Professional Documents

Culture Documents

Comment Resolution Sheet (CRS) : Contractor/Supplier Name: LTHE

Comment Resolution Sheet (CRS) : Contractor/Supplier Name: LTHE

Uploaded by

balajikrishnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comment Resolution Sheet (CRS) : Contractor/Supplier Name: LTHE

Comment Resolution Sheet (CRS) : Contractor/Supplier Name: LTHE

Uploaded by

balajikrishnanCopyright:

Available Formats

COMMENT RESOLUTION SHEET (CRS)

Contractor/Supplier Name: LTHE

Client Document No:

2340-F-TNK-GEN-DL-H-E-001 Rev. No: R0 Document Title: Safeguarding Philosophy DSN: S130

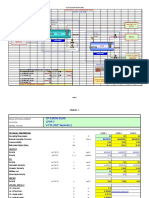

S. No. PMC Comments Contractor/Supplier Reply PMC / OWNER Reply Contractor/Supplier Reply

Abbreviations are provided to assist the reader in reviewing the

document and prevent ambiguity. They are unnecessary for common Abbreviations appearing only once in the document have been defined at the point of use (therefore

The section-2 shall be updated based abbreviation used in this acronyms that are generally understood and both reviewer and Noted. Some of the abbreviation used in this it is clear).

1 philosophy. contractor are familiar with. document are not detailed in section-2.Example

VRV,EDP etc. However, to avoid unnecessary return comment, they have now been added in the Section 2.

Abbreviations will not be added for codes and standards such as

NFPA, EN, OISD etc. Only relevant abbreviations will be added.

Reference to SMPV 2016 has been added in the document to prevent return comment. However,

WEL maintains that Schedule IV, Section 1, Paragraph B is not applicable to refrigerated storage tank.

See the defination of cryogenic pressure vessel from SMPV 2016 below. Note that the two LNG tank

Reference to OISD-113 will be included in the next revision. on Dhamra project are 180,000m3 each.

The section-3 shall also include the local code/regulation Contractors could refer the Schedule-IV,section-

2 (India).Example Area classification OISD-113,SMPV 2016 etc.. The LNG storage tank is not a pressure vessel and so SMPV 2016 is 1,Paragraph B of SMPV 2016.

“cryogenic pressure vessel” means a pressure vessel intended for storage or transportation of

not applicable to the tank scope.

cryogenic liquid and includes cold converters, vacuum insulated evaporators, vacuum insulated

storage or transport tanks and thermosyphon tanks and includes a permanently installed cryogenic

pressure vessel of 1000 litre water capacity or less for storage of cryogenic liquid;

Emergency response shall be included in the Section-4 under

3 mitigation. Noted. Emergency response will be added under Item 3 in Section 4. Noted

4 Cross reference also be included for the BPCS related Noted. Reference will be made to the Control and Operating

Noted

documents. Philosophy 2340-E-TNK-GEN-DP-H-E-007 in the next revision.

Thermal Stresses shall be considered as one of the hazard and Noted. Use of bellows expansion joints should be

5 impact shall be detailed in the section 6.0.Since it is applicable Noted. Thermal stress to be discussed in the next revision.

avoided.

for the LNG tank as well as associated piping's.

In Section 6.1 the cause shall be rearranged like LNG tank

Comment not implemented. As long as all potential causes are listed,

5 specific shall be listed on top and general items at bottom Noted.Since it is a philosophy document.

the order is irrelevant.

Example Roll over on top and external pool fire at bottom.

In Section 6.3 the following paragraphs shall be added in line

6 with OISD-194 paragraph 6.3.9 Noted. To be included in the next revision. Noted

"The tank shall not be provided with overflow arrangement"

In section 6.3 the pressure raise in annular space shall be Not implemented. This is a safeguarding philosophy and will not Unnecessary comment. The overpressure of the tank is already discussed in the document and

7 discuss in details the design of relief devices or effect of liquid leak Cross reference could be added

mentioned. reference made to OISD 194. However, to avoid return comment, the sentence has been added.

into outer tank.

This is a preferential comment and unnecessary. The document already makes reference to OISD

194, where the comments are taken. However, the list has now been expanded in the document to

avoid PMC return comment.

Liquid retention (Material of construction), added

Gas tightness, added

In Section 7.1, following Design safe guards shall be elaborated. thermal insulation, added

Liquid retention (Material of construction),Gas tightness,

thermal insulation, Nozzle location (from the top, No side Not implemented. This is a safeguarding philosophy and will not Nozzle location (from the top, No side penetration), added

penetration),Extended bonnet valves, bellows expansion joints discuss in details the tank specifications and internal components Extended bonnet valves, added

8 design. Most of the comment will be done as part of the design of a Cross reference could be added bellows expansion joints should be avoided, added

should be avoided, Roll over avoiding mechanishm,Soil Roll over avoiding mechanishm, added

full containment tank, providing an inherently safer design or good

protection, leak detection in annular space, Over fill of inner

tank, Density meters, Linear and rotational inner tank movement engineering practice. Soil protection, added

indicator, endoscopic inspection provision etc. leak detection in annular space, added in Section 6.3

Over fill of inner tank, already discussed in Section 6.3

Density meters, already discussed as part of rollover prevention.

Linear and rotational inner tank movement indicator, added

endoscopic inspection provision added

etc.

Only the interface of the ESD system for the purpose of safeguarding

is discussed within this philosophy.

In the section 7.2, fail safe design shall be considered for ESD

9 system and also uninterruptible power supply for the all critical The design of the ESD system is discussed in the ESD protection Noted UPS requirement for critical instrument is discussed in section 7.1

instrumentation control and fire and gas system. philosophy which is already referenced in Section 7.2.

Reference will be added to OISD 194.

Only the interface of the PSV/VRV system for the purpose of

safeguarding is discussed in this philosophy.

The Section 7.3 shall be updated in line with OISD-194 paragraph The design of the relief system is discussed in the over/under

10 6.3.7 Noted

pressure protection philosophy which is already referenced in

Section 7.3.

Reference will be added to OISD 194.

The section 8.1 shall be updated considering OISD-194 Agree. The spacing requirement specified in OISD 118 and OISD194

11 paragraph 5.9.1.(Most stringent requirement shall be followed) will be included in this philosophy. Noted

12 The section 8.3 shall be updated inline with OISD-194 Paragraph Reference will be made to OISD-113 and OISD- 194 for design of Noted

5.9.7 and 8.2 (ignition source control) hazardous area classification.

Only the interface of the FGS system for the purpose of safeguarding

is discussed in this philosophy. The design of the fire, gas and spill

The section 8.4 shall be elaborated in line with OISD-194 detection system is discussed in the FSGDS philosophy which is

13 paragraph 8.4 (flammable limit/audio-visual alram,vooting etc. Noted

already referenced in Section 8.4.

Reference will be added to OISD 194.

The content of OISD 194 Section 6.3.7 is already implied in Section

9.3 of this document, ensuring safe dispersion. For clarity, the

second paragraph will be revised as below:

14 The section 9.3 shall be updated in line with OISD-194 Paragraph Noted

The PSV valve should be sized to relief the worst case emergency

6.3.7 point No:3

flow. The PSV tailpipe height should be located to ensure safe

dispersion of LNG vapour for unignited discharges and to prevent

thermal radiation from exceeding acceptable limits for an ignited

discharge.

You might also like

- DNVGL ST 0145 - 2021Document221 pagesDNVGL ST 0145 - 2021bruno gandiNo ratings yet

- Quench Tube CalculationDocument5 pagesQuench Tube CalculationNavneet SumanNo ratings yet

- ASHRAE-VRF Standard15Document7 pagesASHRAE-VRF Standard15jijijadjoe100% (1)

- ASTM C 219 Standard Terminology Relating To Hydraulic CementDocument3 pagesASTM C 219 Standard Terminology Relating To Hydraulic CementRyan LasacaNo ratings yet

- CRS 4154 25 61 03 0005Document1 pageCRS 4154 25 61 03 0005Ahmed AdelNo ratings yet

- Comments Response Sheet (CRS) : Major Projects Template MAJOR ASY MPQA MPQA FOR 000005 - Rev02Dated 14/11/2019Document23 pagesComments Response Sheet (CRS) : Major Projects Template MAJOR ASY MPQA MPQA FOR 000005 - Rev02Dated 14/11/2019Idris SiddiquiNo ratings yet

- CRS 4154 25 61 03 005Document4 pagesCRS 4154 25 61 03 005Ahmed AdelNo ratings yet

- MSC Circ1120 Solas CH II-2 InterpretationsDocument40 pagesMSC Circ1120 Solas CH II-2 InterpretationsVirgil Mutu100% (1)

- PP-1999-06 Opening in Blind FlangeDocument4 pagesPP-1999-06 Opening in Blind FlangesaudimanNo ratings yet

- CRS 4154 25 61 03 005Document3 pagesCRS 4154 25 61 03 005Ahmed AdelNo ratings yet

- 340-RPT-ES-SYN-5004 - HVAC Improvement Recommendation Report - Rev 0 1Document148 pages340-RPT-ES-SYN-5004 - HVAC Improvement Recommendation Report - Rev 0 1Den Bagus BlitarNo ratings yet

- Comments Response Sheet (CRS) : Page 1 of 5Document27 pagesComments Response Sheet (CRS) : Page 1 of 5Idris SiddiquiNo ratings yet

- SP-1167-Specification For Welding On Pressurised PipesDocument11 pagesSP-1167-Specification For Welding On Pressurised Pipesarjunprasannan7No ratings yet

- Applying VRF?: Don't Overlook Standard 15Document7 pagesApplying VRF?: Don't Overlook Standard 15Eric G. MagnayeNo ratings yet

- Fire ExtDocument16 pagesFire ExtANYMOUSNo ratings yet

- FDB WU CWOG Latest 1644862726203Document64 pagesFDB WU CWOG Latest 1644862726203v100% (2)

- Main Rules July 2019 PDFDocument2,020 pagesMain Rules July 2019 PDFchekka DandiyyaNo ratings yet

- Fundamentals of Safety Relief Valves in Ammonia Refrigeration SystemsDocument3 pagesFundamentals of Safety Relief Valves in Ammonia Refrigeration SystemsBehnam AshouriNo ratings yet

- URL - StabilityDocument14 pagesURL - StabilityCinthia Lidia Hidrogo PaulinoNo ratings yet

- 60-01-11-2617 Rev 00Document121 pages60-01-11-2617 Rev 00KalpeshJadhavNo ratings yet

- Asme Viii - Div.1Document2 pagesAsme Viii - Div.1cwkimNo ratings yet

- WPD G81 5 Comm Ind MaterialsDocument17 pagesWPD G81 5 Comm Ind Materialsjaramib776No ratings yet

- DNV Os C103Document57 pagesDNV Os C103路耀No ratings yet

- Was Alb Aeb MST Ar 0009 2 PDFDocument66 pagesWas Alb Aeb MST Ar 0009 2 PDFChris EnyinnayaNo ratings yet

- 1.EBS1-EPFA76-EBRT-CNPR-1001-D00 EPF Fire Water System Validation ReportDocument4 pages1.EBS1-EPFA76-EBRT-CNPR-1001-D00 EPF Fire Water System Validation ReportRedhaa .kNo ratings yet

- O20361-S-Via-01-Dc-03000 R1Document130 pagesO20361-S-Via-01-Dc-03000 R1Shubham GaglaniNo ratings yet

- Safety CH II.2 IntroductionDocument1 pageSafety CH II.2 IntroductionCanumalla RamkumarNo ratings yet

- Part 5Document221 pagesPart 5Nithin KumarNo ratings yet

- FCHEA Regulatory Matrix Markup September 30 2020Document12 pagesFCHEA Regulatory Matrix Markup September 30 2020rodlandi2750No ratings yet

- Design IV Spesifications of Compressed Air SystemsDocument6 pagesDesign IV Spesifications of Compressed Air SystemsFransiskusNo ratings yet

- FP 46-5 - Proposed Unified Interpretations For Revised SOLAS Chapter II-2 and The FTP Code (United States)Document7 pagesFP 46-5 - Proposed Unified Interpretations For Revised SOLAS Chapter II-2 and The FTP Code (United States)Michael BettoniNo ratings yet

- Rules For Classification: YachtsDocument16 pagesRules For Classification: YachtsAnte KezicNo ratings yet

- Api 650Document12 pagesApi 650Efrain TiradoNo ratings yet

- DS Ha8Document6 pagesDS Ha8Adilson Aliaga SanchezNo ratings yet

- Sp-In-Ii-016-Control ValveDocument12 pagesSp-In-Ii-016-Control ValveKurniadi WibowoNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesDocument20 pagesTransport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesHenry HNo ratings yet

- Maharashtra State Agricultural Marketing Board, Pune (MSAMB)Document5 pagesMaharashtra State Agricultural Marketing Board, Pune (MSAMB)jiteshNo ratings yet

- DNV Guideline - Allowable Thickness Diminution For Hull StructureDocument38 pagesDNV Guideline - Allowable Thickness Diminution For Hull StructureDmitrii Pustoshkin100% (1)

- Tank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ADocument59 pagesTank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ABurak GülenNo ratings yet

- Rules For Classification: YachtsDocument14 pagesRules For Classification: YachtsAnte KezicNo ratings yet

- EN3503 Accuset-SB KatalogversionDocument6 pagesEN3503 Accuset-SB Katalogversionjuan jose claros morenoNo ratings yet

- Pumy-P60nkmu Techservice Och502b 05-13Document114 pagesPumy-P60nkmu Techservice Och502b 05-13Marco RualesNo ratings yet

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgNo ratings yet

- XX Paper 18 PDFDocument21 pagesXX Paper 18 PDFFauzi SaputraNo ratings yet

- Mil PRF 25690BDocument32 pagesMil PRF 25690BIvan Dario Oyola RNo ratings yet

- DNV Os C103Document57 pagesDNV Os C103Wilson Barreta JuniorNo ratings yet

- Seal Qualification TestDocument25 pagesSeal Qualification TestvigneshNo ratings yet

- MS Balustrade and Wall Mounting Handrail Report Stair 1&2Document59 pagesMS Balustrade and Wall Mounting Handrail Report Stair 1&2noorgggggNo ratings yet

- Accuset SB: 1. Description 2. Technical DataDocument4 pagesAccuset SB: 1. Description 2. Technical DatabarryNo ratings yet

- p021.46 Db54 Mat Mep Mech 027 Float Valve, Angle Valve, Bibtap Rev 00Document44 pagesp021.46 Db54 Mat Mep Mech 027 Float Valve, Angle Valve, Bibtap Rev 00p4p7 projectsNo ratings yet

- Synopsis of The 2017 Edition To The ASME PDFDocument27 pagesSynopsis of The 2017 Edition To The ASME PDFPratik ThakkarNo ratings yet

- CRS 4154 25 61 03 005Document1 pageCRS 4154 25 61 03 005Ahmed AdelNo ratings yet

- Petroleum Development Oman L.L.C.: (AMENDMENTS/SUPPLEMENTS TO ISO 15590-2: 2003)Document19 pagesPetroleum Development Oman L.L.C.: (AMENDMENTS/SUPPLEMENTS TO ISO 15590-2: 2003)Sapana MallaNo ratings yet

- Chapter 32 - Cryogenic FluidsDocument6 pagesChapter 32 - Cryogenic FluidsRajesh RadeNo ratings yet

- Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksDocument6 pagesMinimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage Tanksaegean227No ratings yet

- 4 Leak Scenarios TN 4 PDFDocument21 pages4 Leak Scenarios TN 4 PDFigor VladimirovichNo ratings yet

- Requirements Concerning Load Line: International Association of Classification SocietiesDocument18 pagesRequirements Concerning Load Line: International Association of Classification SocietiesmramicoNo ratings yet

- 012E2434C1140195 - 2 - Def - Tank Venting - Vapour Relief - V2.0Document25 pages012E2434C1140195 - 2 - Def - Tank Venting - Vapour Relief - V2.0Manuel Alejandro González MarcanoNo ratings yet

- DNV-RU-SHIP Pt.4 Ch.6 (2022.07) - Ship Piping SystemsDocument122 pagesDNV-RU-SHIP Pt.4 Ch.6 (2022.07) - Ship Piping Systemsnanotech123No ratings yet

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Document11 pagesDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanNo ratings yet

- Owner Status Code: PMC Status CodeDocument4 pagesOwner Status Code: PMC Status CodebalajikrishnanNo ratings yet

- 9000 Books Engineering 2017Document430 pages9000 Books Engineering 2017balajikrishnan100% (2)

- Relief System PipingDocument7 pagesRelief System PipingbalajikrishnanNo ratings yet

- Comment Resolution Sheet (CRS) : Contractor/Supplier Name: LTHE/WhessoeDocument1 pageComment Resolution Sheet (CRS) : Contractor/Supplier Name: LTHE/WhessoebalajikrishnanNo ratings yet

- Advanced Surge Control and Incipient Surge Protection/OverrideDocument4 pagesAdvanced Surge Control and Incipient Surge Protection/OverridebalajikrishnanNo ratings yet

- Sizing and Selection Procedure of Pressure Relieving Devices - R0Document47 pagesSizing and Selection Procedure of Pressure Relieving Devices - R0balajikrishnan100% (1)

- Technical Manual - O - Inka Aeration System - ADocument92 pagesTechnical Manual - O - Inka Aeration System - AbalajikrishnanNo ratings yet

- Flare System Design TipsDocument5 pagesFlare System Design TipsbalajikrishnanNo ratings yet

- Design Manual For Hdo MixerDocument127 pagesDesign Manual For Hdo Mixerbalajikrishnan100% (1)

- Mixers ADocument71 pagesMixers AbalajikrishnanNo ratings yet

- Process Description DM - 100610 R1Document7 pagesProcess Description DM - 100610 R1balajikrishnanNo ratings yet

- Unit Sizing Calc For Tanks-DMDocument7 pagesUnit Sizing Calc For Tanks-DMbalajikrishnanNo ratings yet

- DAF & TPI CalculationDocument25 pagesDAF & TPI CalculationbalajikrishnanNo ratings yet

- COMPLETREATORDocument7 pagesCOMPLETREATORbalajikrishnanNo ratings yet

- V-710 CPRP-7Document22 pagesV-710 CPRP-7balajikrishnanNo ratings yet

- Column PSV SizingDocument10 pagesColumn PSV SizingbalajikrishnanNo ratings yet

- 65 Liv API 6a 150 To 10000 Psi LT WT FT Check VDocument15 pages65 Liv API 6a 150 To 10000 Psi LT WT FT Check VRiddhesh PatelNo ratings yet

- Superconductivity PresentationDocument26 pagesSuperconductivity PresentationSabrina Palazzese Di BasilioNo ratings yet

- Nikkiso Guide EngDocument15 pagesNikkiso Guide EngMkgt Hemaautomation100% (1)

- Fives Cryogenics DELTA N BrochureDocument2 pagesFives Cryogenics DELTA N BrochureAhmed BenjellounNo ratings yet

- Superconductivity-Notes-Dr. KK-Physics-BMSCEDocument15 pagesSuperconductivity-Notes-Dr. KK-Physics-BMSCEamritanshu.is22No ratings yet

- LNG WeldingDocument12 pagesLNG Weldingrodofgod100% (1)

- Introduction To High - Temperature Superconductivity PDFDocument578 pagesIntroduction To High - Temperature Superconductivity PDFMarlon José Do CarmoNo ratings yet

- EIGA Publication 24 08 EDocument19 pagesEIGA Publication 24 08 EManton ArksNo ratings yet

- 10 - Cryogenic Heat Exchanger Selection and SizingDocument15 pages10 - Cryogenic Heat Exchanger Selection and SizinghfNo ratings yet

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Ethylene StorageDocument5 pagesEthylene StoragedatNo ratings yet

- Safe Handling of Cryogenic Liquids: Safetygram 16Document8 pagesSafe Handling of Cryogenic Liquids: Safetygram 16Alok RanjanNo ratings yet

- Vacuum Insulated CO2Document13 pagesVacuum Insulated CO2dragosm78No ratings yet

- History of Cryogenics - A Cryo Central Resource From The CSA PDFDocument7 pagesHistory of Cryogenics - A Cryo Central Resource From The CSA PDFJaque BauerNo ratings yet

- Eng Phy-Ii Unit 2 Superconductivity and PDFDocument15 pagesEng Phy-Ii Unit 2 Superconductivity and PDFKhushbu SavaliyaNo ratings yet

- BoiloffDocument8 pagesBoiloffJetul PatelNo ratings yet

- Operating Manual Filling Station Type FS-DDocument31 pagesOperating Manual Filling Station Type FS-DPurnagiri ChowdaryNo ratings yet

- Bcga Code of Practice CP 22: Bulk Liquid Argon or Nitrogen Storage at Production SitesDocument45 pagesBcga Code of Practice CP 22: Bulk Liquid Argon or Nitrogen Storage at Production SiteszhangjieNo ratings yet

- A Seminar On Cryogenic EngineDocument3 pagesA Seminar On Cryogenic EngineMonoranjan MondalNo ratings yet

- As2683-Hose StandardDocument7 pagesAs2683-Hose StandardMina Ghofrani MaabNo ratings yet

- Proceeding of The 2nd International Youth Symposium On Creative Agriculture, Bogor, 2017Document99 pagesProceeding of The 2nd International Youth Symposium On Creative Agriculture, Bogor, 2017Qurrota Ayunin DianandaNo ratings yet

- LNG Simulation PDFDocument28 pagesLNG Simulation PDFRobert WatersNo ratings yet

- Iso 21013 4 2012 en PDFDocument8 pagesIso 21013 4 2012 en PDFds14me001 SvnitNo ratings yet

- Compressed Gas CylinderDocument70 pagesCompressed Gas CylinderIrvansyah RazadinNo ratings yet

- Series: C80/C89 C70/C74Document12 pagesSeries: C80/C89 C70/C74Anupam MehraNo ratings yet

- Condensers Control and Reclaim VOCsDocument3 pagesCondensers Control and Reclaim VOCsgpcshfNo ratings yet

- LNG W000370451 enDocument37 pagesLNG W000370451 enClaude BouillotNo ratings yet

- Practical CryogenicsDocument96 pagesPractical CryogenicsdieucmoiNo ratings yet

- Continue: Cryogenic Fuel Level Indicator PDFDocument2 pagesContinue: Cryogenic Fuel Level Indicator PDFShubman GillNo ratings yet