Professional Documents

Culture Documents

Case Study of E-Det

Case Study of E-Det

Uploaded by

ADSAOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study of E-Det

Case Study of E-Det

Uploaded by

ADSAOCopyright:

Available Formats

A CASE STUDY OF CONTROLLED BLASTING WITH e-

DET AT BANKOLA OPENCAST MINE OF EASTERN

COALFIELDS LIMITED

By- A Maulik 1, M O Sarthy 2 , & Mithilesh Tiwari 3

Bankola Open Cast Mine is working on method with deep-hole blasting and

the Jambad Top (R-VIII T) and Jambad deployment of HEMM The permission was

bottom (R-VIII B) seam. The granted by Director of Mines Safety,

thickness of the top coal seam varies Sitarampur granted with a condition that all

from 3.2 to 4.6m. The thickness of the the blasting operations should be carried

bottom seam is between 6.2 to 7.0m. The out with the use of electronic detonators

overburden cover is between 17 to 24m. along with a scientific study of the effect of

The inter-burden between the top and the blast induced ground vibrations on the

bottom seams varies from 1.5 to 3.0 m. following:

The OB is being removed by shovel

dumper combination. 100 mm and 160 a) Stability of the pillar and roof of

mm dia. Electric Drills are being used in underlying Bankola seam and Bonbhal

3.5 m to 6.0m high benches for blasting seam of Bankola colliery.

with Large Diameter explosives . b) Surface structures (dwelling houses and

school located at 100 to 150 m) at nearby

The Bankola UG colliery, which is around village.

160m from the open cast working, is

developing the Bonbhal seam. The Accordingly, the mine management

thickness of the seam is 2.7 to 3.05m. It is engaged CMPDI Ltd, Asansol who in turn

around 74 to 84m below surface. The mine recommended use of electronic detonators

management of Bankola Patch OCP of for controlled blasting. The mine sought

Eastern Coalfields Limited applied for services of M/s Gulf Oil Corporation

DGMS permission for extraction of pillars Limited for the supply and application of

of Jambad Top (R-VIII T) and Jambad their electronic detonators (e-Det) for the

Bottom (R-VIII B) seam by open cast above study

Electronic detonator (e-DET)

e-Det is an indigenously developed desired delay between 1-100 ms can be set

electronic detonator by M/s GOCL. e-Dets on the e-Xploder, which is custom designed

are be used in association with a to fire e-Det.

programmable e-xploder device. The e- The service end of the e-Det is inserted into

xploder transfers desired delay interval the cap sensitive booster charge and

data to the firing circuit and sends coded lowered down the hole, and the other end is

signal to the detonators to initiate the connected to the surface connector. All the

timing sequence in the firing circuit. The e- holes are connected in series with the

Det is having delay number 0 & 1-30 and a surface connecter, which is finally

maximum delay window of 3000ms. The connected to the e-Xploder for firing.

PHOTO-1

e-DET with Polarized water-proof

male/female Connector and Field Surface PHOTO-2

Connector with male connector at one end e-XPLODER

and female connector at the other end

Blasting Trials and Analysis

During trial period, first round of blasts explosive charge per delay and with

were monitored for blast vibration. The varying distance.The minimum peak

details of the results are given in Table-I. particle velocity observed on surface

From ten blasts, fifteen readings of near the Gram Pradhan’s house at the

ground vibration levels were taken on village was 2.35 mm / sec at a distance

surface at different locations near the of 170m from the blast site with

residential structures, club and Kali maximum explosive charge per delay of

temple of the village and at school 25 kg, in blasting round consisting of

buildings near ECL quarters. total explosive charge 525 kg. The

frequency level was recorded as 17 Hz.

The vibration monitoring stations were

selected in consultation with the mine The minimum peak particle velocity was

officials and the distance from the blast observed on pillar on Bonbahal seam as

site to the monitoring stations were 3.30 mm / sec at a radial distance of 87.8

measured by the mine surveyor. The m from the blast site with maximum

vibrations were monitored with varying explosive charge per delay as 12.5 kg in

a blasting round of 75 kg where the mine and prior to this the HEMM

frequency was not available. were excavating the soft strata of the

mine.

The minimum peak particle velocity The maximum peak particle velocity was

observed on roof on Bonbahal seam was observed on roof on Bonbahal seam as

6.35 mm / sec at a distance of 114.56 m 25.1 mm / sec at a radial distance of

from the blast site with maximum 87.73 m from the blast site with

explosive charge per delay as 19.5 kg in maximum explosive charge per delay as

a blasting round of 389.2 kg where Zc 25 kg in a blasting round of 319.7 kg

frequency was 51 Hz. where Zc frequency was 85 Hz.

The maximum peak particle velocity was

The maximum peak particle velocity was observed on roof on Bonbahal seam as

observed on surface (within the mine 25.1 mm/sec at a radial distance of 87.73

premises) as 16.0 mm / sec at a distance m from blast site with maximum

of 90 m from the blast site with explosive charge per delay as 25 kg in a

maximum explosive charge per delay of blasting round of 319.7 kg where

25 kg in a blasting round of 750 kg frequency level was 85 Hz.

where frequency level was 8Hz. The

reasons for the high level of vibration The following data (Table 1) was

were due to the excessive toe burden in generated during the trial blast of

the first blast. This was the first blast in Bankola OC patch:

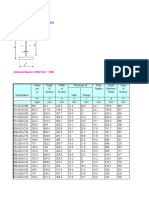

TABLE-I

BLASTWISE DETAILS OF PEAK PARTICLE VELOCITY AND AIR

OVER PRESSURE IN BANKOLA MINE TRIAL BLASTS WITH e-

DET

Maximum Total Blast Results

Date Charge/Delay Charge PPV AOP

Distance

(KG) (KG) (mm/sec) (dB)

17.02.09 25 750 90 16 100

150 2.73 118

19.02.09 20 417

120 7.11 100

100 8.89 115

23.02.09 19.60 411.6

117 4.70 100

135 4.83 121

140 4.45 100

26.02.09 25.0 525

142 4.06 113

170 1.40 115

02.03.09 16 319.70 155 2.79 100

02.03.09 19.50 389.0 140 2.98 100

08.03.09 16 305.8 140 2.16 100

15.03.09 22 525 140 2.60 112

26.03.09 25 375 158 3.18 110

26.03.09 12.5 75 110 2.67 110

120 3.05 116

27.03.09 11 412.5 130 3.18 118

150 2.67 116

110 2.10 100

31.03.09 19.40 465.36

160 1.65 100

01.04.09 19.5 350 120 1.71 100

10.04.09 19.5 525 130 1.18 100

24.04.09 20.8 250 100 1.84 100

Observations: More significantly in the Indian scenario,

use of e-DETs will help unlock millions

With regular blasting operations, the of tonnes of coal currently locked up in

formation of benches in the mine became the opencast mine benches presently un-

proper and the ground vibration levels in mineable, due to proximity to

the successive blasts reduced habitations. DGMS is presently not

considerably. No fly rock was observed. allowing mining of benches within 100

The fragmentation of the blasted muck meters to dwellings. With the use of e-

was satisfactory and suitable to the

DET, there exists a potential to reduce

excavator in use.

this distance to 50 meters, thus helping

mining of millions of ones of coal which

Further development with e-DET- otherwise would have been left un-

mined in the pits.

GOCL is now ready with the fully “Field

Programmable’ version where individual Acknowledgement-

detonators can be programmed at the

field commensurate to need. The new Authors are thankful to the officials of

version is having a programmable delay Bankola Area and CMPDIL for giving

window of 9000 milliseconds in them an opportunity to develop relevant

increments of 1 millisecond delay. This data and establish the efficacy of e-Det

will open up tremendous opportunities to for controlled blasting. Authors also

the blasting engineer while carrying out thank GOCL Management for according

blasts, whether in mining or civil them permission to present this case

infrastructure sector. study paper.

------------------------------------------------------------------------------------------------------------

1. Regional Sales Manager, GOCL, Asansol.

2. Dy. GM (Application Services), GOCL, Hyderabad.

3. Sr. Sales Engineer, GOCL, Asansol.

PHOTO-1

e-DET with Polarized water-proof PHOTO-2

male/female Connector and Field Surface e-XPLODER

Connector with male connector at one end

and female connector at the other end

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CAT 330 B - Parts Catalog PDFDocument1,343 pagesCAT 330 B - Parts Catalog PDFSumudu Adikari92% (12)

- Ebook-Free-Pdf-Tai-Pan-By-James-Clavell 2Document2 pagesEbook-Free-Pdf-Tai-Pan-By-James-Clavell 2ADSAO100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- NA 2 Notes 3 - Power TransmissionDocument8 pagesNA 2 Notes 3 - Power TransmissionSudheendra ck0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 278702843-1965-War-the-Inside-Story-1 3 PDFDocument5 pages278702843-1965-War-the-Inside-Story-1 3 PDFADSAONo ratings yet

- Pentadyne HPDocument3 pagesPentadyne HPADSAONo ratings yet

- BhavalkingDocument15 pagesBhavalkingADSAONo ratings yet

- Hot Roled SectionsDocument58 pagesHot Roled Sectionsmohamed AlasadyNo ratings yet

- Republic of The Philippines City of Davao: LongitudeDocument7 pagesRepublic of The Philippines City of Davao: LongitudeSersio BordiosNo ratings yet

- Estimation of A RCCslab CulvertDocument5 pagesEstimation of A RCCslab CulvertShah Mohammad IqbalNo ratings yet

- Bonded Washers: Product DescriptionDocument4 pagesBonded Washers: Product DescriptionRomeo Lemus LainezNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Calorifier Data SheetDocument4 pagesCalorifier Data SheetgksakthiNo ratings yet

- Machining Processes - I MT 164: LatheDocument45 pagesMachining Processes - I MT 164: LatheMusab LatifNo ratings yet

- EGL and HGLDocument17 pagesEGL and HGLMuhammad Bilal GhouriNo ratings yet

- Industial Training - Ashok Layland LTDDocument14 pagesIndustial Training - Ashok Layland LTDTechnical KingNo ratings yet

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Part A-MillingDocument108 pagesPart A-MillingSayed qasimNo ratings yet

- SNK 500-600Document3 pagesSNK 500-600AmanNo ratings yet

- DHR242 DHR243 ManualDocument64 pagesDHR242 DHR243 ManualTjell KeunNo ratings yet

- Totten CatalogDocument19 pagesTotten CatalogxpertsteelNo ratings yet

- Mechanics of Solids Laboratory Manual: Tensile TestDocument8 pagesMechanics of Solids Laboratory Manual: Tensile TestVIPAN KUMARNo ratings yet

- Hydraulic Systems - Lecture 15Document13 pagesHydraulic Systems - Lecture 15Vinith PrashanNo ratings yet

- Stair Case Design: Schematic PlanDocument6 pagesStair Case Design: Schematic Planthanigai veluNo ratings yet

- Concertina CoilDocument4 pagesConcertina CoilvklsNo ratings yet

- Chilled Water Qty Take OffDocument20 pagesChilled Water Qty Take OffProject enghvacNo ratings yet

- DOC-Electro Magnetic Abrasive Final YearDocument11 pagesDOC-Electro Magnetic Abrasive Final YearJagadish KumarNo ratings yet

- 9853 1163 01 - RC 50 Service Poster - HIGHresDocument1 page9853 1163 01 - RC 50 Service Poster - HIGHresRachid AmansagNo ratings yet

- Fire Fighting Drawing ListDocument18 pagesFire Fighting Drawing ListIshwar AltNo ratings yet

- Calculation of Allowable Load of Profile - Aluminium Profiles - PBA Leader Motion MalaysiaDocument3 pagesCalculation of Allowable Load of Profile - Aluminium Profiles - PBA Leader Motion MalaysiaSanket Ganesh PokharkarNo ratings yet

- Analisis Sistem Pembumian Untuk Mengamankan Instalasi Listrik Di Program Studi Teknik Elektro Fakultas Teknik Universitas Udayana Jimbaran BaliDocument8 pagesAnalisis Sistem Pembumian Untuk Mengamankan Instalasi Listrik Di Program Studi Teknik Elektro Fakultas Teknik Universitas Udayana Jimbaran BaliMerlin MerlitaNo ratings yet

- Drill Press Table PlanDocument7 pagesDrill Press Table Planyoranvaneekelen100% (1)

- 03 ZJ40DBⅣ钻机图册Document68 pages03 ZJ40DBⅣ钻机图册jimmy__428No ratings yet

- RENASYS Ordering Information RENASYS Ordering InformationDocument2 pagesRENASYS Ordering Information RENASYS Ordering Informationpedro906.pfNo ratings yet

- Vertipack 320: High Speed Zipper AttachmentDocument2 pagesVertipack 320: High Speed Zipper AttachmentkunalkakkadNo ratings yet