Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

49 viewsApplication For Approval - UL HF HEAT SHRINKABLE TUBE

Application For Approval - UL HF HEAT SHRINKABLE TUBE

Uploaded by

Enzo AscañoApplication for Approval_UL HF HEAT SHRINKABLE TUBE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KEPITAL-POM - KEPITAL F20-03 LOF - en - RoHSDocument8 pagesKEPITAL-POM - KEPITAL F20-03 LOF - en - RoHSEnzo AscañoNo ratings yet

- LTK Catalogue PDFDocument108 pagesLTK Catalogue PDFEnzo AscañoNo ratings yet

- JST Terminal CrimpdataDocument16 pagesJST Terminal CrimpdataEnzo Ascaño25% (4)

- KET Catalog 2018 PDFDocument436 pagesKET Catalog 2018 PDFEnzo Ascaño75% (4)

- UL PVC Hitachi CAbleDocument23 pagesUL PVC Hitachi CAbleEnzo AscañoNo ratings yet

- 15001WR 04 (20151007)Document74 pages15001WR 04 (20151007)Enzo AscañoNo ratings yet

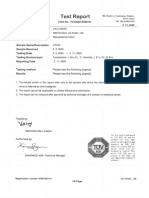

- Test Report: Intertek Testing Services Korea LTDDocument8 pagesTest Report: Intertek Testing Services Korea LTDEnzo AscañoNo ratings yet

- Test Report: Intertek Testing Services Korea LTDDocument8 pagesTest Report: Intertek Testing Services Korea LTDEnzo AscañoNo ratings yet

- HSE-04 HGF32 SUPER MSDS-eng - 190215Document7 pagesHSE-04 HGF32 SUPER MSDS-eng - 190215Enzo AscañoNo ratings yet

- Heat Tube MSDS en (Black)Document34 pagesHeat Tube MSDS en (Black)Enzo AscañoNo ratings yet

- PVC TUBE MSDS - (2019) - EngDocument25 pagesPVC TUBE MSDS - (2019) - EngEnzo AscañoNo ratings yet

- C2600 (TP) EH 0.25T - 200107 - 원본대조필Document1 pageC2600 (TP) EH 0.25T - 200107 - 원본대조필Enzo AscañoNo ratings yet

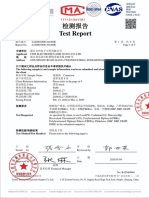

- Test Report: No. F690101/LF-CTSAYGU20-00379Document7 pagesTest Report: No. F690101/LF-CTSAYGU20-00379Enzo AscañoNo ratings yet

- Brass MsdsDocument2 pagesBrass MsdsEnzo AscañoNo ratings yet

- RoHS+Phthalates HT700 200311 TCOA20-0069-01Document6 pagesRoHS+Phthalates HT700 200311 TCOA20-0069-01Enzo AscañoNo ratings yet

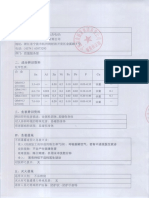

- 【 Certificate Of Analysis 】: Name of Test Method Unit Spec ResultDocument1 page【 Certificate Of Analysis 】: Name of Test Method Unit Spec ResultEnzo AscañoNo ratings yet

- 5556 Series Approval SpecificationDocument8 pages5556 Series Approval SpecificationEnzo AscañoNo ratings yet

- LS Shrinkable - Tube Catalog PDFDocument41 pagesLS Shrinkable - Tube Catalog PDFEnzo AscañoNo ratings yet

- Test Report: Applicant AddressDocument7 pagesTest Report: Applicant AddressEnzo AscañoNo ratings yet

- Test Report: Applicant AddressDocument9 pagesTest Report: Applicant AddressEnzo AscañoNo ratings yet

- Test Report: No. F690101/LF-CTSAYGU20-00379Document7 pagesTest Report: No. F690101/LF-CTSAYGU20-00379Enzo AscañoNo ratings yet

- Test Report: Applicant AddressDocument9 pagesTest Report: Applicant AddressEnzo AscañoNo ratings yet

- Myungbo Catalogue PDFDocument49 pagesMyungbo Catalogue PDFEnzo Ascaño0% (2)

- CWB Terminal MsdsDocument3 pagesCWB Terminal MsdsEnzo AscañoNo ratings yet

- Test Report: Report No. Applicant AddressDocument7 pagesTest Report: Report No. Applicant AddressEnzo AscañoNo ratings yet

- IWASE EXLON-Tubing Catalogue1Document52 pagesIWASE EXLON-Tubing Catalogue1Enzo AscañoNo ratings yet

- 110 Terminal (Ket & MolexDocument6 pages110 Terminal (Ket & MolexEnzo AscañoNo ratings yet

- LTK Ul 1430 #26Document1 pageLTK Ul 1430 #26Enzo AscañoNo ratings yet

- PCDDocument3 pagesPCDEnzo AscañoNo ratings yet

- 110 Terminal (Ket & MolexDocument6 pages110 Terminal (Ket & MolexEnzo AscañoNo ratings yet

Application For Approval - UL HF HEAT SHRINKABLE TUBE

Application For Approval - UL HF HEAT SHRINKABLE TUBE

Uploaded by

Enzo Ascaño0 ratings0% found this document useful (0 votes)

49 views4 pagesApplication for Approval_UL HF HEAT SHRINKABLE TUBE

Original Title

Application for Approval_UL HF HEAT SHRINKABLE TUBE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentApplication for Approval_UL HF HEAT SHRINKABLE TUBE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

49 views4 pagesApplication For Approval - UL HF HEAT SHRINKABLE TUBE

Application For Approval - UL HF HEAT SHRINKABLE TUBE

Uploaded by

Enzo AscañoApplication for Approval_UL HF HEAT SHRINKABLE TUBE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

Customer :

APPLICATION FOR APPROVAL

HEAT-SHRINKABLE TUBING

TYPE Halogen Free

CAT, NO, DC-125

DATE 2017. 08. 02

REMARK

DAE CHANG ELECCOM CO.,LTD

#25-2, MOK-RI MAJANG-MYEON,

ICHEON UNG GI-DO.

‘TEL. 82-31-637-9930 FAX. 82-31-637-9939

SPECIFCATION

ISSUED | soa2.07.01

apr HEAT-SHRINKABLE TUBING DATE —

E CAT. NO. DC-125 REYES 2017.03.02

DATE —

1. Scope of Application : This Specifications shall be applied to the electrically

insulated thermal contractible tubes manufactured according to UL Subject 224

standard.

2. File Number and Grade

(1) File No : UL 120268

(2) Grade : 600V / 125°C

3. Structure and Dimension : Please, refer to Table below.

|. Colors : Black, White, Red, Blue, Yellow, Green, etc

5. Material and Properties

(1) Material : polyolefin

(2) Contraction ratio : 2 : 1 (10% lengthwise)

(3) Working temperature : -40~125C

6. Features

6.1 Mechanic features

Condition Division Tensile strength Elongation ratio

Room temperature Min 10.4 MPa Min. 200%.

‘After having Not less than 70% of

been aged (Air-oven | the result with an Min. 100%

for 168H at 15841°C) | unaged specimen

6.2 Corrosion of copper: When a copper cable is put into the tube to be aged according

to the aging conditions specified in Tab. I and then, is cooled

down at room temperature, the surface of the copper cable

should not be discolored or corrosion.

6.3 Flexibility: When the specimen is bent after having been aged according to the 1

1 conditions, nether its outside nor its inside is cracked,

2,500V for a minute

6.4 Voltage resistance: The specimen should resist

65 Thermal deformation : When the specimen is put into a thermal deformation tester

to be subject to a load, its thickness should be changed less

than 5096 after aging at 136+1°C for an hour.

6.6 Thermal winding: When the specimen has been aged at 131+1'C for 14 days and

then, cooled down at room temperature to be wound around

a beam 6 times, it should not be cracked.

6.7 Low-temperature winding: When the specimen has been frozen at -30+1'C for

an hour and then, wound around a beam 6 times, its

outside/inside should not be cracked.

6.8 Flammability: When a flame has been applied to the specimen for 15 seconds

five times at the interval do 15 seconds,

(1) more than 25% of the paper should not be burnt, and

(2) no spark should fall to burn the cotton, and

(3) any fire should be extinguished within 60 seconds

spontaneously.

7.Marking : The following letters shall be marked at less than 6 inch intervals

on the surface of the product.

XLPO ANe 120268 600V 125 VW-1 DC-125 # mm

DAE CHANG - H/F

8. Packaging

8.1 Packaging as per Spool

Inside dia, Winding length

45 ~ 50mm 25m

25 ~ 40mm 50m

3. - 22mm 100m

1 - 25mm. 200m

8.2 Marking of spool

Each spook has its own label showing the followings:

(1)Name of commodity

(2) Grade (3) Size (4) Quantity

(5) Color (6) Rating

(7) Date (8)Name of manufacture

STANDARD SIZE (DC-12:

a As Supplied(mm) After Recovered(mm)

Inside Diameter | Well Thickness [Inside Diameter. Max] Wall Thickness. Min

0.8mm 0.9403 0.1740.05 0.50 0,280.05

1.0mm 13403 0.1740,05 0.60 0,280.05

1.5mm 1840.3 0.1740.05 0.80 0,300.05

2.0mm 2.4203 0.1740.05 1.00 0,350.05

2.5mm 2.9203 0,380.05

3.0mm 3.4404 0,380.07

3.5mm 3.8404 0,400.07

4.0mm 4420.4 0,450.07,

5.0mm 0.47+0.10

6.0mm 0.55%0.10

7.0mm 0.55%0.10

8.0mm 0,600.10

9.0mm. 0. 0.60+0.10

10.0mm 0,320.05 0,600.10

1.0mm 0,320.05 0,600.10

120mm 0,320.05

13.0mm 0,350.05

4.0mm 14.5405, 0,350.05 70 0,650.10

150mm 15.5406 0,380.05 15 0.75+0.10

160mm 16.5406 0,380.05 8.0 0.75+0.10

180mm 18.506 0.43+0,05 9.0 0,800.18

20.0mm 20.620.7, 0,430.05 0,800.18

220mm 0,480.05 0,800.18

250mm 2 0,480.05 0.95+0.18

280mm 29.0407 0,480.05 0,950.18

30.0mm 31.040.7 0,550.05 0,950.18

35.0mm 36.0410 540.05, 1.10+0.20

38.0mm 39.5410 0,550.05 18.0 1.10+0.20

40.0mm, 41.5+L.0 0,550.05 1.10+0.20

450mm, 47.0+1.0 0,600.05 1.15+0.20

50.0mm 52.0#1.0 0,600.05 1.15+0.20

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KEPITAL-POM - KEPITAL F20-03 LOF - en - RoHSDocument8 pagesKEPITAL-POM - KEPITAL F20-03 LOF - en - RoHSEnzo AscañoNo ratings yet

- LTK Catalogue PDFDocument108 pagesLTK Catalogue PDFEnzo AscañoNo ratings yet

- JST Terminal CrimpdataDocument16 pagesJST Terminal CrimpdataEnzo Ascaño25% (4)

- KET Catalog 2018 PDFDocument436 pagesKET Catalog 2018 PDFEnzo Ascaño75% (4)

- UL PVC Hitachi CAbleDocument23 pagesUL PVC Hitachi CAbleEnzo AscañoNo ratings yet

- 15001WR 04 (20151007)Document74 pages15001WR 04 (20151007)Enzo AscañoNo ratings yet

- Test Report: Intertek Testing Services Korea LTDDocument8 pagesTest Report: Intertek Testing Services Korea LTDEnzo AscañoNo ratings yet

- Test Report: Intertek Testing Services Korea LTDDocument8 pagesTest Report: Intertek Testing Services Korea LTDEnzo AscañoNo ratings yet

- HSE-04 HGF32 SUPER MSDS-eng - 190215Document7 pagesHSE-04 HGF32 SUPER MSDS-eng - 190215Enzo AscañoNo ratings yet

- Heat Tube MSDS en (Black)Document34 pagesHeat Tube MSDS en (Black)Enzo AscañoNo ratings yet

- PVC TUBE MSDS - (2019) - EngDocument25 pagesPVC TUBE MSDS - (2019) - EngEnzo AscañoNo ratings yet

- C2600 (TP) EH 0.25T - 200107 - 원본대조필Document1 pageC2600 (TP) EH 0.25T - 200107 - 원본대조필Enzo AscañoNo ratings yet

- Test Report: No. F690101/LF-CTSAYGU20-00379Document7 pagesTest Report: No. F690101/LF-CTSAYGU20-00379Enzo AscañoNo ratings yet

- Brass MsdsDocument2 pagesBrass MsdsEnzo AscañoNo ratings yet

- RoHS+Phthalates HT700 200311 TCOA20-0069-01Document6 pagesRoHS+Phthalates HT700 200311 TCOA20-0069-01Enzo AscañoNo ratings yet

- 【 Certificate Of Analysis 】: Name of Test Method Unit Spec ResultDocument1 page【 Certificate Of Analysis 】: Name of Test Method Unit Spec ResultEnzo AscañoNo ratings yet

- 5556 Series Approval SpecificationDocument8 pages5556 Series Approval SpecificationEnzo AscañoNo ratings yet

- LS Shrinkable - Tube Catalog PDFDocument41 pagesLS Shrinkable - Tube Catalog PDFEnzo AscañoNo ratings yet

- Test Report: Applicant AddressDocument7 pagesTest Report: Applicant AddressEnzo AscañoNo ratings yet

- Test Report: Applicant AddressDocument9 pagesTest Report: Applicant AddressEnzo AscañoNo ratings yet

- Test Report: No. F690101/LF-CTSAYGU20-00379Document7 pagesTest Report: No. F690101/LF-CTSAYGU20-00379Enzo AscañoNo ratings yet

- Test Report: Applicant AddressDocument9 pagesTest Report: Applicant AddressEnzo AscañoNo ratings yet

- Myungbo Catalogue PDFDocument49 pagesMyungbo Catalogue PDFEnzo Ascaño0% (2)

- CWB Terminal MsdsDocument3 pagesCWB Terminal MsdsEnzo AscañoNo ratings yet

- Test Report: Report No. Applicant AddressDocument7 pagesTest Report: Report No. Applicant AddressEnzo AscañoNo ratings yet

- IWASE EXLON-Tubing Catalogue1Document52 pagesIWASE EXLON-Tubing Catalogue1Enzo AscañoNo ratings yet

- 110 Terminal (Ket & MolexDocument6 pages110 Terminal (Ket & MolexEnzo AscañoNo ratings yet

- LTK Ul 1430 #26Document1 pageLTK Ul 1430 #26Enzo AscañoNo ratings yet

- PCDDocument3 pagesPCDEnzo AscañoNo ratings yet

- 110 Terminal (Ket & MolexDocument6 pages110 Terminal (Ket & MolexEnzo AscañoNo ratings yet