Professional Documents

Culture Documents

Redressing Diamond Discs

Redressing Diamond Discs

Uploaded by

aranicki8587Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Redressing Diamond Discs

Redressing Diamond Discs

Uploaded by

aranicki8587Copyright:

Available Formats

GET THE MOST OUT OF YOUR GRINDING DISKS

Here is a method of resharpening the disks for when they begin to wear out and grind too slowly. The disks

usually ‘feel’ sharp to your hand but slow on the glass. Note that this technique is only for the metal diamond disks and

not the smoothing pad (see our web page on smoothing pads for tips on extending the life of the smoothing pads).

We have had success by rubbing the disk (the machine must be turned off) with a piece of silicon carbide dressing stick

(or part of an old silicon carbide grinding wheel from a bench grinder). The silicon carbide should be coarse and a

size you can hold in your hand. With the wheel wet (the machine unplugged) and with a little soap in the water, rub

the dressing stick firmly from the center to the edge (like spokes of a wheel) and back ... do this all the way around

the diamond disk and then once again around the outer half of the wheel (where it is the most worn). This process

actually breaks some of the diamonds and will give the surface a fresh, sharp edge to grind. Disks can be “dressed”

several times thereby extending their life, but realize that each time it is resharpened it will wear out the diamonds

more quickly. Rinse top and bottom of the disk well before using it. This is a resharpening/redressing step because

the normal wear pattern of the diamonds will eventually orient them into less efficient service. This should extend

the life of the disk but it will not be like a brand new disk. You will know that the disk is totally worn out when the

resharpening process does not last very long in the grinding application.

Basically what is happening is this... When the disk is new the diamonds are at slightly different heights and

when the glass is ground on it perhaps 10% of the diamonds are ‘tall’ enough to do the grinding. That is when it

feels very aggressive and fast. As the diamonds begin to ‘wear’, some points are actually breaking off and then you are

grinding on 20% of the diamonds, then 30%, 40%, and so on. Eventually the glass is being ground by the majority

of the diamonds and they are actually supporting the glass more than grinding it. It will feel sharp to your hand, but

not to the glass! The resharpening process actually breaks the diamonds and the process begins again ‘almost’ like new.

Never quite like new but a definite improvement over a worn disk.

****If there are smooth areas on the disk and you cannot feel any diamonds in the “bald” areas then the disk is not

going to be improved by resharpening.

Note: Most Important!!! This process is destructive to the diamonds (in a constructive manner) and should be done

only when the disk is in need of sharpening.

You might also like

- Simmons Pads ReconditioningDocument5 pagesSimmons Pads ReconditioningAnonymous cdQSIU03AQNo ratings yet

- INTERCHANGE 2 - RQUIZ UNITS 13 & 14 - Revisión Del IntentoDocument5 pagesINTERCHANGE 2 - RQUIZ UNITS 13 & 14 - Revisión Del IntentoAURA ARTEAGA100% (4)

- DLL Grade - 7 CookeryDocument9 pagesDLL Grade - 7 CookeryJiety PlarisanNo ratings yet

- Whetstone: The Complete Guide To Using A Knife Sharpening Stone; Learn How To Sharpen Your Knives And Achieve The Ultimate Japanese Blade Cut With The Waterstone Sharpener TechniqueFrom EverandWhetstone: The Complete Guide To Using A Knife Sharpening Stone; Learn How To Sharpen Your Knives And Achieve The Ultimate Japanese Blade Cut With The Waterstone Sharpener TechniqueRating: 5 out of 5 stars5/5 (30)

- U 929 RPM MeterDocument7 pagesU 929 RPM MeterAmit KumarNo ratings yet

- Carve Your Clay: Techniques to Bring the Ceramics Surface to LifeFrom EverandCarve Your Clay: Techniques to Bring the Ceramics Surface to LifeRating: 5 out of 5 stars5/5 (2)

- 1 Background: Control System Design of A Continuous-Flow Stirred Tank Reactor (CSTR)Document6 pages1 Background: Control System Design of A Continuous-Flow Stirred Tank Reactor (CSTR)JalenstoneNo ratings yet

- Cutting A GemDocument18 pagesCutting A Gemmobsivac100% (1)

- Getting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsFrom EverandGetting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsRating: 1 out of 5 stars1/5 (1)

- GoldDocument23 pagesGoldBapake MariaNo ratings yet

- 3 Position Toggle Switch On-Off Wiring-Diagram 2 PoleDocument1 page3 Position Toggle Switch On-Off Wiring-Diagram 2 Polearanicki8587No ratings yet

- Tricking Out Asian 9x20 LatheDocument48 pagesTricking Out Asian 9x20 Lathearanicki8587No ratings yet

- T-Drill PCS UsDocument2 pagesT-Drill PCS Usaranicki8587No ratings yet

- Sample SoP For Vigilance SystemDocument4 pagesSample SoP For Vigilance Systemsogic100% (5)

- Tool SharpeningDocument16 pagesTool SharpeningLito BenitoNo ratings yet

- The Dilucot Method: A Clear Shot at An Excellent EdgeDocument6 pagesThe Dilucot Method: A Clear Shot at An Excellent EdgeJohn DoverNo ratings yet

- LapidaryDocument7 pagesLapidarykkeshner100% (1)

- Please Read The Instructions!: 26195 Otter DR Willits, CA 95490-8046 USA Toll Free: 1-866-419-4879Document4 pagesPlease Read The Instructions!: 26195 Otter DR Willits, CA 95490-8046 USA Toll Free: 1-866-419-4879wanker52No ratings yet

- Lapidary Fundamentals - Cabochon Cutting - International Gem SociDocument17 pagesLapidary Fundamentals - Cabochon Cutting - International Gem SociNick M100% (1)

- How To Make A Thin SectionDocument16 pagesHow To Make A Thin SectionM Arif HidayatullahNo ratings yet

- Greensand Aluminum CastingDocument22 pagesGreensand Aluminum CastingNazeeh Abdulrhman AlbokaryNo ratings yet

- How To CabDocument8 pagesHow To CabSarah Immel100% (2)

- Tumble Finishing: Tumble Finishing Tumbling RumblingDocument18 pagesTumble Finishing: Tumble Finishing Tumbling Rumblingaryan brianNo ratings yet

- TopperDocument6 pagesTopperLe site de thierry thierryNo ratings yet

- Sharpening Plane Irons & ChiselsDocument7 pagesSharpening Plane Irons & ChiselssesostrisserbiusNo ratings yet

- Dremel and Rowe StuffDocument5 pagesDremel and Rowe StuffEdwin HarrisNo ratings yet

- Citric Acid Rust Removal Brochure 4Document4 pagesCitric Acid Rust Removal Brochure 4Dewi AnggrainiNo ratings yet

- Polishing Hard Stones - Jewelry Discussion - Ganoksin Orchid Jewelry Forum Community For Jewelers and MetalsmithsDocument1 pagePolishing Hard Stones - Jewelry Discussion - Ganoksin Orchid Jewelry Forum Community For Jewelers and Metalsmithsmuhammad hamzaNo ratings yet

- Sharpening Techniques and EquipmentDocument3 pagesSharpening Techniques and EquipmentColumbia GomezNo ratings yet

- .Au Agnet Make Piston RingsDocument6 pages.Au Agnet Make Piston Ringsashishgoel102No ratings yet

- Regreasing GPDXDocument51 pagesRegreasing GPDXSamuel DiRoccoNo ratings yet

- How To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionsDocument2 pagesHow To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionstwinscrewcanoeNo ratings yet

- Working With Diatoms: Dailey@sas - Upenn.eduDocument7 pagesWorking With Diatoms: Dailey@sas - Upenn.eduNadia Valeria HerreraNo ratings yet

- Buck Knives Knife Sharpening InstructionsDocument6 pagesBuck Knives Knife Sharpening Instructionshedzer100% (1)

- Tank HeavenDocument6 pagesTank HeavenLory Dena HeathNo ratings yet

- Polished DiamondsDocument9 pagesPolished DiamondspedroNo ratings yet

- Circular CD Slide RuleDocument9 pagesCircular CD Slide RuleHermesNo ratings yet

- Victoria Skimboards Repair GuideDocument4 pagesVictoria Skimboards Repair GuideOrfelino CatralinoNo ratings yet

- How To Make A Coin RingsDocument4 pagesHow To Make A Coin RingsPeter Snyder100% (1)

- The Scraper: A Most Versatile ToolDocument3 pagesThe Scraper: A Most Versatile ToolAdrian Cocis100% (2)

- Reed Seasoningand AdjustingDocument8 pagesReed Seasoningand AdjustingJason May100% (1)

- How I Made The Water For 03353: Pirate King and Queen: Supply ListDocument11 pagesHow I Made The Water For 03353: Pirate King and Queen: Supply ListHamsterglueNo ratings yet

- How To Mount A TireDocument8 pagesHow To Mount A Tirewrb36usaNo ratings yet

- Make A Resin Ring No LatheDocument7 pagesMake A Resin Ring No LatheJuank GiroNo ratings yet

- Ski Tuning Guide PDFDocument6 pagesSki Tuning Guide PDFЂорђе ЏамбасNo ratings yet

- Crystalline Glaze Class Dan DermerDocument4 pagesCrystalline Glaze Class Dan DermerJesus MorenoNo ratings yet

- NotesDocument73 pagesNotescleophas siameNo ratings yet

- Plansnow SandingDocument5 pagesPlansnow SandingTa JavoNo ratings yet

- Making Rock SlidesDocument3 pagesMaking Rock Slidesloz10No ratings yet

- Freezecoring TecnologyDocument5 pagesFreezecoring TecnologyTati NoelNo ratings yet

- Advanced Tool SharpeningDocument10 pagesAdvanced Tool SharpeningjenrocoNo ratings yet

- Norton Water Stone Users GuideDocument2 pagesNorton Water Stone Users Guidejb71xx100% (1)

- Grinding Tools Without EpoxyDocument4 pagesGrinding Tools Without EpoxymohamadazareshNo ratings yet

- How To Fix The Wobbling Table Saw ArborDocument5 pagesHow To Fix The Wobbling Table Saw ArborSonia CireaşăNo ratings yet

- Basic Plane Blade SharpeningDocument3 pagesBasic Plane Blade SharpeningJoshua HNo ratings yet

- Sandpaper Sharpening: ©2020 Active Interest Media Holding CoDocument3 pagesSandpaper Sharpening: ©2020 Active Interest Media Holding CoFrancois VaaltynNo ratings yet

- Sharp Class Hand OutDocument30 pagesSharp Class Hand OutJoshua HNo ratings yet

- Finishing EssentialsDocument12 pagesFinishing Essentialsmax_schofield100% (2)

- 300zx Z32 Headlight DisassemblyDocument10 pages300zx Z32 Headlight DisassemblyRyan JohnsonNo ratings yet

- Sanding TipsDocument2 pagesSanding Tipspaulo passosNo ratings yet

- Twist DrillDocument7 pagesTwist DrillMartinus Oda AdiNo ratings yet

- How To Sharpen An AxeDocument26 pagesHow To Sharpen An AxeBrettNo ratings yet

- Glass CutterDocument21 pagesGlass CutterganeshNo ratings yet

- Using Diamond Pasted Balsa Strops A Summary: (See Appendix B)Document7 pagesUsing Diamond Pasted Balsa Strops A Summary: (See Appendix B)tester1972No ratings yet

- 1537CylinderBor 00000001942Document6 pages1537CylinderBor 00000001942wahyufirmansyah.officeNo ratings yet

- Gold Leaf TechniqueDocument4 pagesGold Leaf TechniqueBapake Maria100% (1)

- Estrella de MoravianDocument21 pagesEstrella de MoravianclannecchNo ratings yet

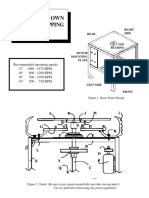

- Build Your Own Diamond Lapping MachineDocument2 pagesBuild Your Own Diamond Lapping Machinearanicki8587No ratings yet

- Dan Brown Bibliografija PDFDocument1 pageDan Brown Bibliografija PDFaranicki8587No ratings yet

- BT Big Button 200 UputstvoDocument28 pagesBT Big Button 200 Uputstvoaranicki8587No ratings yet

- Tuna Salad Recipe - Ina Garten - Food NetworkDocument1 pageTuna Salad Recipe - Ina Garten - Food Networkaranicki8587No ratings yet

- Battlestar Galactica TimelineDocument4 pagesBattlestar Galactica Timelinearanicki8587No ratings yet

- Dan Brown Bibliografija PDFDocument1 pageDan Brown Bibliografija PDFaranicki8587No ratings yet

- Price List: Wheel CutterDocument2 pagesPrice List: Wheel Cutteraranicki8587No ratings yet

- Rociprolap Installation Instructions: Never Start The Rociprolap With The Lap Plate RemovedDocument4 pagesRociprolap Installation Instructions: Never Start The Rociprolap With The Lap Plate Removedaranicki8587No ratings yet

- W B F H MS001: ALL Racket LAG OlderDocument1 pageW B F H MS001: ALL Racket LAG Olderaranicki8587No ratings yet

- Wiring A Linear Actuator With A DPDT Rocker SwitchDocument1 pageWiring A Linear Actuator With A DPDT Rocker Switcharanicki8587No ratings yet

- D M MS002: Ecorative AnholeDocument1 pageD M MS002: Ecorative Anholearanicki8587No ratings yet

- Grilled Stuffed Zucchini With BaconDocument2 pagesGrilled Stuffed Zucchini With Baconaranicki8587No ratings yet

- How To Make Tzatziki: Leyla Kazim Around The World Recipe Roundup Step-By-StepDocument2 pagesHow To Make Tzatziki: Leyla Kazim Around The World Recipe Roundup Step-By-Steparanicki8587No ratings yet

- Mach3 - Camera AlingmentDocument1 pageMach3 - Camera Alingmentaranicki8587No ratings yet

- CNC ConsoleDocument1 pageCNC Consolearanicki8587No ratings yet

- Freeship Manual 2.6Document57 pagesFreeship Manual 2.6Bill GeronikolasNo ratings yet

- Toughbook FaqsDocument7 pagesToughbook Faqsaranicki8587No ratings yet

- E Governance UPSC NotesDocument5 pagesE Governance UPSC NotesranbirkhanNo ratings yet

- Sep 3, Conduct of An Interview and Focused - Group Discussions With Division Personnel, School Heads and Teachers From The Division of Carcar and Cebu Province - Ictu DepedrviiDocument4 pagesSep 3, Conduct of An Interview and Focused - Group Discussions With Division Personnel, School Heads and Teachers From The Division of Carcar and Cebu Province - Ictu DepedrviiAnonymous qWGWIIRSNo ratings yet

- Alien Agenda InvestigatingDocument1 pageAlien Agenda InvestigatingImmigg AnationNo ratings yet

- Hunter Tire ChangerDocument4 pagesHunter Tire Changertayyab abbasNo ratings yet

- Nabhasa Yogas Nabhasa Yogas Nabhasa Yogas Nabhasa Yogas: Sara "Arrow" Yoga: All Planets in All 4 Houses Commencing FromDocument1 pageNabhasa Yogas Nabhasa Yogas Nabhasa Yogas Nabhasa Yogas: Sara "Arrow" Yoga: All Planets in All 4 Houses Commencing FromNeoHoodaNo ratings yet

- QHP Bladder Booklet Multi LanguageDocument44 pagesQHP Bladder Booklet Multi Languageravichandran0506No ratings yet

- Department of Education: Republic of The PhilippinesDocument5 pagesDepartment of Education: Republic of The PhilippinesErnesto Mayo FogataNo ratings yet

- Communication Techniques. A Case Study: Negotiation in A BankDocument7 pagesCommunication Techniques. A Case Study: Negotiation in A BankLuthfi FarhanaNo ratings yet

- FRP Construction With DERAKANE Epoxy Vinylester ResinsDocument65 pagesFRP Construction With DERAKANE Epoxy Vinylester ResinstyNo ratings yet

- High Hour Runner Caterpillar 3412 DIT 540HP Diesel Marine EngineDocument2 pagesHigh Hour Runner Caterpillar 3412 DIT 540HP Diesel Marine EngineAnoop VijayakumarNo ratings yet

- Accredited Service and Repair Shops As of Feb 2010Document45 pagesAccredited Service and Repair Shops As of Feb 2010elite20% (1)

- 234348199-Plasma-Spray-Coating - 2024-02-23T001110.506Document153 pages234348199-Plasma-Spray-Coating - 2024-02-23T001110.506hinhhits07No ratings yet

- Siemens SIVACON S8, IEC 61439 Switchgear and Control PanelDocument43 pagesSiemens SIVACON S8, IEC 61439 Switchgear and Control PanelGyanesh Bhujade100% (2)

- Programmable Unijunction TransistorDocument2 pagesProgrammable Unijunction TransistorBaquiran John Paul Baquiran100% (1)

- Microsoft Project 2021Document11 pagesMicrosoft Project 2021Batara Sinaga100% (1)

- A Preliminary Assessment of Ndoola (Ndoro)Document16 pagesA Preliminary Assessment of Ndoola (Ndoro)Samuel EkpoNo ratings yet

- Ece4890 NotesDocument72 pagesEce4890 NoteshenrydclNo ratings yet

- DF AntennaDocument5 pagesDF Antennajose eliasNo ratings yet

- DBB2102 Unit-01Document21 pagesDBB2102 Unit-01Silent KillerNo ratings yet

- Environmental Science Guide and CoorelationDocument25 pagesEnvironmental Science Guide and Coorelationapi-232424041No ratings yet

- CH 1 VPO - Guest Weekly BillDocument17 pagesCH 1 VPO - Guest Weekly BillKhushali OzaNo ratings yet

- Ict-Based Semi-Detailed Lesson PlanDocument22 pagesIct-Based Semi-Detailed Lesson Planejmsato00089No ratings yet

- Five Ways To Drive Experience Led Growth in BankingDocument9 pagesFive Ways To Drive Experience Led Growth in Bankingitzel riveraNo ratings yet

- Gravity and The Quantum Vacuum Inertia Hypothesis. I. Formalized Groundwork For Extension To GravityDocument13 pagesGravity and The Quantum Vacuum Inertia Hypothesis. I. Formalized Groundwork For Extension To GravityMilan StepanovNo ratings yet

- Individual Inventory FormDocument1 pageIndividual Inventory FormNorhana LumambasNo ratings yet