Professional Documents

Culture Documents

224700, Drinking Fountains and Water Coolers

224700, Drinking Fountains and Water Coolers

Uploaded by

srp. mohammedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

224700, Drinking Fountains and Water Coolers

224700, Drinking Fountains and Water Coolers

Uploaded by

srp. mohammedCopyright:

Available Formats

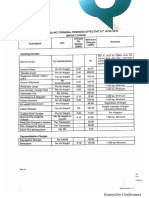

MARCH 27, 2020

SECTION 224700

DRINKING FOUNTAINS AND WATER COOLERS

PART 1 - GENERAL

1.1 SUMMARY

A. This Section includes the following:

1. Pressure water coolers.

2. Fixture supports.

1.2 DEFINITIONS

A. Accessible Water Cooler: Fixture that can be approached and used by people with disabilities.

B. Fitting: Device that controls flow of water into or out of fixture.

C. Fixture: Water cooler, unless one is specifically indicated.

D. Water Cooler: Electrically powered fixture for generating and delivering cooled drinking water.

1.3 SUBMITTALS

A. Product Data for each plumbing fixture category and type specified. Include selected fixture, trim,

fittings, accessories, appliances, appurtenances, equipment, and supports. Indicate materials and

finishes, dimensions, construction details, and flow-control rates.

B. Wiring diagrams from manufacturer for electrically operated units.

C. Maintenance data for plumbing fixtures and components to include in the operation and

maintenance manuals.

1.4 QUALITY ASSURANCE

A. Electrical Components, Devices, and Accessories: Listed and labeled as defined in Article 100 of

NFPA 70, by a testing agency acceptable to Project Director/COR, and marked for intended use.

B. Regulatory Requirements: Comply with accessibility requirements in Chapter 11 of the OBO

Building Code.

C. NSF Standard: Comply with NSF 61, "Drinking Water System Components--Health Effects," for

fixture materials that will be in contact with potable water.

D. ARI Standard: Comply with ARI 1010, "Self-Contained, Mechanically Refrigerated Drinking-

Water Coolers," for water coolers and with ARI's "Directory of Certified Drinking Water

Coolers" for type and style classifications.

DRINKING FOUNTAINS AND WATER COOLERS 224700 - 1

MARCH 27, 2020

PART 2 - PRODUCTS

2.1 PRESSURE WATER COOLERS

A. Water Coolers and bottle filler: Accessible, VRCHDTL8S-NF Bi-Level vandal resistance 14 GA

Stainless Steel electric water cooler, with chrome-plated two-stream double bubbler, built-in

bottle filling station, wall-hanging left-hand high and right-hand low fixture.

1. Cabinet: Bilevel with two attached cabinets and all stainless steel.

2. Bubbler: One, with automatic stream regulator, located on each cabinet deck.

3. Control: Self-closing Pushbutton.

4. Supply: DN 10 with ball, gate, or globe valve.

5. Drain(s): Grid with DN 32 minimum horizontal waste and trap complying with

ASME A112.18.1M.

6. Cooling System: Electric, with hermetically sealed compressor, cooling coil, air-cooled

condensing unit, corrosion-resistant tubing, refrigerant, corrosion-resistant-metal storage

tank, and adjustable thermostat.

a. Capacity: 0.0084 L/s of 10◦C cooled water from 27◦C inlet water and 32◦C ambient

air temperature.

b. Electrical Characteristics: 370Watts, 4.0 FLA, 120 volts and 60 HZ frequency.

B. Water Coolers and bottle filler with remote Chiller: Accessible, EDFPR217C Bi-level wall

mount-fully exposed drinking fountain with built-in bottle filling station and wall plate.

1. Bubbler: One, with automatic stream regulator, located on each cabinet deck.

2. Control: Self-closing vandal-resistant Pushbutton.

3. Drain(s): Grid with DN 32 minimum horizontal waste and trap complying with

ASME A112.18.1M.

4. Supply: DN 10 with ball, gate, or globe valve.

5. Remote Chiller: Cooling System: Electric, with hermetically sealed compressor, cooling

coil, air-cooled condensing unit, corrosion-resistant tubing, refrigerant, corrosion-resistant-

metal storage tank, and adjustable thermostat.

a. Capacity: 0.0084 L/s of 10◦C cooled water from 27◦C inlet water and 32◦C ambient

air temperature.

b. Electrical Characteristics: 370Watts, 4.0 FLA, 120 volts and 60 HZ frequency.

2.2 FIXTURE SUPPORTS

A. Off-Floor, Plumbing Fixture Supports: ASME A112.6.1M, water-cooler carriers. Include

vertical, steel uprights with feet and tie rods and bearing plates with mounting studs matching

fixture to be supported.

1. Bilevel, hanger-type carrier with three vertical uprights.

2. Supports for Accessible Fixtures: Include rectangular, vertical, steel uprights instead of

steel pipe uprights.

DRINKING FOUNTAINS AND WATER COOLERS 224700 - 2

MARCH 27, 2020

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine roughing-in for water and waste piping systems to verify actual locations of piping

connections before fixture installation. Verify that sizes and locations of piping and types of

supports match those indicated.

B. Examine walls and floors for suitable conditions where fixtures are to be installed.

C. Proceed with installation only after unsatisfactory conditions have been corrected.

3.2 INSTALLATION

A. Install off-floor supports affixed to building substrate and attach wall-hanging fixtures, unless

otherwise indicated.

B. Install fixtures level and plumb.

C. Install water-supply piping with shutoff valve on supply to each fixture to be connected to water

distribution piping. Use ball, gate, or globe valve. Install valves in locations where they can be

easily reached for operation. Refer to Division 22 Section "General-Duty Valves for Plumbing

Piping" for general-duty valves.

D. Install trap and waste piping on drain outlet of each fixture to be connected to sanitary drainage

system.

E. Install pipe escutcheons at wall penetrations in exposed, finished locations. Use deep-pattern

escutcheons where required to conceal protruding pipe fittings. Refer to Division 23 Section

"Common Work Results for Fire-Suppression, Plumbing and HVAC" for escutcheons.

F. Seal joints between fixtures and walls and floors using sanitary-type, one-part, mildew-resistant,

silicone sealant. Match sealant color to fixture color. Refer to Division 07 Section "Joint Sealants"

for sealant and installation requirements.

3.3 CONNECTIONS

A. Piping installation requirements are specified in other Division 22 Sections. Drawings indicate

general arrangement of piping, fittings, and specialties.

B. Connect water supplies from water distribution piping to fixtures.

C. Connect drain piping from fixtures to drainage piping.

D. Ground equipment.

1. Tighten electrical connectors and terminals according to manufacturer's published torque-

tightening values. If manufacturer's torque values are not indicated, use those specified in

UL 486A and UL 486B.

DRINKING FOUNTAINS AND WATER COOLERS 224700 - 3

MARCH 27, 2020

3.4 FIELD QUALITY CONTROL

A. Water-Cooler Testing: After electrical circuitry has been energized, test for compliance with

requirements. Test and adjust controls and safeties.

B. Repair or replace malfunctioning units. Retest as specified above after repairs or replacements

are made.

C. Report test results in writing.

3.5 ADJUSTING

A. Adjust fixture flow regulators for proper flow and stream height.

B. Adjust water-cooler temperature settings.

3.6 CLEANING

A. After completing fixture installation, inspect unit. Remove paint splatters and other spots, dirt,

and debris. Repair damaged finish to match original finish.

B. Clean fixtures, on completion of installation, according to manufacturer's written instructions.

END OF SECTION

DRINKING FOUNTAINS AND WATER COOLERS 224700 - 4

You might also like

- Water Softener 223100Document7 pagesWater Softener 223100ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Manual DestiladorDocument28 pagesManual DestiladorMaritza Josefina Colina RamonesNo ratings yet

- Typical Solar BQDocument7 pagesTypical Solar BQngarinyagaNo ratings yet

- 221005, Plumbing SpecialtiesDocument16 pages221005, Plumbing Specialtiessrp. mohammedNo ratings yet

- 224215, Commercial Plumbing FixturesDocument13 pages224215, Commercial Plumbing Fixturessrp. mohammed100% (1)

- Feed Water UnitDocument2 pagesFeed Water UnitEslam ElsayedNo ratings yet

- Domestic Water PipingDocument13 pagesDomestic Water PipingEN LeedNo ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- Plumbing Fixtures StandardDocument12 pagesPlumbing Fixtures StandardPamela Joyce MaddumaNo ratings yet

- Section 21 12 00Document3 pagesSection 21 12 00Ismail MohammadNo ratings yet

- SECTION 15520 Feedwater Equipment General 1.1Document6 pagesSECTION 15520 Feedwater Equipment General 1.1fatREVITNo ratings yet

- Project Standard Specification: Plumbing Specialties 15430 - Page 1 of 19Document19 pagesProject Standard Specification: Plumbing Specialties 15430 - Page 1 of 19adel rihanaNo ratings yet

- Va 22 33 00Document9 pagesVa 22 33 00RicardoNo ratings yet

- Rubber Gasket TypesDocument92 pagesRubber Gasket Typessushant_moreyNo ratings yet

- GRP Tank SpecDocument5 pagesGRP Tank SpecRamesh arumugamNo ratings yet

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- Plumbing FixturesDocument30 pagesPlumbing Fixturesadel rihanaNo ratings yet

- Cooling TowersDocument11 pagesCooling Towerszarzoura001No ratings yet

- 22 10 00 - Plumbing Piping and Pumps: Design & Construction Standards, Revised January2014 22.10.00-1Document8 pages22 10 00 - Plumbing Piping and Pumps: Design & Construction Standards, Revised January2014 22.10.00-1Teguh SetionoNo ratings yet

- P.O. Number: 7200018725Document6 pagesP.O. Number: 7200018725sethu1091No ratings yet

- Specification For Hot Water Boilers-9-10Document2 pagesSpecification For Hot Water Boilers-9-10Karthik AnandanNo ratings yet

- 15570Document6 pages15570JhoNo ratings yet

- Facility Sanitary SewersDocument14 pagesFacility Sanitary SewerssamNo ratings yet

- Hvac-05 Air CoilsDocument3 pagesHvac-05 Air CoilsCosphiiiNo ratings yet

- Cooling TowersDocument4 pagesCooling TowersAmando GonzalesNo ratings yet

- 15-1-6 - Chilled Water Piping SystemDocument10 pages15-1-6 - Chilled Water Piping Systemfarshan296015No ratings yet

- Mechanical Draft Cooling TowerDocument6 pagesMechanical Draft Cooling TowerNoushad P HamsaNo ratings yet

- Dartmouth College Design November 15, 2007 & Construction GuidelinesDocument4 pagesDartmouth College Design November 15, 2007 & Construction GuidelinesIndira SharanNo ratings yet

- Section 15183 - Refrigerant PipingDocument11 pagesSection 15183 - Refrigerant PipingJavier BarbosaNo ratings yet

- Plumbing SectionDocument16 pagesPlumbing SectionJanNo ratings yet

- QCS-2010 Section 19 Part 2 Water DistributionDocument12 pagesQCS-2010 Section 19 Part 2 Water Distributionbryanpastor106100% (1)

- Project Standard Specification: Electric, Domestic Water Heaters 15485 - Page 1/10Document10 pagesProject Standard Specification: Electric, Domestic Water Heaters 15485 - Page 1/10adel rihanaNo ratings yet

- SEC 226200 Laboratory Vacuum SystemDocument8 pagesSEC 226200 Laboratory Vacuum SystemAkilaJosephNo ratings yet

- Rowan University Design Guide 2013Document4 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Water and ArregationDocument9 pagesWater and ArregationYasser FathiNo ratings yet

- Airport PlumbingDocument11 pagesAirport Plumbingquanghai1301No ratings yet

- (Expansion and Compression Tanks)Document3 pages(Expansion and Compression Tanks)Mostafa SalemNo ratings yet

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITNo ratings yet

- Refrigerant Piping Sample-2Document4 pagesRefrigerant Piping Sample-2Hazrat AminNo ratings yet

- SECTION 15640 Packaged Cooling Towers General 1.1Document7 pagesSECTION 15640 Packaged Cooling Towers General 1.1Munir RasheedNo ratings yet

- SECTION 15180 Heating and Cooling Piping General 1.1: - Page 1 of 18Document18 pagesSECTION 15180 Heating and Cooling Piping General 1.1: - Page 1 of 18Munir RasheedNo ratings yet

- Riyadh Avenue Mall - Mechanical CommentsDocument3 pagesRiyadh Avenue Mall - Mechanical CommentsMohamed SokarNo ratings yet

- 94 TMSS 02 R0Document0 pages94 TMSS 02 R0hasanmnhNo ratings yet

- 224500, Emergency Plumbing FixtureDocument5 pages224500, Emergency Plumbing Fixturesrp. mohammedNo ratings yet

- SECTION 15670 Refrigerant Condensing Units General 1.1: - Page 1 of 5Document5 pagesSECTION 15670 Refrigerant Condensing Units General 1.1: - Page 1 of 5Munir RasheedNo ratings yet

- Bradley Keltech 223313.02-ElectricDomesticWaterHeaters-SNA SKID PDFDocument9 pagesBradley Keltech 223313.02-ElectricDomesticWaterHeaters-SNA SKID PDFImtiyaz KhanNo ratings yet

- Hydronic PipingDocument11 pagesHydronic PipingLjubomir DjurinNo ratings yet

- HEP-23-02-232105 Mech Systems PipingDocument14 pagesHEP-23-02-232105 Mech Systems Pipingsenseiann.eslNo ratings yet

- 23 21 13 Iei - Hvac PipingDocument10 pages23 21 13 Iei - Hvac PipingAiman AliNo ratings yet

- Steam, Domestic Storage Water HeaterDocument7 pagesSteam, Domestic Storage Water Heaterbandithaguru6338No ratings yet

- General Ducty Valves SpecDocument12 pagesGeneral Ducty Valves SpecpursuitofhappynessinNo ratings yet

- 11/29/19 Design No. - SECTION 15580 Feedwater EquipmentDocument20 pages11/29/19 Design No. - SECTION 15580 Feedwater EquipmentJhoNo ratings yet

- Condenser ManualDocument48 pagesCondenser ManualVishal Kumar Laddha100% (2)

- C6 PotWaterPumpDocument3 pagesC6 PotWaterPumpadel agustiNo ratings yet

- Bart Facilities StandardDocument8 pagesBart Facilities StandardBehnam AshouriNo ratings yet

- W C Ss 011 (Water Dranage)Document14 pagesW C Ss 011 (Water Dranage)zfrlNo ratings yet

- PDFDocument7 pagesPDFMuhammad Ali SakrNo ratings yet

- 220CDocument6 pages220Cmacanipharoldf6220No ratings yet

- HIA Mid-Field Fuel Farm Expansion - Welding of Steel StructuresDocument18 pagesHIA Mid-Field Fuel Farm Expansion - Welding of Steel Structuressrp. mohammedNo ratings yet

- WFF Steel Structure (Specifications, Standard, Documents and Drawings) Section Completion 3Document1 pageWFF Steel Structure (Specifications, Standard, Documents and Drawings) Section Completion 3srp. mohammedNo ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- 224215, Commercial Plumbing FixturesDocument13 pages224215, Commercial Plumbing Fixturessrp. mohammed100% (1)

- 221005, Plumbing SpecialtiesDocument16 pages221005, Plumbing Specialtiessrp. mohammedNo ratings yet

- Maldives Holiday: INR 77,430 For 2 Traveller(s)Document11 pagesMaldives Holiday: INR 77,430 For 2 Traveller(s)srp. mohammedNo ratings yet

- 224500, Emergency Plumbing FixtureDocument5 pages224500, Emergency Plumbing Fixturesrp. mohammedNo ratings yet

- Charge PDFDocument3 pagesCharge PDFsrp. mohammedNo ratings yet

- Holiday Assist - Thailand (D-5)Document7 pagesHoliday Assist - Thailand (D-5)srp. mohammedNo ratings yet

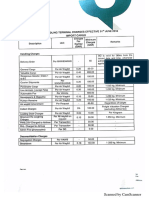

- Terminal HandlingDocument3 pagesTerminal Handlingsrp. mohammedNo ratings yet

- Annex 2 Course Outline (Revised)Document3 pagesAnnex 2 Course Outline (Revised)Suvesh nlnNo ratings yet

- Consequences of Deforestation and Climate Change On BiodiversityDocument27 pagesConsequences of Deforestation and Climate Change On Biodiversitydokifi6985nonicamy.comNo ratings yet

- Manual Masina de Spalat Slim SamsungDocument1,020 pagesManual Masina de Spalat Slim SamsungPerfectreviewNo ratings yet

- Brgy. Taba Ao Mangrove Assessment Report DraftDocument8 pagesBrgy. Taba Ao Mangrove Assessment Report DraftJohn Lyndel AlolonNo ratings yet

- 08 Hydro PowerDocument65 pages08 Hydro PowerMuhammad BurhanNo ratings yet

- Oakley Etal 2010 J Ecol EngDocument12 pagesOakley Etal 2010 J Ecol EngMashaelNo ratings yet

- COA Spiritus EnvironexDocument1 pageCOA Spiritus EnvironexwisonoNo ratings yet

- Water 08 00511Document18 pagesWater 08 00511Pedro Silva de SouzaNo ratings yet

- GIS - PPT - DT 20-7-21Document45 pagesGIS - PPT - DT 20-7-21Sankar100% (1)

- The Extractive Industries and Society: Original ArticleDocument11 pagesThe Extractive Industries and Society: Original ArticlehenryNo ratings yet

- FeedrequestDocument16 pagesFeedrequestVictor DvornikovNo ratings yet

- Passenham Quarry: Hydrogeological Impact AssessmentDocument76 pagesPassenham Quarry: Hydrogeological Impact AssessmentSergio CunhaNo ratings yet

- Iso 6425 2018Document11 pagesIso 6425 2018alexeigeNo ratings yet

- Plastic PollutionDocument21 pagesPlastic PollutionMG MaheshBabuNo ratings yet

- Chillerft WFC SC SH 30 enDocument2 pagesChillerft WFC SC SH 30 enKristina BožićNo ratings yet

- JPF WASH Engineer Written Test 10 October - Dhafer ObeidatDocument8 pagesJPF WASH Engineer Written Test 10 October - Dhafer Obeidatnour mostafa100% (1)

- ZIC M9 4T 10W-40: Material Safety Data SheetDocument10 pagesZIC M9 4T 10W-40: Material Safety Data SheetAqui GacusanNo ratings yet

- BenefitsDocument5 pagesBenefitsNhecel PascuaNo ratings yet

- Application Note: Best Practices For Successful Filter Integrity Testing Using The Water Intrusion Test (WIT) MethodDocument8 pagesApplication Note: Best Practices For Successful Filter Integrity Testing Using The Water Intrusion Test (WIT) MethodSlavaNo ratings yet

- Hydrological Study For Mini-Hydropower Plant in The Pyrenees Master ThesisDocument33 pagesHydrological Study For Mini-Hydropower Plant in The Pyrenees Master ThesisAliya ZehraNo ratings yet

- Syllabus Physical GeologyDocument6 pagesSyllabus Physical GeologyiwanNo ratings yet

- 1.1 Plumbing History and Terminologies - Building Utilities 1 (Course Materials)Document13 pages1.1 Plumbing History and Terminologies - Building Utilities 1 (Course Materials)Princessdy CocadizNo ratings yet

- Horizontal and Vertical Soilless Growing Systems Under Cyprus ConditionsDocument5 pagesHorizontal and Vertical Soilless Growing Systems Under Cyprus ConditionsShailendra RajanNo ratings yet

- Bqs568 Group 5 Green BuildingDocument48 pagesBqs568 Group 5 Green BuildingAmirah RozeliNo ratings yet

- Dav Project EngDocument24 pagesDav Project EngMonster GamerNo ratings yet

- 2019 LSS Catalogue (English) Double Page VersionDocument28 pages2019 LSS Catalogue (English) Double Page VersionFILID MADNo ratings yet

- Site Instruction FormatDocument26 pagesSite Instruction FormatMesfin100% (4)

- JACOBI TDS AQUASORB 2000 Plus A4 ENG C1118Document2 pagesJACOBI TDS AQUASORB 2000 Plus A4 ENG C1118Lam NgọcNo ratings yet

- Wind Farms Chart: KingfisherDocument3 pagesWind Farms Chart: KingfishersmashfacemcgeeNo ratings yet

- Caring For The Environment Is Our FutureDocument13 pagesCaring For The Environment Is Our FutureEdinson SNNo ratings yet