Professional Documents

Culture Documents

PTC Industries Limited (AMTC) Sarai Sahjadi, Lucknow-227101: 8D Report

PTC Industries Limited (AMTC) Sarai Sahjadi, Lucknow-227101: 8D Report

Uploaded by

Deepak DasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC Industries Limited (AMTC) Sarai Sahjadi, Lucknow-227101: 8D Report

PTC Industries Limited (AMTC) Sarai Sahjadi, Lucknow-227101: 8D Report

Uploaded by

Deepak DasCopyright:

Available Formats

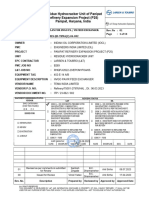

Format No. F-CCM-03(Rev.

01)

PTC INDUSTRIES LIMITED

(AMTC) Sarai Sahjadi,

Lucknow-227101

8D Report Date: Tuesday, July 02, 2019

Customer : Supplier: PTC INDUSTRIES LIMITED

Westad Industrie AS Name: Mr.Deepak Das

Heggenveien Position: Manager QC

N-3369 Geithus,Norway email: deepak.das@ptcil.com

1. Reference & Team

NCR No.: 8D-1, email communication dated 13/06/2019 Notification Date: 13-Jun-19

Material .: CF8M Description: Ext. Bonnet

Part No.: --- Quantity : ---

Team: Mr. Alok Agarwal, Mr. Jim Collins, Mr Deepak Das, Mr. Ranjit Singh

2. Defect Description

RT certs dated before casting is poured

o RT cert 8191, linked to heat no 1911G-3, cert is dated 12.12.18

§ The date in your RT log states that RT8191 is performed mid Januar 2019 => date in cert is expected to be a typo

o RT cert 7970, linked to heat 1917G, cert is dated 27.12.18

§ Based on the reported RT number, we found this inspection to be done, December 2018. No heat no reported in the log. Information

from your log, does not comply with the PTC RT cert that we have received.

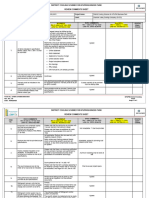

3. Containment - Response expected within 24hrs Responsible Date

No reported parts available to contain. --- ---

4. Root Cause - Consider Why Made? Responsible

Background:

Internal Investigation of all documents showed that:

• Both films with RT#7970 dated27/12/2018 and RT #8211 dated 21/01/2019 exist and that of Bonnet

Extension DN 400.

• RT #7970 is of Bonnet bearing I.D #18B6A-20 and was dispatched in Dec’2018.

• However as per requirement, RT of 1 piece of this lot was required and was to be sent for RT #7969

Mr Ranjit

and I.D 18B6A-20 15-06-2019

Mr Deepak

• RT #7970 was additionally carried out to check the part and with us. • RT

#8211 dated 21/01/2019 was done for DN 400Bonnet Extension bearing ID 1917G-10.

• Both RT films 7970 & 8211 were available here at AMTC in Jan 2019

Root Cause:

1. Mix up of films before reporting.

2. Lack of review mechanism at the time of final report.

5. Formulate and Verify Corrective Actions Responsible

we have to work towards making the reporting system more robust and following actions have been

proposed.:

1. A master log matrix to be prepared for all westad parts poured & reporting to be verified from the

log. The points on the Matrix would be

Part Description

PO Number

Melt No /ID, Date of Pouring

Certifying Agency

RT Number

Inspection Date (Internal) Mr Deepak 15-07-2019

Classifying Society Inspection Date

Dispatch Date

Invoice Date

2. To avoid mix up of the films identification of the films with master log matrix to be done before

offering for surveyor inspection.

6. Correct the Problem and Confirm the Effects Responsible

Implemented

The above system to be verified. Mr Deepak & Verified

15-07-2019

7. Prevent the Problem Responsible

Mr Deepak/

RT Certificate shall be generated using 1-Factory software. 01-01-2020

Mr Ranjit

8. Congratulate the Team

Would be informed after customer approval

Approval: Deepak Das, Manager QC

Supplier Management Signature:

You might also like

- Method Statement Installation of Duct BankDocument63 pagesMethod Statement Installation of Duct BankGerry Dwi Putra100% (2)

- Assessment 3 - HIT172 - 2023Document5 pagesAssessment 3 - HIT172 - 2023F&B ManagerNo ratings yet

- Lighting Control SystemDocument48 pagesLighting Control SystemAli AK100% (1)

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- NR-L3-SIG-10064 ISSUE 7 - AkA C001 For Clearance PDFDocument501 pagesNR-L3-SIG-10064 ISSUE 7 - AkA C001 For Clearance PDFKelvin bongNo ratings yet

- A Case Study On Time RobbersDocument9 pagesA Case Study On Time RobbersEkwubiri ChidozieNo ratings yet

- Dynamic Response of Fixed Offshore Structures Under Environmental LoadsDocument16 pagesDynamic Response of Fixed Offshore Structures Under Environmental LoadsxautraixxxxxxNo ratings yet

- 01 01 02 02 01 - Incident - Rack - SPR 02 - 20190315Document4 pages01 01 02 02 01 - Incident - Rack - SPR 02 - 20190315vaibhav sinhaNo ratings yet

- 4000046273-PGCA-EA-C01-010 - C1 - 1 - Package InstrumentDocument4 pages4000046273-PGCA-EA-C01-010 - C1 - 1 - Package Instrumentrajindo1No ratings yet

- VD V220 BSL DWG 0015 - eDocument26 pagesVD V220 BSL DWG 0015 - eabdulNo ratings yet

- Precheck Reply of C&RDocument3 pagesPrecheck Reply of C&Rq.khalid.mNo ratings yet

- Inspection Report: 0. Supplier Contact Information: Name: Position: Email: Phone #Document4 pagesInspection Report: 0. Supplier Contact Information: Name: Position: Email: Phone #Brain AliveNo ratings yet

- CS 220802djpcme714 Exco00 13Document2 pagesCS 220802djpcme714 Exco00 13nimrod napituNo ratings yet

- Inspection Report: ITT-1808 Fabcon Industrial Services FZ LLCDocument6 pagesInspection Report: ITT-1808 Fabcon Industrial Services FZ LLCBrain AliveNo ratings yet

- TR 01023 Sie MSP 00015Document1 pageTR 01023 Sie MSP 00015BumiLangitNo ratings yet

- Eds Lan S03Document69 pagesEds Lan S03boy leeNo ratings yet

- Irf - Small PowerDocument8 pagesIrf - Small PowerJohny AdvientoNo ratings yet

- Flash Report For ProservDocument1 pageFlash Report For ProservChitti Raju DendukuriNo ratings yet

- Sup 2019 0003Document3 pagesSup 2019 0003james.anitNo ratings yet

- Inspection Report: 0. Supplier Contact Information: Name: Position: Email: Phone #Document4 pagesInspection Report: 0. Supplier Contact Information: Name: Position: Email: Phone #Brain AliveNo ratings yet

- C8516-CLT-QMT-0031 - Rev-00 Inspection Checklist For GRP LaminationDocument1 pageC8516-CLT-QMT-0031 - Rev-00 Inspection Checklist For GRP LaminationJabin100% (1)

- Service AgrementDocument36 pagesService AgrementAnnu ThukuranNo ratings yet

- 402-E-09 B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-001Document14 pages402-E-09 B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-001tarun gotiNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- Response To Request For Approval For Non Categorised ItemDocument3 pagesResponse To Request For Approval For Non Categorised ItemHery MukhlisNo ratings yet

- Request For Inspection: RTCC Material Storage / Ware HouseDocument1 pageRequest For Inspection: RTCC Material Storage / Ware Housevijayendar84No ratings yet

- Spp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic CableDocument14 pagesSpp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic Cablechandrahai hrangkhawlNo ratings yet

- IMAC FormDocument1 pageIMAC Formsuresh prakasamNo ratings yet

- P-10 PDSDocument8 pagesP-10 PDSmohamedNo ratings yet

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberDocument4 pagesDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1No ratings yet

- Satpura Thermal Power Station Office of The Superintending Engineer (Et&I) Iv P.O. SARNI: DISTT: BETUL (M.P.) 460 447Document3 pagesSatpura Thermal Power Station Office of The Superintending Engineer (Et&I) Iv P.O. SARNI: DISTT: BETUL (M.P.) 460 4474D EngineeringNo ratings yet

- TP-CGDF-80280-SPC-A4 - A2 - Specification For Platforms, Stairs, Ladders and HandrailsDocument11 pagesTP-CGDF-80280-SPC-A4 - A2 - Specification For Platforms, Stairs, Ladders and HandrailsPrasad BaleNo ratings yet

- 4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied FuelDocument6 pages4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied Fuelrajindo1No ratings yet

- AAC-MS-EL-0005 Earthing & Lightning Protection System, 25 July 2013Document25 pagesAAC-MS-EL-0005 Earthing & Lightning Protection System, 25 July 2013aayasirNo ratings yet

- viewNitPdf 2547183Document19 pagesviewNitPdf 2547183EMJAYNo ratings yet

- STATUS OF SYSTEM INSPECTION AS ON 03.01.2019 (Civil Part) : Sr. No. Project Name of Work Agency & PO/WODocument5 pagesSTATUS OF SYSTEM INSPECTION AS ON 03.01.2019 (Civil Part) : Sr. No. Project Name of Work Agency & PO/WOMANNANo ratings yet

- Replacement of Defective Parts For A1 CMC Crau UnitDocument5 pagesReplacement of Defective Parts For A1 CMC Crau UnitEzhilanNo ratings yet

- Consumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Document27 pagesConsumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Kannan MurugesanNo ratings yet

- DRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Document61 pagesDRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Rafat KhanNo ratings yet

- Hertz Inspection Service PVT LTD Irc1Document18 pagesHertz Inspection Service PVT LTD Irc1Rahul N PatelNo ratings yet

- EngineeringDocument6 pagesEngineeringmohelectro70No ratings yet

- 0909-GS-R-TA-12002 - A1 - LP, MP Gas Compressors Tag No. 923XT001A-B - Instrument I-O ScheduleDocument5 pages0909-GS-R-TA-12002 - A1 - LP, MP Gas Compressors Tag No. 923XT001A-B - Instrument I-O SchedulechuminhNo ratings yet

- 402-E-14 Ab B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-002Document14 pages402-E-14 Ab B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-002tarun gotiNo ratings yet

- Crown Light CommissioningDocument41 pagesCrown Light CommissioningAli AKNo ratings yet

- VFD InquiryDocument3 pagesVFD InquirypreethiNo ratings yet

- 4000046273-PGCA-EA-C09-004 - 5.2 - 1 - Control NarrativeDocument47 pages4000046273-PGCA-EA-C09-004 - 5.2 - 1 - Control Narrativerajindo1No ratings yet

- MDC Opmc Rfa TV Ar 487 01 Proposed Glass Barrier For Atrium RailingsDocument7 pagesMDC Opmc Rfa TV Ar 487 01 Proposed Glass Barrier For Atrium Railingsiankevinantonio123No ratings yet

- JKTD17025-0060.S-RFI-WP2-IX-19 B1 Beam Supporting Escalator and TravellatorDocument2 pagesJKTD17025-0060.S-RFI-WP2-IX-19 B1 Beam Supporting Escalator and TravellatormarklesterNo ratings yet

- PDFDocument3 pagesPDFnate anantathatNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorDocument6 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorVasanth KumarNo ratings yet

- 220802DJPCME714 Rev01 Pipeline Drying and Draining ProcedureDocument15 pages220802DJPCME714 Rev01 Pipeline Drying and Draining Procedurenimrod napituNo ratings yet

- 016 - Daikin Chillers 20-4-2020 - District Cooling Scheme For KFUPM Business ParkDocument7 pages016 - Daikin Chillers 20-4-2020 - District Cooling Scheme For KFUPM Business ParkMuhammad NoumanNo ratings yet

- PH No. 07146-278425 Email: Website: MPPGCL - Gov.nic - In: M.P. Power Generating Company LimitedDocument3 pagesPH No. 07146-278425 Email: Website: MPPGCL - Gov.nic - In: M.P. Power Generating Company Limited4D EngineeringNo ratings yet

- INFRA-TES-MST-CCC-CIV-00023 Rev. 0 - Excavation and BackfillingDocument25 pagesINFRA-TES-MST-CCC-CIV-00023 Rev. 0 - Excavation and BackfillingTaiwo OshinNo ratings yet

- 001CSIR - SMART-Poblacion Cabadbaran Cell SiteDocument8 pages001CSIR - SMART-Poblacion Cabadbaran Cell SiteHoney GimoNo ratings yet

- Registration Form Paver Block 114 2022Document4 pagesRegistration Form Paver Block 114 2022nagarjunareddyNo ratings yet

- 8D For Big ID DepthDocument18 pages8D For Big ID DepthKuldeep SinghNo ratings yet

- Epcm Services For Installation of "Indresid " Demonstration Plant at PanipatDocument19 pagesEpcm Services For Installation of "Indresid " Demonstration Plant at Panipatrutuja100% (2)

- Alignment Report PDFDocument4 pagesAlignment Report PDFmohamadhakim.19789No ratings yet

- Request For Information: Subject: Release of On-Hold Structural Elements at GFDocument2 pagesRequest For Information: Subject: Release of On-Hold Structural Elements at GFMark RamirezNo ratings yet

- GSF Registration CertificateDocument1 pageGSF Registration Certificateshivi mishraNo ratings yet

- Industrial Enterprises Act 2020 (2076): A brief Overview and Comparative AnalysisFrom EverandIndustrial Enterprises Act 2020 (2076): A brief Overview and Comparative AnalysisNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Qap - Kongsberg - NabDocument4 pagesQap - Kongsberg - NabDeepak DasNo ratings yet

- Occupational Health & Safety PolicyDocument2 pagesOccupational Health & Safety PolicyDeepak DasNo ratings yet

- Print ListDocument1 pagePrint ListDeepak DasNo ratings yet

- 212GM 2,3,4Document2 pages212GM 2,3,4Deepak DasNo ratings yet

- Application Format 2023Document13 pagesApplication Format 2023Deepak DasNo ratings yet

- EHS Objectives 21-22Document3 pagesEHS Objectives 21-22Deepak DasNo ratings yet

- Stage Wise Flow Diagram of R&D DepttDocument1 pageStage Wise Flow Diagram of R&D DepttDeepak DasNo ratings yet

- Rdi Af Blank ApplicationDocument10 pagesRdi Af Blank ApplicationDeepak DasNo ratings yet

- Current Status of R&D ProjectsDocument3 pagesCurrent Status of R&D ProjectsDeepak DasNo ratings yet

- 211DH 2Document2 pages211DH 2Deepak DasNo ratings yet

- 212KG 2Document1 page212KG 2Deepak DasNo ratings yet

- All Data (403843)Document2 pagesAll Data (403843)Deepak DasNo ratings yet

- Drawing-Impeller 29A5Document1 pageDrawing-Impeller 29A5Deepak DasNo ratings yet

- Impeller 32A3 2063J-2&5Document2 pagesImpeller 32A3 2063J-2&5Deepak DasNo ratings yet

- Impeller 50A3 20CYS-7 & 5Document2 pagesImpeller 50A3 20CYS-7 & 5Deepak DasNo ratings yet

- Impeller 50A3 2111R-6 & 7Document2 pagesImpeller 50A3 2111R-6 & 7Deepak DasNo ratings yet

- Impeller 50A3 20CYS-6Document2 pagesImpeller 50A3 20CYS-6Deepak DasNo ratings yet

- Structure & Classification of Vascular Bundles in PlantsDocument20 pagesStructure & Classification of Vascular Bundles in PlantsSwati Upadhyay0% (1)

- Lesson 1 (Circles)Document25 pagesLesson 1 (Circles)Anna Victoria MadrilejosNo ratings yet

- Final Construction Dossier HandoverDocument1 pageFinal Construction Dossier Handovercsc EXPERTISENo ratings yet

- Nuclear Plant - Tdl-011webDocument133 pagesNuclear Plant - Tdl-011webMayer FernandesNo ratings yet

- UNIT-11-JUST-SUPPOSEDocument13 pagesUNIT-11-JUST-SUPPOSECesar RodriguezNo ratings yet

- Ethiopian Construction LawDocument128 pagesEthiopian Construction LawFreedom Love Nabal100% (4)

- Determinants of Job SatisfactionDocument4 pagesDeterminants of Job SatisfactionEINSTEIN2DNo ratings yet

- Volkswagen TransporterDocument3 pagesVolkswagen TransporterTasawar ShahNo ratings yet

- B. Inggris - Putri AprilliaDocument8 pagesB. Inggris - Putri AprilliaPutri AprilliaNo ratings yet

- E38 DSC System PDFDocument32 pagesE38 DSC System PDFjoker63000No ratings yet

- WhitePaper AVEVA PredictiveAnalyticsPower 22-04Document6 pagesWhitePaper AVEVA PredictiveAnalyticsPower 22-04matiasnNo ratings yet

- Nethravathi River - Water Supply Scheme in DakshinDocument8 pagesNethravathi River - Water Supply Scheme in DakshinMitria WidianingtiasNo ratings yet

- Technical Specification 150917Document517 pagesTechnical Specification 150917Amit Kumar MishraNo ratings yet

- Pondoc Kee Jay Work 5Document5 pagesPondoc Kee Jay Work 5Spring IrishNo ratings yet

- PL Parcel Special Price ListDocument28 pagesPL Parcel Special Price ListMuhammadUsman UsmanNo ratings yet

- CATIA V5 Design With Analysis: (Tutorial 3 - Deep Fry Basket)Document136 pagesCATIA V5 Design With Analysis: (Tutorial 3 - Deep Fry Basket)Oscar Al KantNo ratings yet

- Analysis of Urban Heat Island IntensityDocument14 pagesAnalysis of Urban Heat Island IntensityItishree RanaNo ratings yet

- H12 211-2Document24 pagesH12 211-2fraesser90% (10)

- MD ShaftDocument18 pagesMD Shaftiftikhar ahmedNo ratings yet

- Delhi Building Bye Law Related To FireDocument68 pagesDelhi Building Bye Law Related To FireTaniya SahaNo ratings yet

- ExergyDocument27 pagesExergyniralnaikNo ratings yet

- Paint Finishing Quality and Defect AnalysisDocument6 pagesPaint Finishing Quality and Defect AnalysisAnurag SrivastavaNo ratings yet

- Instruction Manual of PLC WS3U-B Series: For The Following Models: WS3U-14MR-K-B WS3U-14MT-K-B WS3U-14MRT-K-BDocument17 pagesInstruction Manual of PLC WS3U-B Series: For The Following Models: WS3U-14MR-K-B WS3U-14MT-K-B WS3U-14MRT-K-BLegendNo ratings yet

- Chapter 8 Thermal LoadsDocument2 pagesChapter 8 Thermal LoadsCarlo DizonNo ratings yet

- CH 4 Determinants Worksheet 1Document2 pagesCH 4 Determinants Worksheet 1khushi GoyalNo ratings yet

- Physics - XIIDocument3 pagesPhysics - XIIPrabith GuptaNo ratings yet