Professional Documents

Culture Documents

Gatco, Inc.: Grease Lubrication Recommendations For Gatco Rotary Bushings and Tool Holders

Gatco, Inc.: Grease Lubrication Recommendations For Gatco Rotary Bushings and Tool Holders

Uploaded by

JotheeswaranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gatco, Inc.: Grease Lubrication Recommendations For Gatco Rotary Bushings and Tool Holders

Gatco, Inc.: Grease Lubrication Recommendations For Gatco Rotary Bushings and Tool Holders

Uploaded by

JotheeswaranCopyright:

Available Formats

Gatco, Inc.

Grease Lubrication Recommendations

for Gatco Rotary Bushings

and Tool Holders Data Sheet 1009-1

Lubrication Lubrication

Proper lubrication is essential for successful performance of rotary bushings Benefits

and tool holders. Gatco Rotary Bushings require very little maintenance. Only

in severe applications or contaminated environments will they require re- • Minimizes friction at

greasing. Although a frequency calculation is provided re-lubrication must be points of contact

determined by the end user based on the environment, loads applied and

within the bushing.

running speed as well as other variables. Recommended grease lubricant is

Alvania #2 by Shell Oil (or equivalent). The lubricant’s purpose is to reduce

friction, prevent bearing wear, dissipate heat and prevent corrosion between the • Prevents Corrosion

bearing races and rolling element. from forming within

the bushing or Tool

This Data Sheet is intended to provide the customer with general lubrication Holder.

guidelines. Due to the overwhelming number of lubricants, lubricating systems

and environments it is best to work directly with the in-house lube engineer,

• Aids in Dissipating

bearing companies and auto lube system suppliers for specific

recommendations.

Heat.

• Eliminates bearing

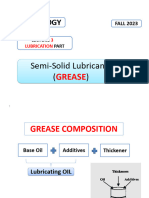

Grease Lubrication

and spindle wear.

• Provides extra

Grease lubrication is usually the first choice of lubricant. As technology

advances the thinking on lubrication has changed. The major oil companies sealing to exclude

now formulate greases that combat against the deterioration, and the washout Contamination.

ability that coolant causes in machine operations.

• Forms a thin film

Grease lubricated rotary bushings are suitable for a wide range of speeds. between the rolling

Lubricating high-precision bushings and tool holders with suitable quantities of element and the

good quality grease permits relatively high-speed operation without an

bearing race which

excessive rise in temperature.

is capable of

The use of grease also means that the design of a bearing arrangement can be supporting load.

relatively simple because grease is more easily retained in the bushing. Grease

also protects the bearing by contributing to sealing against solid contaminants • Prevents

and moisture. Grease provides an effective, inexpensive means of lubricating Premature failure of

rotary bushings and tool holders. Housings are simplified as opposed to oil the bearings.

lubrication and eliminates the need for motors, pumps, lube lines, metering

valves and nozzles.

• Dampens running

noise.

Gatco, Inc. Tel. 734-453-2295

42330 Ann Arbor Road E. Fax: 734-453-2310

Plymouth, MI 48170 USA www.gatcobushing.com Email: info@gatcobushing.com 06/09/2016

Gatco, Inc.

Data Sheet 1009-1

Re-greasing Frequency

Re-greasing quantity and frequency are two of the most common questions when referring to the application of grease in

rotary bushings and tool holders.

Some applications do not require re-greasing at all, but most others should be re-lubricated periodically to replace grease

that has deteriorated, leaked away, or become contaminated. In practice, these factors are extremely important to

bearing performance, as both undergreasing and overgreasing can lead to major maintenance issues. Undergreasing

can cause metal-to-metal contact between the rolling element and the bearing race, resulting in pre-mature failure.

Overgreasing can cause overheating, seal damage, and dissipation due to grease churning.

Re-greasing frequency calculation is somewhat more complex than the calculation for re-greasing quantity, and it largely

depends on the operating conditions of the application. Factors that affect the re-greasing frequency include:

temperature, quantity of grease in the bushing or tool holder, size and speed of the bearing, vibration, exposure to

contaminants, effectiveness of seals and the grease’s suitability for the particular service.

A common calculation for re-lubrication frequency, which incorporates the operating conditions, is:

14,000,000

Regreasing Frequency (hours) = - 4(bearing ID) (F1) (F2) (F3)

(shaft rpm) √(bearing ID)

Where:

• Bearing ID = bearing internal diameter in mm

• F1 bearing type = 1.0 for spherical or thrust bearing, 5.0 for cylindrical bearing, 10.0 for ball bearing

• F2 temperature = 1.0 for under 70°C, divide by two for every 10 above 70°C (e.g. 0.25 for 90°C)

• F3 contamination = 0.1 to 1.0 depending on the level of contamination

Using this example, for a spherical bearing application operating at 80°C, with shaft speed 1000 rpm, a bearing internal

diameter of 100 mm and minimal contamination, the frequency at which an operator should re-grease the bearing can be

calculated. 14,000,000

[Example] Frequency (hours) = - 4(100) (1) (0.5) (1) = 500 hours

(1000) √(100)

Grease Volume

In most applications adequate lubrication is assured if the amount of grease is maintained at 25%-35% of the free space

of the bearings and the space adjacent. This is the volume of grease pack maintained when bushings and tool holders

are shipped from the factory. Extremely contaminated applications dictate that the bearing be packed full if the operating

speed is low. At start up after re-greasing, grease will continue to purge past the seals and will stop when the bearings

have purged themselves. (Grease meters are commercially available for accurate grease volume.)

An industry accepted equation for grease volume:

cm3 = ƒx10-5 (D2-d2) B C

Where, Approximate filling amount (cm3)

D: Nominal outside diameter (mm)

d: Nominal bore (mm)

B: Nominal bearing width (mm)

ƒ = 1.5 for Needle Roller Bearings, Tapered Roller Bearings, Cylindrical Bearings

ƒ = 1.7 for Angular Contact Bearings, Deep Groove Bearings

C = Quantity of bearings in unit

10-5 = .00001

Gatco, Inc. Tel. 734-453-2295

42330 Ann Arbor Road E. Fax: 734-453-2310

Plymouth, MI 48170 USA www.gatcobushing.com Email: info@gatcobushing.com 06/09/2016

You might also like

- Universal Automatic Super Zig Zag MSAZ Sewing Machine InstructionDocument28 pagesUniversal Automatic Super Zig Zag MSAZ Sewing Machine InstructioniliiexpugnansNo ratings yet

- WSK 400 For 16 S 151, 16 S 221 WSK 440 For 16 S 251Document76 pagesWSK 400 For 16 S 151, 16 S 221 WSK 440 For 16 S 251gustavoqr2779% (14)

- Visual Guide To Lockpicking PDFDocument57 pagesVisual Guide To Lockpicking PDFRami Mohammed100% (2)

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationDocument9 pagesLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoNo ratings yet

- Grease Refill QtyDocument3 pagesGrease Refill QtyParmasamy SubramaniNo ratings yet

- Design Engineer's Guide - Selecting A Lubricant For Ball ScrewsDocument10 pagesDesign Engineer's Guide - Selecting A Lubricant For Ball ScrewsDat RomanNo ratings yet

- ENB 04 0555 Rev B Bearing Lubrication PDFDocument5 pagesENB 04 0555 Rev B Bearing Lubrication PDFIrwan SyahNo ratings yet

- 4660 LubricationDocument16 pages4660 LubricationCAT CYLINDERNo ratings yet

- Bearing SpecificationDocument6 pagesBearing SpecificationMuhammad Munirul AlamNo ratings yet

- Lubrication of Rolling Bearings Tips and AdviceDocument44 pagesLubrication of Rolling Bearings Tips and AdvicealanrinNo ratings yet

- NyedampinggreaseDocument8 pagesNyedampinggreaseM DNo ratings yet

- Make Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsDocument24 pagesMake Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsMario MullerNo ratings yet

- The Dangers of Over-GreasingDocument3 pagesThe Dangers of Over-GreasingfahazumeeNo ratings yet

- Choosing A High-Speed GreaseDocument34 pagesChoosing A High-Speed GreaseArtur MkrtchyanNo ratings yet

- Q & A: When To Clean and Repack BearingsDocument4 pagesQ & A: When To Clean and Repack BearingsMachineryengNo ratings yet

- Lubricant Application - Grease Volumes and Frequencies - TLT Article - April09Document7 pagesLubricant Application - Grease Volumes and Frequencies - TLT Article - April09Fiananta FauziNo ratings yet

- 05 - Lubrifiere PDFDocument14 pages05 - Lubrifiere PDFRadu BurloiuNo ratings yet

- Guide To Electric Motor Bearing LubricationDocument7 pagesGuide To Electric Motor Bearing LubricationUber_Konstruktor100% (2)

- Lubricant Application: Grease Volumes and FrequenciesDocument7 pagesLubricant Application: Grease Volumes and FrequenciesAmjedNo ratings yet

- 05 - LubrifiereDocument14 pages05 - Lubrifieresandel123No ratings yet

- Tribology and Gear ReducersDocument7 pagesTribology and Gear ReducersAnibal Rios100% (1)

- B162001002 Wind EN 0420Document28 pagesB162001002 Wind EN 0420Ludovic LeroyNo ratings yet

- Bearing Lubrication BasicsDocument2 pagesBearing Lubrication BasicsMadan YadavNo ratings yet

- Brochure Wind Industry Solutions For More Wind Force PDFDocument28 pagesBrochure Wind Industry Solutions For More Wind Force PDFphucdc095041No ratings yet

- The Dangers of OvergreasingDocument3 pagesThe Dangers of OvergreasingLuiz MacárioNo ratings yet

- Guide To EM Bearing LubricationDocument12 pagesGuide To EM Bearing LubricationAnonymous alQXB11EgQ100% (1)

- Product Data Sheet: Optimol OptipitDocument2 pagesProduct Data Sheet: Optimol OptipitFBNo ratings yet

- Electric Motor LubricationDocument4 pagesElectric Motor LubricationKamal ArabNo ratings yet

- Lecture 3Document52 pagesLecture 3saxadi4814No ratings yet

- Lubrication For Linear Bearings RacewaysDocument7 pagesLubrication For Linear Bearings RacewaysDaniel0010No ratings yet

- Sleeve Bearing LubricationDocument12 pagesSleeve Bearing Lubricationquan nguyenNo ratings yet

- Greasing and ChurningDocument7 pagesGreasing and ChurningHenrique Do PradoNo ratings yet

- Electric Motor Bearing Grease SelectionDocument1 pageElectric Motor Bearing Grease SelectionProject Sales CorpNo ratings yet

- Speciality Lubricants For Machine ToolsDocument15 pagesSpeciality Lubricants For Machine ToolsDarmawan PutrantoNo ratings yet

- LubeCoach Volume and Frequency Recommendations PDFDocument13 pagesLubeCoach Volume and Frequency Recommendations PDFEstebanRivera100% (1)

- TT Components and Characteristics of GreaseDocument2 pagesTT Components and Characteristics of GreaseAnonymous alQXB11EgQNo ratings yet

- Ofd en WebDocument6 pagesOfd en WebSanjoy Kr. DeyNo ratings yet

- How To Avoid Over-LubricationDocument7 pagesHow To Avoid Over-Lubricationsyuhaimi82No ratings yet

- Lubrication of GearsDocument6 pagesLubrication of GearsCesar VasquesNo ratings yet

- Gleitlager enDocument32 pagesGleitlager enMarcelo Topon100% (1)

- Molykote AerossoisDocument6 pagesMolykote AerossoisMarcos Tati CunhaNo ratings yet

- Gear Box NoiseDocument3 pagesGear Box NoiseKumar SanthanamNo ratings yet

- Mobilgear 600 XP: The Industr y Requirement For Wear ProtectionDocument2 pagesMobilgear 600 XP: The Industr y Requirement For Wear ProtectionprateekNo ratings yet

- LEC5 Lubrication 2022Document37 pagesLEC5 Lubrication 2022mohamed hodiriNo ratings yet

- Greases For Gear ApplicationsDocument16 pagesGreases For Gear ApplicationsTeknik LasallefoodNo ratings yet

- LZ 360 - Fluid Technology - IGO N OGL - Z124Document45 pagesLZ 360 - Fluid Technology - IGO N OGL - Z124tiến thử huỳnhNo ratings yet

- TDS Sinopec HP-R Grease enDocument2 pagesTDS Sinopec HP-R Grease ennghiaNo ratings yet

- Bearings With Solid Grease: NTN CorporationDocument11 pagesBearings With Solid Grease: NTN Corporationshan_1299No ratings yet

- A Review On Lubrication Systems With Case Study: Seybold Report July 2020Document9 pagesA Review On Lubrication Systems With Case Study: Seybold Report July 2020Herrera Jorge AgustínNo ratings yet

- RKB Proper Lubricant Selection For Rolling Bearing Applications PDFDocument8 pagesRKB Proper Lubricant Selection For Rolling Bearing Applications PDFJako MishyNo ratings yet

- Gears and Gear LubricationDocument8 pagesGears and Gear LubricationFabrícioNo ratings yet

- Guide To Electric Motor Lubrication ExxonDocument0 pagesGuide To Electric Motor Lubrication Exxont_syamprasad100% (1)

- Mill and Kiln Open Gear Lubrication - Part IDocument2 pagesMill and Kiln Open Gear Lubrication - Part ISounak SasmalNo ratings yet

- LEC7 Lubrication 2022Document29 pagesLEC7 Lubrication 2022mohamed hodiriNo ratings yet

- En Open Gear GBDocument12 pagesEn Open Gear GBArnaldo Macchi MillanNo ratings yet

- Mobil SHC 600 SeriesDocument2 pagesMobil SHC 600 SerieskievegokoolNo ratings yet

- How To Calculate Grease Quantity 17.07.2020Document11 pagesHow To Calculate Grease Quantity 17.07.2020bhaskarNo ratings yet

- SHE73 LubricaciónDocument48 pagesSHE73 Lubricacióngonzalo valderramaNo ratings yet

- Special Lubricants For Textile MachineryDocument40 pagesSpecial Lubricants For Textile MachineryMarcos Silva100% (1)

- 4 Article TLT Grease AdditivesDocument11 pages4 Article TLT Grease AdditivesYasir ShaikhNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Lamella Clarifier SeDocument1 pageLamella Clarifier SeJotheeswaranNo ratings yet

- Structural and Dynamic Analysis of Optimized Four Bar Mechanism Considering Counterweight in Coupler Link - ScienceDirectDocument1 pageStructural and Dynamic Analysis of Optimized Four Bar Mechanism Considering Counterweight in Coupler Link - ScienceDirectJotheeswaranNo ratings yet

- PSG Tech Alumni Congress BrochureDocument3 pagesPSG Tech Alumni Congress BrochureJotheeswaranNo ratings yet

- Spring Mounts - Damped Type - To 2469 LbsDocument2 pagesSpring Mounts - Damped Type - To 2469 LbsJotheeswaranNo ratings yet

- Excelsior, Inc. Material List: Corks and Cork Rubber: Non-Asbestos Compressed and Beater Mix Additions Plastic: RubberDocument1 pageExcelsior, Inc. Material List: Corks and Cork Rubber: Non-Asbestos Compressed and Beater Mix Additions Plastic: RubberJotheeswaranNo ratings yet

- Is.7001.1989 0 PDFDocument14 pagesIs.7001.1989 0 PDFJotheeswaranNo ratings yet

- Site Safety Inspection Report - Ssir: NHC-KAC-AH-JFR-SSIR-051 Sunday, August 16, 2020Document2 pagesSite Safety Inspection Report - Ssir: NHC-KAC-AH-JFR-SSIR-051 Sunday, August 16, 2020farrukhNo ratings yet

- Drill Pipe 5 VX-57Document2 pagesDrill Pipe 5 VX-57Henry Garavito RamirezNo ratings yet

- I - Model 411 (Normal Category), Approved August 17, 1964 Model 411A (Normal Category), Approved January 26, 1967Document24 pagesI - Model 411 (Normal Category), Approved August 17, 1964 Model 411A (Normal Category), Approved January 26, 1967Ingeniero 1No ratings yet

- SSP 372 The Shiftmatic Gearbox 0B81Document68 pagesSSP 372 The Shiftmatic Gearbox 0B81Robert AsafteiNo ratings yet

- Pantry ModelDocument1 pagePantry ModeldmsupunNo ratings yet

- Unit 4 AssignmentsDocument5 pagesUnit 4 AssignmentsbattuarunNo ratings yet

- Agitator DatasheetDocument1 pageAgitator DatasheetpavanNo ratings yet

- Manual Tooling CatalogDocument70 pagesManual Tooling CatalogGuillaume JaNo ratings yet

- Guayas AntilatigoDocument2 pagesGuayas AntilatigoDiego Fnd BarreraNo ratings yet

- EEB 334 Lab 2 Documentation DraftDocument4 pagesEEB 334 Lab 2 Documentation DraftBosics BenomNo ratings yet

- Welding SymbolsDocument26 pagesWelding Symbolssamy7354No ratings yet

- S04 BoomDocument82 pagesS04 BoomLUIS MICHAEL SUNI ILACHOQUENo ratings yet

- Martin J.L. Turner Turbomachinery Design andDocument404 pagesMartin J.L. Turner Turbomachinery Design andFebrian Nur AsaNo ratings yet

- 装箱清单Akramnjim 7Document4 pages装箱清单Akramnjim 7Akram Abu MariamNo ratings yet

- Komatsu Pw130es 6k Shop ManualDocument20 pagesKomatsu Pw130es 6k Shop Manualdonald100% (32)

- H1 P045-053 - Repair Instructions - 520L0957 - Rev AC - April 2008Document44 pagesH1 P045-053 - Repair Instructions - 520L0957 - Rev AC - April 2008Jose Manuel Barroso PantojaNo ratings yet

- MS-E011-ALF-MS For Installation of LVAC PanelsDocument7 pagesMS-E011-ALF-MS For Installation of LVAC PanelsvipinrajNo ratings yet

- Wall Saw DZ-S2 Spare Parts Manual PDFDocument68 pagesWall Saw DZ-S2 Spare Parts Manual PDFMarko VukovićNo ratings yet

- Singer-201-Service-Adjusters-Manual Ocr PDFDocument72 pagesSinger-201-Service-Adjusters-Manual Ocr PDFenviroswNo ratings yet

- Specialized Construction Techniques - FinalDocument102 pagesSpecialized Construction Techniques - FinalSabella JimenezNo ratings yet

- E PL905 Handbook PDFDocument16 pagesE PL905 Handbook PDFuripssNo ratings yet

- Bombas Reciprocantes PDFDocument43 pagesBombas Reciprocantes PDFSamuel Arias CamachoNo ratings yet

- Proses Manufaktur (Proses Tempa)Document34 pagesProses Manufaktur (Proses Tempa)PRADITYO PUTRA PURNOMO ,No ratings yet

- Fscb50a Sinus Cosinus Potentiometer enDocument1 pageFscb50a Sinus Cosinus Potentiometer enKosasihNo ratings yet

- Stopple ProceduresDocument3 pagesStopple ProceduresBensmatNo ratings yet

- Efs Group Hydraulic Rock Drill E-CatalogDocument50 pagesEfs Group Hydraulic Rock Drill E-CatalogJesus AcostaNo ratings yet

- Our Critical Slab DesignDocument5 pagesOur Critical Slab DesignIsmail AbdiNo ratings yet