Professional Documents

Culture Documents

Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch List

Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch List

Uploaded by

nadeemCopyright:

Available Formats

You might also like

- Precommissioning Procedures of Testing & CommissioningDocument96 pagesPrecommissioning Procedures of Testing & CommissioningTasawar Hussain85% (34)

- Mep Boq Plot No.6721148Document53 pagesMep Boq Plot No.6721148ArifHadiNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Annexure 4 - TransformerDocument36 pagesAnnexure 4 - TransformerBala MNo ratings yet

- Cooling Tower Construction ChecklistDocument6 pagesCooling Tower Construction ChecklistGopinath GopiNo ratings yet

- Check List For CommissioningDocument18 pagesCheck List For CommissioningAnil Radheshwar100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Arthur Capper History Time Line July 5Document13 pagesArthur Capper History Time Line July 5Johanna Bockman100% (1)

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument11 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListEswari AnandNo ratings yet

- 8 NCC Etp Vol II Sec C1-ADocument4 pages8 NCC Etp Vol II Sec C1-AShanjiNo ratings yet

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarNo ratings yet

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- Ahu Documentantion Minimum RequirementsDocument7 pagesAhu Documentantion Minimum RequirementsdanielsilvavNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0407 (3) Rev001Document2 pagesQic-Qsp-Uni-Tdr-Cl-0407 (3) Rev001Ragab EisaNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Layover Inspection Schedule Issue 06Document17 pagesLayover Inspection Schedule Issue 06Pankaj Khondge100% (1)

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Saic - K-4006Document2 pagesSaic - K-4006Bander Al–kouhlaniNo ratings yet

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDocument37 pagesRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaNo ratings yet

- SATR-J-6911Rev 0 PDFDocument6 pagesSATR-J-6911Rev 0 PDFAdel KlkNo ratings yet

- SATR-J-6501 - Rev 0 PDFDocument5 pagesSATR-J-6501 - Rev 0 PDFAdel KlkNo ratings yet

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Pipework Oil SystemDocument12 pagesPipework Oil SystemSamNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- MQ SP M 4033 PDFDocument16 pagesMQ SP M 4033 PDFjaseelNo ratings yet

- Mvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.Document2 pagesMvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.wazakifyNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocument10 pagesThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Mvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.Document2 pagesMvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.wazakifyNo ratings yet

- Example Technical ReportDocument4 pagesExample Technical ReportAhmed ElhoniNo ratings yet

- Red Bag Checklist For Mechanical CompletionDocument9 pagesRed Bag Checklist For Mechanical Completionhitm357No ratings yet

- Spec Upt Page 41Document58 pagesSpec Upt Page 41midhunvarNo ratings yet

- 6-66 KV SF6 BKR R3 May12Document26 pages6-66 KV SF6 BKR R3 May12PB MehtaNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- Ac Panel Test ProsedureDocument6 pagesAc Panel Test ProsedureUtku Can KılıçNo ratings yet

- SAIC-D-2012 Rev 2Document4 pagesSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATR-J-6912 Rev 0 PDFDocument4 pagesSATR-J-6912 Rev 0 PDFAdel KlkNo ratings yet

- Pre-Com. Procedure For Tertiray - 415V SWGRDocument13 pagesPre-Com. Procedure For Tertiray - 415V SWGRBalamurugan SelvarajNo ratings yet

- SECTION 26 36 23 Automatic Transfer SwitchesDocument16 pagesSECTION 26 36 23 Automatic Transfer SwitchesAdam SatrioNo ratings yet

- Volume-IIIB Part-3 Electrical and InstrumentationDocument211 pagesVolume-IIIB Part-3 Electrical and InstrumentationVikas Dwivedi100% (1)

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic - K-4015Document3 pagesSaic - K-4015Bander Al–kouhlaniNo ratings yet

- Commissioning Responsibilty Matrix Rev.0 12-Nov-2014Document4 pagesCommissioning Responsibilty Matrix Rev.0 12-Nov-2014Dinesh Radhakrishnan100% (1)

- Ssem 564 C27 SKM 01Document6 pagesSsem 564 C27 SKM 01Ahmed Mostafa Fadly MadyNo ratings yet

- Standard Commissioning Procedure For Building Exhaust Fans: General NotesDocument9 pagesStandard Commissioning Procedure For Building Exhaust Fans: General NotesAbdul Mohid SheikhNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- V 341001Document1 pageV 341001mdkakhanNo ratings yet

- Pneumatic Actuator Specs Including Hydrant Line POVs PDFDocument12 pagesPneumatic Actuator Specs Including Hydrant Line POVs PDFrka0503No ratings yet

- SECTION 16208 Engine GeneratorsDocument38 pagesSECTION 16208 Engine Generatorsno nameNo ratings yet

- JW Marriot Abu Dhabi Resort & Spa Otak InternationalDocument15 pagesJW Marriot Abu Dhabi Resort & Spa Otak InternationalPeanut d. DestroyerNo ratings yet

- Tender Technical Specification For Material of UG WorkDocument205 pagesTender Technical Specification For Material of UG WorkAshish bhattNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- Saudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- In-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportDocument2 pagesIn-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportnadeemNo ratings yet

- Release Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportDocument2 pagesRelease Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechnadeemNo ratings yet

- Saes Z 004Document40 pagesSaes Z 004nadeem100% (1)

- Saes A 100Document6 pagesSaes A 100nadeemNo ratings yet

- BOQ - Method of Measurement and BOQ PDFDocument176 pagesBOQ - Method of Measurement and BOQ PDFyousef100% (1)

- ICC ES Report ESR 1961: The Dow Chemical CompanyDocument3 pagesICC ES Report ESR 1961: The Dow Chemical CompanymurdicksNo ratings yet

- Hoja de Vida Maquina Piloteadora Sany 330Document3 pagesHoja de Vida Maquina Piloteadora Sany 330Tefi OrtizNo ratings yet

- Komatsu 0000279c H0120-001002A PageDocument2 pagesKomatsu 0000279c H0120-001002A PageCristhian Sullon SosaNo ratings yet

- Fatigue Life Testing in Metal Expansion JointsDocument1 pageFatigue Life Testing in Metal Expansion JointsNaresh ANo ratings yet

- Resultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDocument4 pagesResultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDIEGO FERNANDO CADENA ARANGONo ratings yet

- Flexible Pavement DistressDocument33 pagesFlexible Pavement DistressMohammed Omer KufishahNo ratings yet

- Ungureanu 2020Document16 pagesUngureanu 2020Zeyad F SaadNo ratings yet

- Meeting Minutes - Construction Progress MeetingDocument4 pagesMeeting Minutes - Construction Progress Meetingmech_sahilNo ratings yet

- Concrete and Formwork in NYCDocument60 pagesConcrete and Formwork in NYCKannon TamNo ratings yet

- Accepted Manuscript: International Journal of Impact EngineeringDocument52 pagesAccepted Manuscript: International Journal of Impact EngineeringMickey DalbeheraNo ratings yet

- Interior Non-Load Bearing Partition Bracing Option: NWCB Technical DocumentDocument2 pagesInterior Non-Load Bearing Partition Bracing Option: NWCB Technical DocumentClaudio ColettaNo ratings yet

- SantaCountyWTv0.5.4 b1 CompressedDocument27 pagesSantaCountyWTv0.5.4 b1 CompresseddougchiNo ratings yet

- Bomba Active ChecklistDocument6 pagesBomba Active ChecklistPerwira Khusairi RahmanNo ratings yet

- Technical Graphics RubricDocument1 pageTechnical Graphics Rubricapi-268923331100% (2)

- Technical Schedule A To D & H Pkg-2Document101 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- Kanowit Progress Report NO.10Document28 pagesKanowit Progress Report NO.10Kevin ChangNo ratings yet

- GROHE Specification Sheet 23296000Document2 pagesGROHE Specification Sheet 23296000hehehe heheheheheheNo ratings yet

- 1.3 SCP201 Assignment Worksheet - Jan 2023 PDFDocument4 pages1.3 SCP201 Assignment Worksheet - Jan 2023 PDFfang weiNo ratings yet

- Brutalism Style AssignmentDocument23 pagesBrutalism Style Assignmentcartiallan21No ratings yet

- Week 11 Lecture Material - WatermarkDocument57 pagesWeek 11 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- Interventions, Professionals and User InputsDocument7 pagesInterventions, Professionals and User InputsMohamedNo ratings yet

- Bridge Working DrawingsDocument16 pagesBridge Working DrawingsAashish kumar100% (1)

- AppendixDocument24 pagesAppendixSecret SecretNo ratings yet

- Ardo - MekanikDocument11 pagesArdo - Mekaniksastro wijoyoNo ratings yet

- Describing Objects - Paragraph ExampleDocument4 pagesDescribing Objects - Paragraph ExampleDylweisNo ratings yet

- Lesson 2 4Document51 pagesLesson 2 4MR P PinnyNo ratings yet

- Architecture of 19th Century PDFDocument12 pagesArchitecture of 19th Century PDFrajat charayaNo ratings yet

Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch List

Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch List

Uploaded by

nadeemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch List

Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch List

Uploaded by

nadeemCopyright:

Available Formats

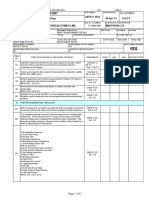

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018) Rev.2018.05.

00 31-May-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Originator/Agency: Approved By:

Covered Req'd for

Verified/

ITEMApproved By: By Scope Start-Up Completion

No. Description (Item entry date) Date Accepted Remarks

(scheduled) By:

Y/N Y/N

GENERAL

Provide proper ID for all equipment. ID numbers shall be legible

1.1 from 50 feet for process equipment

Remove all rust preventatives, oil, grease, etc. used to

preserve equipment during construction, and install proper

1.2 lubricants after review with Operations.

At time of turnover, all fire proofing and rough insulation shall

be complete. All equipment, piping, instruments, instruments

leads, etc. requiring insulation for heat conservation or proper

operation shall be covered so that startup operations will not be

1.3 delayed due to excessive heat loss. Insulation required for

personnel protection shall also be completed.

At time of turnover, painting shall be complete enough so that

an excessive amount of scaffolding is not left still standing in

1.4 the areas where the operators must work to start up the plant.

At the time of turnover, operating areas including platforms

shall be free of debris, tools and extraneous materials which

would impede operation or cause an unsafe condition. All

1.5 accessways shall be open for emergency vehicles

1.6 Check lighting intensities

Complete all necessary paving, fencing, and items of like

1.7 nature.

All testing of lifting equipment shall be witnessed by the

Inspection Department's Crane Inspection Representative

1.8 which can then be provided with a current inspection sticker or

the completion of the successful tests.

Perform Leak test of all piping and equipment handling process

fluids in accordance with SAES-L- 150 and repair all leaks.

Check all nuts and bolts to see that threads are fully engaged.

1.9 All torque procedures for bolting and bolt pre-loads should be

verified on (ANSI 600# and above) piping and equipment where

applicable

Verify all spare parts data packages have been submitted and

1.10 accepted by Material Supply Organization

All temporary fencing or barricades must be removed to allow

1.11 free access to the operating units.

Saudi Aramco: Company General Use

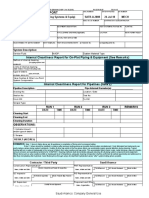

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

All start up spare parts required by contract are available on

site.

1.12

1.13 CIVIL/STRUCTURAL

Inspect sewer lines and check all cleanouts manholes, and

service connections for proper installation and functioning.

1.14 Check manholes for leak tightness by filling and then observing

the water level for ten hours

Test buildings for leak tightness and maintenance of required

1.15 internal positive pressure. (Refer to SAES-J-801 and SAES-K-

002)

1.16 Access platforms, ladders, stairs, walkways and handrails.

Perform a "Flood Test" for verification of process area OWS

1.17 catch basins and a "Flow Test" of the floor drain for battery

rooms to the acid neutralization pits

Check access around equipment at grade and at elevated

areas to ensure it is proper for normal operation and

1.18 maintenance as well as for emergency escape. Refer to SAES-

B-054 for more details

Verify that all valves and instruments are provided with proper

access for normal operation and maintenance purposes as per

1.19 SAES-B-054.

ELECTRICAL

Perform dielectric strength tests on power transformer and

2.1 disconnect switch insulating oil and install when satisfactory.

Check condition of grease in grease lubricated motor and

2.2 generator bearings

Perform all necessary prestart-up non-operating tests and Hi

Pot checks on all power cables, generators, Switchgear, MCCs,

transformers and grounding resistors following manufacturers'

instructions and guidelines given in the applicable Saudi

2.3

Aramco Pre-Commissioning Forms Manual available from

Consulting Services Department

Measure and record the insulation resistance (Megger Testing)

of all power (480V or less), instrument wiring (including

2.4 thermocouple leads) and lighting circuits from conductor to

conductor and from each conductor to ground

Perform applicable checks, adjustments and field tests using, if

necessary in order to maintain schedule, temporary

2.5

construction power.

Calibrate and set substation relays on all circuit breakers. Set

2.6 time delays. Set and test fault pressure relays and transformer

taps.

Energize substations and load centers by connection to

electrical distribution systems (Energized by authorized

2.7 electrical systems operator after obtaining approved

"Energization Authorization Certificate")

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Check operability of emergency and instrument power systems

2.8 as well as emergency lighting system

Paint or tag all electrical apparatus (Push button boxes,

2.9 connection boxes, etc) according to Saudi Aramco's color code

or regulations

Perform a final functional checkout for all equipment and

2.10 systems.

PIPING

Flush, clean and hydro/pressure test, per SAEP-327, SAES-A-

004 and SAES-G-116, all piping and piping systems as

required by drawings, standards and specifications prior to

MCC. All orifice plates, strainers, control valves, thermowells,

and other items, which may be damaged during flushing and

3.1 testing, are to be removed from the system. With systems in

LPG service, and on completion of hydrotesting, system shall

be fully drained and dried.

Provide and install all strainers, both temporary and permanent,

3.2 spec. blinds, and temporary blinds, called for on drawings and

specifications

Check that all temporary blanks, plugs, caps, spectacle blinds

and temporary spools installed for the hydro/pressure test have

been removed and that all spectacle plates, blinds, etc. that are

3.3 to remain in the system are in their correct locations as per the

P&ID.

Provide and install other temporary blinds required for startup,

3.4 as specified by Proponent Operations.

Check packing and packing materials and lubrication of valves,

3.5 repack and lubricate as necessary

Supply supervised labor (Note 1) and necessary tools for post

hydro/pressure test, air blowing and/or water flushing

operations that may be required by Commissioning/Operations.

This will include opening flanges, dropping out control valves,

soft-seat valves, and spool pieces, installation of temporary

blinds and piping connections, removing all debris, blowing cut

lines, cleaning temporary strainers, replacing valves,

3.6 reassembling piping, repairing insulation and painting, etc., as

required for additional flushing of piping and equipment run-in

subsequent to MCC. Steam lines serving turbines shall be

cleaned by steam prior to placing into service

Schedule and direct additional Post MCC air blowing/steam

blowing and/or water flushing operations. Perform Leak test at

3.7 operational pressure of all piping and equipment handling

process fluids and repair all leaks.

Provide all replacement gaskets, spool pieces, temporary

connections, hoses, rigging and hoisting equipment, and blinds

3.8 required for additional post MCC Hydro/Pressure testing or

flushing operation

Supply and install line identification tags and signs. Stencil lines

3.9 for identification

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Provide list and location of all blinds installed for start-up and

3.10 not detailed on P&ID's

Commission spring hangers and supports after hydro test,

3.11 check spring hangers and pipe anchors and guides in hot

position, provide cold and hot setting data

3.12 Check pipe anchors and guides.

3.13 Install corrosion probes

3.14 Remove temporary strainers (Normally after start-up

Confirm that bleeds and vents used during commissioning are

3.15 properly plugged.

MECHANICAL EQUIPMENT

4.1 AIR FIN COOLERS

Perform all hydro/pressure tests as required per SAES-A-004.

4.2

Check levels and dimensions of substructure, machinery

4.3 mount, fan ring, Furnish record of measurements

Perform decoupled motor running test, (Min. 4 hours), check

4.4 vibration and perform necessary corrective work

4.5 Set and align fan assembly, fan shaft, sheave and driver

Demonstrate satisfactory operation of louvers; adjust as

4.6 necessary

Clean inside of the hood and remove all extraneous articles

4.7 around the air fin cooler

4.8 Set and adjust V-Belts

4.9 Check and verify fan tip clearances

BOILERS, DUCTWORK AND STACK

Perform hydrostatic tests per SAES-A-004. Empty water

5.1 completely after test and dry. Alternatively, can be laid up with

inhibitor added to test water.

5.2 Perform air leak test on completed casing

Check to see if provision has been made for thermal expansion

5.3 of all boiler parts and attached piping

Clean out stack and duct, open manholes and other opening for

inspection. Check operation of dampers. Close stack and duct

5.4 after inspection.

5.5 Check mechanical operation of soot blowers

Prepare boiler dry-out procedure including manufacturer's

recommendations and review with proponent 90 days in

5.6

advance of turnover

5.7 Re-couple fans to drivers after successful run-in of driver

Inspect internal surfaces of drums, remove all debris and

5.8 provide supervised labor to open, clear and close boilers after

boil out and/or acid cleaning.

Verify proper relief valve rating, certification, and installation

5.9

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

5.10 Repair damage to liners if it occurs during cureout

COMPRESSORS

Install compressor piping and make piping corrections as

required by manufacturer's tolerances. Set and cold align

6.1 compressor and driver. Furnish record of alignment to

Operations

Clean suction piping of gas compressors, mechanically and/or

6.2 chemically

Ensure that compressor suction piping, suction and interstage

drums, lube and seal oil piping, are in clean condition, free of

mill scale, weld spatter and all loose and foreign material.

6.3 Disassemble piping for cleanliness inspection as required.

Run-in the uncoupled compressor drive motor (minimum 4

6.4 hours).

Recouple compressor to driver after successful run-in of driver.

6.5 Complete cold alignment of train.

COOLING TOWERS

Clean inside and outside the tower. Remove all extraneous

7.1 articles around the tower.

Clean the cold water basin, water distribution deck and ensure

7.2 all spray nozzles are installed.

Couple fans to drivers. After the motor has been checked for

7.3 rotation, run-in 4 hours uncoupled, and check bearings.

FURNACES AND FIXED HEATERS

8.1 Perform hydrostatic test per SAES-A-004

Empty water from coil and air blow if necessary. Add corrosion

8.2 inhibitor to water in non-drainable coils.

Provide furnace dryout procedure based on manufacturer's

8.3 recommendations.

8.4 Check mechanical operation of soot blowers and dampers

Pre-Commission instruments on furnace and ensure all skin

8.5 thermocouples are properly installed and functional

8.6 Verify proper relief valve rating certification and installation

Check operation of stack dampers and verify correct position of

damper to correspond with instrumentation and external

8.7 pointer(s).

WEIGHING SCALES/PRODUCT METERS

Calibrate all solids weighing & measuring devices in their field-

installed operating positions. Furnish record of all calibration

data. Show that equipment meets the specified tolerance for

accuracy over full range of operating conditions Note:

9.1 Operations will arrange for independent calibration of weigh

scales and product meters for custody transfer where required

by government regulations

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

PUMPS

10.1 Set and cold align pump inlet and outlet piping and driver. Furni

Check the motor for rotation, run-in four hours uncoupled, and

10.2 check bearings.

10.3 Recouple pump to driver. Furnish record to Operations

10.4 Install temporary packing if permanent packing or mechanical

seal is notmechanical

Reinstall suitable forseals

flushing. (If pump used

or permanent for flushing.)

packing prior to

10.5 startup

Make final check of cold alignment after pipe flushing. Correct if

10.6 necessary.

Check and run-in pump. All temporary strainers should be in

10.7 place

Make final hot alignment check and do any required doweling

10.8 of the pump and driver

If fire water or other permanent plant pumps are to be used for

supply of water during construction period they are to be

10.9

operated by Operations.

Maintenance of pumps covered by "h" above will be by

Contractor. At end of construction, pumps are to be put in first

10.10 class condition by Contractor.

TANKAGE

11.1 Hydrotest tank and internal piping, and clean inside tank

11.2 Close manways

Strap tank and issue record. (As an exception, Oper. will

11.3 arrange for independent calibration of product tanks for custody

transfer where required by government regulations.

11.4 Install and test appurtenances

11.5 Paint floating roof and inside of tank if required

Water flood floating roof rainwater sumps and test for leaks on

11.6 swivel joints subsequent to floating roof.

Verify proper operation of floating roof and ensure all pressure

release systems and vacuum breakers are clear and functional.

11.7

Test the manifolded foam fire protection system for storage

11.8 tanks if provided in accordance with SAES-B-017

TURBINE DRIVERS

Set and cold align turbine and associated piping. Check

12.1 parallel flange alignment. Furnish record of alignment to

operations

12.2 Chemically clean lube, seal, and hydraulic control lines

Install all permanent packing and accessories after flushing and

12.3 immediately prior to startup.

Check and run-in turbine, make vibration tests, check governor

12.4 and trips.

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Recouple turbine driver to equipment. Make final hot alignment

12.5 check and dowel as necessary

VESSELS - TOWERS, REACTORS AND DRUMS

13.1 Hydrotest all vessels per SAES-A-004

Provide supervised labor to open, clean and close vessels

13.2 during and after flushing, if required

Cure and dry out castable linings. Contractor will provide

procedure, including time/temperature to be used, during drying

13.3 period source of heat must first be accepted by MCC.

Install all tower, reactor and drum internals and perform tray

13.4 leakage tests and leveling adjustments as required.

Clean out all vessels and open manholes and other openings

13.5 for inspection

Perform a detailed inspection of the vessel internals to include

holiday detection of internal coating as well as installation of

13.6

mechanical internals

Release Construction Agency to issue to Contractor written

13.7 authority to close up each vessel.

Properly close up all vessel internal manways and openings per

the proper torquing procedures, after final inspection or after

13.8 charging of chemicals, catalysts, etc., is completed.

For vessels where Contractor has responsibility for loading

13.9 chemicals

HEAT EXCHANGERS

14.1 Check that slide plates have been properly installed.

Open exchangers to allow detailed inspection of the internals.

For shell and tube exchangers, provide a source of high

pressure air, appropriate lances, and other arrangements

14.2 required for safe air blowing and/or flushing of the tubes during

initial operation if required for PAC

14.3 Check for damage to tubes and tube sheets.

14.4 Perform all hydrotesting per SAES-A-004

At the conclusion of flushing and cleaning, inspection, hydro-

testing, and correction of all deficiencies, issue authorization

14.5 (closure certificate) to close the exchangers

Install new gaskets on all broken connections, and then close

14.6 all ports to the exchanger following the proper torquing

procedures.

Low Pressure (SAES-A-004) leak test exchangers

MIXERS

15.1 Rotate mixers by hand to ascertain that they turn freely

Disassemble bearings and other components to allow

15.2 inspection, then reassemble.

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Check alignment & set blades at proper height per vendor

15.3 requirements

15.4 Confirm rotation is correct for blade installation.

15.5 Conduct four (4) hour uncoupled running test of motor

AIR CONDITIONING AND AIR HANDLING EQUIPMENT

Air conditioning and air handling units, individual components

appurtenances, piping and wiring connected to the units, and

16.1 instrumentation controlling the units shall be precommissioned

per vendor instructions

Provide all freon or other cooling medium and charge or

16.2 recharge the units as required

All ductwork shall be inspected prior to closing, to verify that all

fittings and air volume control devices, and duct heaters have

been properly fabricated, installed and operate properly. All

dampers shall be thoroughly cleaned to insure proper

operation. Ducts plenums and casings shall be cleaned of all

debris and blown free of particles fiberglass, dust and rubbish

16.3 before installation of registers and grills. Equipment shall be

properly lubricated. Filters and strainers used during

construction shall be cleaned or replaced

Conduct capacity tests of air conditioning and air handling units.

16.4

16.5 Conduct building fire damper "closure" test

PRESSURE RELIEF AND DISPOSAL SYSTEM (FLARES &

BURN PIT)

Check pressure relief valves (PZV), pressure relief and

blowdown piping, relief knockout drums, flares and burn pits for

17.1 completeness and proper line up prior to placing the facility in

service

Check all PZVs tags to ensure that the PZVs are not overdue

17.2 for T&I and the set pressure is correct as per the P&ID.

Verify that all block valves upstream and downstream pressure

relief valves (PZV) are car-sealed in their proper position. The

inlet block valve to the PZV that is in service shall be open. The

inlet block valve to the standby PZV shall be closed and all PZV

17.3 outlet block valves shall be car-sealed open. All inlet and outlet

block valves for PZVs shall be painted orange

Check bellow-type PZVs to ensure their bonnets are painted

17.4 green

Verify that the outlets and vents of all PZVs are pointed to a

safe location away from equipment, piping, walkways and

17.5

working platforms

Check the flare/burn pit ignition system for completeness and

17.6 proper labeling

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Ensure that flare and burn pit areas have proper warning signs

17.7 for toxic gas and heat radiation

MISCELLANEOUS MECHANICAL EQUIPMENT

All equipment and components not otherwise addressed by this

list shall where applicable, be installed, adjusted, lubricated,

18.1 tested, confirmed for proper functioning

FIRE AND SAFETY SYSTEMS

Conduct Capacity and Flush Tests of the Fire Water System

19.1

Schedule relief valve testing with Aramco's agreement,

sufficiently in advance of startup to permit orderly installation.

All relief valves are to be tested within 90 days prior to turnover

19.2 date. Remove as necessary and transport all relief valves to

and from the approved Aramco facility.

Test, set, and tag relief valves prior to final installation. Install

all relief valves after Aramco or approved Agency, sets and test

19.3 them

19.4 Install all road signs, safety shields, warning signs, barriers

Paint and/or tag all relief valves, car sealed valves and safety

equipment per Aramco Standards. Verify valve position per

19.5 P&ID and then install car seals on block valves where required

in accordance with SAES J 600

Install and pre-commission Fire and Safety systems: Portable

fire extinguishers Stretchers Emergency air packs and

containers Deluge systems, sprinkler systems Safety showers

and eyebaths Tag all fire extinguishers and all fixed fire

protection equipment Fire protection equipment layout map for

19.6 facility Gas detection systems Fire detection and alarm

systems New or revised plant evacuation, stop-work, etc. alarm

systems

COMMUNICATIONS

OSP: cables, manholes, conduits, protection and termination.

Tower: Structure and foundation, wave guide bridge, grounding,

20.1 etc. Buildings and Support utilities; grounding, etc. Power: DC

Plant, Standby, etc.

Ensure Communications equipment, transmission switches,

muxes data equipment alarms and miscellaneous equipment

20.2 etc. is correctly installed

Ensure equipment correctly installed and pre-commissioned

INSTRUMENTATION AND CONTROL

SYSTEMS

Perform required tightness tests on instrument take-off piping

21.1 and air piping and tubing

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

Check continuity and identification of transmission and control

systems loops for each instrument to insure proper hook-up.

This applies to both pneumatic and electrical systems (analog

and digital). Identification refers to the proper tagging of cable

and / or each control loop conductor where it is terminated at

21.2 multiple connection points (instrument, junction box, termination

panel, marshalling cabinet, etc.)

Remove rotameters, orifice places, flow nozzles, venturi and

other in-line primary flow elements, strainers, and other

21.3 equipment as necessary before hydrostatic testing, flushing or

chemical cleaning prior to MC

Reinstall above equipment. Check for direction of flow and

21.4 proper operation, e.g. travel, action with air failure, etc.

Check and tag orifice plates and flow nozzles, calibrate all

instruments and transmitters and receiver readings for each

21.5 instrument loop

Install pressure and temperature gauges after line flushing, and

21.6 check air supply for required pressure.

21.7 Provide and install sealing fluids where required

Perform final loop check which is a full functional demonstration

21.8 of I/O, DCS & ESD systems.

Continuity check alarms, computer inputs, digital inputs and

21.9 other wiring

21.10 Install analyzers and check continuity

21.11 Micrometer and inspect all meter runs

Provide calibration gas and test analyzers. Synchronize

21.12 transmitter and receiver, bring onstream and fine tune

Complete Control System/Site Acceptance Test W p Complete

ESD Fire & Gas Site Acceptance Tests W q. Complete

21.13 Metering Systems Site Acceptance Tests

Complete all Auxiliary Systems Site Acceptance Tests (Burner

21.14 Systems, Compressor Controls etc)

CATALYST, CHEMICALS AND

DESICCANTS

Inspect all towers and drums for cleanliness before loading

22.1 catalysts, etc

Install first loading of any chemical purchased as a package

22.2 with the equipment.

Supply supervised labor to load all other chemicals and

catalyst, catalyst baskets, tower packings. (Operations

22.3

schedule and direct).

22.4 Air blow if required

22.5 Inspect after final loading. Obtain samples of all

Saudi Aramco: Company General Use

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE SUBMITTED DISCIPLINE

SATR-A-6133 Civil / Plumb

Final Inspection/Re-Instatement Punch List 24-Mar-16 Electrical

(Punch List by Contractor)

FEIL-Mech Mechanical

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

MCC No.: Test Package No.:

System Description:

END OF CHECKLIST

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018)

Saudi Aramco: Company General Use

Rev.2018.05.00

15-Jul-18

Saudi Aramco: Company General Use

###

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018)

Saudi Aramco: Company General Use

Rev.2018.05.00

15-Jul-18

Saudi Aramco: Company General Use

###

Saudi Aramco: Company General Use

You might also like

- Precommissioning Procedures of Testing & CommissioningDocument96 pagesPrecommissioning Procedures of Testing & CommissioningTasawar Hussain85% (34)

- Mep Boq Plot No.6721148Document53 pagesMep Boq Plot No.6721148ArifHadiNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Annexure 4 - TransformerDocument36 pagesAnnexure 4 - TransformerBala MNo ratings yet

- Cooling Tower Construction ChecklistDocument6 pagesCooling Tower Construction ChecklistGopinath GopiNo ratings yet

- Check List For CommissioningDocument18 pagesCheck List For CommissioningAnil Radheshwar100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Arthur Capper History Time Line July 5Document13 pagesArthur Capper History Time Line July 5Johanna Bockman100% (1)

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument11 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListEswari AnandNo ratings yet

- 8 NCC Etp Vol II Sec C1-ADocument4 pages8 NCC Etp Vol II Sec C1-AShanjiNo ratings yet

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarNo ratings yet

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- Ahu Documentantion Minimum RequirementsDocument7 pagesAhu Documentantion Minimum RequirementsdanielsilvavNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0407 (3) Rev001Document2 pagesQic-Qsp-Uni-Tdr-Cl-0407 (3) Rev001Ragab EisaNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Layover Inspection Schedule Issue 06Document17 pagesLayover Inspection Schedule Issue 06Pankaj Khondge100% (1)

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Saic - K-4006Document2 pagesSaic - K-4006Bander Al–kouhlaniNo ratings yet

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDocument37 pagesRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaNo ratings yet

- SATR-J-6911Rev 0 PDFDocument6 pagesSATR-J-6911Rev 0 PDFAdel KlkNo ratings yet

- SATR-J-6501 - Rev 0 PDFDocument5 pagesSATR-J-6501 - Rev 0 PDFAdel KlkNo ratings yet

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Pipework Oil SystemDocument12 pagesPipework Oil SystemSamNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- MQ SP M 4033 PDFDocument16 pagesMQ SP M 4033 PDFjaseelNo ratings yet

- Mvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.Document2 pagesMvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.wazakifyNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocument10 pagesThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Mvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.Document2 pagesMvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.wazakifyNo ratings yet

- Example Technical ReportDocument4 pagesExample Technical ReportAhmed ElhoniNo ratings yet

- Red Bag Checklist For Mechanical CompletionDocument9 pagesRed Bag Checklist For Mechanical Completionhitm357No ratings yet

- Spec Upt Page 41Document58 pagesSpec Upt Page 41midhunvarNo ratings yet

- 6-66 KV SF6 BKR R3 May12Document26 pages6-66 KV SF6 BKR R3 May12PB MehtaNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- Ac Panel Test ProsedureDocument6 pagesAc Panel Test ProsedureUtku Can KılıçNo ratings yet

- SAIC-D-2012 Rev 2Document4 pagesSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATR-J-6912 Rev 0 PDFDocument4 pagesSATR-J-6912 Rev 0 PDFAdel KlkNo ratings yet

- Pre-Com. Procedure For Tertiray - 415V SWGRDocument13 pagesPre-Com. Procedure For Tertiray - 415V SWGRBalamurugan SelvarajNo ratings yet

- SECTION 26 36 23 Automatic Transfer SwitchesDocument16 pagesSECTION 26 36 23 Automatic Transfer SwitchesAdam SatrioNo ratings yet

- Volume-IIIB Part-3 Electrical and InstrumentationDocument211 pagesVolume-IIIB Part-3 Electrical and InstrumentationVikas Dwivedi100% (1)

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic - K-4015Document3 pagesSaic - K-4015Bander Al–kouhlaniNo ratings yet

- Commissioning Responsibilty Matrix Rev.0 12-Nov-2014Document4 pagesCommissioning Responsibilty Matrix Rev.0 12-Nov-2014Dinesh Radhakrishnan100% (1)

- Ssem 564 C27 SKM 01Document6 pagesSsem 564 C27 SKM 01Ahmed Mostafa Fadly MadyNo ratings yet

- Standard Commissioning Procedure For Building Exhaust Fans: General NotesDocument9 pagesStandard Commissioning Procedure For Building Exhaust Fans: General NotesAbdul Mohid SheikhNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- V 341001Document1 pageV 341001mdkakhanNo ratings yet

- Pneumatic Actuator Specs Including Hydrant Line POVs PDFDocument12 pagesPneumatic Actuator Specs Including Hydrant Line POVs PDFrka0503No ratings yet

- SECTION 16208 Engine GeneratorsDocument38 pagesSECTION 16208 Engine Generatorsno nameNo ratings yet

- JW Marriot Abu Dhabi Resort & Spa Otak InternationalDocument15 pagesJW Marriot Abu Dhabi Resort & Spa Otak InternationalPeanut d. DestroyerNo ratings yet

- Tender Technical Specification For Material of UG WorkDocument205 pagesTender Technical Specification For Material of UG WorkAshish bhattNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- Saudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- In-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportDocument2 pagesIn-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportnadeemNo ratings yet

- Release Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportDocument2 pagesRelease Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Recorder SATR-A-2005 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechnadeemNo ratings yet

- Saes Z 004Document40 pagesSaes Z 004nadeem100% (1)

- Saes A 100Document6 pagesSaes A 100nadeemNo ratings yet

- BOQ - Method of Measurement and BOQ PDFDocument176 pagesBOQ - Method of Measurement and BOQ PDFyousef100% (1)

- ICC ES Report ESR 1961: The Dow Chemical CompanyDocument3 pagesICC ES Report ESR 1961: The Dow Chemical CompanymurdicksNo ratings yet

- Hoja de Vida Maquina Piloteadora Sany 330Document3 pagesHoja de Vida Maquina Piloteadora Sany 330Tefi OrtizNo ratings yet

- Komatsu 0000279c H0120-001002A PageDocument2 pagesKomatsu 0000279c H0120-001002A PageCristhian Sullon SosaNo ratings yet

- Fatigue Life Testing in Metal Expansion JointsDocument1 pageFatigue Life Testing in Metal Expansion JointsNaresh ANo ratings yet

- Resultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDocument4 pagesResultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDIEGO FERNANDO CADENA ARANGONo ratings yet

- Flexible Pavement DistressDocument33 pagesFlexible Pavement DistressMohammed Omer KufishahNo ratings yet

- Ungureanu 2020Document16 pagesUngureanu 2020Zeyad F SaadNo ratings yet

- Meeting Minutes - Construction Progress MeetingDocument4 pagesMeeting Minutes - Construction Progress Meetingmech_sahilNo ratings yet

- Concrete and Formwork in NYCDocument60 pagesConcrete and Formwork in NYCKannon TamNo ratings yet

- Accepted Manuscript: International Journal of Impact EngineeringDocument52 pagesAccepted Manuscript: International Journal of Impact EngineeringMickey DalbeheraNo ratings yet

- Interior Non-Load Bearing Partition Bracing Option: NWCB Technical DocumentDocument2 pagesInterior Non-Load Bearing Partition Bracing Option: NWCB Technical DocumentClaudio ColettaNo ratings yet

- SantaCountyWTv0.5.4 b1 CompressedDocument27 pagesSantaCountyWTv0.5.4 b1 CompresseddougchiNo ratings yet

- Bomba Active ChecklistDocument6 pagesBomba Active ChecklistPerwira Khusairi RahmanNo ratings yet

- Technical Graphics RubricDocument1 pageTechnical Graphics Rubricapi-268923331100% (2)

- Technical Schedule A To D & H Pkg-2Document101 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- Kanowit Progress Report NO.10Document28 pagesKanowit Progress Report NO.10Kevin ChangNo ratings yet

- GROHE Specification Sheet 23296000Document2 pagesGROHE Specification Sheet 23296000hehehe heheheheheheNo ratings yet

- 1.3 SCP201 Assignment Worksheet - Jan 2023 PDFDocument4 pages1.3 SCP201 Assignment Worksheet - Jan 2023 PDFfang weiNo ratings yet

- Brutalism Style AssignmentDocument23 pagesBrutalism Style Assignmentcartiallan21No ratings yet

- Week 11 Lecture Material - WatermarkDocument57 pagesWeek 11 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- Interventions, Professionals and User InputsDocument7 pagesInterventions, Professionals and User InputsMohamedNo ratings yet

- Bridge Working DrawingsDocument16 pagesBridge Working DrawingsAashish kumar100% (1)

- AppendixDocument24 pagesAppendixSecret SecretNo ratings yet

- Ardo - MekanikDocument11 pagesArdo - Mekaniksastro wijoyoNo ratings yet

- Describing Objects - Paragraph ExampleDocument4 pagesDescribing Objects - Paragraph ExampleDylweisNo ratings yet

- Lesson 2 4Document51 pagesLesson 2 4MR P PinnyNo ratings yet

- Architecture of 19th Century PDFDocument12 pagesArchitecture of 19th Century PDFrajat charayaNo ratings yet