Professional Documents

Culture Documents

Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessment

Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessment

Uploaded by

jmz mtzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessment

Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessment

Uploaded by

jmz mtzCopyright:

Available Formats

Document Responsibility: Pumps, Seals and Mixers SABP-G-017

Issue Date: 10 April 2010

Next Planned Update: TBD Equipment Criticality Assessment

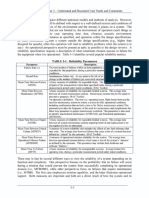

Failure Mode Effects and Criticality Analysis (FMECA): quantitative

method of reliability analysis which involves a fault modes and effects analysis

together with a consideration of the probability of failure modes, their

consequence and ranking of effects and the seriousness of the faults.

Failure Mode: the physical, chemical or other processes, which lead or have

led to the failure (generally used for equipment other than static).

Failure Rate: the number of failures of an equipment, system or component at

a given time interval.

Failure: any event resulting in a loss or degradation of the function of the

equipment being analyzed.

Fault: the state of equipment characterized by inability to perform a required

function, excluding the inability during preventive maintenance or other planned

actions, or due to lack of external resources.

Infant Mortality: term used when new or overhauled equipment breaks down

shortly after startup. It corresponds to the first part of failure bathtub curve

where the failure rate is decreasing, known also as early failures.

Layer Of Protection Analysis (LOPA): semi-quantitative methodology that

can be used to identify safeguards that meet the Independent Protection Layer

(IPL) criteria established by Center for Chemical Process Safety (CCPS1) in

1993.

Lost Production Opportunities: an estimate of the damage inflicted on the

business in terms of quantity and quality of finished products lost due to

unplanned production shutdowns, slowdowns and upsets.

Maintenance Management: all management activities that determine the

maintenance objectives, strategies, enablers, work processes, KPIs, roles and

responsibilities and implement them by means such as maintenance planning,

maintenance control and supervision, improvement of methods in the

organization including economical aspects.

Maintenance: combination of all technical, administrative and managerial

actions, including supervision actions, during the lifecycle of an equipment

intended to retain it in, or restore it to, a state in which it can perform the

required function.

Mean Time between Failures (MTBF): the average (mean) number of life

units (duty cycles, time cycles, distance, events, etc.) during which all

component of an equipment or system perform the required function within their

specified operating envelops, under specified conditions.

Page 5 of 20

You might also like

- Race de Priest - Swipe-Seduction - 05142015-Opt PDFDocument67 pagesRace de Priest - Swipe-Seduction - 05142015-Opt PDFKoleksi Buku Bekas50% (2)

- Fabrication CADmep 2015 Fundamentals Courseware - Sample PDFDocument43 pagesFabrication CADmep 2015 Fundamentals Courseware - Sample PDFPantha Mallick67% (3)

- Maintenance EngineeringDocument67 pagesMaintenance EngineeringV.Muthu KumarNo ratings yet

- TOP 101 Growth Hacks 2 - by Aladdin HappyDocument139 pagesTOP 101 Growth Hacks 2 - by Aladdin HappyDylan Rivera Floyd100% (1)

- Design Quality Engineering Terms 1677951026Document9 pagesDesign Quality Engineering Terms 1677951026carvalho.uk.engNo ratings yet

- Sabp-G-017 13Document1 pageSabp-G-017 13jmz mtzNo ratings yet

- Glossary: Andon (J) Availability Failure Modes and Effects Analysis (FMEA)Document3 pagesGlossary: Andon (J) Availability Failure Modes and Effects Analysis (FMEA)Juan Camilo MolanoNo ratings yet

- Glossary: The Following Is A List of Terms Used in This Book, Along With Their Meaning or Definition As Applied HereinDocument8 pagesGlossary: The Following Is A List of Terms Used in This Book, Along With Their Meaning or Definition As Applied HereinArturo Tipacti QuijanoNo ratings yet

- RCM - Parte 3Document2 pagesRCM - Parte 3bruno gomesNo ratings yet

- Met82 Maintenanceandsafetyengineering (3 0 0 3) Unit-IDocument51 pagesMet82 Maintenanceandsafetyengineering (3 0 0 3) Unit-IM.ThirunavukkarasuNo ratings yet

- Maintenance ManagementDocument20 pagesMaintenance ManagementRiya GuptaNo ratings yet

- Unit -1 soft-reliDocument14 pagesUnit -1 soft-relileeveshk12No ratings yet

- TABLE 3-1: Reliability Parameters: Parameter DescriptionDocument1 pageTABLE 3-1: Reliability Parameters: Parameter Descriptiontony SalvatoriNo ratings yet

- Maintenance and Reliability Glossaries 1698390516Document5 pagesMaintenance and Reliability Glossaries 1698390516suman_tkgtppNo ratings yet

- Development of Maintenance Programs: by Capt. Furqan HussainDocument17 pagesDevelopment of Maintenance Programs: by Capt. Furqan HussainasadNo ratings yet

- Failure Mode and Effect AnalysisDocument21 pagesFailure Mode and Effect AnalysisAnkita SinhaNo ratings yet

- Affiliated To APJ Abdul Kalam Technological UniversityDocument19 pagesAffiliated To APJ Abdul Kalam Technological UniversitySHANASHIRIN CNo ratings yet

- 1&2 - Chapter 1 Introduction Maintenance and Chapter 2 Theories of DamagesDocument39 pages1&2 - Chapter 1 Introduction Maintenance and Chapter 2 Theories of Damageskeno teshomeNo ratings yet

- Definitions and Nomenclature: Acceptable RiskDocument3 pagesDefinitions and Nomenclature: Acceptable RiskFebbyNo ratings yet

- EH SISchemicalWP20Document6 pagesEH SISchemicalWP20Gabriel AcuñaNo ratings yet

- MM 25th AugustDocument12 pagesMM 25th AugustAbhishek ChaubeyNo ratings yet

- Maintenance: Maintenance Functions Are Referred To As Maintenance, Repair and OperationsDocument2 pagesMaintenance: Maintenance Functions Are Referred To As Maintenance, Repair and OperationsLloyd AlmonteNo ratings yet

- Maintenance ManagementDocument27 pagesMaintenance ManagementFurqan Shabbir100% (1)

- 2-1 RCMDocument25 pages2-1 RCMDwi Mulyanti DwimulyantishopNo ratings yet

- Maintenance QualificationDocument5 pagesMaintenance QualificationqlfangNo ratings yet

- E8 Mechanical IntegrityDocument26 pagesE8 Mechanical IntegrityEl Sayed Saad ShehataNo ratings yet

- Group 1Document35 pagesGroup 1Princess Mae DesaculaNo ratings yet

- Appendix A: Engineering Standards Manual ISD 341-2Document29 pagesAppendix A: Engineering Standards Manual ISD 341-2amijetomar08No ratings yet

- Failure Defense PlanningDocument5 pagesFailure Defense PlanningManel Montesinos100% (1)

- Maintenance TypesDocument4 pagesMaintenance TypesMotasem AbushanabNo ratings yet

- 3-Industrial ACTSelecting EquipmentDocument16 pages3-Industrial ACTSelecting EquipmentMesafint kassieNo ratings yet

- Chapter-1 IntroductionDocument21 pagesChapter-1 Introductiondawit solomonNo ratings yet

- Technical Integrity Engineering Is A Term Applied To The Engineering Disciplines Associated With TheDocument5 pagesTechnical Integrity Engineering Is A Term Applied To The Engineering Disciplines Associated With TheVenkatesh PethurajNo ratings yet

- Nasa Systems Engineering Handbook 0-201-297Document97 pagesNasa Systems Engineering Handbook 0-201-297nazmiNo ratings yet

- Introduction To Maintenance Task AnalysisDocument4 pagesIntroduction To Maintenance Task AnalysisFreddy Roa100% (1)

- Chapter 2Document29 pagesChapter 2searetekeste20102014No ratings yet

- From Reactive Maintenance ToDocument8 pagesFrom Reactive Maintenance ToArdelean PaulNo ratings yet

- Track 1 - Cesar Malpica - PaperDocument10 pagesTrack 1 - Cesar Malpica - PaperfredyNo ratings yet

- Reliability Centred MaintenanceDocument8 pagesReliability Centred MaintenancemiriamanastasioNo ratings yet

- CH 01 IntrouctionDocument49 pagesCH 01 Introuctionlayike alemayehuNo ratings yet

- FMEA GuidelinesDocument9 pagesFMEA Guidelines80ALLA86iNo ratings yet

- Reliability-Is Probability That The System Will Perform A Function Without A Failure For A Specific TimeDocument5 pagesReliability-Is Probability That The System Will Perform A Function Without A Failure For A Specific TimeLungelo HlongwaneNo ratings yet

- Chapter 2 Development of Maintenance Programs2 1670987397286Document67 pagesChapter 2 Development of Maintenance Programs2 1670987397286RohitMeenaNo ratings yet

- StrategiesDocument6 pagesStrategiesLungelo HlongwaneNo ratings yet

- Reliability-Centered Maintenance Methodology and ADocument12 pagesReliability-Centered Maintenance Methodology and AFa ResNo ratings yet

- Technical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Document14 pagesTechnical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Elisony EdwardNo ratings yet

- CH 01, Introduction To MaintenanceDocument50 pagesCH 01, Introduction To MaintenanceSurafel AlemuNo ratings yet

- M M Sanoop: Prepared ByDocument36 pagesM M Sanoop: Prepared Byvappichi00No ratings yet

- Preventive MaintenanaceDocument19 pagesPreventive MaintenanaceMohammed NerissaNo ratings yet

- Machine Condition Monitoring and Fault DiagnosticsDocument28 pagesMachine Condition Monitoring and Fault Diagnosticsزيد فؤاد اليافعيNo ratings yet

- Sistemas AutomtizadosDocument9 pagesSistemas AutomtizadosFernando AdroguéNo ratings yet

- FMEA CostDocument6 pagesFMEA CostNhan HuynhNo ratings yet

- ISTQB Foundation AnswersDocument95 pagesISTQB Foundation AnswersLost FilesNo ratings yet

- (Code: ITM315) : Software Quality ManagementDocument24 pages(Code: ITM315) : Software Quality ManagementdineshgomberNo ratings yet

- Appendix C - Glossary - Note Some of The Definitions I - 2006 - Practical MacDocument10 pagesAppendix C - Glossary - Note Some of The Definitions I - 2006 - Practical MacAliirshad10No ratings yet

- Topic 1 Basics of MaintenanceDocument7 pagesTopic 1 Basics of Maintenancedsjghd78No ratings yet

- How Does Maintenance Management Loop Work?Document10 pagesHow Does Maintenance Management Loop Work?Fred VoNo ratings yet

- دراسة 1Document28 pagesدراسة 1SALIM HUSAYN AMBEEYAH ALOUKILINo ratings yet

- Measure of LogisticDocument34 pagesMeasure of LogisticshafiqNo ratings yet

- PaeoDocument14 pagesPaeomrms092004No ratings yet

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- Municipal Solid Waste Management Practice (A) : Knowledge Co-Creation Program (Group and Region Focus)Document33 pagesMunicipal Solid Waste Management Practice (A) : Knowledge Co-Creation Program (Group and Region Focus)Nejema PerualilaNo ratings yet

- Flame WarriorsDocument5 pagesFlame WarriorsBlack SkyNo ratings yet

- Cmos Metal GateDocument56 pagesCmos Metal GateSubin AlexNo ratings yet

- 2CSE302: Data Structures (4 0 4 6) : Learning OutcomesDocument2 pages2CSE302: Data Structures (4 0 4 6) : Learning OutcomesAkashdeep BhattacharjeeNo ratings yet

- Formatting Guides For ReportDocument8 pagesFormatting Guides For ReportJaymee Amor CulanagNo ratings yet

- Sarah Hollister ResumeDocument1 pageSarah Hollister Resumeapi-351760386No ratings yet

- M Sher - ResumeDocument2 pagesM Sher - Resumem sherNo ratings yet

- Lean Maintenance ManagementDocument42 pagesLean Maintenance ManagementJoaquim ReisNo ratings yet

- Ubuntu For Raspberry PiDocument4 pagesUbuntu For Raspberry PisandeepNo ratings yet

- Roan MDocument35 pagesRoan MJollibar ArcalasNo ratings yet

- Exclusive-OR Gate Tutorial With Ex-OR Gate Truth TableDocument10 pagesExclusive-OR Gate Tutorial With Ex-OR Gate Truth TableGowri ShankarNo ratings yet

- Supply Chain Management: Executive EducationDocument6 pagesSupply Chain Management: Executive EducationdegapramukaNo ratings yet

- Google Tulip: Presenting by GuideDocument10 pagesGoogle Tulip: Presenting by GuideAparna GattimiNo ratings yet

- W1 W2 W6 W3 W5 W4: Schedule of WindowsDocument1 pageW1 W2 W6 W3 W5 W4: Schedule of WindowsMiguel GarciaNo ratings yet

- RRC EstablishmentDocument4 pagesRRC Establishmentevil_dragonNo ratings yet

- Ɜ Ɫɪɟɞɟ LINUXDocument17 pagesꞫ Ɫɪɟɞɟ LINUXAlexander PoghosyanNo ratings yet

- Anti-Phishing System Using LSTM and CNNDocument6 pagesAnti-Phishing System Using LSTM and CNNrahul dandonaNo ratings yet

- CSS Lesson 6 Driver Installation and UpdatesDocument18 pagesCSS Lesson 6 Driver Installation and Updatesdelacruzkeizia3No ratings yet

- Application InvestorsDocument2 pagesApplication InvestorsIsuru Sri SampathNo ratings yet

- No.2 Activity Based CostingDocument20 pagesNo.2 Activity Based CostinganuradhaNo ratings yet

- Getting Started Guide: IpartitionDocument14 pagesGetting Started Guide: Ipartitiondatura64No ratings yet

- MPPT-3000 RS232 Communication ProtocolDocument13 pagesMPPT-3000 RS232 Communication ProtocolДмитрий КарасёвNo ratings yet

- Maths AssignmentDocument63 pagesMaths Assignmentudesh ishankaNo ratings yet

- Ws80 UsingDocument198 pagesWs80 UsingAngeloHidalgoNo ratings yet

- CCNA 2 SyllabusDocument1 pageCCNA 2 SyllabusNaidan DensmaaNo ratings yet

- SONY VAIO VGNSZ REPAIR MANUAL PDFDocument46 pagesSONY VAIO VGNSZ REPAIR MANUAL PDFAmanda WilliamsNo ratings yet

- GST SounderDocument1 pageGST SounderMohammed HaroonNo ratings yet