassembling the engine. Before working on the engine, read and understand the

text and in particular each NOTE, CAUTION and WARNING.

Some illustrations may show components that differ from your engine. This is the result of ongoing improvements to the

engine design.

Kawasaki Engine Shop Rebuild Manual Page vii

Notes:

Page viii Kawasaki Engine Shop Rebuild Manual

ENGINE TOP END DISASSEMBLY

TABLE OF CONTENTS FOR SECTION ‘A’

SECTION TITLE

A

PAGE NO.

ENGINE TOP END.............................................................................................................................A-1

Tool List ...................................................................................................................................A-1

CYLINDER HEAD ..............................................................................................................................A-1

Remove Cylinder Head ...........................................................................................................A-1

VALVES .............................................................................................................................................A-2

Remove Valve Mechanism......................................................................................................A-2

SPECIFICATIONS .............................................................................................................................A-3

EXPLODED VIEW..............................................................................................................................A-4

LIST OF ILLUSTRATIONS

Fig. 1 Cylinder Head..........................................................................................................................A-4

Kawasaki Engine Shop Rebuild Manual Page A-i

ENGINE TOP END DISASSEMBLY

Notes:

Page A-ii Kawasaki Engine Shop Rebuild Manual

ENGINE TOP END DISASSEMBLY

ENGINE TOP END CYLINDER HEAD

A

Tool List Qty. Required Remove Cylinder Head

Compression Gauge, 20 kgf/cm²: A. Several components must be removed in order to

gain access to the cylinder head (for example carbu-

E-Z-GO Part No. N/A .................................................. 1 rator and exhaust). Refer to the service manual of

Valve Seat Cutter, 45° - 32: your vehicle for removal procedures.

E-Z-GO Part No. 608665 ............................................ 1 B.

Valve Seat Cutter, 45° - 35:

E-Z-GO Part No. 608666 ............................................ 1

Valve Seat Cutter, 32° - 35:

E-Z-GO Part No. 608667 ............................................ 1

Valve Seat Cutter, 32° - 38.5:

E-Z-GO Part No. 608668 ............................................ 1

Valve Seat Cutter Holder, 7:

E-Z-GO Part No. 608669 ............................................ 1

Valve Seat Cutter Holder Bar:

Remove clamp and hose [A], bolts [B], and engine

E-Z-GO Part No. 608670 ............................................ 1 shroud [C].

Compression Gauge Adapter, M14 × 1.25: C.

E-Z-GO Part No. N/A .................................................. 1

Keep your work area clean and well organized while performing

the operations described in this manual. This will help prevent

accidents and reduce the possibility of mistakes that could

damage or impair the performance of the engine.

Crankshaft and balancer shaft bearings should be cleaned and

inspected, and removed only if they appear to be damaged or

excessively worn. Remove bearings that are pitted, nicked, Remove spark plug cap [A], dipstick [B], valve cover

burred, discolored or that rotate roughly or noisily. bolts [C], and valve cover [D].

D. Position the crankshaft at TDC of the end of the com-

pression stroke.

Because some mating parts with wear surfaces were machined

together when the engine was manufactured, or have estab-

lished wear patterns during operation, the reassembly of engine

parts in their original positions and orientations, with their origi-

nal mating parts, is critical to the performance and life expectan-

cy of the engine. Mark and sort all parts as they are

disassembled so that they will be reassembled and installed in

their original positions.

Kawasaki Engine Shop Rebuild Manual Page A-1

ENGINE TOP END DISASSEMBLY

E. VALVES

Remove Valve Mechanism

A. Remove cylinder head (see Remove Cylinder Head).

B. Support the valve head in the combustion chamber

with a folded shop towel.

C.

Loosen lock screws [A].

Tag and mark push rods during removal. Push rods should be

installed in their original orientation and position during assem-

bly.

Remove valve clearance adjusting nuts [B], rocker arms

[C], and push rods [D].

F.

Wear eye protection while removing collets. Valve springs are

under tension and may propel collets during removal, causing

injury to eyes.

To remove the collets [A], push down the valve retainer

[B] with thumbs and remove the collets.

D. Remove the valve retainer, spring [C], and valve [D].

It is not necessary to remove the stem seal unless it is being

replaced.

Stem seals should be replaced during a top end overhaul.

Valve guide [B] is not replaceable; do not remove it.

E.

The cylinder head may be held in place by the gasket during

removal. Pry tabs are located on the cylinder head to allow the

head to be removed without damaging the fins. Do not pry on

the cylinder head fins during removal. Damage to the fins will

occur if they are used as pry points.

Remove cylinder head bolts [A], push rod guides [B], and

cylinder head [C]. Remove the stem seals [A].

Page A-2 Kawasaki Engine Shop Rebuild Manual

ENGINE TOP END DISASSEMBLY

SPECIFICATIONS

Item Standard Service Limit

Cylinder Head

Cylinder Compression 880 ~ 1 080 kPa (9 ~ 11 kgf/cm², 128 ~156 psi) __ __ __

@ 500 ~ 700 r/min (rpm)

Rocker Arm Push Rod Runout __ __ __ TIR 0.5 mm (0.02 in.)

Cylinder Head Warp __ __ __ 0.03 mm (0.001 in.)

Valves

Valve Clearance (when cold) 0.10 ~ 0.15 mm (0.0039 ~ 0.0059 in.) __ __ __

Valve Seating Surface:

Outside Diameter:

Inlet 32.8 mm (1.29 in.) __ __ __

Exhaust 27.6 mm (1.09 in.) __ __ __

Width:

Inlet 1.1 ~ 1.7 mm (0.043 ~ 0.067 in.) __ __ __

Exhaust 1.0 ~ 1.5 mm (0.039 ~ 0.059 in.) __ __ __

Valve Seat Cutting Angle 45° __ __ __

Valve Spring Free Length 35 mm (1.38 in.) 32.6 mm (1.28 in.)

Valve Head Thickness 0.4 mm (0.016 in.) 0.4 mm (0.016 in.)

TIR 0.05 mm (0.0020

Valve Stem Bend Less than 0.01 mm (0.0004 in.) TIR in.)

Valve Stem Diameter:

Inlet 6.960 ~ 6.975 mm (0.2740 ~ 0.2746 in.) 6.95 mm (0.274 in.)

Exhaust 6.945 ~ 6.960 mm (0.2734 ~ 0.2740 in.) 6.93 mm (0.273 in.)

Valve Guide Inside Diameter 7.000 ~ 7.015 mm (0.2756 ~ 0.2762 in.) 7.08 mm (0.279 in.)

Valve/guide Clearance

(wobble method):

Inlet 0.06 ~ 0.13 mm (0.0024 ~ 0.0051 in.) 0.29 mm (0.011 in.)

Exhaust 0.10 ~ 0.17 mm (0.0039 ~ 0.0067 in.) 0.33 mm (0.013 in.)

Kawasaki Engine Shop Rebuild Manual Page A-3

ENGINE TOP END DISASSEMBLY

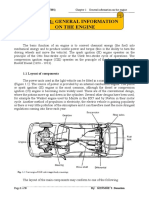

Exploded View

Fig. 1 Cylinder Head

Page A-4 Kawasaki Engine Shop Rebuild Manual

ENGINE TOP END DISASSEMBLY

Torque

E-Z-GO

No. Part No. Fastener N•m kgf/m ft-lb/in-lb Remarks

1 603523 Cylinder Head Cover Bolts 6.9 0.70 61 in-lb

2 603525 Cylinder Head Bolts 37 3.8 27 ft-lb S

3 603570 Engine Shroud Bolts 5.9 0.60 52 in-lb

4 603545 Valve Adjusting Nut Lock Screws 6.9 0.70 61 in-lb

5 603549 Rocker Arm Bolts 28 2.9 21 ft-lb

EO: Apply engine oil.

M: Apply molybdenum disulfide grease.

R: Replacement Parts

S: Follow the specific tightening sequence.

Kawasaki Engine Shop Rebuild Manual Page A-5

Notes:

Page A-6 Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END DISASSEMBLY

TABLE OF CONTENTS FOR SECTION ‘B’

SECTION TITLE

B

PAGE NO.

ENGINE BOTTOM END.....................................................................................................................B-1

Tool List ...................................................................................................................................B-1

CRANKCASE .....................................................................................................................................B-1

Remove Crankcase Cover ......................................................................................................B-1

CAMSHAFT AND TAPPETS..............................................................................................................B-1

Remove Camshaft, Tappet......................................................................................................B-1

CYLINDERS AND PISTONS .............................................................................................................B-2

Remove Piston ........................................................................................................................B-2

CRANKSHAFT AND CONNECTING RODS......................................................................................B-3

Remove Connecting Rod ........................................................................................................B-3

Remove Crankshaft.................................................................................................................B-3

BALANCER SHAFT ...........................................................................................................................B-3

Remove Balancer Shaft...........................................................................................................B-3

BREATHER VALVE ...........................................................................................................................B-3

Remove Breather Valve ..........................................................................................................B-3

SPECIFICATIONS .............................................................................................................................B-4

EXPLODED VIEW..............................................................................................................................B-6

LIST OF ILLUSTRATIONS

Fig. 1 Crankcase ................................................................................................................................B-6

Kawasaki Engine Shop Rebuild Manual Page B-i

ENGINE BOTTOM END DISASSEMBLY

Notes:

Page B-ii Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END DISASSEMBLY

ENGINE BOTTOM END C.

B

Tool List Qty. Required

Piston Ring Compressor Grip:

E-Z-GO Part No. N/A .................................................. 1

Piston Ring Compressor Belt, 80 ~ 91:

E-Z-GO Part No. N/A .................................................. 1

Bearing Driver Set:

E-Z-GO Part No. N/A .................................................. 1

Remove valve cover [A].

Use clutch puller bolt E-Z-GO Part No. 608429 to remove the

drive clutch if it has not yet been removed from the PTO of the

D. Position the piston TDC at the end of the compres-

crankshaft.

sion stroke.

CRANKCASE E.

Remove Crankcase Cover

A. Drain the engine oil.

If the crankcase cover sticks, tap lightly with a wooden or plastic

mallet near the dowel pins [C].

B.

Remove the lock screws [A] and the valve clearance

adjusting nuts [B], which fasten the rocker arm [C],

and pull the rocker arm off the push rods [D].

F. Remove the push rods and mark them so they can be

installed in their original positions during assembly.

G.

C. Remove crankcase cover bolts [A] and crankcase

cover [B].

CAMSHAFT AND TAPPETS

Remove Camshaft, Tappet

A. Drain the engine oil.

B. Remove crankcase cover (see Remove Crankcase

Cover). Pull the camshaft [A] out of the crankcase.

Kawasaki Engine Shop Rebuild Manual Page B-1

ENGINE BOTTOM END DISASSEMBLY

H. E.

Remove the tappets [A] and mark them so they can Remove one of the piston pin snap rings [A] with

be installed in their original positions during assem- needle nose pliers.

bly.

F.

CYLINDERS AND PISTONS

Remove Piston

A. Remove crankcase cover (see Remove Crankcase

Cover), camshaft (see Remove Camshaft, Tappet

Removal), and balancer shaft (see Remove Balancer

Shaft).

B.

Remove the piston by pushing the piston pin [A] out

the side from which the snap ring was removed.

G.

Turn the crankshaft to expose the connecting rod cap

bolts [A].

C. Remove the bolts and take off the connecting rod cap

[B].

Carefully spread the ring opening with your thumbs

and then push up on the opposite side of the ring [A]

Note the position of the connecting rod cap for reinstalling the to remove it.

cap.

D. Push the connecting rod end into the cylinder, and H. Remove the 3-piece oil ring with your thumbs in the

pull the piston and connecting rod out of the cylinder. same manner.

Page B-2 Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END DISASSEMBLY

CRANKSHAFT AND CONNECTING RODS BREATHER VALVE

Remove Connecting Rod Remove Breather Valve

The function of the breather is to create a negative pres-

A. Refer to Remove Piston. sure in the crankcase, which prevents oil from being

forced out of the engine through the piston rings, oil seals

Remove Crankshaft or gaskets. A sealed-type crankcase emission control

system is used to prevent blow-by gases from emitting in

A. Drain the engine oil. the air. The blow-by gases are drawn into the clean side

of the air cleaner through the crankcase and the cylinder

B. Remove alternator rotor, camshaft (see Remove

head and mixed with the clean airflow, and subsequently

Camshaft, Tappet), balancer shaft (see Remove Bal-

come into the combustion chamber through the carbure-

ancer Shaft), and connecting rod cap (see Remove

tor. Oil is primarily separated from the gases while pass-

Piston).

ing through the inside of the rocker chamber from the

C. crankcase, and secondly separated from the gases in the

breather chamber, and then brought back to the crank-

case.

Pull the crankshaft [A] out of the crankcase. Tap gen-

tly with a wooden or plastic mallet if necessary to

loosen the crankshaft.

BALANCER SHAFT

Remove Balancer Shaft A. Remove the cylinder head assembly (see Remove

Cylinder Head in Section A).

A.

B.

Remove crankcase cover (see Remove Crankcase

Cover) and balancer shaft [A]. Unscrew the breather valve screw [A].

Kawasaki Engine Shop Rebuild Manual Page B-3

ENGINE BOTTOM END DISASSEMBLY

SPECIFICATIONS

Item Standard Service Limit

Camshaft and Tappets

Cam Lobe Height:

Inlet 29.95 ~ 30.05 mm 29.86 mm

(1.179 ~ 1.183 in.) (1.176 in.)

Exhaust 29.95 ~ 30.05 mm 29.86 mm

(1.179 ~ 1.183 in.) (1.176 in.)

Camshaft Journal Diameter:

Crankcase Side 19.967 ~ 19.980 mm 19.94 mm

(0.78610 ~ 0.78661 in.) (0.7850 in.)

Crankcase Cover Side 49.959 ~ 49.975 mm 49.93 mm

(1.9669 ~ 1.9675 in.) (1.966 in.)

Camshaft Bearing Inside Diameter:

Crankcase Side 20.000 ~ 20.013 mm 20.07 mm

(0.78740 ~ 0.78791 in.) (0.7902 in.)

Crankcase Cover Side 50.000 ~ 50.025 mm 50.09 mm

(1.9685 ~ 1.9695 in.) (1.972 in.)

Crankshaft and Connecting Rods

Connecting Rod Bend ––– 0.15/100 mm

––– (0.006/3.94 in.)

Connecting Rod Twist ––– 0.15/100 mm

––– (0.006/3.94 in.)

Connecting Rod Big End Width 27.4 ~ 27.7 mm 27.0 mm

(1.08 ~ 1.09 in.) (1.06 in.)

Crankpin Width 28.0 ~ 28.2 mm 28.4 mm

(1.10 ~ 1.11 in.) (1.12 in.)

Connecting Rod Big End Inside Diameter 43.004 ~ 43.015 mm 43.04 mm

(1.6931 ~ 1.6935 in.) (1.694 in.)

Crankpin Outside Diameter 42.963 ~ 42.976 mm 42.95 mm

(1.6915 ~ 1.6920 in.) (1.691 in.)

Crankshaft Runout TIR 0.02 mm TIR 0.05 mm

(0.0008 in.) or less (0.002 in.)

Crankshaft Main Journal Diameter:

Crankcase Side 34.955 ~ 34.980 mm 34.93 mm

(1.3762 ~ 1.3772 in.) (1.375 in.)

Crankshaft Main Bearing Inside Diameter:

Crankcase Side 35.002 ~ 35.015 mm 35.05 mm

(1.3780 ~ 1.3785 in.) (1.380 in.)

Page B-4 Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END DISASSEMBLY

Item Standard Service Limit

Cylinder and Piston

Piston Ring/Groove Clearance:

Top, Second 0.04 ~ 0.08 mm 0.18 mm

Piston Ring Thickness: (0.002 ~ 0.003 in.) (0.0071 in.)

Top, Second 1.47 ~ 1.49 mm 1.40 mm

(0.0579 ~ 0.0587 in.) (0.0551 in.)

Piston Ring End Gap:

Top 0.15 ~ 0.40 mm 0.7 mm

(0.0059 ~ 0.016 in.) (0.03 in.)

Second 0.23 ~ 0.48 mm 0.8 mm

(0.0091 ~ 0.019 in.) (0.03 in.)

Oil 0.25 ~ 0.75 mm 1.0 mm

(0.0098 ~ 0.030 in.) (0.039 in.)

Piston Pin Outside Diameter 18.995 ~ 19.000 mm 18.96 mm

(0.74783 ~ 0.74803 in.) (0.7465 in.)

Piston Pin Hole Inside Diameter 19.004 ~ 19.015 mm 19.08 mm

(0.74819 ~ 0.74862 in.) (0.7512 in.)

Connecting Rod Small End Inside Diameter 19.010 ~ 19.021 mm 19.06 mm

(0.74842 ~ 0.74886 in.) (0.7504 in.)

Piston Diameter 81.935 ~ 81.955 mm 81.79 mm

(3.2258 ~ 3.2266 in.) (3.220 in.)

Cylinder Inside Diameter 81.97 ~ 81.99 mm 82.10 mm

(3.227 ~ 3.228 in.) (3.232 in.)

Cylinder Bore Out-Round ––– 0.05 mm

––– (0.002 in.)

Piston/Cylinder Clearance 0.015 ~ 0.055 mm –––

(0.00059 ~ 0.0022 in.) –––

Balancer Shaft

Balancer Shaft Journal Diameter 31.959 ~ 31.975 mm 31.935 mm

(1.2582 ~ 1.2589 in.) (1.2573 in.)

Balancer Shaft Bearing Inside Diameter:

Crankcase Side 32.000 ~ 32.016 mm 32.06 mm

(1.2598 ~ 1.2605 in.) (1.262 in.)

Crankcase Cover Side 32.000 ~ 32.016 mm 32.06 mm

(1.2598 ~ 1.2605 in.) (1.262 in.)

Kawasaki Engine Shop Rebuild Manual Page B-5

ENGINE BOTTOM END DISASSEMBLY

Exploded View

Fig. 1 Crankcase

Page B-6 Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END DISASSEMBLY

Torque

E-Z-GO

No. Part No. Fastener N•m kgf/m ft-lb/in-lb Remarks

1 603535 Connecting Rod Big End Cap Bolts 5.9 0.60 52 in-lb EO

2 603526 Breather Valve Screw 37 0.35 30 in-lb

3 603518* Oil Filter Joint 6.9 0.70 61 in-lb

4 603522 Oil Line Plugs 3.9 0.40 34 in-lb L

5 603524 Crankcase Cover Bolts 22 2.2 16 ft-lb S

* with crankcase

EO: Apply engine oil.

G: Apply grease.

L: Apply a non-permanent locking agent.

M: Apply molybdenum disulfide grease.

R: Replacement Parts

S: Follow the specific tightening sequence.

Kawasaki Engine Shop Rebuild Manual Page B-7

Notes:

Page B-8 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

TABLE OF CONTENTS FOR SECTION ‘C’

SECTION TITLE

C

PAGE NO.

ENGINE MEASUREMENTS AND SPECIFICATIONS...................................................................... C-1

Tool List .................................................................................................................................. C-1

Using Telescoping Gauges and Hole Gauges ....................................................................... C-1

CYLINDER HEAD ............................................................................................................................. C-1

Measure Cylinder Compression ............................................................................................. C-1

Inspect Push Rod ................................................................................................................... C-3

Inspect Rocker Arm ................................................................................................................ C-3

Measure Cylinder Head Warp ................................................................................................ C-3

VALVES ............................................................................................................................................ C-4

Inspect Valve Clearance......................................................................................................... C-4

Adjust Valve Clearance .......................................................................................................... C-4

Inspect Valve Seat.................................................................................................................. C-4

Repair Vavle Seat................................................................................................................... C-4

Operating Procedures ............................................................................................................ C-5

Measure Valve Spring Free Length ....................................................................................... C-8

Measure Vavle Head Thickness............................................................................................. C-8

Measure Valve Stem Bend .................................................................................................... C-8

Measure Valve Stem Diameter .............................................................................................. C-9

Measure Valve Guide Inside Diameter................................................................................... C-9

Measure Valve/Guide Clearance (Wobble Method) ............................................................... C-9

CAMSHAFT AND TAPPETS........................................................................................................... C-10

Measure Camshaft Bearing/Journal Wear ........................................................................... C-10

CYLINDER AND PISTONS............................................................................................................. C-11

Clean Piston ......................................................................................................................... C-11

Check Piston Ring and Ring Groove Wear ......................................................................... C-11

Measure Piston Ring End Gap ............................................................................................. C-12

Measure Piston Pin, Piston Pin Hole, and Connecting Rod Wear ...................................... C-13

Measure Piston Diameter ..................................................................................................... C-13

Check Cylinder Inside Diameter ........................................................................................... C-14

CRANKSHAFT AND CONNECTING RODS................................................................................... C-14

Clean/Inspect........................................................................................................................ C-14

Measure Connecting Rod Bend/Twist .................................................................................. C-14

Measure Connecting Rod Big End/Crankpin Width Wear .................................................... C-15

Measure Connecting Rod Big End Bearing/Crankpin Wear ................................................ C-15

Measure Crankshaft Runout................................................................................................. C-16

Measure Crankshaft Main Bearing/Journal Wear ................................................................ C-16

BALANCER SHAFT ........................................................................................................................ C-17

Measure Balancer Shaft Bearing/Journal Wear .................................................................. C-17

BREATHER VALVE ........................................................................................................................ C-17

Inspect Breather Valve ......................................................................................................... C-17

Kawasaki Engine Shop Rebuild Manual Page C-i

ENGINE MEASUREMENTS

Notes:

Page C-ii Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

ENGINE MEASUREMENTS AND

C

Telescoping gauges and hole gauges are “transfer-type”

measuring instruments. They are not calibrated and are

SPECIFICATIONS used to record a distance, which is then transferred to a

Tool List Qty. Required micrometer for measurement.

Compression Gauge, 20 kgf/cm²: Position the gauge in the hole or bore and “set” the tele-

E-Z-GO Part No. N/A .................................................. 1 scoping arms or ball to its true diameter. Make sure that

Compression Gauge Adapter, M14 × 1.25: the handle of the gauge is in line with the centerline of

E-Z-GO Part No. N/A .................................................. 1 the hole or bore.

Valve Seat Cutter, 45° - 35

E-Z-GO Part No. 608666 ............................................ 1 Lock and remove the gauge. Measure its setting with a

Valve Seat Cutter, 32° - 38.5 micrometer.

E-Z-GO Part No. 608668 ............................................ 1

Valve Seat Cutter, 45° - 32

CYLINDER HEAD

E-Z-GO Part No. 608665 ............................................ 1

Valve Seat Cutter, 32° - 35 Measure Cylinder Compression

E-Z-GO Part No. 608667 ............................................ 1

Valve Seat Cutter Holder, 7 A. Thoroughly warm up the engine so that the engine oil

E-Z-GO Part No. 608669 ............................................ 1 between the piston and the cylinder wall will help seal

compression as it does during normal running.

Valve Seat Cutter Holder Bar

E-Z-GO Part No. 608670 ............................................ 1 B.

All engine parts must be thoroughly cleaned, and free of all dirt,

oil, grease, carbon deposits or residue of any kind before begin-

ning this section. It is especially important that your work area

be clean and well organized while performing the operations

described in this section.

Stop the engine, remove the spark plug, and attach a

compression gauge [A] firmly into the spark plug hole

[B].

In some cases, time may be saved by setting measuring instru- Special Tools

ments at limit specifications and using them as “go-no-go” fix- Compression Gauge, 20 kgf/cm²

tures. Check preset instrument fit in bores, on shafts, etc. to E-Z-GO Part No. N/A

determine part acceptability. We recommend that parts bound

to be acceptable but near limits be replaced if the engine will

Compression Gauge Adapter, M14 × 1.25 [B]

see high usage. E-Z-GO Part No. N/A

C. Using the starter, turn the engine over with the throt-

tle fully open until the compression gauge stops ris-

ing; this is the highest compression reading

obtainable.

Check micrometers for proper calibration before beginning the

operations described in this section. Cylinder Compression

Using Telescoping Gauges and Hole Usable Range: 880 ~ 1 080 kPa (9 ~ 11 kgf/cm², 128 ~

Gauges 156 psi) @500 ~ 700 r/min (rpm)

Kawasaki Engine Shop Rebuild Manual Page C-1

ENGINE MEASUREMENTS

The following table should be consulted if the obtainable compression reading is not within the usable range.

Problem Diagnosis Remedy (Action)

Carbon accumulation on piston and cylinder Remove the carbon

head, and in combustion chamber possibly deposits and replace

Cylinder compression due to damaged valve stem oil seal and/or damaged parts if

higher than usable damaged piston oil rings necessary.

range Replace with a gasket

Incorrect cylinder head gasket thickness of the proper thick-

ness.

Replace damaged gas-

Gas leakage around cylinder head ket and check cylin-

der head warp.

Bad condition of valve seating Repair if possible.

Cylinder compression

Incorrect valve, piston/cylinder clearance Adjust.

lower than usable

range Inspect cylinder and

Piston seizure liner and replace/

repair as necessary.

Bad condition of piston ring and/or piston ring

Replace.

grooves

Page C-2 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

Inspect Push Rod Measure Cylinder Head Warp

A. A.

Place the rocker arm push rod on V blocks that are as Lay a straightedge [A] across the lower surface of the

far apart as possible, and set a dial gauge [A] on the head at several different points, and measure warp by

rod at a point halfway between the blocks. Turn the inserting a thickness gauge [B] between the straight-

rod to measure the runout. The difference between edge and the head.

highest and the lowest dial readings is the amount of B. If warp exceeds the service limit, repair the mating

runout. surface. Replace the cylinder head if the mating sur-

B. If the runout exceeds the service limit, replace the face is badly damaged.

rod. Cylinder Head Warp

Rocker Arm Push Rod Runout Service Limit: 0.03 mm (0.001 in.)

Service Limit: TIR 0.5 mm (0.02 in.)

Inspect Rocker Arm

A.

Clean and inspect the rocker arm where it touches

the push rod and valve stem.

B. If the contact points [A] are worn or damaged,

replace the rocker arm.

Kawasaki Engine Shop Rebuild Manual Page C-3

ENGINE MEASUREMENTS

VALVES

Inspect Valve Clearance

The valve stem and guide must be in good condition, or this

A. Refer to the Specifications table in Section A. check will not be valid.

G. If the valve seating pattern is not correct, repair the

Adjust Valve Clearance seat.

A. Refer to the Specifications table in Section A. H. Measure the outside diameter [D] of the seating pat-

tern on the valve seat.

Inspect Valve Seat I. If the outside diameter of the valve seating pattern is

too large or too small, repair the seat.

A. Remove the valve. See Remove Valve Mechanism in

Section A. Valve Seating Surface Outside Diameter

Inlet 32.8 mm (1.29 in.)

B.

Exhaust 27.6 mm (1.09 in.)

J. Measure the seat width [E] of the portion where there

is no build-up carbon (white portion) of the valve seat

with a vernier caliper.

• Good [F]

• Too Wide [G]

• Too Narrow [H]

• Uneven [J]

K. If the width is too wide, too narrow or uneven, repair

the seat (see Repair Valve Seat).

Valve Seating Surface Width Standard

Inlet 1.1 ~ 1.7 mm (0.043 ~ 0.067 in.)

Exhaust 1.0 ~ 1.5 mm (0.039 ~ 0.059 in.)

Repair Valve Seat

A. Follow the manufacturer’s instructions for use of valve

seat cutters.

Special Tools

Valve Seat Cutter, 45° - 35

E-Z-GO Part No. 608666

Check the valve seating surface [A] between the Valve Seat Cutter, 32° - 38.5

valve [B] and valve seat [C]. E-Z-GO Part No. 608668

Valve Seat Cutter, 45° - 32

C. Coat the valve seat with machinist’s dye. E-Z-GO Part No. 608665

D. Push the valve into the guide. Valve Seat Cutter, 32° - 35

E-Z-GO Part No. 608667

E. Rotate the valve against the seat with a lapping tool.

Valve Seat Cutter Holder, 7

F. Pull the valve out, and check the seating pattern on E-Z-GO Part No. 608669

the valve head. It must be the correct width and even Valve Seat Cutter Holder Bar

all the way around. E-Z-GO Part No. 608670

Page C-4 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

If the manufacture’s instructions are not available, use Marks Stamped on the Cutter

the following procedure:

Seat Cutter Operating Cares

1. The valve seat cutter is designed only for valve

seat repair. Therefore the cutter must not be used

for other purposes.

2. Do not drop or hit the valve seat cutter, or the dia-

mond particles may fall off.

3. Do not fail to apply engine oil to the valve seat cut-

ter before grinding the seat surface. Also, use The marks stamped on the back of the cutter [A] repre-

washing oil to wash off ground particles sticking to sent the following:

the cutter.

60 ...................................................... Cutter angle [B]

37.5 ............................... Outer diameter of cutter [C]

Operating Procedures

Do not use a wire brush to remove the metal particles from the

cutter. It will take off the diamond particles.

A. Clean the seat area carefully.

4. B. Coat the seat with machinist’s dye.

C. Fit a 45° cutter to the holder and slide it into the valve

guide.

D. Press down lightly on the handle and turn it right or

left.

E. Grind the seating surface only until it is smooth.

Setting the valve seat cutter holder [A] in position,

operate the cutter [B] with one hand [C]. Do not Do not grind the seat too much. Overgrinding will reduce valve

apply too much force to the diamond portion. clearance by sinking the valve into the head. If the valve sinks

too far into the head, it will be impossible to adjust the clear-

ance, and the cylinder head must be replaced.

F. Measure the outside diameter (O.D.) of the seating

surface with a vernier caliper.

Prior to grinding, apply oil to the cutter, and during the operation G. If the O.D. of the seating surface is too small, repeat

use washing oil to wash off any ground particles sticking to the the 45° grind until the diameter is within the specified

cutter. range.

5. After use, wash the cutter with washing oil and H. If the O.D. of the seating surface is too large, make

apply a thin layer of engine oil before storing. the 32° grind described below.

Kawasaki Engine Shop Rebuild Manual Page C-5

ENGINE MEASUREMENTS

To make the 32° grind, fit a 32° cutter to the holder, and slide it Be sure to remove all grinding compound before assembly

into the valve guide. P. When the engine is assembled, be sure to adjust the

1. Grind the seat at a 32° angle until the seat O.D. is valve clearances.

within the specified range.

2. Turn the holder one turn at a time while pressing

down very lightly. Check the seat after each turn.

The 32° cutter removes material very quickly.

3. Check the seat outside diameter frequently to pre-

vent overgrinding.

I. After making the 32° grind, return to the seat O.D.

measurement step above.

J. Lap the valve to the seat, once the seat width and

O.D. are within the ranges specified above.

K. Put a little coarse grinding compound on the face of

the valve in a number of places around the valve

head.

L. Spin the valve against the seat until the grinding com-

pound produces a smooth, matched surface on both

the seat and the valve.

M. Repeat the process with a fine grinding compound.

[A] Lapping Tool

[B] Valve Seat

[C] Valve

N. The seating area should be marked about in the mid-

dle of the valve face.

O. If the seat area is not in the right place on the valve,

check to be sure the valve is the correct part. If it is, it

may have been refaced too much; replace it.

Page C-6 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

Kawasaki Engine Shop Rebuild Manual Page C-7

ENGINE MEASUREMENTS

Measure Valve Spring Free Length Measure Valve Stem Bend

A. A.

Measure the valve spring [A] free length. Place the valve in V blocks at each end of the stem,

B. If the free length is less than the service limit, replace and set a dial gauge [A] on the stem at a point half-

the valve spring with a new one. way between the blocks. Turn the valve to measure

the bend. The difference between the highest and the

Valve Spring Free Length lowest dial readings is the amount of bend.

Standard: 35 mm (1.38 in.) B. If the valve stem bend is greater than the service

Service Limit: 32.6 mm (1.28 in.) limit, replace the valve with a new one.

Measure Valve Head Thickness Valve Stem Bend

A. Standard: Less than 0.01 mm (0.0004 in.) TIR

Service Limit: TIR 0.05 mm (0.0020 in.)

Measure the thickness [A] of the valve head.

B. If the valve head thickness is less than the service

limit, replace the valve with a new one.

Valve Head Thickness

Standard: 0.4 mm (0.016 in.)

Service Limit: 0.4 mm (0.016 in.)

Page C-8 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

Measure Valve Stem Diameter Measure Valve/Guide Clearance (Wobble

A. Method)

A.

Measure the diameter of the valve stem [A] in two

directions at right angles, and at four different posi-

If a small bore gauge is not available, inspect the

tions on the stem.

valve guide wear by measuring the valve/guide clear-

B. If any single measurement is less than the service ance with the wobble method, as indicated below.

limit, replace the valve with a new one.

B. Insert a new valve [A] into the guide [B] from the top

Valve Stem Diameter of the head.

Standard:

Inlet 6.960 ~ 6.975 mm (0.2740 ~ 0.2746 in.) C. Set a dial gauge against the stem perpendicular to it

as close as possible to the cylinder head upper sur-

Exhaust 6.945 ~ 6.960 mm (0.2734 ~ 0.2740 in.)

face.

Service Limit:

Inlet 6.95 mm (0.274 in.) D. Move the stem back and forth [C] to measure valve/

Exhaust 6.93 mm (0.273 in.) guide clearance.

Measure Valve Guide Inside Diameter E. Repeat the measurement in a direction at a right

angle to the first.

A.

F. If the reading exceeds the service limit, replace the

cylinder head.

The reading is not actual valve/guide clearance because the

measuring point is above the guide.

Valve/Guide Clearance (Wobble Method)

Standard:

Measure the inside diameter [A] of the valve guide

[B]. Inlet 0.06 ~ 0.13 mm (0.0024 ~ 0.0051 in.)

B. If the valve guide has worn enough to exceed the ser- Exhaust 0.10 ~ 0.17 mm (0.0039 ~ 0.0067 in.)

vice limit, replace the cylinder head.

Service Limit:

Valve Guide Inside Diameter

Standard: 7.000 ~ 7.015 mm (0.2756 ~ 0.2762 in.) Inlet 0.29 mm (0.011 in.)

Service Limit: 7.08 mm (0.279 in.) Exhaust 0.33 mm (0.013 in.)

Kawasaki Engine Shop Rebuild Manual Page C-9

ENGINE MEASUREMENTS

CAMSHAFT AND TAPPETS Crankcase Cover Side Camshaft Journal Diameter

Measure Camshaft Bearing/Journal Wear Standard: 49.959 ~ 49.975 mm (1.9669 ~ 1.9675 in.)

A. Service Limit: 49.93 mm (1.966 in.)

E.

Measure the height of each cam lobe [A].

B. If the cam height is less than the service limit for Measure the inside diameter [A] of the camshaft

either lobe, replace the camshaft. bearing on the crankcase at several points.

Cam Lobe Height

F. Replace the crankcase if the inside diameter is more

Standard: than the service limit.

Inlet 29.95 ~ 30.05 mm (1.179 ~ 1.183 in.)

Camshaft Bearing Inside Diameter (Crankcase)

Exhaust 29.95 ~ 30.05 mm (1.179 ~ 1.183 in.)

Standard: 20.000 ~ 20.013 mm (0.78740 ~ 0.78791 in.)

Service Limit: Service Limit: 20.07 mm (0.7902 in.)

Inlet 29.86 mm (1.176 in.)

G.

Exhaust 29.86 mm (1.176 in.)

C.

Measure the inside diameter [A] of the camshaft

bearing on the crankcase cover at several points.

Measure both camshaft journals at several points

H. Replace the crankcase cover if the inside diameter is

around the journal circumference.

more than the service limit.

D. If the journal diameter is less than the service limit,

replace the camshaft. Camshaft Bearing Inside Diameter (Crankcase

Cover)

Crankcase Side Camshaft Journal Diameter

Standard: 19.967 ~ 19.980 mm (0.78610 ~ 0.78661 in.) Standard: 50.000 ~ 50.025 mm (1.9685 ~ 1.9695 in.)

Service Limit: 19.94 mm (0.7850 in.) Service Limit: 50.09 mm (1.972 in.)

Page C-10 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

CYLINDER AND PISTONS C.

Clean Piston

A. Remove the piston and piston rings (see Remove

Piston in Section A).

B.

Be careful not to widen the ring grooves. Damaged ring

grooves will require piston replacement.

D. Clean the piston ring grooves [A] with a broken piston

ring or other suitable tools.

Never clean the piston head with the engine assembled. Carbon

particles will fall between the piston and cylinder, and damage Check Piston Ring and Ring Groove Wear

the crankshaft bearings.

A. Clean the piston (see Clean Piston).

Visually inspect the piston rings and ring grooves.

Use the scraping tools carefully. Do not gouge the piston head.

B. If the piston rings are worn unevenly or damaged,

To avoid gouging, use scrapers that are made of a material that replace them.

will not cause damage.

C. If the ring grooves are worn unevenly or damaged,

Scrape the carbon off the piston head with a scraper [A].

replace both the piston and piston rings.

D.

Measure the clearance between the top and second

rings and their grooves using a thickness gauge [A].

Kawasaki Engine Shop Rebuild Manual Page C-11

ENGINE MEASUREMENTS

E. If the piston ring/groove clearance is greater than the B. Push each ring (one at a time) into the cylinder bore

specified value, replace the piston. to a point close to the bottom of the cylinder bore.

Piston Ring/Groove Clearance C. Use the piston to push it in to be sure it is square.

Standard: D.

Top, Second 0.04 ~ 0.08 mm (0.002 ~ 0.003 in.)

Service Limit:

Top, Second 0.18 mm (0.0071 in.)

The oil ring is a three-piece assembled ring. It is difficult to

measure the ring groove clearance and thickness; visually

inspect only.

F.

Measure the gap [A] between the ends of the ring [B]

with a thickness gauge.

E. If the end gap of any ring is greater than the service

limit, replace the entire set of rings.

Piston Ring End Gap

Standard:

Top 0.15 ~ 0.40 mm (0.0059 ~ 0.016 in.)

Second 0.23 ~ 0.48 mm (0.0091 ~ 0.019 in.)

Oil 0.25 ~ 0.75 mm (0.0098 ~ 0.030 in.)

Service Limit:

Measure the piston ring thickness [A]. Top 0.7 mm (0.03 in.)

G. Use a micrometer to measure at several points Second 0.8 mm (0.03 in.)

around the rings.

Oil 1.0 mm (0.039 in.)

H. If any of the measurements are less than the service

limit, replace the entire set of rings.

Piston Ring Thickness

Standard:

Top, Second 1.47 ~ 1.49 mm (0.0579 ~ 0.0587 in.)

Service Limit:

Top, Second 1.40 mm (0.0551 in.)

When using new rings in a used piston, check for uneven

groove wear. The rings should fit perfectly parallel to the groove

sides. If not, replace the piston.

Measure Piston Ring End Gap

A. Remove the piston rings.

Page C-12 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

Measure Piston Pin, Piston Pin Hole, and F.

Connecting Rod Wear

A. Remove the piston pin.

B.

Measure the inside diameter [A] of the small end of

the connecting rod at several points. Use a dial bore

gauge.

G. If the inside diameter is more than the service limit,

Measure the outside diameter of the piston pin with a replace the connecting rod.

micrometer at several points.

Connecting Rod Small End Inside Diameter

C. If the outside diameter is less than service limit,

replace the piston pin. Standard: 19.010 ~ 19.021 mm (0.74842 ~ 0.74886 in.)

Piston Pin Outside Diameter Service Limit: 19.06 mm (0.7504 in.)

Standard: 18.995 ~ 19.000 mm (0.74783 ~ 0.74803 in.)

Measure Piston Diameter

Service Limit: 18.96 mm (0.7465 in.)

A.

D.

Measure the outside diameter [A] of the piston 18 mm

Measure the inside diameter [A] of the piston pin hole (0.71 in.) up [B] from the bottom of the piston at a

at several points on both sides. Use a dial bore right angle to the direction of the piston pin hole.

gauge.

B. If the measurement is less than the service limit,

E. If the inside diameter is more than the service limit,

replace the piston.

replace the piston.

Piston Pin Hole Inside Diameter Piston Diameter

Standard: 19.004 ~ 19.015 mm (0.74819 ~ 0.74862 in.) Standard: 81.935 ~ 81.955 mm (3.2258 ~ 3.2266 in.)

Service Limit: 19.08 mm (0.7512 in.) Service Limit: 81.79 mm (3.220 in.)

Kawasaki Engine Shop Rebuild Manual Page C-13

ENGINE MEASUREMENTS

Check Cylinder Inside Diameter CRANKSHAFT AND CONNECTING RODS

A. Clean and measure the cylinder inside diameter.

Clean/Inspect

B. Use a dial bore gauge to measure front-to-back and

A. After removing, clean the crankshaft and connecting

side-to-side at the points as shown in the figure.

rods with a high-flash point solvent and dry them with

C. compressed air.

B. Inspect the teeth of the crankshaft gear for pitting,

fatigue cracks, burrs and evidence of improper tooth

contact.

C. Replace the gear if necessary.

D. Inspect the crankshaft and connecting rods espe-

cially at the bearing surfaces for wear, scratches, evi-

dence of improper contact or other damages.

E. Replace them if necessary.

Measure Connecting Rod Bend/Twist

If any of the cylinder bore measurements is greater A. Measure connecting rod bend.

than the service limit, replace the crankcase. B. Select an arbor of the same diameter as the connect-

10 mm (0.39 in.) [A] ing rod big end, and insert the arbor through the con-

necting rod big end.

35 mm (1.38 in.) [B]

Cylinder Inside Diameter C. Select an arbor of the same diameter as the piston

Standard: 81.97 ~ 81.99 mm (3.227 ~ 3.228 in.) pin and at least 100 mm long, and insert the arbor

through the connecting rod small end.

Service Limit: 82.10 mm (3.232 in.)

Cylinder Bore Out-Round D.

Service Limit: 0.05 mm (0.002 in.)

On a surface plate, set the big-end arbor on V blocks

[A].

E. With the connecting rod held vertically, use a height

gauge [B] to measure the difference in the height of

the small end arbor above the surface plate over a

100 mm length to determine the amount of connect-

ing rod bend.

F. If connecting rod bend exceeds the service limit, the

connecting rod must be replaced.

Connecting Rod Bend

Service Limit: 0.15/100 mm (0.006/3.94 in.)

Page C-14 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

G. Measure connecting rod twist. C.

H.

Measure the crankpin width [A] with a dial caliper.

With the big-end arbor still on the V blocks [A], hold D. If the crankpin width is more than the service limit,

the connecting rod horizontally. Use a height gauge replace the crankshaft.

[B] to measure the amount that the small end arbor

varies from being parallel with the surface plate over Crankpin Width

a 100 mm length of the arbor to determine the Standard: 28.0 ~ 28.2 mm (1.10 ~ 1.11 in.)

amount of connecting rod twist.

Service Limit: 28.4 mm (1.12 in.)

I. If connecting rod twist exceeds the service limit, the

connecting rod must be replaced. Measure Connecting Rod Big End Bearing/

Connecting Rod Twist Crankpin Wear

Service Limit: 0.15/100 mm (0.006/3.94 in.) A. Apply a thin film of oil on the thread of the cap bolts.

Measure Connecting Rod Big End/Crankpin B. Install the cap bolts and tighten the bolts to the speci-

fied torque (see Install Piston in Section D).

Width Wear

A. C.

Measure the connecting rod big end width [A] with a Measure the inside diameter [A] of big end at several

micrometer or dial caliper. points with a telescoping gauge or inside micrometer.

B. If the measurement is less than the service limit, D. If the inside diameter is more than the service limit,

replace the connecting rod. replace the connecting rod with a new one.

Connecting Rod Big End Width Connecting Rod Big End Inside Diameter

Standard: 27.4 ~ 27.7 mm (1.08 ~ 1.09 in.) Standard: 43.004 ~ 43.015 mm (1.6931 ~ 1.6935 in.)

Service Limit: 27.0 mm (1.06 in.) Service Limit: 43.04 mm (1.694 in.)

Kawasaki Engine Shop Rebuild Manual Page C-15

ENGINE MEASUREMENTS

E. Measure Crankshaft Main Bearing/Journal

Wear

A.

Measure the crankpin outside diameter [A].

F. Use a micrometer to measure several points around

the crankpin circumference.

Measure the diameter [A] of the crankshaft main jour-

G. If the crankpin diameter is less than the service limit, nal.

replace the crankshaft with a new one.

Crankpin Outside Diameter B. If the journal has worn enough to exceed the service

limit, replace the crankshaft with a new one.

Standard: 42.963 ~ 42.976 mm (1.6915 ~ 1.6920 in.)

Service Limit: 42.95 mm (1.691 in.) Crankcase Side Crankshaft Main Journal Diameter

Measure Crankshaft Runout Standard: 34.955 ~ 34.980 mm (1.3762 ~ 1.3772 in.)

A. Measure the crankshaft runout.

Service Limit: 34.93 mm (1.375 in.)

B.

C.

Set the crankshaft in a flywheel alignment jig [A] or on

V blocks gauge. Measure the inside diameter [A] of the crankshaft

C. Set a dial gauge [B] against both bearing journals. main bearing (crankcase side).

D. Turn the crankshaft slowly to measure the runout.

D. If the bearing has worn enough to exceed the service

The difference between the highest and lowest dial

limit, replace the crankcase with a new one.

gauge readings (TIR) is the amount of runout.

E. If the measurement exceeds the service limit, replace Crankshaft Main Bearing Inside Diameter (Crankcase

the crankshaft. Side)

Crankshaft Runout

Standard: 35.002 ~ 35.015 mm (1.3780 ~ 1.3785 in.)

Standard: TIR 0.02 mm (0.0008 in.) or less

Service Limit: TIR 0.05 mm (0.002 in.) Service Limit: 35.05 mm (1.380 in.)

Page C-16 Kawasaki Engine Shop Rebuild Manual

ENGINE MEASUREMENTS

BALANCER SHAFT E.

Measure Balancer Shaft Bearing/Journal

Wear

A.

Measure the inside diameter [A] of the balancer shaft

bearing on the crankcase cover at several points.

F. If inside diameter is more than the service limit,

replace the crankcase cover with a new one.

Measure both balancer shaft journal diameters [A] at Balancer Shaft Bearing Inside Diameter (Crankcase

several points around the journal’s circumference. cover)

Standard: 32.000 ~ 32.016 mm (1.2598 ~ 1.2605 in.)

B. If journal diameter is less than the service limit,

Service Limit: 32.06 mm (1.262 in.)

replace the balancer shaft with a new one.

Balancer Shaft Journal Diameter BREATHER VALVE

Standard: 31.959 ~ 31.975 mm (1.2582 ~ 1.2589 in.) Inspect Breather Valve

Service Limit: 31.935 mm (1.2573 in.) A. Remove the breather valve (see Remove Breather

Valve).

C.

B. Inspect the reed valve for breakage, hair cracks or

distortion; replace it if necessary.

C. Inspect the back plate for damage or rough contact

surface; replace it if necessary.

D. Inspect the valve seating surface. The surface should

be free of nicks or burrs.

E. Align center of the valve seat with center of the reed

valve and back plate, then tighten the breather valve

screw.

Measure the inside diameter [A] of the balancer shaft

bearing on the crankcase at several points.

D. If inside diameter is more than the service limit,

replace the crankcase with a new one.

Balancer Shaft Bearing Inside Diameter (Crankcase)

Standard: 32.000 ~ 32.016 mm (1.2598 ~ 1.2605 in.)

Service Limit: 32.06 mm (1.262 in.)

Kawasaki Engine Shop Rebuild Manual Page C-17

Notes:

Page C-18 Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END REASSEMBLY

TABLE OF CONTENTS FOR SECTION ‘D’

SECTION TITLE

D PAGE NO.

ENGINE BOTTOM END.................................................................................................................... D-1

Tool List .................................................................................................................................. D-1

BREATHER VALVE .......................................................................................................................... D-1

Install Breather Valve ............................................................................................................. D-1

BALANCER SHAFT .......................................................................................................................... D-1

Install Balancer Shaft.............................................................................................................. D-1

CRANKSHAFT AND CONNECTING RODS..................................................................................... D-2

Install Crankshaft.................................................................................................................... D-2

Install Connecting Rod ........................................................................................................... D-2

CYLINDERS AND PISTONS ............................................................................................................ D-2

Install Piston ........................................................................................................................... D-2

CAMSHAFT AND PISTONS ............................................................................................................. D-4

Install Camshaft, Tappet......................................................................................................... D-4

CRANKCASE .................................................................................................................................... D-4

Assemble Crankcase Cover .................................................................................................. D-4

Install Crankcase Cover ......................................................................................................... D-4

Kawasaki Engine Shop Rebuild Manual Page D-i

ENGINE BOTTOM END REASSEMBLY

Notes:

Page D-ii Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END REASSEMBLY

ENGINE BOTTOM END BREATHER

D

Tool List Qty. Required Install Breather Valve

Piston Ring Compressor Grip: A.

E-Z-GO Part No. N/A .................................................. 1

Piston Ring Compressor Belt, 80 ~ 91:

E-Z-GO Part No. N/A .................................................. 1

Bearing Driver Set:

E-Z-GO Part No. N/A .................................................. 1

If the engine is not going to be put back into

service immediately, completely coat all inter-

nal engine components with assembly lube. Tape intake and

exhaust openings.

Prior to engine reassembly, all parts

must be thoroughly cleaned; free of

Install the reed valve [A] and back plate [B], then

dirt, oil, grease, carbon deposits, or residue of any kind; free of

nicks, burrs, or damage of any kind to wear surfaces; and tighten the breather valve screw [C].

inspected for excessive wear. Parts that are damaged or are not Torque - Breather Valve Screw: 3.4 N•m ( 0.35 kgf•m,

within dimensional specifications should be replaced (or 30 in-lb)

machined if applicable). We recommend that parts found to be B. Install the cylinder head (see Install Cylinder Head in

acceptable but near limits be replaced if the engine will have Section A).

high usage.

Because some mating parts with wear surfaces were machined BALANCER SHAFT

together when the engine was manufactured, or have estab-

lished wear patterns during operation, the reassembly of engine Install Balancer Shaft

parts in their original positions and orientations with their origi-

A. Install the balancer shaft to the balancer shaft bear-

nal mating parts is critical to the performance and life expectan-

ing on the crankcase.

cy of the engine.

When tightening (torquing) a number of screws or bolts in a giv- B. Install the crankcase cover (see Install Crankcase

en pattern, tighten them in two stages. Tighten them to 1/2 of Cover).

specified torque in one pass through the pattern, and then to C.

specified torque on the second pass.

All 4-cycle engine fasteners are plated, and

some are lubricated when installed. They are

considered “wet” and require approximately 80% of the speci-

fied torque of dry fasteners.

Align the punch marks [A] on the crankshaft gear and

on the balancer shaft gear.

Kawasaki Engine Shop Rebuild Manual Page D-1

ENGINE BOTTOM END REASSEMBLY

CRANKSHAFT AND CONNECTING RODS C.

Install Crankshaft

A. Clean the crankshaft and crankcase thoroughly, Do not mix up the top and second rings.

especially at the bearing contact surfaces. Install the second ring so that the notched edge [A] faces

down.

B. Pack grease to 60% volume between the lips of the

oil seal on the crankcase. Press in the new oil seal 0

~1 mm (0 ~ 0.04 in.) below the crankcase surface.

C. Apply molybdenum disulfide grease to the alternator The rings should turn freely in the grooves.

side journal. D. Install the top ring.

D. Apply engine oil to the crank pin and bearing.

E. Insert the crankshaft into the crankcase.

Install Connecting Rod

A. Refer to Install Piston.

CYLINDERS AND PISTONS

Install Piston Piston Head [B]

A. Top Ring [C]

Second Ring [D]

E.

Install the expander [A] in the piston oil ring groove so

that the expander ends [B] touch; never overlap.

B. Align the piston and rings with the piston ring end gap

as shown.

Arrow Match Marks [A]

Top Ring End Gap, Upper Steel Rail End Gap [B]

There is no up or down to the rails. They can be installed either About 45° [C]

way.

Second Ring End Gap, Lower Steel Rail End Gap [D]

Install the upper and lower steel rails. F. Apply engine oil to the piston pins.

Page D-2 Kawasaki Engine Shop Rebuild Manual

ENGINE BOTTOM END REASSEMBLY

G. J.

Assemble the piston onto the connecting rod so that Using the piston ring compressor grip [A] and the belt

the arrow mark [A] on the top of the piston can be [B], lightly tap the top of the piston with a plastic mal-

aligned with “MADE IN USA” [B] on the connecting let [C] to insert the piston and connecting rod into the

rod. cylinder.

Special Tools - Piston Ring Compressor Grip:

H. E-Z-GO Part No. N/A

Piston Ring Compressor Belt, 80 ~ 91:

E-Z-GO Part No. N/A

K. Position the arrow mark [D] on the top of the piston

toward the alternator rotor side [E].

The connecting rod and the connecting rod big end cap are

machined at the factory in the assembled state, so they must be

Fit a new piston pin snap ring into the side of the pis- replaced together as a set.

ton so that the ring opening [A] does not coincide with

L.

the notch [B] in the edge of the piston pin hole.

When installing a piston pin snap ring, compress it only enough

to install it and no more.

Apply engine oil to the inner surface [A] of the con-

Do not reuse the snap rings, as removal weakens and deforms necting rod big end [B] and cap [C].

them. They could fall out and score the cylinder wall.

M. Install the connecting rod big end cap in its original

I. Apply engine oil to the piston skirt and the cylinder position on the connecting rod big end by matching

bore. the marks [D].

Kawasaki Engine Shop Rebuild Manual Page D-3

ENGINE BOTTOM END REASSEMBLY

N. Apply a small amount of engine oil to the thread and CRANKCASE

seating surface of the cap bolts [E].

Assemble Crankcase Cover

O. Tighten the cap bolts.

A.

Torque - Connecting Rod Big End Cap Bolts: 5.9 N•m

(0.60 kgf•m, 52 in-lb)

P. Install camshaft (see Install Camshaft, Tappet Instal-

lation) and crankcase cover (see Install Crankcase

Cover).

CAMSHAFT AND PISTONS

Install Camshaft, Tappet

A. Apply engine oil to the tappet journal, cam lobe sur-

face, and camshaft gear.

Install the ball bearing [A] until it is bottomed.

B. Apply molybdenum disulfide grease to the camshaft Special Tool - Bearing Driver Set:

journal. E-Z-GO Part No. N/A

C. Install the tappets in their original positions. B. Apply grease to 60% volume between seal lips.

D. C. Install the oil seal [B] at specified position as shown.

[C] Crankcase Cover

[D] 4.0 ~ 4.5 mm (0.16 ~ 0.18 in.)

Install Crankcase Cover

A.

Align the punch marks [A] on the crankshaft gear and

on the camshaft gear.

E. Install the crankcase cover (see Install Crankcase

Cover).

F. Install the push rods (see Install Cylinder Head in Check to see that the dowel pins [A] are in place on

Section A). the crankcase.

G. Mount the rocker arms on the push rods, and install B. Install the new gasket on the crankcase.

the valve clearance adjusting nuts and the lock

screws.