Professional Documents

Culture Documents

AMCA 210 - Laboratory Methods of Testing Fans For Ratings

AMCA 210 - Laboratory Methods of Testing Fans For Ratings

Uploaded by

Zander MctrevorCopyright:

Available Formats

You might also like

- D.P.transmitter Spriano 47B ManualDocument22 pagesD.P.transmitter Spriano 47B ManualBruno100% (1)

- XRFDocument46 pagesXRFFrancisco José Ager Vázquez100% (1)

- Steel Grade SpecificationsDocument9 pagesSteel Grade SpecificationsSiti Rahayu Permita Sari100% (1)

- P 6410 Ip Iom-1Document5 pagesP 6410 Ip Iom-1victorvelasquezchalcoNo ratings yet

- Genesis Series 2" & 3" Steel Meters: Smith Meter PD MeterDocument6 pagesGenesis Series 2" & 3" Steel Meters: Smith Meter PD MeterEnder ZenginobuzNo ratings yet

- Seat Tightness of Pressure Relief Valves Api Standard 527 Fourth Edition November 2014 PDF FreeDocument15 pagesSeat Tightness of Pressure Relief Valves Api Standard 527 Fourth Edition November 2014 PDF FreestudentmgmNo ratings yet

- Control Air Bubble-Tube Level System L100 - IOMDocument6 pagesControl Air Bubble-Tube Level System L100 - IOMjnbxyzNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- ReportDocument14 pagesReportMuhammad AbdullahNo ratings yet

- Anemometro ManualDocument8 pagesAnemometro Manualjose norberto santillan zazuetaNo ratings yet

- Standard Procedure For Calibration of GaugesDocument12 pagesStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyNo ratings yet

- Instruction Manual Oss-B1 Universal Current Meter: Hyquest Solutions Pty LTDDocument22 pagesInstruction Manual Oss-B1 Universal Current Meter: Hyquest Solutions Pty LTDWidia NantaNo ratings yet

- Circuito Medidor PresiónDocument4 pagesCircuito Medidor Presiónfredy8704No ratings yet

- Interview Questions For Instrument EngineersDocument4 pagesInterview Questions For Instrument EngineerszhangyiliNo ratings yet

- Pressure ControlDocument50 pagesPressure ControlKashan AliNo ratings yet

- Wall-Mount Barometers: Operating InstructionsDocument8 pagesWall-Mount Barometers: Operating InstructionssaporobitusNo ratings yet

- Industrial InstrumentationDocument14 pagesIndustrial Instrumentationjayashree sNo ratings yet

- DS HP W T 300 6 Differential en Us 17183Document3 pagesDS HP W T 300 6 Differential en Us 17183behnamatgNo ratings yet

- Fisher Big Joe Type 630 321 ManualDocument11 pagesFisher Big Joe Type 630 321 ManualAbigail Lupe Aguilar YapuraNo ratings yet

- Introduction:-: Training On GET-Instrumentation November 2014 Document Title: Pressure Measurment and Control Code: PIDocument7 pagesIntroduction:-: Training On GET-Instrumentation November 2014 Document Title: Pressure Measurment and Control Code: PISANJAYNo ratings yet

- Transductor FLOWSERVE NT3000Document20 pagesTransductor FLOWSERVE NT3000Xavier EspinozaNo ratings yet

- Chapter 7 Measuring Pressure, Temperature, and HumidityDocument22 pagesChapter 7 Measuring Pressure, Temperature, and HumidityDestroy GameNo ratings yet

- Horiba ABX Micros 60 - Technical Manual 2 PDFDocument205 pagesHoriba ABX Micros 60 - Technical Manual 2 PDFAniela RosalesNo ratings yet

- Pressure Measuring Instruments: Dr. Fahad Rehman CUI, Lahore CampusDocument69 pagesPressure Measuring Instruments: Dr. Fahad Rehman CUI, Lahore CampusAhmed Mustafa100% (1)

- Wise Catalog PDFDocument177 pagesWise Catalog PDFMinhthien NguyenNo ratings yet

- Pressure MeasurementDocument41 pagesPressure MeasurementBlowndudeNo ratings yet

- Module 3Document219 pagesModule 3Sourav PoddarNo ratings yet

- Experiment 5 (Calibration of Pressure Measuring Devices - A4)Document17 pagesExperiment 5 (Calibration of Pressure Measuring Devices - A4)Jamiel Catapang100% (1)

- Local Media8092592512293728315Document8 pagesLocal Media8092592512293728315Bowie S. PascualNo ratings yet

- Experiment No: 2: Study of SRM University Supersonic Wind TunnelDocument16 pagesExperiment No: 2: Study of SRM University Supersonic Wind Tunnelbad guyNo ratings yet

- Vuheat User Manual VHU20 VHU40Document10 pagesVuheat User Manual VHU20 VHU40Bram RossinghNo ratings yet

- Performance Testing Procedure For Centrifugal PumpsDocument5 pagesPerformance Testing Procedure For Centrifugal Pumpssandii123No ratings yet

- Manual CDI 5200Document2 pagesManual CDI 5200Martin CastroNo ratings yet

- Turbine Cascade LaboratoryDocument13 pagesTurbine Cascade LaboratorytexascaaNo ratings yet

- Westinghouse Type CODocument24 pagesWestinghouse Type CORicardo Hernandez100% (1)

- Differential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsDocument8 pagesDifferential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsdhaktodesatyajitNo ratings yet

- Method Statement Pressure TestDocument5 pagesMethod Statement Pressure TestAnand NarayananNo ratings yet

- Q&A PressureDocument3 pagesQ&A PressureZenif Fatkhur RohmanNo ratings yet

- Arcilla, Zoren - Me Lab1 - Exp4 - M4act5Document12 pagesArcilla, Zoren - Me Lab1 - Exp4 - M4act5dracarysNo ratings yet

- Pressure Sensor No. 84370-Series: General DescriptionDocument8 pagesPressure Sensor No. 84370-Series: General DescriptionOghale OkoroNo ratings yet

- Pressure Sensor ModulesDocument3 pagesPressure Sensor Modulesphani22No ratings yet

- Measurement and Instrumentation Lab 8Document9 pagesMeasurement and Instrumentation Lab 8abdulrehmanmani418383No ratings yet

- Turbine Flow Meter User Manual (003) Manual Del MedidorDocument22 pagesTurbine Flow Meter User Manual (003) Manual Del MedidorDAMASO MARTINEZ RODRIGUEZNo ratings yet

- Section 28 - Deadweight TesterDocument22 pagesSection 28 - Deadweight TesterhammamiNo ratings yet

- Thincyl PDFDocument2 pagesThincyl PDFPriyanshuNo ratings yet

- Thincylind PDFDocument2 pagesThincylind PDFPriyanshuNo ratings yet

- 2.venturimeter Theory PDFDocument9 pages2.venturimeter Theory PDFSWETHANo ratings yet

- Elastic Element Pressure Gauges: DescriptionDocument4 pagesElastic Element Pressure Gauges: DescriptionknchnNo ratings yet

- Tutorial: Valve Closure and Transient Pressure Wave (Part 2)Document8 pagesTutorial: Valve Closure and Transient Pressure Wave (Part 2)Anonymous I4CTAwUNo ratings yet

- Pneumatic InstrumentsDocument9 pagesPneumatic InstrumentsHnd FinalNo ratings yet

- 4156342Document19 pages4156342Th GmNo ratings yet

- Bourdon GageDocument5 pagesBourdon GageMark Aldaba ReytiranNo ratings yet

- Pressure & Temperature Gause NotesDocument9 pagesPressure & Temperature Gause NotesNazimNo ratings yet

- CP No.601-Hydraulic Type (Pressure) - RevDocument18 pagesCP No.601-Hydraulic Type (Pressure) - Revamelchan_tiqueNo ratings yet

- MicroCal P100Document2 pagesMicroCal P100Paul ChiriacescuNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

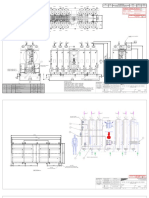

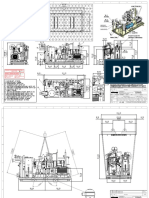

- Detail E: Issued by Greenlane BiogasDocument4 pagesDetail E: Issued by Greenlane BiogasZander MctrevorNo ratings yet

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Model FGV (B, D) FEV (B, D) : Issued by Greenlane BiogasDocument1 pageModel FGV (B, D) FEV (B, D) : Issued by Greenlane BiogasZander MctrevorNo ratings yet

- Isometric: 2395 Vacuum SystemDocument1 pageIsometric: 2395 Vacuum SystemZander MctrevorNo ratings yet

- IndiceDocument10 pagesIndiceZander MctrevorNo ratings yet

- PrefaceDocument4 pagesPrefaceZander MctrevorNo ratings yet

- Cartas para Mazo Requeridas)Document3 pagesCartas para Mazo Requeridas)Zander MctrevorNo ratings yet

- Statically Indeterminate ProblemsDocument16 pagesStatically Indeterminate ProblemsJake CanlasNo ratings yet

- Product Technical Specification-Polypropylene (POLYTAM)Document1 pageProduct Technical Specification-Polypropylene (POLYTAM)Axel Mahya AvichenaNo ratings yet

- Lec 12 Design of An EAFDocument14 pagesLec 12 Design of An EAFSakunaPappu100% (1)

- IR and Raman in Inorganic Solid No 20Document7 pagesIR and Raman in Inorganic Solid No 20Diego CarvalhoNo ratings yet

- Roi SC 304 Conductors and Insulators of Heat Powerpoint Ver 1Document16 pagesRoi SC 304 Conductors and Insulators of Heat Powerpoint Ver 1Asmaa JoudehNo ratings yet

- Crystallization and Transformation of Pharmaceutical Solid FormsDocument11 pagesCrystallization and Transformation of Pharmaceutical Solid FormsAlex-Mihai CiubaraNo ratings yet

- A Poor Man's Derivation of Scaling Laws For The Kondo ProblemDocument7 pagesA Poor Man's Derivation of Scaling Laws For The Kondo ProblemTianhaoRenNo ratings yet

- PHYSICS Own NotesDocument4 pagesPHYSICS Own NotesMica BernardoNo ratings yet

- III B.tech. (Autonomous)Document62 pagesIII B.tech. (Autonomous)divya dungaNo ratings yet

- 2-ERT252 Distance MeasurementDocument32 pages2-ERT252 Distance Measurementiffatul mahyaNo ratings yet

- 1st Year Chemistry Chapter No. 5-6 - SQs - NOTESPKDocument14 pages1st Year Chemistry Chapter No. 5-6 - SQs - NOTESPKZeeshan ahmedNo ratings yet

- Cambering Steel BeamsDocument2 pagesCambering Steel BeamsFernando PizarroNo ratings yet

- Using Diaminomethanal As An Entrainer For The Separation of Isopropanol + Water MixtureDocument12 pagesUsing Diaminomethanal As An Entrainer For The Separation of Isopropanol + Water MixturenehaNo ratings yet

- The Climatological, Ecological, Solar and Wind Considerations, Day Lighting in Architectural DesignDocument25 pagesThe Climatological, Ecological, Solar and Wind Considerations, Day Lighting in Architectural DesignAr Frank EpeNo ratings yet

- Practice Exam No. 4 2018 PDFDocument43 pagesPractice Exam No. 4 2018 PDFJevan CalaqueNo ratings yet

- Foods As Dispersed Systems. Thermodynamic Aspects of Composition-Property Relationships in Formulated FoodDocument14 pagesFoods As Dispersed Systems. Thermodynamic Aspects of Composition-Property Relationships in Formulated FoodMichael AbdulaiNo ratings yet

- Iwaki Diafragma 1.25 inDocument4 pagesIwaki Diafragma 1.25 inRaul ArizagaNo ratings yet

- Mymensingh Engineering College: An Assignment On Optoelectronics EEE - 809Document8 pagesMymensingh Engineering College: An Assignment On Optoelectronics EEE - 809rafiNo ratings yet

- What Are Turbines ? - Types of Turbines & Their ApplicationsDocument6 pagesWhat Are Turbines ? - Types of Turbines & Their ApplicationsAnonymous m2GmeVnY100% (1)

- Module 3 Construction and DesignDocument5 pagesModule 3 Construction and DesignDhimas Surya Negara100% (1)

- Annex 4 Calcualtion DesignDocument124 pagesAnnex 4 Calcualtion Designfaisal100% (1)

- Staircase Beam Design - 2Document28 pagesStaircase Beam Design - 2Sai Sushank67% (3)

- KIMFIS3 Ikatan Dan Gaya InteraksiDocument55 pagesKIMFIS3 Ikatan Dan Gaya InteraksiRagil ayu rendasariNo ratings yet

- A2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidDocument2 pagesA2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidSachitra Wijethunga100% (2)

- Choudhury (1991) - Design Analysis of Corrugated and Flat Plate Solar Aire HeatersDocument13 pagesChoudhury (1991) - Design Analysis of Corrugated and Flat Plate Solar Aire HeatersAlonso1593No ratings yet

- Effect of PbO Percent On Mechanical Prop PDFDocument6 pagesEffect of PbO Percent On Mechanical Prop PDFFocuNo ratings yet

- Gateways Institute of Science & Technology: Configuration of The Following Nuclides. (2pts - Each)Document2 pagesGateways Institute of Science & Technology: Configuration of The Following Nuclides. (2pts - Each)Donna RemitarNo ratings yet

- Topografi + GeodeticDocument11 pagesTopografi + GeodeticShinta Aritonang100% (1)

AMCA 210 - Laboratory Methods of Testing Fans For Ratings

AMCA 210 - Laboratory Methods of Testing Fans For Ratings

Uploaded by

Zander MctrevorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AMCA 210 - Laboratory Methods of Testing Fans For Ratings

AMCA 210 - Laboratory Methods of Testing Fans For Ratings

Uploaded by

Zander MctrevorCopyright:

Available Formats

AIR MOVEMENT AND CONTROL

ASSOCIATION INTERNATIONAL, INC.

The International Authority on Air System Components

Pitot-static tube, and the other leg connected to a static proportions shown in Figure 1 are considered primary

pressure sensor, such as the static tap of the same Pitot- instruments and need not be calibrated provided they are

static tube. The differential pressure between two points maintained in the specified condition.

shall be measured on an indicator, such as a manometer,

with one leg connected to the upstream sensor, such as a 5.2.2.2 Size. The Pitot-static tube shall be of suffi-

static pressure tap, and the other leg connected to the cient size and strength to withstand the pressure forces

downstream sensor, such as a static pressure tap. exerted upon it. The outside diameter of the tube shall

not exceed 1130 of the test duct diameter except that

5.2.1 Manometers and Other Pressure Indicating when the length of the supporting stem exceeds 24 tube

Instruments. Pressure shall be measured on manometers diameters, the stem may be progressively increased

of the liquid column type using inclined or vertical legs beyond this distance. The minimum practical tube

or other instruments which provide a maximum diameter is 2.5 mm (0.10 in.).

uncertainty of 1% of the maximum observed test reading

during the test or I Pa (0.005 in. wg) whichever is larger. 5.2.2.3 Support. Rigid support shall be provided to

See Note I. hold the Pitot-static tube axis parallel to the axis of the

duct within 1 degree and at the head locations specified

5.2.1.] Calibration. Each pressure indicating in- in Figure 3 within I mm (0.05 in.) or 25% of the duct

strument shall be calibrated at both ends of the scale and diameter, whichever is larger.

at least nine equally spaced intermediate points in

accordance with the following: 5.2.3 Static Pressure Taps. The static pressure at

(I) When the pressure to be indicated falls in the a point may be sensed with a pressure tap of the pro-

range of a to 2.5 kPa (0 to lOin. wg), calibration shall be portions shown in Figure 2A. The pressure signal can

against a water-filled hook gauge of the micrometer type then be transmitted to an indicator.

or a precision micromanometer.

(2) When the pressure to be indicated is above 2.5 5.2.3.1 Calibration. Pressure taps having the pro-

kPa (lOin. wg), calibration shall be against a water-filled portions shown in Figure 2A are considered primary

hook gauge of the micrometer type, a precision micro- instruments and need not be calibrated provided they are

manometer, or a water-filled U-tube. maintained in the specified condition. Every precaution

should be taken to ensure that the air velocity does not

5.2.1.2 Averaging. Since the airflow and the pres- influence the pressure measurement.

sures produced by a fan are never strictly steady, the

pressure indicated on any instrument will fluctuate with 5.2.3.2 Averaging. An individual pressure tap is

time. In order to obtain a representative reading, either sensitive only to the pressure in the immediate vicinity of

the instrument must be damped or the readings must be the hole. In order to obtain an average, at least four taps

averaged in a suitable manner. Averaging can sometimes in accordance with Figure 2A shall be manifolded into a

be accomplished mentally, particularly if the fluctuations piezometer ring. The manifold shall have an inside area

are small and regular. Multi-point or continuous record at least four times that of each tap. An example in shown

averaging can be accomplished with instruments and in Appendix G.

analyzers designed for this purpose.

5.2.3.3 Piezometer Rings. Piezometer rings are

5.2.1.3 Corrections. Manometer readings should be specified for upstream and downstream nozzle taps and

corrected for any difference in specific weight of gauge for outlet duct or chamber measurements unless a Pitot

fluid from standard, any difference in gas column bal- traverse is specified. Measuring planes shall be located

ancing effect from standard, or any change in length of as shown in the figure for the appropriate setup.

the graduated scale due to temperature. However,

corrections may be omitted for temperatures between 5.2.4 Total Pressure Tubes. The total pressure in

14 DC and 26°C (58 of and 78° F) , latitudes between 30° an inlet chamber may be sensed with a stationary tube of

and 60 D , and elevations up to 1500 m (5000 it). the proportions shown in Figure 2B. The pressure signal

can then be transmitted to an indicator. The tube shall

5.2.2 Pitot-Static Tubes. [3] [4]. The total pressure face directly into the air flow and the open end shall be

or the static pressure at a point may be sensed with a smooth and free from burrs.

Pitot-static tube of the proportions shown in Figure

I.Either or both of these pressure signals can then be 5.2.4.1 Calibration. Total pressure tubes are

transmitted to a manometer or other indicator. If both considered primary instruments and need not be

pressure signals are transmitted to the same indicator, the calibrated if they are maintained in a condition

differential is considered velocity pressure at the point conforming to this standard.

of the impact opening.

5.2.4.2 Averaging. The total pressure tube is sensi-

5.2.2.1 Calibration. Pitot-static tubes having the tive only to the pressure in the immediate vicinity of the

6 ANSI/AMCA STANDARD 210 ANSI/ASHRAE STANDARD 51

~-----160

A I 80

0.'0

-1/T o

ATU'

A.J 0.40

NOTES:

I. SURFACE FINISH SHALL BE 0.8 micrometer (32 micro-

@

~ in.) OR BETTER. THE STATIC ORIFICES MAY NOT

90° :to.10 W EXCEED I mm (0.04 in.) DIAMETER. THE MINIMUM

PITOT TUBE STEM DIAMETER RECOGNIZED UNDER

THIS STANDARD SHALL BE 2.5 mm (0.10 in.). IN NO

SECTION A-A CASE SHALL THE STEM DIAMETER EXCEED 1/30 OF

THE TEST DUCT DIAMETER.

II.-. 2. HEAD SHALL BE FREE FROM NICKS AND BURRS

I Static Pressure

3. ALL DIMENSIONS SHALL BE WITHIN ±2%.

~ Total Pressure

4. SECTION A-A SHOWS 8 HOLES EQUALLY SPACED

AND FREE FROM BURRS. HOLE DIAMETER SHALL BE

0.13 D, BUT NOT EXCEEDING 1 mm (0.04 in.) HOLE DEPTH

SHALL NOT BE LESS THAN THE HOLE

DIAMETER

PITOT-STATIC TUBE WITH SPHERICAL HEAD

ALL OTHER DIMENSIONS ARE THE SAME

AS FOR SPHERICAL HEAD PITOT-STATIC

X/D V/D X/D VID

TUBES.

0.000 0.500 1.602 0.314

0.237 0.496 1.657 0.295

0.336 0.494 1.698 0.279

i"-- 8D

0.474

0.622

0.487

0.477

1.730

1.762

0.266

0.250

0.741 0.468 1.796 0.231

0.936 0.449 1.830 0.211

1.025 0.436 1.858 0.192

1.134 0.420 1.875 0.176

1.228 0.404 1.888 0.163

1.313 0.388 1.900 0.147

1.390 0.371 1.910 0.131

0.2D

1.442 0.357 1.918 0.118

v 1.506 0.343 1.920 0.109

1.538 0.333 1.921 0.100

1.570 0.323

AL TERNA TE PITOT-ST A TIC TUBE WITH ELLIPSOIDAL HEAD

Figure 1 Pitot-Static Tubes

20 ANSI/AMCA STANDARD 210 ANSI/ASHRAE STANDARD 51

You might also like

- D.P.transmitter Spriano 47B ManualDocument22 pagesD.P.transmitter Spriano 47B ManualBruno100% (1)

- XRFDocument46 pagesXRFFrancisco José Ager Vázquez100% (1)

- Steel Grade SpecificationsDocument9 pagesSteel Grade SpecificationsSiti Rahayu Permita Sari100% (1)

- P 6410 Ip Iom-1Document5 pagesP 6410 Ip Iom-1victorvelasquezchalcoNo ratings yet

- Genesis Series 2" & 3" Steel Meters: Smith Meter PD MeterDocument6 pagesGenesis Series 2" & 3" Steel Meters: Smith Meter PD MeterEnder ZenginobuzNo ratings yet

- Seat Tightness of Pressure Relief Valves Api Standard 527 Fourth Edition November 2014 PDF FreeDocument15 pagesSeat Tightness of Pressure Relief Valves Api Standard 527 Fourth Edition November 2014 PDF FreestudentmgmNo ratings yet

- Control Air Bubble-Tube Level System L100 - IOMDocument6 pagesControl Air Bubble-Tube Level System L100 - IOMjnbxyzNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- ReportDocument14 pagesReportMuhammad AbdullahNo ratings yet

- Anemometro ManualDocument8 pagesAnemometro Manualjose norberto santillan zazuetaNo ratings yet

- Standard Procedure For Calibration of GaugesDocument12 pagesStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyNo ratings yet

- Instruction Manual Oss-B1 Universal Current Meter: Hyquest Solutions Pty LTDDocument22 pagesInstruction Manual Oss-B1 Universal Current Meter: Hyquest Solutions Pty LTDWidia NantaNo ratings yet

- Circuito Medidor PresiónDocument4 pagesCircuito Medidor Presiónfredy8704No ratings yet

- Interview Questions For Instrument EngineersDocument4 pagesInterview Questions For Instrument EngineerszhangyiliNo ratings yet

- Pressure ControlDocument50 pagesPressure ControlKashan AliNo ratings yet

- Wall-Mount Barometers: Operating InstructionsDocument8 pagesWall-Mount Barometers: Operating InstructionssaporobitusNo ratings yet

- Industrial InstrumentationDocument14 pagesIndustrial Instrumentationjayashree sNo ratings yet

- DS HP W T 300 6 Differential en Us 17183Document3 pagesDS HP W T 300 6 Differential en Us 17183behnamatgNo ratings yet

- Fisher Big Joe Type 630 321 ManualDocument11 pagesFisher Big Joe Type 630 321 ManualAbigail Lupe Aguilar YapuraNo ratings yet

- Introduction:-: Training On GET-Instrumentation November 2014 Document Title: Pressure Measurment and Control Code: PIDocument7 pagesIntroduction:-: Training On GET-Instrumentation November 2014 Document Title: Pressure Measurment and Control Code: PISANJAYNo ratings yet

- Transductor FLOWSERVE NT3000Document20 pagesTransductor FLOWSERVE NT3000Xavier EspinozaNo ratings yet

- Chapter 7 Measuring Pressure, Temperature, and HumidityDocument22 pagesChapter 7 Measuring Pressure, Temperature, and HumidityDestroy GameNo ratings yet

- Horiba ABX Micros 60 - Technical Manual 2 PDFDocument205 pagesHoriba ABX Micros 60 - Technical Manual 2 PDFAniela RosalesNo ratings yet

- Pressure Measuring Instruments: Dr. Fahad Rehman CUI, Lahore CampusDocument69 pagesPressure Measuring Instruments: Dr. Fahad Rehman CUI, Lahore CampusAhmed Mustafa100% (1)

- Wise Catalog PDFDocument177 pagesWise Catalog PDFMinhthien NguyenNo ratings yet

- Pressure MeasurementDocument41 pagesPressure MeasurementBlowndudeNo ratings yet

- Module 3Document219 pagesModule 3Sourav PoddarNo ratings yet

- Experiment 5 (Calibration of Pressure Measuring Devices - A4)Document17 pagesExperiment 5 (Calibration of Pressure Measuring Devices - A4)Jamiel Catapang100% (1)

- Local Media8092592512293728315Document8 pagesLocal Media8092592512293728315Bowie S. PascualNo ratings yet

- Experiment No: 2: Study of SRM University Supersonic Wind TunnelDocument16 pagesExperiment No: 2: Study of SRM University Supersonic Wind Tunnelbad guyNo ratings yet

- Vuheat User Manual VHU20 VHU40Document10 pagesVuheat User Manual VHU20 VHU40Bram RossinghNo ratings yet

- Performance Testing Procedure For Centrifugal PumpsDocument5 pagesPerformance Testing Procedure For Centrifugal Pumpssandii123No ratings yet

- Manual CDI 5200Document2 pagesManual CDI 5200Martin CastroNo ratings yet

- Turbine Cascade LaboratoryDocument13 pagesTurbine Cascade LaboratorytexascaaNo ratings yet

- Westinghouse Type CODocument24 pagesWestinghouse Type CORicardo Hernandez100% (1)

- Differential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsDocument8 pagesDifferential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsdhaktodesatyajitNo ratings yet

- Method Statement Pressure TestDocument5 pagesMethod Statement Pressure TestAnand NarayananNo ratings yet

- Q&A PressureDocument3 pagesQ&A PressureZenif Fatkhur RohmanNo ratings yet

- Arcilla, Zoren - Me Lab1 - Exp4 - M4act5Document12 pagesArcilla, Zoren - Me Lab1 - Exp4 - M4act5dracarysNo ratings yet

- Pressure Sensor No. 84370-Series: General DescriptionDocument8 pagesPressure Sensor No. 84370-Series: General DescriptionOghale OkoroNo ratings yet

- Pressure Sensor ModulesDocument3 pagesPressure Sensor Modulesphani22No ratings yet

- Measurement and Instrumentation Lab 8Document9 pagesMeasurement and Instrumentation Lab 8abdulrehmanmani418383No ratings yet

- Turbine Flow Meter User Manual (003) Manual Del MedidorDocument22 pagesTurbine Flow Meter User Manual (003) Manual Del MedidorDAMASO MARTINEZ RODRIGUEZNo ratings yet

- Section 28 - Deadweight TesterDocument22 pagesSection 28 - Deadweight TesterhammamiNo ratings yet

- Thincyl PDFDocument2 pagesThincyl PDFPriyanshuNo ratings yet

- Thincylind PDFDocument2 pagesThincylind PDFPriyanshuNo ratings yet

- 2.venturimeter Theory PDFDocument9 pages2.venturimeter Theory PDFSWETHANo ratings yet

- Elastic Element Pressure Gauges: DescriptionDocument4 pagesElastic Element Pressure Gauges: DescriptionknchnNo ratings yet

- Tutorial: Valve Closure and Transient Pressure Wave (Part 2)Document8 pagesTutorial: Valve Closure and Transient Pressure Wave (Part 2)Anonymous I4CTAwUNo ratings yet

- Pneumatic InstrumentsDocument9 pagesPneumatic InstrumentsHnd FinalNo ratings yet

- 4156342Document19 pages4156342Th GmNo ratings yet

- Bourdon GageDocument5 pagesBourdon GageMark Aldaba ReytiranNo ratings yet

- Pressure & Temperature Gause NotesDocument9 pagesPressure & Temperature Gause NotesNazimNo ratings yet

- CP No.601-Hydraulic Type (Pressure) - RevDocument18 pagesCP No.601-Hydraulic Type (Pressure) - Revamelchan_tiqueNo ratings yet

- MicroCal P100Document2 pagesMicroCal P100Paul ChiriacescuNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Detail E: Issued by Greenlane BiogasDocument4 pagesDetail E: Issued by Greenlane BiogasZander MctrevorNo ratings yet

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Model FGV (B, D) FEV (B, D) : Issued by Greenlane BiogasDocument1 pageModel FGV (B, D) FEV (B, D) : Issued by Greenlane BiogasZander MctrevorNo ratings yet

- Isometric: 2395 Vacuum SystemDocument1 pageIsometric: 2395 Vacuum SystemZander MctrevorNo ratings yet

- IndiceDocument10 pagesIndiceZander MctrevorNo ratings yet

- PrefaceDocument4 pagesPrefaceZander MctrevorNo ratings yet

- Cartas para Mazo Requeridas)Document3 pagesCartas para Mazo Requeridas)Zander MctrevorNo ratings yet

- Statically Indeterminate ProblemsDocument16 pagesStatically Indeterminate ProblemsJake CanlasNo ratings yet

- Product Technical Specification-Polypropylene (POLYTAM)Document1 pageProduct Technical Specification-Polypropylene (POLYTAM)Axel Mahya AvichenaNo ratings yet

- Lec 12 Design of An EAFDocument14 pagesLec 12 Design of An EAFSakunaPappu100% (1)

- IR and Raman in Inorganic Solid No 20Document7 pagesIR and Raman in Inorganic Solid No 20Diego CarvalhoNo ratings yet

- Roi SC 304 Conductors and Insulators of Heat Powerpoint Ver 1Document16 pagesRoi SC 304 Conductors and Insulators of Heat Powerpoint Ver 1Asmaa JoudehNo ratings yet

- Crystallization and Transformation of Pharmaceutical Solid FormsDocument11 pagesCrystallization and Transformation of Pharmaceutical Solid FormsAlex-Mihai CiubaraNo ratings yet

- A Poor Man's Derivation of Scaling Laws For The Kondo ProblemDocument7 pagesA Poor Man's Derivation of Scaling Laws For The Kondo ProblemTianhaoRenNo ratings yet

- PHYSICS Own NotesDocument4 pagesPHYSICS Own NotesMica BernardoNo ratings yet

- III B.tech. (Autonomous)Document62 pagesIII B.tech. (Autonomous)divya dungaNo ratings yet

- 2-ERT252 Distance MeasurementDocument32 pages2-ERT252 Distance Measurementiffatul mahyaNo ratings yet

- 1st Year Chemistry Chapter No. 5-6 - SQs - NOTESPKDocument14 pages1st Year Chemistry Chapter No. 5-6 - SQs - NOTESPKZeeshan ahmedNo ratings yet

- Cambering Steel BeamsDocument2 pagesCambering Steel BeamsFernando PizarroNo ratings yet

- Using Diaminomethanal As An Entrainer For The Separation of Isopropanol + Water MixtureDocument12 pagesUsing Diaminomethanal As An Entrainer For The Separation of Isopropanol + Water MixturenehaNo ratings yet

- The Climatological, Ecological, Solar and Wind Considerations, Day Lighting in Architectural DesignDocument25 pagesThe Climatological, Ecological, Solar and Wind Considerations, Day Lighting in Architectural DesignAr Frank EpeNo ratings yet

- Practice Exam No. 4 2018 PDFDocument43 pagesPractice Exam No. 4 2018 PDFJevan CalaqueNo ratings yet

- Foods As Dispersed Systems. Thermodynamic Aspects of Composition-Property Relationships in Formulated FoodDocument14 pagesFoods As Dispersed Systems. Thermodynamic Aspects of Composition-Property Relationships in Formulated FoodMichael AbdulaiNo ratings yet

- Iwaki Diafragma 1.25 inDocument4 pagesIwaki Diafragma 1.25 inRaul ArizagaNo ratings yet

- Mymensingh Engineering College: An Assignment On Optoelectronics EEE - 809Document8 pagesMymensingh Engineering College: An Assignment On Optoelectronics EEE - 809rafiNo ratings yet

- What Are Turbines ? - Types of Turbines & Their ApplicationsDocument6 pagesWhat Are Turbines ? - Types of Turbines & Their ApplicationsAnonymous m2GmeVnY100% (1)

- Module 3 Construction and DesignDocument5 pagesModule 3 Construction and DesignDhimas Surya Negara100% (1)

- Annex 4 Calcualtion DesignDocument124 pagesAnnex 4 Calcualtion Designfaisal100% (1)

- Staircase Beam Design - 2Document28 pagesStaircase Beam Design - 2Sai Sushank67% (3)

- KIMFIS3 Ikatan Dan Gaya InteraksiDocument55 pagesKIMFIS3 Ikatan Dan Gaya InteraksiRagil ayu rendasariNo ratings yet

- A2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidDocument2 pagesA2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidSachitra Wijethunga100% (2)

- Choudhury (1991) - Design Analysis of Corrugated and Flat Plate Solar Aire HeatersDocument13 pagesChoudhury (1991) - Design Analysis of Corrugated and Flat Plate Solar Aire HeatersAlonso1593No ratings yet

- Effect of PbO Percent On Mechanical Prop PDFDocument6 pagesEffect of PbO Percent On Mechanical Prop PDFFocuNo ratings yet

- Gateways Institute of Science & Technology: Configuration of The Following Nuclides. (2pts - Each)Document2 pagesGateways Institute of Science & Technology: Configuration of The Following Nuclides. (2pts - Each)Donna RemitarNo ratings yet

- Topografi + GeodeticDocument11 pagesTopografi + GeodeticShinta Aritonang100% (1)