Professional Documents

Culture Documents

(Stone Age, Bronze Age, and Iron Age) : Design, Production, and Utilization of Materials

(Stone Age, Bronze Age, and Iron Age) : Design, Production, and Utilization of Materials

Uploaded by

رائد عبد العزيز فرحانOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Stone Age, Bronze Age, and Iron Age) : Design, Production, and Utilization of Materials

(Stone Age, Bronze Age, and Iron Age) : Design, Production, and Utilization of Materials

Uploaded by

رائد عبد العزيز فرحانCopyright:

Available Formats

SUBJECT: Properties of Engineering Materials

1.1 Introduction

Materials are probably more deep-seated in our culture than most of us realize.

Every segment of our everyday lives is influenced to one degree or another by

materials Transportation, housing, clothing, communication, recreation, and food

production.

Historically, the development and advancement of societies have been intimately tied

to the members’ ability to produce and manipulate materials to fill their needs. In fact,

early civilizations have been classified by the level of their materials development

(Stone Age, Bronze Age, and Iron Age)

The earliest humans had access to only a very limited number of materials, those that

occur naturally: stone, wood, clay, skins, and so on. With time they discovered

techniques for producing materials that had properties superior to those of the natural

ones; furthermore, it was discovered that the properties of a material could be altered

by heat treatments and by the addition of other substances; such as pottery.

Now different materials have developed with rather specialized properties that meet

the needs of our modern and complex society; these include metals, plastics, glasses,

rubber, and fibers

1.2 Materials Science and Engineering

Q/ what the difference between materials science and engineering?

The role of a materials scientist is to develop or synthesize new materials, whereas a

materials engineer is called upon to create new products or systems using existing

materials, and/or to develop techniques for processing materials.

Design, production, and utilization of materials

Most graduates in materials programs are trained to be both materials scientists and

materials engineers.

“Structure” the structure of a material usually relates to the arrangement of its

internal components. Subatomic structure involves electrons within the individual

atoms and interactions with their nuclei. On an atomic level, structure encompasses the

organization of atoms or molecules relative to one another. The next larger structural,

which contains large groups of atoms that are normally agglomerated together, is

termed ―microscopic,‖ meaning that which is subject to direct observation using some

BY: Ali Abdulsalam 1

SUBJECT: Properties of Engineering Materials

type of microscope. Finally, structural elements that may be viewed with the naked

eye are termed ―macroscopic.‖

“Property” While in service use, all materials are exposed to external effects that

evoke some type of response. For example, a specimen subjected to forces will

experience deformation, or a polished metal surface will reflect light.

A property is the kind and magnitude of response to a specific imposed stimulus.

Almost all important properties of solid materials may be grouped into six different

categories:

1-Mechanical, relate deformation to an applied load or force

2- Electrical, such as electrical conductivity and dielectric constant

3- Thermal, such as thermal conductivity

4- Magnetic, such as response of a material to the application of a magnetic field.

5- Optical, such as light reflection

6- Deteriorative, relate to the chemical reactivity of materials.

Two other important components are involved in the science and engineering of

materials—namely, ―processing‖ and ―performance. "With regard to the relationships

of these four components, the structure of a material will depend on how it is

processed. Furthermore, a material’s performance will be a function of its properties.

Why Study Materials Science and Engineering?

Why do we study materials? Many an applied scientist or engineer, whether

mechanical, civil, chemical, or electrical, will at one time or another be exposed to a

design problem involving materials. Examples might include a transmission gear, the

superstructure for a building, an oil refinery component, or an integrated circuit chip.

Of course, materials scientists and engineers are specialists who are totally involved in

the investigation and design of materials.

BY: Ali Abdulsalam 2

SUBJECT: Properties of Engineering Materials

Materials selection process.

Many times, a materials problem is one of selecting the right material from the many

thousands that are available. There are several criteria on which the final decision is

normally based.

1 - First, service conditions must be characterized, for these will dictate the properties

required of the material. On only rare occasions does a material possess the maximum

or ideal combination of properties. Thus, it may be necessary to trade off one

characteristic for another. The classic involves strength and ductility; normally, a

material having a high strength example will have only a limited ductility.

2 - A second selection consideration is any deterioration of material properties that

may occur during service operation. For example, significant reductions in mechanical

strength may result from exposure to elevated temperatures or corrosive environments.

3- Finally, probably the consideration of economics: What will the finished product

cost? A material may be found that has the ideal properties but is very expensive.

1.3 CLASSIFICATION OF MATERIALS

Solid materials have been grouped into three basic classifications: metals, Ceramics

and polymers. This classification is based primarily on chemical and atomic

structure, and most materials fall into one distinct grouping.

1 – Metals:

Materials in this group are composed of one or more metallic elements (such as iron,

aluminum, copper, titanium, gold, and nickel). Atoms in metals and their alloys are

arranged in a very orderly manner and in comparison to the ceramics and polymers,

are relatively dense.

BY: Ali Abdulsalam 3

SUBJECT: Properties of Engineering Materials

Fig1.2 Bar-chart of room temperature density values for various metals, ceramics,

polymers, and composite materials.

With regard to mechanical characteristics, these materials are relatively stiff and

strong, yet are ductile (i.e., capable of large amounts of deformation without fracture),

and are resistant to fracture. Metallic materials have large numbers of non-localized

electrons; these electrons are not bound to particular atoms. Many properties of metals

are directly attributable to these electrons. For example, metals are extremely good

conductors of electricity and heat, and are not transparent to visible light.

Fig1.3 Objects that are made of metals and metal alloys:

BY: Ali Abdulsalam 4

SUBJECT: Properties of Engineering Materials

2 – Ceramics:

Ceramics are compounds between metallic and nonmetallic elements; they are most

frequently oxides, nitrides, and carbides. For example, some of the common ceramic

materials include aluminum oxide (or alumina, Al2O3), silicon dioxide (or silica,

SiO2), and, in addition, what some refer to as the traditional ceramics—those

composed of clay minerals (i.e., porcelain), as well as cement, and glass. The typical

properties of ceramics are:

- Relatively stiff and strong stiffness and strengths are comparable to those of the

metals.

- Very hard. On the other hand, they are extremely brittle (lack ductility), and are

highly subject to fracture.

- Typically insulative to the passage of heat and electricity (i.e., have low electrical

conductivities)

- They have more resistant to high temperatures and harsh environments than metals

and polymers.

- With regard to optical characteristics, ceramics may be transparent,

- Some of the oxide ceramics (e.g., Fe3O4) exhibit magnetic behavior.

Fig1.4 Common objects that are made of ceramic materials:

BY: Ali Abdulsalam 5

SUBJECT: Properties of Engineering Materials

3 – Polymers:

Polymers include the familiar plastic and rubber materials. Many of them are organic

compounds (that are chemically based on carbon, hydrogen), and other nonmetallic

elements (O, N, and Si). Furthermore, they have very large molecular structures, often

chain-like in nature that has a backbone of carbon atoms. Some of the common and

familiar polymers are polyethylene (PE), nylon, poly (vinyl chloride) (PVC),

polycarbonate (PC), polystyrene (PS), and silicone rubber.

These materials typically

- Have low densities, whereas their mechanical characteristics are generally dissimilar

to the metallic and ceramic materials they are not as stiff nor as strong as these other

material types.

- However, on the basis of their low densities, many times they are stiff and strong

Fig1.5 Several common objects that are made of polymeric materials

BY: Ali Abdulsalam 6

SUBJECT: Properties of Engineering Materials

4 - Composites

A composite is composed of two (or more) individual materials, which come from the

categories discussed above ( metals, ceramics, and polymers).The design goal of a

composite is to achieve a combination of properties that is not displayed by any single

material,

Some natural materials are also considered to be composites for example, wood and

bone. However, most of those we consider in our discussions are synthetic (or man-

made) composites. One of the most common and familiar composites is fiberglass, in

which small glass fibers are embedded within a polymeric material (normally an

epoxy or polyester). The glass fibers are relatively strong and stiff (but also brittle),

whereas the polymer is ductile (but also weak and flexible). Thus, the resulting

fiberglass is relatively stiff, strong, flexible, and ductile. In addition, it has a low

density.

1.4 ADVANCED MATERIALS:

Materials that are utilized in high-technology (or high-tech) applications are

sometimes termed advanced materials. Examples include electronic equipment,

computers, fiber-optic systems, spacecraft, and aircraft. These advanced materials are

typically traditional materials whose properties have been enhanced, and, also newly

developed, high-performance materials. Furthermore, they may be of all material types

(e.g., metals, ceramics, polymers), and are normally expensive. Advanced materials

include

- Semiconductors

- Biomaterials

- Smart materials

- Nano engineered materials

Example of advanced materials:

- Lasers

- Integrated circuits

- Magnetic information storage

- Liquid crystal displays (LCDs)

- Fiber optics.

1 – Semiconductors:

Semiconductors have electrical properties that are intermediate between the electrical

conductors (metals and metal alloys) and insulators (ceramics and polymers) , the

BY: Ali Abdulsalam 7

SUBJECT: Properties of Engineering Materials

electrical characteristics of these materials are extremely sensitive to the presence of

minute concentrations of impurity atoms, for which the concentrations may be

controlled over very small spatial regions.

2 – Biomaterials:

Biomaterials are employed in components implanted into the human body for

replacement of diseased or damaged body parts. These materials must not produce

toxic substances and must be compatible with body tissues (i.e., must not cause

adverse biological reactions).

3 - Smart Materials:

The adjective ―smart‖ implies that these materials are able to sense changes in their

environments and then respond to these changes in predetermined manners traits that

is also found in living organisms.

For Example, Piezoelectric ceramics expand and contract in response to an applied

electric field (or voltage); conversely, they also generate an electric field when their

dimensions are changed.

4 – Nano engineered Materials:

1 nanometer = 10-9 m

1 human hair ~ 100,000 nanometer

A nanometer (nm) is one billionth of a meter, or 10–9 m. One nanometer is

approximately the length equivalent to 10 hydrogen or 5 silicon atoms aligned in a line

as a rule, less than 100 nanometers (equivalent to approximately 500 atom diameters).

On Nano scale, some physical and chemical material properties can differ significantly

from those of the bulk structured materials of the same composition. One example of a

material of this type is the carbon nanotube

1.6 Carbon Nano tube

BY: Ali Abdulsalam 8

You might also like

- WBS For Wedding ProjectDocument1 pageWBS For Wedding ProjectKhushboo Katyayan50% (2)

- Introduction To Materials Science & EngineeringDocument30 pagesIntroduction To Materials Science & Engineering2zvhqpfxy2No ratings yet

- Bonga University: Engineering Material (Meng2091)Document19 pagesBonga University: Engineering Material (Meng2091)Mul'isaa JireenyaaNo ratings yet

- MS Study MaterialDocument142 pagesMS Study MaterialNeha YarapothuNo ratings yet

- 04.materials Selection in Engineering Modeling IDocument15 pages04.materials Selection in Engineering Modeling IMarapa SimonNo ratings yet

- MM PDF Ia1Document109 pagesMM PDF Ia1M.41Mohd AnasNo ratings yet

- Chapter One, Introduction PDFDocument9 pagesChapter One, Introduction PDFOmar Abu MahfouthNo ratings yet

- Materials Science and Engineering by Callister Chapter 1 ReviewerDocument3 pagesMaterials Science and Engineering by Callister Chapter 1 ReviewerTy ztickNo ratings yet

- TestDocument36 pagesTestRashedNo ratings yet

- Week 1 - IPE 2203-LecturesDocument51 pagesWeek 1 - IPE 2203-LecturesMD Al-AminNo ratings yet

- Chapter-1 Introduction To Basic MetallurgyDocument15 pagesChapter-1 Introduction To Basic Metallurgysafeer ahmad100% (1)

- Material Science - Properties of MaterialsDocument13 pagesMaterial Science - Properties of MaterialsBlessings James Bwalya100% (1)

- Lecture 1 IntroductionDocument21 pagesLecture 1 IntroductionKelvin Ken WitsNo ratings yet

- Material ScienceDocument33 pagesMaterial Sciencesvdecoration eventsNo ratings yet

- 19.Msm Lectruer NotesDocument163 pages19.Msm Lectruer Notessaitejapopuri123No ratings yet

- Get 226 Lecture NoteDocument20 pagesGet 226 Lecture NoteRaphael GodfreyNo ratings yet

- Materials Science CHAPTER 1Document5 pagesMaterials Science CHAPTER 1KTINE08No ratings yet

- MME 201 Summarised Lesson NoteDocument102 pagesMME 201 Summarised Lesson Notegeorgeolumba33No ratings yet

- Notes - Modern MaterialsDocument70 pagesNotes - Modern MaterialsAnusha PanchumarthiNo ratings yet

- MCM MaterialDocument32 pagesMCM MaterialGeleta BekeleNo ratings yet

- Requirme - Ass AcbetDocument2 pagesRequirme - Ass AcbetCyber RoseNo ratings yet

- Engineering Materials, PPTDocument42 pagesEngineering Materials, PPTKemal Getiso100% (2)

- TOPIC 1 - Introduction To Material Science and EngineeeringDocument8 pagesTOPIC 1 - Introduction To Material Science and EngineeeringGian Carlo MaltoNo ratings yet

- Chapter-1 Funad. Eng MaterialDocument47 pagesChapter-1 Funad. Eng Materialtazeb AbebeNo ratings yet

- Introduction To Materials Science: Course Code: PHY-657Document36 pagesIntroduction To Materials Science: Course Code: PHY-657JawadNo ratings yet

- Material EngineeringDocument135 pagesMaterial EngineeringM006Ashish JhaNo ratings yet

- Material Science PrinciplesDocument5 pagesMaterial Science PrinciplesIsaiah LuleNo ratings yet

- Lesson 1 - Types of Engineering MaterialsDocument5 pagesLesson 1 - Types of Engineering MaterialsOwen GichangiNo ratings yet

- Chapter 1 Introduction On Material ScienceDocument33 pagesChapter 1 Introduction On Material ScienceZjian Wai100% (1)

- Structure of Materials Properties of Materials Processing of Materials Performance of MaterialsDocument5 pagesStructure of Materials Properties of Materials Processing of Materials Performance of MaterialsLazat M Hesnbakri100% (1)

- UNIT 1 PPT 2Document30 pagesUNIT 1 PPT 2neha yarrapothuNo ratings yet

- Lecture Note Engg MaterialDocument122 pagesLecture Note Engg MaterialSHADULLA SHAIKNo ratings yet

- Introduction To Smart MaterialsDocument47 pagesIntroduction To Smart MaterialsRajat AgrawalNo ratings yet

- Unit - 1 FinalDocument134 pagesUnit - 1 FinalGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Materials Science and EngineeringDocument4 pagesMaterials Science and EngineeringZesi Villamor Delos SantosNo ratings yet

- National Institute of Technology, Durgapur Department of Metallurgical and Materials Engineering MME 521: Materials ScienceDocument12 pagesNational Institute of Technology, Durgapur Department of Metallurgical and Materials Engineering MME 521: Materials ScienceAyanNo ratings yet

- Lecture 1423814208Document94 pagesLecture 1423814208placementtigNo ratings yet

- MaterialogyDocument181 pagesMaterialogyrajraj3550No ratings yet

- MatSci Reviewer Lesson 1-3Document8 pagesMatSci Reviewer Lesson 1-3Gabriel Glenn FernandezNo ratings yet

- 1st ReporterDocument15 pages1st ReporterCedrick Earl D. GuhitiaNo ratings yet

- Bab 1 (Material Science)Document9 pagesBab 1 (Material Science)Muhd AriffNo ratings yet

- Material Science1Document6 pagesMaterial Science1Manju KumariNo ratings yet

- Introduction-History of Materials As Used in Building Construction, Material Properties and Its ApplicationDocument4 pagesIntroduction-History of Materials As Used in Building Construction, Material Properties and Its ApplicationJobert BautistaNo ratings yet

- Unit 1 WorkDocument26 pagesUnit 1 WorkJohny SkNo ratings yet

- Introduction To Materials and Processes PDFDocument0 pagesIntroduction To Materials and Processes PDFjayeshjpillaiNo ratings yet

- Materials EngineeringDocument61 pagesMaterials EngineeringAshwit KumarNo ratings yet

- Introduction To Materials ScienceDocument13 pagesIntroduction To Materials ScienceEmmanuel OlalekanNo ratings yet

- 3.structure of MaterialDocument49 pages3.structure of MaterialTouhidul Islam RonyNo ratings yet

- Mse CCDocument252 pagesMse CCXychoNo ratings yet

- FME 8 - Material Science and Engineering For ME: Prepared By: Engr. Adrian Agonos, ME, RMPDocument61 pagesFME 8 - Material Science and Engineering For ME: Prepared By: Engr. Adrian Agonos, ME, RMPLESTER JOHN SALANGONo ratings yet

- JosephAyoBabalola1904 1959Document33 pagesJosephAyoBabalola1904 1959gben65448No ratings yet

- Course Title: Engineering Materials (Cheg) : InformationDocument35 pagesCourse Title: Engineering Materials (Cheg) : Informationkere evaNo ratings yet

- Material Science and EngineeringDocument13 pagesMaterial Science and Engineeringebrahim maicomNo ratings yet

- FINAL - Engineering Materials (Lecture 1)Document89 pagesFINAL - Engineering Materials (Lecture 1)Paderes Yeshue EmmanuelleNo ratings yet

- Emt 2132 Introduction To Material Science PDFDocument52 pagesEmt 2132 Introduction To Material Science PDFStephanie MirañyiNo ratings yet

- Materials Science and Engineering: An IntroductionDocument22 pagesMaterials Science and Engineering: An IntroductionFlorenzo Miguel AclanNo ratings yet

- CH 1Document25 pagesCH 1Winta BreaNo ratings yet

- Solid State Chemistry and Materials Characterization SyllabusDocument27 pagesSolid State Chemistry and Materials Characterization SyllabusNgọc Hà NguyễnNo ratings yet

- Chapter 1 - Introduction To Materials Science and EngineeringDocument6 pagesChapter 1 - Introduction To Materials Science and Engineeringaldz5No ratings yet

- Introduction To Materials PDFDocument96 pagesIntroduction To Materials PDFMircea Dubenco100% (1)

- DoubleVision PpsDocument6 pagesDoubleVision Ppsرائد عبد العزيز فرحانNo ratings yet

- Pipe Friction Losses: Fundamental Principles For Project WorkDocument3 pagesPipe Friction Losses: Fundamental Principles For Project Workرائد عبد العزيز فرحانNo ratings yet

- To My FriendsDocument14 pagesTo My Friendsرائد عبد العزيز فرحانNo ratings yet

- Double VisionDocument6 pagesDouble Visionرائد عبد العزيز فرحانNo ratings yet

- B) To Feel Shy and Silly, A Big Cup Make Liquid Flow OutDocument1 pageB) To Feel Shy and Silly, A Big Cup Make Liquid Flow Outرائد عبد العزيز فرحانNo ratings yet

- 518d163be4b062a8d1d9f903-.Sam.-1368204347334-4 Factors Affecting Viscosity PDFDocument5 pages518d163be4b062a8d1d9f903-.Sam.-1368204347334-4 Factors Affecting Viscosity PDFرائد عبد العزيز فرحانNo ratings yet

- Viscosity and Density Measurement Methods For Polymer Melts: R. Kažys, R. RekuvienėDocument6 pagesViscosity and Density Measurement Methods For Polymer Melts: R. Kažys, R. Rekuvienėرائد عبد العزيز فرحانNo ratings yet

- Exp3 DensityDocument1 pageExp3 Densityرائد عبد العزيز فرحانNo ratings yet

- 8.4 Changes in Matter: Hot Ice and The Carbon Snake: Grade 8 Activity PlanDocument7 pages8.4 Changes in Matter: Hot Ice and The Carbon Snake: Grade 8 Activity Planرائد عبد العزيز فرحانNo ratings yet

- 08-Mechanical Properties-BU-HandoutsDocument13 pages08-Mechanical Properties-BU-Handoutsرائد عبد العزيز فرحانNo ratings yet

- ChemicalDocument1 pageChemicalرائد عبد العزيز فرحانNo ratings yet

- Packed Columns Simplified Design Methods For Absorption of Dilute Gas Mixtures in Packed and Trays TowersDocument1 pagePacked Columns Simplified Design Methods For Absorption of Dilute Gas Mixtures in Packed and Trays Towersرائد عبد العزيز فرحانNo ratings yet

- Chapter Two Interest and Investment CostDocument6 pagesChapter Two Interest and Investment Costرائد عبد العزيز فرحانNo ratings yet

- Riphah International University: Faculty of Management Sciences Riphah School of Leadership (Meezan Campus)Document2 pagesRiphah International University: Faculty of Management Sciences Riphah School of Leadership (Meezan Campus)SAL MANNo ratings yet

- Executive SummaryDocument8 pagesExecutive SummarysiriusNo ratings yet

- Final Ko Ni Final 1234Document53 pagesFinal Ko Ni Final 1234Prajwol TamangNo ratings yet

- Philippines, Inc. v. Secretary of Agrarian Reform (1989), The Court Declared ThatDocument53 pagesPhilippines, Inc. v. Secretary of Agrarian Reform (1989), The Court Declared ThatChap ChoyNo ratings yet

- Doc 20221108 Wa0005.Document12 pagesDoc 20221108 Wa0005.UzmaamehendiartNo ratings yet

- Park View Enclave (PVT) Limited.: Account StatementDocument1 pagePark View Enclave (PVT) Limited.: Account Statementamirali.bme4527No ratings yet

- Shop Establishment Certificate HyderabadDocument3 pagesShop Establishment Certificate HyderabadINAMUL HAQUENo ratings yet

- STUDY GUIDE Part 3 ProblemsDocument2 pagesSTUDY GUIDE Part 3 ProblemsBaylon RachelNo ratings yet

- State of Louisiana Uniform Commercial Code - Financing Statement UCC-1Document2 pagesState of Louisiana Uniform Commercial Code - Financing Statement UCC-1Yudah Israel0% (1)

- Full Download Ebook Ebook PDF Managerial Economics in A Global Economy 9th Edition PDFDocument41 pagesFull Download Ebook Ebook PDF Managerial Economics in A Global Economy 9th Edition PDFdaniel.graves434100% (45)

- Pfrs 13 Fair Value MeasurementDocument22 pagesPfrs 13 Fair Value MeasurementShane PasayloNo ratings yet

- Semi Final Exam at ReviewerDocument18 pagesSemi Final Exam at ReviewerXyra GeveraNo ratings yet

- Chapter 7S Learning Curve - Mar 18.pptljbDocument14 pagesChapter 7S Learning Curve - Mar 18.pptljbMichaela WongNo ratings yet

- Prominence and Issues of CSR & Social ContractDocument14 pagesProminence and Issues of CSR & Social ContractVasneas NewNo ratings yet

- Salem Analytics Panera Bread Company Final ReportDocument31 pagesSalem Analytics Panera Bread Company Final ReportCecille TaguiamNo ratings yet

- Currency Exchange Rate and International Trade and Capital FlowsDocument39 pagesCurrency Exchange Rate and International Trade and Capital FlowsudNo ratings yet

- VictoriaDocument2 pagesVictoriaapi-535156077No ratings yet

- Chapter 3 Financial MarketsDocument29 pagesChapter 3 Financial MarketsHoy HoyNo ratings yet

- Leonardo Cross Belt Sorter For AirportDocument4 pagesLeonardo Cross Belt Sorter For AirportraptorNo ratings yet

- Eir June2016Document119 pagesEir June2016Nazim KhanNo ratings yet

- Clearlake City Council PacketDocument57 pagesClearlake City Council PacketLakeCoNewsNo ratings yet

- Strategic Management of AmazonDocument17 pagesStrategic Management of AmazonAyushNo ratings yet

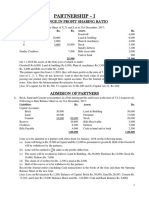

- Partnership - I: Change in Profit Sharing RatioDocument33 pagesPartnership - I: Change in Profit Sharing RatioUjjwal BeriwalNo ratings yet

- Saudi PPPP Show Catalogue 2019Document164 pagesSaudi PPPP Show Catalogue 2019Mostafa AlakhliNo ratings yet

- Connected Manufacturing RoadmapDocument41 pagesConnected Manufacturing RoadmapAnnirban BhattacharyaNo ratings yet

- Delivering Profitable Salesat UPSDocument6 pagesDelivering Profitable Salesat UPSblankNo ratings yet

- ResumeAaishaShaikh PDFDocument4 pagesResumeAaishaShaikh PDFpandit_sandeep84No ratings yet

- SGC ConstitutionDocument11 pagesSGC ConstitutionRaulJunioRamos100% (1)

- INCOTERMS 2000 - Chart of ResponsibilityDocument3 pagesINCOTERMS 2000 - Chart of Responsibilityredback666No ratings yet