Professional Documents

Culture Documents

Read The Theory On WWW - Leanlab.name: 000000page 1#

Read The Theory On WWW - Leanlab.name: 000000page 1#

Uploaded by

Balaji SCopyright:

Available Formats

You might also like

- BON 410 2020 Exam Paper With MemoDocument10 pagesBON 410 2020 Exam Paper With MemoDantè ChiapperiniNo ratings yet

- Problem 1 4 8Document2 pagesProblem 1 4 8gaziahmad100% (2)

- Bollard Pull Test ProcedureDocument8 pagesBollard Pull Test ProcedureMey Rudy100% (3)

- WIP and Throughput TimeDocument17 pagesWIP and Throughput TimeNitta MallikNo ratings yet

- Lean Manufacturing - TWI Case Study Model Answers PDFDocument11 pagesLean Manufacturing - TWI Case Study Model Answers PDFBianka NaulaNo ratings yet

- Inventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyFrom EverandInventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyRating: 5 out of 5 stars5/5 (2)

- 2006 Acm1dDocument2 pages2006 Acm1dTran Hong HiepNo ratings yet

- Earthbag Building: Hobbit House PlanDocument10 pagesEarthbag Building: Hobbit House Planlighteagles131100% (1)

- Acnis Brochure-Titanium GradesDocument12 pagesAcnis Brochure-Titanium Gradesanilsamuel0077418No ratings yet

- Permeate Recycle To Improve The Performance of A Spiral-Wound RO PlantDocument8 pagesPermeate Recycle To Improve The Performance of A Spiral-Wound RO Planttata_77No ratings yet

- Common Work Results For PlumbingDocument16 pagesCommon Work Results For PlumbingMac ShaikNo ratings yet

- Engineering Drawings Review Checklist-Example2 PDFDocument1 pageEngineering Drawings Review Checklist-Example2 PDFjblumbeNo ratings yet

- Wimax Mac Ieee 802-16Document37 pagesWimax Mac Ieee 802-16Gajendra GanigaNo ratings yet

- Kan Ban CalculatorDocument3 pagesKan Ban Calculatorulribeiro1No ratings yet

- Invtry MGMT by Suhas RaneDocument51 pagesInvtry MGMT by Suhas RanePruthviNo ratings yet

- M - IDocument47 pagesM - IJagan MahatoNo ratings yet

- COMM204 (Little's Law and Its Application)Document18 pagesCOMM204 (Little's Law and Its Application)Sahil ParekhNo ratings yet

- Safari - 10 Nov 2018 at 22:02Document1 pageSafari - 10 Nov 2018 at 22:02berekettsegaye215No ratings yet

- Chapter 4 - Inventory MGTDocument31 pagesChapter 4 - Inventory MGTMelak TsehayeNo ratings yet

- Key Formulas - BSCMDocument10 pagesKey Formulas - BSCMsamsoon80No ratings yet

- Chap 12 Inventory ManagementDocument25 pagesChap 12 Inventory Managementapi-3827845100% (2)

- OMG 402 - Operations Management Spring 1997: Class 2: Process AnalysisDocument33 pagesOMG 402 - Operations Management Spring 1997: Class 2: Process AnalysisGurunathan MariayyahNo ratings yet

- Chapter 8Document7 pagesChapter 8BobNo ratings yet

- Materi KanbanisasiDocument11 pagesMateri Kanbanisasiratyas erlanggaNo ratings yet

- JIT Problems and SolutionsDocument4 pagesJIT Problems and SolutionsTrân LêNo ratings yet

- 2024 02 15 Fe Webinar Disruption WebsiteDocument26 pages2024 02 15 Fe Webinar Disruption WebsiteKrishan RodrigoNo ratings yet

- Talk 06. Inventory ManagementDocument23 pagesTalk 06. Inventory ManagementPhuong Thanh NguyenNo ratings yet

- Session 3-Process Analysis II-V1Document13 pagesSession 3-Process Analysis II-V1Jiny Lee0% (1)

- Inventory ManagementDocument23 pagesInventory ManagementAiron Keith Along67% (3)

- P3 - InventoryControlDocument43 pagesP3 - InventoryControlamirah khansaNo ratings yet

- Inventory Management For EM StudentsDocument24 pagesInventory Management For EM StudentsShahriar KabirNo ratings yet

- 01 AC212 Lecture 1-Material PDFDocument30 pages01 AC212 Lecture 1-Material PDFJam JamNo ratings yet

- 01 AC212 Lecture 1-Material PDFDocument30 pages01 AC212 Lecture 1-Material PDFsengpisalNo ratings yet

- Supply Chain MetricsDocument9 pagesSupply Chain MetricsÖmer KarahanNo ratings yet

- Aggregate Production Planning (Chapter 11)Document53 pagesAggregate Production Planning (Chapter 11)qweryNo ratings yet

- AAM3691 Unit 2 Accounting For Materials - Part 1Document31 pagesAAM3691 Unit 2 Accounting For Materials - Part 1joseswartzsr31No ratings yet

- Just-in-Time and Backflushing 1Document6 pagesJust-in-Time and Backflushing 1Claudette ClementeNo ratings yet

- ACCA F2 Sample Study NoteDocument21 pagesACCA F2 Sample Study Notebillyryan10% (1)

- 07 PPC Ch7 Theory of ConstraintsDocument52 pages07 PPC Ch7 Theory of ConstraintsziadatzNo ratings yet

- OM Group-6 ReportDocument10 pagesOM Group-6 ReportNguyễn Bích NgọcNo ratings yet

- Time Trap AnalysisDocument22 pagesTime Trap AnalysiswongsosoegaliNo ratings yet

- OPER312 Exercise2-SolutionsDocument9 pagesOPER312 Exercise2-SolutionsÖmer AktürkNo ratings yet

- Inventory and EOQDocument21 pagesInventory and EOQArun SudarshanNo ratings yet

- Target and Efficiency Calculation - MeekDocument19 pagesTarget and Efficiency Calculation - Meeknasimul haque100% (1)

- Inventory Management in Supply ChainDocument43 pagesInventory Management in Supply ChainRashi VajaniNo ratings yet

- Inventory ControlDocument32 pagesInventory ControlRanjeet SinghNo ratings yet

- Konsep Dasar Persediaan: OutlineDocument34 pagesKonsep Dasar Persediaan: OutlineErika WijayaNo ratings yet

- OPIM101 - Spring 2009 - Exam 1 PDFDocument12 pagesOPIM101 - Spring 2009 - Exam 1 PDFjoe91bmw0% (1)

- Quiz 2 With AnsDocument4 pagesQuiz 2 With AnsAbhishree JainNo ratings yet

- Unit V PRP U.QDocument10 pagesUnit V PRP U.QGunavathi NalanNo ratings yet

- W2 - Concepts and ApplicationsDocument13 pagesW2 - Concepts and ApplicationsKim Yến100% (1)

- Chapter 5 SCMDocument25 pagesChapter 5 SCMFirzam AmirNo ratings yet

- Material Requirement Planning (MRP)Document55 pagesMaterial Requirement Planning (MRP)Lisa CarlsonNo ratings yet

- Definitioner KPI 20170523Document7 pagesDefinitioner KPI 20170523Haiyong ZhuNo ratings yet

- Little's Law Example Question: Inventory ManagementDocument2 pagesLittle's Law Example Question: Inventory ManagementGauravNo ratings yet

- Assignment 2Document7 pagesAssignment 2tonyfancaesarNo ratings yet

- Chap12-Inventory ManagementDocument6 pagesChap12-Inventory Managementabdulaziz simjeeNo ratings yet

- Jawaban Biaya - ch20Document29 pagesJawaban Biaya - ch20Fitriyeni OktaviaNo ratings yet

- REVIEW QUESTIONS MaterialsDocument4 pagesREVIEW QUESTIONS Materialsdismas malekelaNo ratings yet

- WCM Group5Document11 pagesWCM Group5Prasad DurgaNo ratings yet

- Inventory Planning: Nazmun NaharDocument29 pagesInventory Planning: Nazmun NaharKamrulHassanNo ratings yet

- Running Head: Inventory Management: Inventory Management Student's Name Professor's Name Course Title Institution DateDocument5 pagesRunning Head: Inventory Management: Inventory Management Student's Name Professor's Name Course Title Institution DateHw SolutionNo ratings yet

- Production Planning: Compiled byDocument12 pagesProduction Planning: Compiled byjorgeNo ratings yet

- Lean ManufacturingDocument43 pagesLean Manufacturingminhtien221197No ratings yet

- Midwest Office TDABC MBA-FT 22-24 Blank For ClassroomDocument2 pagesMidwest Office TDABC MBA-FT 22-24 Blank For Classroomsakshi upadhyayNo ratings yet

- Just-in-Time and Lean SystemsDocument27 pagesJust-in-Time and Lean SystemsIrfan Ahmad Awan100% (1)

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Seriously Good Software: Code that works, survives, and winsFrom EverandSeriously Good Software: Code that works, survives, and winsRating: 5 out of 5 stars5/5 (1)

- +PFMEA Rating Scale GuidelinesDocument2 pages+PFMEA Rating Scale GuidelinesBalaji SNo ratings yet

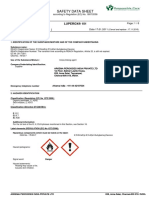

- Luperox 101Document8 pagesLuperox 101Balaji SNo ratings yet

- +GL 01 PfmeaDocument9 pages+GL 01 PfmeaBalaji SNo ratings yet

- SDS - Oks 2101 - enDocument16 pagesSDS - Oks 2101 - enBalaji SNo ratings yet

- TDS Silcogum Black 35815Document1 pageTDS Silcogum Black 35815Balaji SNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. IdentificationBalaji SNo ratings yet

- Constitutional Law - Assignment by S KalaiarasiDocument1 pageConstitutional Law - Assignment by S KalaiarasiBalaji SNo ratings yet

- Silcogum Black 35815Document15 pagesSilcogum Black 35815Balaji SNo ratings yet

- BK Pom Uv Smartbatch - CC10231751BG TDSDocument2 pagesBK Pom Uv Smartbatch - CC10231751BG TDSBalaji SNo ratings yet

- BK Pom Uv Smartbatch - CC10231751BG - MSDSDocument17 pagesBK Pom Uv Smartbatch - CC10231751BG - MSDSBalaji SNo ratings yet

- ISO13645 RequirementsDocument22 pagesISO13645 RequirementsBalaji S100% (1)

- Consumables LIst With PriceDocument3 pagesConsumables LIst With PriceBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M8)Document13 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M8)Balaji SNo ratings yet

- Consultancy ScopeDocument3 pagesConsultancy ScopeBalaji SNo ratings yet

- Contigency Plan Cum Testing Record - HBIDocument1 pageContigency Plan Cum Testing Record - HBIBalaji SNo ratings yet

- Module 2 - Asian Productivity MovementDocument76 pagesModule 2 - Asian Productivity MovementBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M7)Document15 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M7)Balaji SNo ratings yet

- Consultancy Setup ActivitesDocument3 pagesConsultancy Setup ActivitesBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M9)Document15 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M9)Balaji SNo ratings yet

- TPM PoliciesDocument2 pagesTPM PoliciesBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M10)Document12 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M10)Balaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M5)Document20 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M5)Balaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M4)Document26 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M4)Balaji SNo ratings yet

- 3057 Kanban ProposalDocument31 pages3057 Kanban ProposalBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M6)Document12 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M6)Balaji SNo ratings yet

- Internal Quality Auditor Training Quiz (1-15)Document12 pagesInternal Quality Auditor Training Quiz (1-15)Balaji SNo ratings yet

- Resource Planning 2Document10 pagesResource Planning 2Balaji SNo ratings yet

- Flat Belt DriveDocument25 pagesFlat Belt DriveMurugesan RameshNo ratings yet

- IC Contractor Progress Payment Template 8531 V1Document6 pagesIC Contractor Progress Payment Template 8531 V1elbaraniNo ratings yet

- Joint Measurement Sheet: Name of CollegeDocument1 pageJoint Measurement Sheet: Name of CollegeVenu GopalNo ratings yet

- 6 4 4Document3 pages6 4 4Rodolfo PonceNo ratings yet

- Datasheet Vikram Solar Multi Crystalline 72 Cell IndiaDocument2 pagesDatasheet Vikram Solar Multi Crystalline 72 Cell Indiasteffi subaNo ratings yet

- NemaDocument4 pagesNemaMohamed ElfekyNo ratings yet

- Genio E550g User ManualDocument140 pagesGenio E550g User ManualAlbert LugoNo ratings yet

- Introduction: Classification of Layout, Advantages and Limitations of Different LayoutsDocument14 pagesIntroduction: Classification of Layout, Advantages and Limitations of Different LayoutsPadmavathi Putra LokeshNo ratings yet

- H. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFDocument2 pagesH. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFfajrul 2222No ratings yet

- R0030 PDFDocument33 pagesR0030 PDFOscar Gutiérrez-JuncoNo ratings yet

- DT300-Series-manual Timer 04Document2 pagesDT300-Series-manual Timer 04eeindustrialNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- Dermocybin: Structure ofDocument6 pagesDermocybin: Structure ofJohannes Lund VvithNo ratings yet

- Butt Fusion Machines Small-Medium - V2 - LowDocument12 pagesButt Fusion Machines Small-Medium - V2 - LowViorel TomaNo ratings yet

- Guide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFDocument4 pagesGuide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFMFaiz RHamiraNo ratings yet

- Transformer Protection in SubstationDocument20 pagesTransformer Protection in SubstationManu JosephNo ratings yet

- 2016-2018 Road Crash Data For Critical Intersection 2020Document186 pages2016-2018 Road Crash Data For Critical Intersection 2020Ferdinand Fragata RamiterreNo ratings yet

- TI Audio GuideDocument49 pagesTI Audio GuideMarc StagerNo ratings yet

- Sigunit L54-45 AFDocument2 pagesSigunit L54-45 AFDudee DaryanNo ratings yet

- DKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CDocument82 pagesDKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CNoah MusundiNo ratings yet

- Ct-110 Cbs Rev 00 June 19Document76 pagesCt-110 Cbs Rev 00 June 19Satya Prakash Pathak100% (5)

- 2023 01 Gasket-HandbookDocument216 pages2023 01 Gasket-Handbookrbnotosagoro100% (1)

Read The Theory On WWW - Leanlab.name: 000000page 1#

Read The Theory On WWW - Leanlab.name: 000000page 1#

Uploaded by

Balaji SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Read The Theory On WWW - Leanlab.name: 000000page 1#

Read The Theory On WWW - Leanlab.name: 000000page 1#

Uploaded by

Balaji SCopyright:

Available Formats

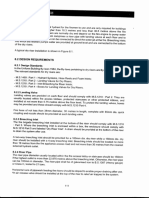

Number of Kanban - Theory

Number of Kanban Calculator ed.A

Read the theory on www.leanlab.name

Base Theory of Calculation

The number of Kanban you need to have in the circuit between downstream and upstream is a simple calculation. It works

Number of Kanban = [ Daily Demand * Lead Time (in days) * (1 + % Safety Stock) ] / [ Quantity in a Container ]

Example:

Let us imagine a downstream process that use 100 tapes/day (on average)

The lead time to obtain new tapes once the signal start from the Point of Use (POU), arrive to the upstream (or supplier) a

The Safety Stock in percentage is 20% (to compensate demand variation or delays)

Every container is of 50 tapes.

N° of Kanban = 100 * 5 * 1,20 / 50 = 12 Kanban

What does it means?

It means that in the "circuit" between upstream and downstream 12 Kanban (Tags, Container or other form of Kanban) ha

Points of attention.

The demand and lead time has to be with the same time base (Days, Hours, Minutes).

The Number of Kanban has to be rounded up to the integer

000000Page 1# 7424aClassification: Restricted

3

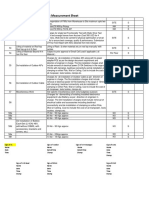

Number of Kanban - Instructions

Number of Kanban Calculator Instruction of use

The simplest instruction ever:

Put the data in the orange box

Read the results in the green box

000000Page 2# 7424aClassification: Restricted

3

Number of Kanban - Calculator

Number of Kanban – Calculator

Input [weekly based] Output

Weekly Demand [pcs] 5760 N° of Kanban 7

Lead Time [weeks] 1.714285714

Safety Stock [%] 20

Kanban/Container Quantity [pcs] 1920

Input [daily based] Output

Daily Demand [pcs] 5 N° of Kanban 1

Lead Time [days] 2

Safety Stock [%] 20

Kanban/Container Quantity [pcs] 20

Input [hourly based] Output

Hourly Demand [pcs] 5 N° of Kanban 1

Lead Time [hours] 2

Safety Stock [%] 20

Kanban/Container Quantity [pcs] 20

000000Page 3# 7424aClassification: Restricted

3

You might also like

- BON 410 2020 Exam Paper With MemoDocument10 pagesBON 410 2020 Exam Paper With MemoDantè ChiapperiniNo ratings yet

- Problem 1 4 8Document2 pagesProblem 1 4 8gaziahmad100% (2)

- Bollard Pull Test ProcedureDocument8 pagesBollard Pull Test ProcedureMey Rudy100% (3)

- WIP and Throughput TimeDocument17 pagesWIP and Throughput TimeNitta MallikNo ratings yet

- Lean Manufacturing - TWI Case Study Model Answers PDFDocument11 pagesLean Manufacturing - TWI Case Study Model Answers PDFBianka NaulaNo ratings yet

- Inventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyFrom EverandInventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyRating: 5 out of 5 stars5/5 (2)

- 2006 Acm1dDocument2 pages2006 Acm1dTran Hong HiepNo ratings yet

- Earthbag Building: Hobbit House PlanDocument10 pagesEarthbag Building: Hobbit House Planlighteagles131100% (1)

- Acnis Brochure-Titanium GradesDocument12 pagesAcnis Brochure-Titanium Gradesanilsamuel0077418No ratings yet

- Permeate Recycle To Improve The Performance of A Spiral-Wound RO PlantDocument8 pagesPermeate Recycle To Improve The Performance of A Spiral-Wound RO Planttata_77No ratings yet

- Common Work Results For PlumbingDocument16 pagesCommon Work Results For PlumbingMac ShaikNo ratings yet

- Engineering Drawings Review Checklist-Example2 PDFDocument1 pageEngineering Drawings Review Checklist-Example2 PDFjblumbeNo ratings yet

- Wimax Mac Ieee 802-16Document37 pagesWimax Mac Ieee 802-16Gajendra GanigaNo ratings yet

- Kan Ban CalculatorDocument3 pagesKan Ban Calculatorulribeiro1No ratings yet

- Invtry MGMT by Suhas RaneDocument51 pagesInvtry MGMT by Suhas RanePruthviNo ratings yet

- M - IDocument47 pagesM - IJagan MahatoNo ratings yet

- COMM204 (Little's Law and Its Application)Document18 pagesCOMM204 (Little's Law and Its Application)Sahil ParekhNo ratings yet

- Safari - 10 Nov 2018 at 22:02Document1 pageSafari - 10 Nov 2018 at 22:02berekettsegaye215No ratings yet

- Chapter 4 - Inventory MGTDocument31 pagesChapter 4 - Inventory MGTMelak TsehayeNo ratings yet

- Key Formulas - BSCMDocument10 pagesKey Formulas - BSCMsamsoon80No ratings yet

- Chap 12 Inventory ManagementDocument25 pagesChap 12 Inventory Managementapi-3827845100% (2)

- OMG 402 - Operations Management Spring 1997: Class 2: Process AnalysisDocument33 pagesOMG 402 - Operations Management Spring 1997: Class 2: Process AnalysisGurunathan MariayyahNo ratings yet

- Chapter 8Document7 pagesChapter 8BobNo ratings yet

- Materi KanbanisasiDocument11 pagesMateri Kanbanisasiratyas erlanggaNo ratings yet

- JIT Problems and SolutionsDocument4 pagesJIT Problems and SolutionsTrân LêNo ratings yet

- 2024 02 15 Fe Webinar Disruption WebsiteDocument26 pages2024 02 15 Fe Webinar Disruption WebsiteKrishan RodrigoNo ratings yet

- Talk 06. Inventory ManagementDocument23 pagesTalk 06. Inventory ManagementPhuong Thanh NguyenNo ratings yet

- Session 3-Process Analysis II-V1Document13 pagesSession 3-Process Analysis II-V1Jiny Lee0% (1)

- Inventory ManagementDocument23 pagesInventory ManagementAiron Keith Along67% (3)

- P3 - InventoryControlDocument43 pagesP3 - InventoryControlamirah khansaNo ratings yet

- Inventory Management For EM StudentsDocument24 pagesInventory Management For EM StudentsShahriar KabirNo ratings yet

- 01 AC212 Lecture 1-Material PDFDocument30 pages01 AC212 Lecture 1-Material PDFJam JamNo ratings yet

- 01 AC212 Lecture 1-Material PDFDocument30 pages01 AC212 Lecture 1-Material PDFsengpisalNo ratings yet

- Supply Chain MetricsDocument9 pagesSupply Chain MetricsÖmer KarahanNo ratings yet

- Aggregate Production Planning (Chapter 11)Document53 pagesAggregate Production Planning (Chapter 11)qweryNo ratings yet

- AAM3691 Unit 2 Accounting For Materials - Part 1Document31 pagesAAM3691 Unit 2 Accounting For Materials - Part 1joseswartzsr31No ratings yet

- Just-in-Time and Backflushing 1Document6 pagesJust-in-Time and Backflushing 1Claudette ClementeNo ratings yet

- ACCA F2 Sample Study NoteDocument21 pagesACCA F2 Sample Study Notebillyryan10% (1)

- 07 PPC Ch7 Theory of ConstraintsDocument52 pages07 PPC Ch7 Theory of ConstraintsziadatzNo ratings yet

- OM Group-6 ReportDocument10 pagesOM Group-6 ReportNguyễn Bích NgọcNo ratings yet

- Time Trap AnalysisDocument22 pagesTime Trap AnalysiswongsosoegaliNo ratings yet

- OPER312 Exercise2-SolutionsDocument9 pagesOPER312 Exercise2-SolutionsÖmer AktürkNo ratings yet

- Inventory and EOQDocument21 pagesInventory and EOQArun SudarshanNo ratings yet

- Target and Efficiency Calculation - MeekDocument19 pagesTarget and Efficiency Calculation - Meeknasimul haque100% (1)

- Inventory Management in Supply ChainDocument43 pagesInventory Management in Supply ChainRashi VajaniNo ratings yet

- Inventory ControlDocument32 pagesInventory ControlRanjeet SinghNo ratings yet

- Konsep Dasar Persediaan: OutlineDocument34 pagesKonsep Dasar Persediaan: OutlineErika WijayaNo ratings yet

- OPIM101 - Spring 2009 - Exam 1 PDFDocument12 pagesOPIM101 - Spring 2009 - Exam 1 PDFjoe91bmw0% (1)

- Quiz 2 With AnsDocument4 pagesQuiz 2 With AnsAbhishree JainNo ratings yet

- Unit V PRP U.QDocument10 pagesUnit V PRP U.QGunavathi NalanNo ratings yet

- W2 - Concepts and ApplicationsDocument13 pagesW2 - Concepts and ApplicationsKim Yến100% (1)

- Chapter 5 SCMDocument25 pagesChapter 5 SCMFirzam AmirNo ratings yet

- Material Requirement Planning (MRP)Document55 pagesMaterial Requirement Planning (MRP)Lisa CarlsonNo ratings yet

- Definitioner KPI 20170523Document7 pagesDefinitioner KPI 20170523Haiyong ZhuNo ratings yet

- Little's Law Example Question: Inventory ManagementDocument2 pagesLittle's Law Example Question: Inventory ManagementGauravNo ratings yet

- Assignment 2Document7 pagesAssignment 2tonyfancaesarNo ratings yet

- Chap12-Inventory ManagementDocument6 pagesChap12-Inventory Managementabdulaziz simjeeNo ratings yet

- Jawaban Biaya - ch20Document29 pagesJawaban Biaya - ch20Fitriyeni OktaviaNo ratings yet

- REVIEW QUESTIONS MaterialsDocument4 pagesREVIEW QUESTIONS Materialsdismas malekelaNo ratings yet

- WCM Group5Document11 pagesWCM Group5Prasad DurgaNo ratings yet

- Inventory Planning: Nazmun NaharDocument29 pagesInventory Planning: Nazmun NaharKamrulHassanNo ratings yet

- Running Head: Inventory Management: Inventory Management Student's Name Professor's Name Course Title Institution DateDocument5 pagesRunning Head: Inventory Management: Inventory Management Student's Name Professor's Name Course Title Institution DateHw SolutionNo ratings yet

- Production Planning: Compiled byDocument12 pagesProduction Planning: Compiled byjorgeNo ratings yet

- Lean ManufacturingDocument43 pagesLean Manufacturingminhtien221197No ratings yet

- Midwest Office TDABC MBA-FT 22-24 Blank For ClassroomDocument2 pagesMidwest Office TDABC MBA-FT 22-24 Blank For Classroomsakshi upadhyayNo ratings yet

- Just-in-Time and Lean SystemsDocument27 pagesJust-in-Time and Lean SystemsIrfan Ahmad Awan100% (1)

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Seriously Good Software: Code that works, survives, and winsFrom EverandSeriously Good Software: Code that works, survives, and winsRating: 5 out of 5 stars5/5 (1)

- +PFMEA Rating Scale GuidelinesDocument2 pages+PFMEA Rating Scale GuidelinesBalaji SNo ratings yet

- Luperox 101Document8 pagesLuperox 101Balaji SNo ratings yet

- +GL 01 PfmeaDocument9 pages+GL 01 PfmeaBalaji SNo ratings yet

- SDS - Oks 2101 - enDocument16 pagesSDS - Oks 2101 - enBalaji SNo ratings yet

- TDS Silcogum Black 35815Document1 pageTDS Silcogum Black 35815Balaji SNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. IdentificationBalaji SNo ratings yet

- Constitutional Law - Assignment by S KalaiarasiDocument1 pageConstitutional Law - Assignment by S KalaiarasiBalaji SNo ratings yet

- Silcogum Black 35815Document15 pagesSilcogum Black 35815Balaji SNo ratings yet

- BK Pom Uv Smartbatch - CC10231751BG TDSDocument2 pagesBK Pom Uv Smartbatch - CC10231751BG TDSBalaji SNo ratings yet

- BK Pom Uv Smartbatch - CC10231751BG - MSDSDocument17 pagesBK Pom Uv Smartbatch - CC10231751BG - MSDSBalaji SNo ratings yet

- ISO13645 RequirementsDocument22 pagesISO13645 RequirementsBalaji S100% (1)

- Consumables LIst With PriceDocument3 pagesConsumables LIst With PriceBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M8)Document13 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M8)Balaji SNo ratings yet

- Consultancy ScopeDocument3 pagesConsultancy ScopeBalaji SNo ratings yet

- Contigency Plan Cum Testing Record - HBIDocument1 pageContigency Plan Cum Testing Record - HBIBalaji SNo ratings yet

- Module 2 - Asian Productivity MovementDocument76 pagesModule 2 - Asian Productivity MovementBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M7)Document15 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M7)Balaji SNo ratings yet

- Consultancy Setup ActivitesDocument3 pagesConsultancy Setup ActivitesBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M9)Document15 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M9)Balaji SNo ratings yet

- TPM PoliciesDocument2 pagesTPM PoliciesBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M10)Document12 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M10)Balaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M5)Document20 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M5)Balaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M4)Document26 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M4)Balaji SNo ratings yet

- 3057 Kanban ProposalDocument31 pages3057 Kanban ProposalBalaji SNo ratings yet

- APO E Learning Integrating Lean MFG System With Ind 4 (M6)Document12 pagesAPO E Learning Integrating Lean MFG System With Ind 4 (M6)Balaji SNo ratings yet

- Internal Quality Auditor Training Quiz (1-15)Document12 pagesInternal Quality Auditor Training Quiz (1-15)Balaji SNo ratings yet

- Resource Planning 2Document10 pagesResource Planning 2Balaji SNo ratings yet

- Flat Belt DriveDocument25 pagesFlat Belt DriveMurugesan RameshNo ratings yet

- IC Contractor Progress Payment Template 8531 V1Document6 pagesIC Contractor Progress Payment Template 8531 V1elbaraniNo ratings yet

- Joint Measurement Sheet: Name of CollegeDocument1 pageJoint Measurement Sheet: Name of CollegeVenu GopalNo ratings yet

- 6 4 4Document3 pages6 4 4Rodolfo PonceNo ratings yet

- Datasheet Vikram Solar Multi Crystalline 72 Cell IndiaDocument2 pagesDatasheet Vikram Solar Multi Crystalline 72 Cell Indiasteffi subaNo ratings yet

- NemaDocument4 pagesNemaMohamed ElfekyNo ratings yet

- Genio E550g User ManualDocument140 pagesGenio E550g User ManualAlbert LugoNo ratings yet

- Introduction: Classification of Layout, Advantages and Limitations of Different LayoutsDocument14 pagesIntroduction: Classification of Layout, Advantages and Limitations of Different LayoutsPadmavathi Putra LokeshNo ratings yet

- H. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFDocument2 pagesH. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFfajrul 2222No ratings yet

- R0030 PDFDocument33 pagesR0030 PDFOscar Gutiérrez-JuncoNo ratings yet

- DT300-Series-manual Timer 04Document2 pagesDT300-Series-manual Timer 04eeindustrialNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- Dermocybin: Structure ofDocument6 pagesDermocybin: Structure ofJohannes Lund VvithNo ratings yet

- Butt Fusion Machines Small-Medium - V2 - LowDocument12 pagesButt Fusion Machines Small-Medium - V2 - LowViorel TomaNo ratings yet

- Guide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFDocument4 pagesGuide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFMFaiz RHamiraNo ratings yet

- Transformer Protection in SubstationDocument20 pagesTransformer Protection in SubstationManu JosephNo ratings yet

- 2016-2018 Road Crash Data For Critical Intersection 2020Document186 pages2016-2018 Road Crash Data For Critical Intersection 2020Ferdinand Fragata RamiterreNo ratings yet

- TI Audio GuideDocument49 pagesTI Audio GuideMarc StagerNo ratings yet

- Sigunit L54-45 AFDocument2 pagesSigunit L54-45 AFDudee DaryanNo ratings yet

- DKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CDocument82 pagesDKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CNoah MusundiNo ratings yet

- Ct-110 Cbs Rev 00 June 19Document76 pagesCt-110 Cbs Rev 00 June 19Satya Prakash Pathak100% (5)

- 2023 01 Gasket-HandbookDocument216 pages2023 01 Gasket-Handbookrbnotosagoro100% (1)