Professional Documents

Culture Documents

Weld Time Chart

Weld Time Chart

Uploaded by

Geovanny SanjuanCopyright:

Available Formats

You might also like

- BRE GuideDocument21 pagesBRE GuideAnonymous BAzcBzWu50% (4)

- Ds 1 Vol 5 Bit Inspection Technical StandardDocument100 pagesDs 1 Vol 5 Bit Inspection Technical StandardNgum Christopher kum100% (3)

- Stetter: MCI 70 N Control System Ver 3.0Document2 pagesStetter: MCI 70 N Control System Ver 3.0DEBU SASMALNo ratings yet

- Aisin AW TF-80SCDocument1 pageAisin AW TF-80SCJesus Alejandro Miranda Palacios100% (1)

- BIM and Coordination Flow ChartDocument1 pageBIM and Coordination Flow Chartsyed fazluddinNo ratings yet

- List of Tins ExemptionsDocument74 pagesList of Tins ExemptionsCaesarKamanzi0% (2)

- Case Study IIT Kanpur Green BuildingDocument5 pagesCase Study IIT Kanpur Green BuildingAnand Chavan Projects-Quality75% (8)

- New BortechCatalog PDFDocument16 pagesNew BortechCatalog PDFGeovanny SanjuanNo ratings yet

- EW2025R ECCO 8.5x11Document1 pageEW2025R ECCO 8.5x11Steven Quintero saldarriagaNo ratings yet

- AFL Substation SolutionsDocument12 pagesAFL Substation SolutionsManali PrajapatiNo ratings yet

- P1-250 Torque InstructionsDocument2 pagesP1-250 Torque InstructionsHugo Dennis Mattos EspinozaNo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Telescopic CylinderDocument2 pagesTelescopic CylinderReference mapiyeNo ratings yet

- DEWALT Technical Manual PDFDocument388 pagesDEWALT Technical Manual PDFRonnie1478100% (1)

- Datasheet HikvisionDocument1 pageDatasheet HikvisionJulio PabonNo ratings yet

- Book 1Document6 pagesBook 1chinna_p_123No ratings yet

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 pageNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدNo ratings yet

- Speedtec® 180C Speedtec® 200C Speedtec® 215C: Many Tasks, Many LocationsDocument1 pageSpeedtec® 180C Speedtec® 200C Speedtec® 215C: Many Tasks, Many LocationsCharlie AltaNo ratings yet

- X4029420-302 Outgoing SchneiderDocument34 pagesX4029420-302 Outgoing SchneiderGitaNo ratings yet

- 02assy Instalasi Moving AcdeDocument1 page02assy Instalasi Moving AcdeRudi SantosoNo ratings yet

- Dokumen - Tips - Coiler VB 2200 Ver f1Document2 pagesDokumen - Tips - Coiler VB 2200 Ver f1Tamo NekoNo ratings yet

- 14-A Revised RCP-upperDocument1 page14-A Revised RCP-upperTanisha AroraNo ratings yet

- Clarifier Tank Layout - 250 CMH PDFDocument1 pageClarifier Tank Layout - 250 CMH PDFepe civil1No ratings yet

- LOC DistDocument2 pagesLOC DistGlenn CastroNo ratings yet

- Book 1Document6 pagesBook 1chinna_p_123No ratings yet

- 2205020250-01 DWGDocument1 page2205020250-01 DWGJuan Carlos TolabaNo ratings yet

- Excel Dryer XLERATOR Spec SheetDocument2 pagesExcel Dryer XLERATOR Spec SheetGaby CamatonNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- 2100 S 40532 - 0 PDFDocument1 page2100 S 40532 - 0 PDFstefano.herradaNo ratings yet

- X4029960-301 - Bus Riser+UTX - R01Document15 pagesX4029960-301 - Bus Riser+UTX - R01MUH ILHAM MARZUKINo ratings yet

- Sulphur Dioxide SO: Handling InstructionsDocument1 pageSulphur Dioxide SO: Handling InstructionsimtiyazNo ratings yet

- Teklite Light Mast RRTM Ses 4.5 4Document8 pagesTeklite Light Mast RRTM Ses 4.5 4Nipun SharmaNo ratings yet

- Visakha Duct Profile Industries: Manufacturer of HVAC Products & ServicesDocument6 pagesVisakha Duct Profile Industries: Manufacturer of HVAC Products & ServicesAnz JoyNo ratings yet

- 14 A Revised RCP MiddleDocument1 page14 A Revised RCP MiddleTanisha AroraNo ratings yet

- Buoyant-U8m12-8PoE - Installation DrawingDocument1 pageBuoyant-U8m12-8PoE - Installation DrawingkkNo ratings yet

- Procedure For Underwater Welding ProceduresDocument5 pagesProcedure For Underwater Welding ProceduresRicardoNo ratings yet

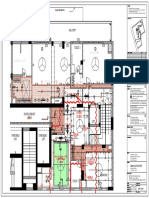

- MH102 - Ground Floor PlanDocument1 pageMH102 - Ground Floor PlankarimNo ratings yet

- Submersible Pumps For Industry and SewerageDocument20 pagesSubmersible Pumps For Industry and SewerageSunil MaharjanNo ratings yet

- D038 Evs Co000 1092 - 00Document1 pageD038 Evs Co000 1092 - 00Mussarat BabasahebNo ratings yet

- TR-8105 Series RTCDocument2 pagesTR-8105 Series RTCBaCresNo ratings yet

- Yib 81 104265 PX 2365 00200 0001 01 Signed SignedDocument1 pageYib 81 104265 PX 2365 00200 0001 01 Signed SignedAhsan Nawax GoGoNo ratings yet

- NHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleDocument11 pagesNHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleMitchell DanielsNo ratings yet

- Vessel Drum Sew DWGDocument2 pagesVessel Drum Sew DWGSANGEETHANo ratings yet

- A (44) SeriesDocument4 pagesA (44) SeriesSsenyonjo EricNo ratings yet

- Metalux WNLED Utility LED Wraparound Spec SheetDocument3 pagesMetalux WNLED Utility LED Wraparound Spec SheetEnrique Medina CalvilloNo ratings yet

- 201 10-nm1 PDFDocument144 pages201 10-nm1 PDFErika MendozaNo ratings yet

- Mold SpecificationDocument1 pageMold SpecificationVictor Villouta LunaNo ratings yet

- 2HH-38A-R4-V2 Line DrawingDocument1 page2HH-38A-R4-V2 Line DrawingDaniel Heitor Silva AssisNo ratings yet

- Regal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDocument1 pageRegal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDANIEL'S SERVICIOS INTEGRALES EN SOLDADURANo ratings yet

- Carrier IdlerDocument22 pagesCarrier Idlerwawan setiawanNo ratings yet

- Solar - 5in 1out ACDB GADocument1 pageSolar - 5in 1out ACDB GAmukeshNo ratings yet

- E12004180 - Light Weight Lub Lower AssyDocument1 pageE12004180 - Light Weight Lub Lower Assysachin kadamNo ratings yet

- MC Cylinder Accessories Clevis Brackets Pins Rod EyesDocument1 pageMC Cylinder Accessories Clevis Brackets Pins Rod EyesCAT CYLINDERNo ratings yet

- Fdocuments - in Engineers Black Book Access Consumablessuttonthe Ultimate Engineers ReferenceDocument1 pageFdocuments - in Engineers Black Book Access Consumablessuttonthe Ultimate Engineers ReferenceLance L. QuistoNo ratings yet

- Bosch Katalog-KonektoruDocument50 pagesBosch Katalog-KonektoruEdison100No ratings yet

- 220kV Thaltej Substation 220 132 33kV, 250MVA ICT-2 HV (BAY-203) 203Document133 pages220kV Thaltej Substation 220 132 33kV, 250MVA ICT-2 HV (BAY-203) 203Ragul VNo ratings yet

- 4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectDocument20 pages4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectрусланNo ratings yet

- Power Transformer No.2 Power Transformer No.1Document1 pagePower Transformer No.2 Power Transformer No.1sartajNo ratings yet

- Steel Racks Steel Racks With Machined Ends: Recommended Mating PinionsDocument1 pageSteel Racks Steel Racks With Machined Ends: Recommended Mating Pinionsindro wibowoNo ratings yet

- FXD Control Outline DrawingDocument1 pageFXD Control Outline DrawingAli MezeliNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Satai TrayDocument3 pagesSatai TrayYudo SpotifyNo ratings yet

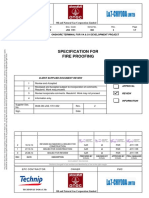

- 0846-ON-JSS-1701-002-Rev 2Document7 pages0846-ON-JSS-1701-002-Rev 2Salman ShaikhNo ratings yet

- Eurasian Cities: New Realities along the Silk RoadFrom EverandEurasian Cities: New Realities along the Silk RoadRating: 3.5 out of 5 stars3.5/5 (1)

- TP - VST69D.PB818 B14501 Schematic DiagramDocument9 pagesTP - VST69D.PB818 B14501 Schematic DiagramGeovanny SanjuanNo ratings yet

- TPD - MS638.PB735 A16047 Schematic DiagramDocument11 pagesTPD - MS638.PB735 A16047 Schematic DiagramGeovanny SanjuanNo ratings yet

- Yeestor-SGM8000C-S27B8G C2924244Document31 pagesYeestor-SGM8000C-S27B8G C2924244Geovanny SanjuanNo ratings yet

- XT172x SUB LayoutDocument2 pagesXT172x SUB LayoutGeovanny SanjuanNo ratings yet

- Kioxia-Thgbmhg7c1lbail C391259Document36 pagesKioxia-Thgbmhg7c1lbail C391259Geovanny SanjuanNo ratings yet

- 16H Motor Grader, Powered by 3406C Engine (SEBP2425 - 112) - DocumentationDocument3 pages16H Motor Grader, Powered by 3406C Engine (SEBP2425 - 112) - DocumentationGeovanny SanjuanNo ratings yet

- 336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFDocument11 pages336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFGeovanny SanjuanNo ratings yet

- Kennametal Universal Milling PDFDocument16 pagesKennametal Universal Milling PDFGeovanny SanjuanNo ratings yet

- Exploit Database SearchSploit Manual PDFDocument8 pagesExploit Database SearchSploit Manual PDFGeovanny SanjuanNo ratings yet

- Widia Is Here.: Kennametal, With OurDocument33 pagesWidia Is Here.: Kennametal, With OurGeovanny SanjuanNo ratings yet

- KitsCatalog Complete PDFDocument80 pagesKitsCatalog Complete PDFGeovanny SanjuanNo ratings yet

- Herramientas KenalmetalDocument10 pagesHerramientas KenalmetalGeovanny SanjuanNo ratings yet

- Tooling Catalog 7022Document20 pagesTooling Catalog 7022Geovanny SanjuanNo ratings yet

- Consumables PDFDocument1 pageConsumables PDFGeovanny SanjuanNo ratings yet

- Reduce Your Heavy Equipment Downtime.: MODEL 4-14Document4 pagesReduce Your Heavy Equipment Downtime.: MODEL 4-14Geovanny SanjuanNo ratings yet

- B02-26 EasyPull Flyer PDFDocument1 pageB02-26 EasyPull Flyer PDFGeovanny SanjuanNo ratings yet

- B03 29 - SurfMine Agg PDFDocument8 pagesB03 29 - SurfMine Agg PDFGeovanny SanjuanNo ratings yet

- New BortechCatalog PDFDocument16 pagesNew BortechCatalog PDFGeovanny SanjuanNo ratings yet

- Catalog 2090Document302 pagesCatalog 2090Geovanny SanjuanNo ratings yet

- Bucket Control Pins and BearingDocument13 pagesBucket Control Pins and BearingGeovanny Sanjuan100% (1)

- Industrial Summer Training Report at Construction Site of CPWD PDFDocument62 pagesIndustrial Summer Training Report at Construction Site of CPWD PDFSUDHANSHU75% (4)

- 14 - DoorsDocument26 pages14 - Doorsmitch1158No ratings yet

- Abutment Design For CausewayDocument7 pagesAbutment Design For CausewayVinay ChandwaniNo ratings yet

- Urban Insert: Lund Cathderal ForumDocument3 pagesUrban Insert: Lund Cathderal Forumsuhani patelNo ratings yet

- PaintDocument6 pagesPaintMegha RajNo ratings yet

- Roofs (1)Document38 pagesRoofs (1)Aster BlackNo ratings yet

- Dry Port As A Link in The Supply ChainDocument28 pagesDry Port As A Link in The Supply Chainsreelekshmi udayanNo ratings yet

- 7110 Brochure VoyagerDocument68 pages7110 Brochure VoyagerDrikDrikonNo ratings yet

- A Modern Underground Storage CellarDocument5 pagesA Modern Underground Storage CellarSoftkiller100% (4)

- Cost of House Construction - PHILCON PRICESDocument3 pagesCost of House Construction - PHILCON PRICESjohn reyesNo ratings yet

- 1319 013Document6 pages1319 013AseriNo ratings yet

- History of Architecture: Influence of Le-Corbusier & Louis I KahnDocument18 pagesHistory of Architecture: Influence of Le-Corbusier & Louis I KahnAthira SureshNo ratings yet

- Concrete Injected ColumnsDocument26 pagesConcrete Injected ColumnsfaisaltmNo ratings yet

- BS En.1996.1.1.2005Document125 pagesBS En.1996.1.1.2005Habib Ur Rahman100% (1)

- Effective Length of Cantilevers: SCI Publication P360Document25 pagesEffective Length of Cantilevers: SCI Publication P360Mahmoud Abdallah MohamedNo ratings yet

- BS EN10025 Structural Steel Plate and Equivalent ASTM: NavigationDocument8 pagesBS EN10025 Structural Steel Plate and Equivalent ASTM: NavigationErikas AbepaNo ratings yet

- JR Rubber IndustriesDocument14 pagesJR Rubber Industriesnikhil antonyNo ratings yet

- Continuity in RC Beams and FramesDocument80 pagesContinuity in RC Beams and Frameszeeshan68No ratings yet

- Bored PilingDocument23 pagesBored PilingRatha MenNo ratings yet

- House's Building Materials AssignmentDocument24 pagesHouse's Building Materials AssignmentUhGuanHongNo ratings yet

- Long Span Trusses - SalahuddinDocument11 pagesLong Span Trusses - SalahuddinSalahuddin ShaikhNo ratings yet

- Structural Design of An Ultra High-Rise Building Using Concrete Filled Tubular Column With Ultra High Strength MaterialsDocument10 pagesStructural Design of An Ultra High-Rise Building Using Concrete Filled Tubular Column With Ultra High Strength MaterialsSaurabh PednekarNo ratings yet

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- S.No. Questions AnswerDocument248 pagesS.No. Questions AnswerSyed Munawar Ali100% (2)

- Research On Sawdust and Coconut Peat As Particle BoardDocument11 pagesResearch On Sawdust and Coconut Peat As Particle BoardAecee Quibod OlivarNo ratings yet

Weld Time Chart

Weld Time Chart

Uploaded by

Geovanny SanjuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Time Chart

Weld Time Chart

Uploaded by

Geovanny SanjuanCopyright:

Available Formats

Covers 5/20/04 10:29 AM Page 2

CO ELD

W

NS

UM IME

Automated BoreWelders – BORTECH Makes BoreWelding

AB C

T

LE HA

S RT

Easier

&

Designed for speed, efficiency and

productivity Factory Trained Representatives WeldCalc

Bortech BoreWelders are sold by a world-wide network of With every machine purchased, Bortech provides a soft-

The Bortech BoreWelder was created in 1982, after 600 hours of factory trained representatives. These representatives can ware program called “WeldCalc.” WeldCalc can be used to

development and testing by the operator of a machine shop that provide on-site demonstrations, model selection assis- help calculate build-up times and weights of welding wire

offered heavy equipment repair for local construction contractors. tance, post-sale training and technical support. To locate for bores and faces. It is not designed to figure settings

The BoreWelder was the answer to the obvious need for a machine your nearest representative, visit www.bortech.com or call for weld parameters, but will estimate the thickness of

to rebuild worn holes on large parts. 1-888-265-1202 the buildup and how long it will take to do a job.

Bortech BoreWelders produce a weld overlay on the worn section Boring Bar Interface #000 Torch for Small Diameters.

of the workpiece. The workpiece can then be machined back to its Bortech's BoreWelders are designed to work well with all To weld diameters of less than .875", Bortech provides

original size. leading boring bars. Bortech’s representatives can help the #000 torch, a retrofit to increase the rotation speed

Automated BoreWelders are superior to hand-welding. They are you select a new boring bar, or assist you in interfacing of the BoreWelder, and the Push/Pull Feed System. We

faster, provide smoother welds, and allow you to access hard-to- your BoreWelder to your existing boring bar. recommend welding parameters of 75 amps at 15 volts

reach or small bores. Enhance Feeding of Low Column Strength Wire with .023 wire.

BoreWelders also provide a superior repair to inserting bushings or If you are welding with low column strength wire such as In addition, the #000 torch can be modified for plug

sleeves. They do not distort nor weaken the base metal and pro- stainless steel, Bortech recommends the “Push-Pull Wire welding applications.

vide a longer lasting solution. Feeder” option.

Hand Welding Attachments

Bortech’s BoreWelders are portable and can be used in both field

To mount your BoreWelder to the workpiece, you must

and shop repairs. The BoreWelder mounts to the workpiece while

tack weld Bortech’s adjustable base or your boring bar’s

the part remains stationary.

alignment bearings to the workpiece. Bortech offers sev-

Bortech BoreWelders can be used with your existing GMAW power eral options so you can use your BoreWelder to

supply – they are compatible with all 300 Amp, Constant Voltage

(CV) power supplies that have remote voltage and contactor con-

hand weld: Weld Time Chart

• Mini MIG guns

trol capability. • Stingers Length of Bore

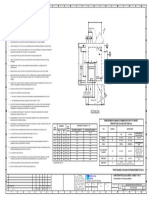

Bortech BoreWelders interface with all leading boring bars. One 1" 2" 3" 4" 6" 10"

quick set-up allows you to align either the BoreWelder or the bor- 1 1.3 2.5 3.8 5.0 7.5 12.6

ing bar. You can even weld one bore while you machine another.

2 2.5 5.0 7.5 10.0 15.1 25.1

Bortech also offers BoreCladders, which can be used to clad round 3 3.8 7.5 11.3 15.1 22.6 37.7

surfaces, such as nozzles for pressure vessels and pumps. When

Bore Diameter

the nozzles require protection against caustic substances or ero- 4 5.0 10.0 15.1 20.1 30.1 50.2

sion from steam or abrasive slurry, they can be built out of mild 5 6.3 12.6 18.8 25.1 37.7 62.8

steel and then coated (or clad) with stainless steel, nickel alloys, 6 7.5 15.1 22.6 30.1 45.2 75.4

or other exotic metals. BoreCladders produce void-free welds.

8 10.0 20.1 30.1 40.2 60.3 100.5

BoreWelder highlights include:

10 12.6 25.1 37.7 50.2 75.4 125.6

• ID’s from 3⁄4" to 12' diameters

• Weld ID’s, OD’s, faces or conical surfaces. 12 15.1 30.1 45.2 60.3 90.4 150.7

• GMAW process with short arc or spray transfer modes 16 20.1 40.2 60.3 80.4 120.6 201.0

• Weld in all positions – horizontal, vertical, or inverted

20 25.1 50.2 75.4 100.5 150.7 251.2

• Weld with all base and filler metals

• 50-75% time reduction vs. hand welding Weld Times (in minutes)All times are calculated

with rotation speed of 20"/min and step size of .125"

You might also like

- BRE GuideDocument21 pagesBRE GuideAnonymous BAzcBzWu50% (4)

- Ds 1 Vol 5 Bit Inspection Technical StandardDocument100 pagesDs 1 Vol 5 Bit Inspection Technical StandardNgum Christopher kum100% (3)

- Stetter: MCI 70 N Control System Ver 3.0Document2 pagesStetter: MCI 70 N Control System Ver 3.0DEBU SASMALNo ratings yet

- Aisin AW TF-80SCDocument1 pageAisin AW TF-80SCJesus Alejandro Miranda Palacios100% (1)

- BIM and Coordination Flow ChartDocument1 pageBIM and Coordination Flow Chartsyed fazluddinNo ratings yet

- List of Tins ExemptionsDocument74 pagesList of Tins ExemptionsCaesarKamanzi0% (2)

- Case Study IIT Kanpur Green BuildingDocument5 pagesCase Study IIT Kanpur Green BuildingAnand Chavan Projects-Quality75% (8)

- New BortechCatalog PDFDocument16 pagesNew BortechCatalog PDFGeovanny SanjuanNo ratings yet

- EW2025R ECCO 8.5x11Document1 pageEW2025R ECCO 8.5x11Steven Quintero saldarriagaNo ratings yet

- AFL Substation SolutionsDocument12 pagesAFL Substation SolutionsManali PrajapatiNo ratings yet

- P1-250 Torque InstructionsDocument2 pagesP1-250 Torque InstructionsHugo Dennis Mattos EspinozaNo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Telescopic CylinderDocument2 pagesTelescopic CylinderReference mapiyeNo ratings yet

- DEWALT Technical Manual PDFDocument388 pagesDEWALT Technical Manual PDFRonnie1478100% (1)

- Datasheet HikvisionDocument1 pageDatasheet HikvisionJulio PabonNo ratings yet

- Book 1Document6 pagesBook 1chinna_p_123No ratings yet

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 pageNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدNo ratings yet

- Speedtec® 180C Speedtec® 200C Speedtec® 215C: Many Tasks, Many LocationsDocument1 pageSpeedtec® 180C Speedtec® 200C Speedtec® 215C: Many Tasks, Many LocationsCharlie AltaNo ratings yet

- X4029420-302 Outgoing SchneiderDocument34 pagesX4029420-302 Outgoing SchneiderGitaNo ratings yet

- 02assy Instalasi Moving AcdeDocument1 page02assy Instalasi Moving AcdeRudi SantosoNo ratings yet

- Dokumen - Tips - Coiler VB 2200 Ver f1Document2 pagesDokumen - Tips - Coiler VB 2200 Ver f1Tamo NekoNo ratings yet

- 14-A Revised RCP-upperDocument1 page14-A Revised RCP-upperTanisha AroraNo ratings yet

- Clarifier Tank Layout - 250 CMH PDFDocument1 pageClarifier Tank Layout - 250 CMH PDFepe civil1No ratings yet

- LOC DistDocument2 pagesLOC DistGlenn CastroNo ratings yet

- Book 1Document6 pagesBook 1chinna_p_123No ratings yet

- 2205020250-01 DWGDocument1 page2205020250-01 DWGJuan Carlos TolabaNo ratings yet

- Excel Dryer XLERATOR Spec SheetDocument2 pagesExcel Dryer XLERATOR Spec SheetGaby CamatonNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- 2100 S 40532 - 0 PDFDocument1 page2100 S 40532 - 0 PDFstefano.herradaNo ratings yet

- X4029960-301 - Bus Riser+UTX - R01Document15 pagesX4029960-301 - Bus Riser+UTX - R01MUH ILHAM MARZUKINo ratings yet

- Sulphur Dioxide SO: Handling InstructionsDocument1 pageSulphur Dioxide SO: Handling InstructionsimtiyazNo ratings yet

- Teklite Light Mast RRTM Ses 4.5 4Document8 pagesTeklite Light Mast RRTM Ses 4.5 4Nipun SharmaNo ratings yet

- Visakha Duct Profile Industries: Manufacturer of HVAC Products & ServicesDocument6 pagesVisakha Duct Profile Industries: Manufacturer of HVAC Products & ServicesAnz JoyNo ratings yet

- 14 A Revised RCP MiddleDocument1 page14 A Revised RCP MiddleTanisha AroraNo ratings yet

- Buoyant-U8m12-8PoE - Installation DrawingDocument1 pageBuoyant-U8m12-8PoE - Installation DrawingkkNo ratings yet

- Procedure For Underwater Welding ProceduresDocument5 pagesProcedure For Underwater Welding ProceduresRicardoNo ratings yet

- MH102 - Ground Floor PlanDocument1 pageMH102 - Ground Floor PlankarimNo ratings yet

- Submersible Pumps For Industry and SewerageDocument20 pagesSubmersible Pumps For Industry and SewerageSunil MaharjanNo ratings yet

- D038 Evs Co000 1092 - 00Document1 pageD038 Evs Co000 1092 - 00Mussarat BabasahebNo ratings yet

- TR-8105 Series RTCDocument2 pagesTR-8105 Series RTCBaCresNo ratings yet

- Yib 81 104265 PX 2365 00200 0001 01 Signed SignedDocument1 pageYib 81 104265 PX 2365 00200 0001 01 Signed SignedAhsan Nawax GoGoNo ratings yet

- NHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleDocument11 pagesNHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleMitchell DanielsNo ratings yet

- Vessel Drum Sew DWGDocument2 pagesVessel Drum Sew DWGSANGEETHANo ratings yet

- A (44) SeriesDocument4 pagesA (44) SeriesSsenyonjo EricNo ratings yet

- Metalux WNLED Utility LED Wraparound Spec SheetDocument3 pagesMetalux WNLED Utility LED Wraparound Spec SheetEnrique Medina CalvilloNo ratings yet

- 201 10-nm1 PDFDocument144 pages201 10-nm1 PDFErika MendozaNo ratings yet

- Mold SpecificationDocument1 pageMold SpecificationVictor Villouta LunaNo ratings yet

- 2HH-38A-R4-V2 Line DrawingDocument1 page2HH-38A-R4-V2 Line DrawingDaniel Heitor Silva AssisNo ratings yet

- Regal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDocument1 pageRegal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDANIEL'S SERVICIOS INTEGRALES EN SOLDADURANo ratings yet

- Carrier IdlerDocument22 pagesCarrier Idlerwawan setiawanNo ratings yet

- Solar - 5in 1out ACDB GADocument1 pageSolar - 5in 1out ACDB GAmukeshNo ratings yet

- E12004180 - Light Weight Lub Lower AssyDocument1 pageE12004180 - Light Weight Lub Lower Assysachin kadamNo ratings yet

- MC Cylinder Accessories Clevis Brackets Pins Rod EyesDocument1 pageMC Cylinder Accessories Clevis Brackets Pins Rod EyesCAT CYLINDERNo ratings yet

- Fdocuments - in Engineers Black Book Access Consumablessuttonthe Ultimate Engineers ReferenceDocument1 pageFdocuments - in Engineers Black Book Access Consumablessuttonthe Ultimate Engineers ReferenceLance L. QuistoNo ratings yet

- Bosch Katalog-KonektoruDocument50 pagesBosch Katalog-KonektoruEdison100No ratings yet

- 220kV Thaltej Substation 220 132 33kV, 250MVA ICT-2 HV (BAY-203) 203Document133 pages220kV Thaltej Substation 220 132 33kV, 250MVA ICT-2 HV (BAY-203) 203Ragul VNo ratings yet

- 4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectDocument20 pages4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectрусланNo ratings yet

- Power Transformer No.2 Power Transformer No.1Document1 pagePower Transformer No.2 Power Transformer No.1sartajNo ratings yet

- Steel Racks Steel Racks With Machined Ends: Recommended Mating PinionsDocument1 pageSteel Racks Steel Racks With Machined Ends: Recommended Mating Pinionsindro wibowoNo ratings yet

- FXD Control Outline DrawingDocument1 pageFXD Control Outline DrawingAli MezeliNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Satai TrayDocument3 pagesSatai TrayYudo SpotifyNo ratings yet

- 0846-ON-JSS-1701-002-Rev 2Document7 pages0846-ON-JSS-1701-002-Rev 2Salman ShaikhNo ratings yet

- Eurasian Cities: New Realities along the Silk RoadFrom EverandEurasian Cities: New Realities along the Silk RoadRating: 3.5 out of 5 stars3.5/5 (1)

- TP - VST69D.PB818 B14501 Schematic DiagramDocument9 pagesTP - VST69D.PB818 B14501 Schematic DiagramGeovanny SanjuanNo ratings yet

- TPD - MS638.PB735 A16047 Schematic DiagramDocument11 pagesTPD - MS638.PB735 A16047 Schematic DiagramGeovanny SanjuanNo ratings yet

- Yeestor-SGM8000C-S27B8G C2924244Document31 pagesYeestor-SGM8000C-S27B8G C2924244Geovanny SanjuanNo ratings yet

- XT172x SUB LayoutDocument2 pagesXT172x SUB LayoutGeovanny SanjuanNo ratings yet

- Kioxia-Thgbmhg7c1lbail C391259Document36 pagesKioxia-Thgbmhg7c1lbail C391259Geovanny SanjuanNo ratings yet

- 16H Motor Grader, Powered by 3406C Engine (SEBP2425 - 112) - DocumentationDocument3 pages16H Motor Grader, Powered by 3406C Engine (SEBP2425 - 112) - DocumentationGeovanny SanjuanNo ratings yet

- 336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFDocument11 pages336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFGeovanny SanjuanNo ratings yet

- Kennametal Universal Milling PDFDocument16 pagesKennametal Universal Milling PDFGeovanny SanjuanNo ratings yet

- Exploit Database SearchSploit Manual PDFDocument8 pagesExploit Database SearchSploit Manual PDFGeovanny SanjuanNo ratings yet

- Widia Is Here.: Kennametal, With OurDocument33 pagesWidia Is Here.: Kennametal, With OurGeovanny SanjuanNo ratings yet

- KitsCatalog Complete PDFDocument80 pagesKitsCatalog Complete PDFGeovanny SanjuanNo ratings yet

- Herramientas KenalmetalDocument10 pagesHerramientas KenalmetalGeovanny SanjuanNo ratings yet

- Tooling Catalog 7022Document20 pagesTooling Catalog 7022Geovanny SanjuanNo ratings yet

- Consumables PDFDocument1 pageConsumables PDFGeovanny SanjuanNo ratings yet

- Reduce Your Heavy Equipment Downtime.: MODEL 4-14Document4 pagesReduce Your Heavy Equipment Downtime.: MODEL 4-14Geovanny SanjuanNo ratings yet

- B02-26 EasyPull Flyer PDFDocument1 pageB02-26 EasyPull Flyer PDFGeovanny SanjuanNo ratings yet

- B03 29 - SurfMine Agg PDFDocument8 pagesB03 29 - SurfMine Agg PDFGeovanny SanjuanNo ratings yet

- New BortechCatalog PDFDocument16 pagesNew BortechCatalog PDFGeovanny SanjuanNo ratings yet

- Catalog 2090Document302 pagesCatalog 2090Geovanny SanjuanNo ratings yet

- Bucket Control Pins and BearingDocument13 pagesBucket Control Pins and BearingGeovanny Sanjuan100% (1)

- Industrial Summer Training Report at Construction Site of CPWD PDFDocument62 pagesIndustrial Summer Training Report at Construction Site of CPWD PDFSUDHANSHU75% (4)

- 14 - DoorsDocument26 pages14 - Doorsmitch1158No ratings yet

- Abutment Design For CausewayDocument7 pagesAbutment Design For CausewayVinay ChandwaniNo ratings yet

- Urban Insert: Lund Cathderal ForumDocument3 pagesUrban Insert: Lund Cathderal Forumsuhani patelNo ratings yet

- PaintDocument6 pagesPaintMegha RajNo ratings yet

- Roofs (1)Document38 pagesRoofs (1)Aster BlackNo ratings yet

- Dry Port As A Link in The Supply ChainDocument28 pagesDry Port As A Link in The Supply Chainsreelekshmi udayanNo ratings yet

- 7110 Brochure VoyagerDocument68 pages7110 Brochure VoyagerDrikDrikonNo ratings yet

- A Modern Underground Storage CellarDocument5 pagesA Modern Underground Storage CellarSoftkiller100% (4)

- Cost of House Construction - PHILCON PRICESDocument3 pagesCost of House Construction - PHILCON PRICESjohn reyesNo ratings yet

- 1319 013Document6 pages1319 013AseriNo ratings yet

- History of Architecture: Influence of Le-Corbusier & Louis I KahnDocument18 pagesHistory of Architecture: Influence of Le-Corbusier & Louis I KahnAthira SureshNo ratings yet

- Concrete Injected ColumnsDocument26 pagesConcrete Injected ColumnsfaisaltmNo ratings yet

- BS En.1996.1.1.2005Document125 pagesBS En.1996.1.1.2005Habib Ur Rahman100% (1)

- Effective Length of Cantilevers: SCI Publication P360Document25 pagesEffective Length of Cantilevers: SCI Publication P360Mahmoud Abdallah MohamedNo ratings yet

- BS EN10025 Structural Steel Plate and Equivalent ASTM: NavigationDocument8 pagesBS EN10025 Structural Steel Plate and Equivalent ASTM: NavigationErikas AbepaNo ratings yet

- JR Rubber IndustriesDocument14 pagesJR Rubber Industriesnikhil antonyNo ratings yet

- Continuity in RC Beams and FramesDocument80 pagesContinuity in RC Beams and Frameszeeshan68No ratings yet

- Bored PilingDocument23 pagesBored PilingRatha MenNo ratings yet

- House's Building Materials AssignmentDocument24 pagesHouse's Building Materials AssignmentUhGuanHongNo ratings yet

- Long Span Trusses - SalahuddinDocument11 pagesLong Span Trusses - SalahuddinSalahuddin ShaikhNo ratings yet

- Structural Design of An Ultra High-Rise Building Using Concrete Filled Tubular Column With Ultra High Strength MaterialsDocument10 pagesStructural Design of An Ultra High-Rise Building Using Concrete Filled Tubular Column With Ultra High Strength MaterialsSaurabh PednekarNo ratings yet

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- S.No. Questions AnswerDocument248 pagesS.No. Questions AnswerSyed Munawar Ali100% (2)

- Research On Sawdust and Coconut Peat As Particle BoardDocument11 pagesResearch On Sawdust and Coconut Peat As Particle BoardAecee Quibod OlivarNo ratings yet