Professional Documents

Culture Documents

Risk Assessment SPD (Updated)

Risk Assessment SPD (Updated)

Uploaded by

Ajith Pillerkatill AntonyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment SPD (Updated)

Risk Assessment SPD (Updated)

Uploaded by

Ajith Pillerkatill AntonyCopyright:

Available Formats

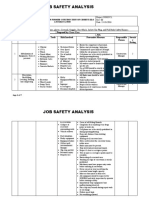

RISK ASSESSMENT Revision 0

Activity: Aluminum & Glazing Installation Ref: RA01

Risk

S.N Hazard Harm Control Measure Controlled By: Residual Risk

LxS L M H

Site set-up

Designated area needs to be identified where there is no access to other vehicles or operations, which can damage installation materials

1 Materials Damage and injury to people. 3x4 12M Supervisor 4Low

Lack of desginated safe lay down/ storage Designated safe storage area to be barricaded.

Pre- installation site check up

- Ensure safe access to men and materials at the work location.

Access for men, material and equipment. - All floor openings must be closed and open edges must be hard barricaded.

2 Unsafe access/egress to men & material. Falling materials and people from height. 3x4 12M Supervisor 4Low

Unsafe conditions such as floor opening, Serious injury - There shall be enough clean and clear space for maneuvering of materials; and prefabricated trolleys.

open edges obstructed maneuvering area,

unclean workplace for cradle. - Provision for arresting accidental fall of materials from height, to protect our employees as well as materials particularly glass.

Site survey

- Fall of survey crew from floor edges/ height. - Wherever the survey crew is exposed to fall hazards, they must wear PPE and full body safety harness and must hook it to a strong point.

3 4x4 16H Supervisor 4Low

Survey near floor edges. - Fall of survey equipment from height. - All survey equipment not to keep near the edge and shall be properly handled and secured to avoid falling from height.

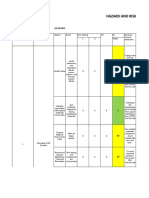

Material unloading, lifting & transfer

- Rigging failure cause dropping load, - Crane operator and the rigger must be competent and clear understandable communication system established between them.

damaging material & injury to personnel.

- Proper rigging practice must be followed. Use standard and sound lifting tackles (belt, steel wire rope, Dee shackles) only for lifting.

- Communication failure between the crane/

power hoist operator and the rigger cause - Cranes and tackles must be load tested and certified and maintained in good condition.

unplanned movements of the load.

. - Operatives need to be trained on the correct manual handling techniques.

- Incompetent crane operator and rigger;

improperly maintained cranes & damaged lifting - Use mechanical aid (pre - fabricated trolleys) as much as possible to reduce the need of manual handling.

4 Material handling within the workplace tackles. 4x4 16H Supervisor 4Low

using cranes, forklifts and pre-fabricated - Operatives must follow correct manual handling techniques and wear hand gloves while handling material.

trolleys - Excessive manual handling and back injury;

- Materials shall be stacked properly and secured on the pallet track/trolley prior to transfer from one place to another.

- Improperly stacked & unsecured materials on

the pallet track/trolley causing falling; sharp - Ensure the pathways are clear and also take care to avoid interference with adjacent activities in the work place.

edges of glass.

- The hazards associated with material handling and the hazard control measures need to be communicated to the operatives.

- All the above cause injury to the operatives

and damage to materials. -Adequate supervision to ensure safe handling of materials.

Installation of Brackets:

- All the personnel exposed to the risk of fall shall wear full body safety harness and attached to the strong point or specially provided vertical lifeline

- Fall of personnel as the work is on the slab with rope grab.

- Installation of brackets, checking the edges.

position. - Materials shall not be stored near the edge

5 3x4 12M Supervisor 4Low

- Fall of brackets/ accessories/ tools from

- Adjustment of the brackets as per the height and injuries to personnel working lower - Tools shall be properly secured by ropes to prevent fall from height.

survey checks and tightens all bolts to the levels.

correct torque. - During erection the lower area shall be barricaded to stop the access of personnel since there is possibility of accidental fall of tools / material.

Installation by cradles:

All lifting accessories must be inspected, tested every 6th months and shall be as per DM code of safety practice.

Use of Mobile crane is subject of lifting plan.

- All Hand tools must be tied with lanyards in hands to prevent fall whilst working at height.

- Appropriate fall protection to Personnel working on the cradle provided to avoid falling from height.

- Only certified competent personnel shall be detailed for working inside the cradle and to operate.

- Damage lifting accessories - Designated area only for boarding and going out in cradle, NO shortcut.

- Lifting operation failures, - Certified load tested monorails/cradles, and hoist to be used.

- Lifting accessories not inspected and not - Fall of tools being use during installation - Certified lifting tackles shall be used for lifting the panels.

as per DM code of construction practice.

- Fall of personnel from balcony and cradle - Overhead protection shall be provided on the cradle to protect the men in the cradle from falling objects.

- Hand Tools not secure. during installation.

- The cradle must be loaded within the limits (SWL) as specified in the third party certificates. Cradle SWL to be adhered too all at all times.

- Poor maintenance and functional failure of - Falling object from height to people working

6 cradle, power hoist. 4x4 16H - No stacking of loose materials inside cradle at all time during operation. Supervisor 4Low

on the cradle.

- Incompetent Hoist operators for lifting - Rigging failure and fall of panel from height - Daily visual inspection of cradle carries out by the operators before use and keep records, used tag lines if require.

panel. due to poor communication.

- All cradles and hanging devices need to be weekly inspected by the supplier or manufacturer to ensure, the continued integrity of components and

- Poor glass Handling technique. - Lifting of heavy awkward objects causes back system, records to provide.

injury, foot injury, and slip, trip and falls.

Not wearing required PPE. - The operator must check cradle operations every day before starting the job to ensure it is fully operational including emergency lowering.

- Hand injury from sharp edge materials being

handle not wearing hand gloves - During high wind condition,( Self assessment by the Operator) the operation must be seized, and secure the cradle properly.

- End of the day, the cradle needs to be lowered to the ground/ slab and secured well to avoid any incident from high wind during off hours.

- Competent hoist operators to details for Installation activities.

- Proper communication shall be established between the hoist operator and the installation team.

- The area below shall be barricaded to prevent entry of other trades.

- All the hazards associated to the work shall be informed to the workers

Installation

- Appropriate edge protection should be provided to avoid falling from height Personnel working at the height and on floor edge must wear safely

harness to avoid falls from height. The area under the operation should be barricaded to avoid entry of personnel in the danger area.

-- Fall of personnel from height. - Certified lifting tackles shall be used for lifting the panels. Proper communication shall be established between the installation teams. The panel

movement from the slab to the specific installation location shall be closely monitored by supervisor through the assistance of signalman to pass

- Fall of tools and accessories from height. through all obstructions safely and to avoid any stuck ups. Nobody to stand below the load while lifting. All pre- fabricated trolleys shall be used to

reduce manual handling and secured well away from the floor edge to avoid rolling over the edge.

7 - Rigging failure and fall of panel from height. 4x4 16H Supervisor 4Low

Profile installations - Best practice and technique shall be followed while handling glass or fragile material to avoid personal injury and material damage. Always wear

- Manual handling and back injuries.

glove to avoid cut /abrasion injuries. The hazard associated while handling glass shall be conveyed to the operatives.

- Exposure to high wind causes loss of control - The wind speed must be assessed before commencing the operation.

while lifting.

- All the hazards associated to the work shall be informed to the workers on a daylily basis. Cradle operation is to be checked daily before

commencing the work. Adequate supervision to ensure compliance of the above requirements.

Installation of glass panels using electrical/

manual glass sucker.

- The glass sucker must be third party inspected and certified before use. The glass surface should be dry and free from dust prior to position the

glass sucker on the glass. Ensure the glass sucker cups are free from dust and damage. Ensure it functions properly and the pressure gauge needle at

green when put in operation. Internal battery of the sucker must be operational to support power in case of main failure. The glass sucker must be

checked and operated by a competent person only. Use sound lifting tackles for attaching the hoist hook on to the glass sucker.

- Dropping glass and serious injury to

8 Wet or presence of dust on the glass, poor operatives and damage to panel. 3z4 12M - Apart from the glass sucker, the panel must be secured using webbing slings to the hoist hook. This to prevent dropping panel in case of sucker Supervisor 4Low

hose connections and cracked cups can - Fall of personnel from height. failure.

cause failure of glass sucker, Unsafe access

to operatives. - Sufficient manpower must be employed to handle the panels. All those exposed to the risk of fall must wear safety harness. Safe access through the

scaffold has to be maintained at every time. The area under the operation must be barricaded. Best practice and techniques shall be followed while

handling materials. Information, instruction and training to be provided to the operatives. Adequate supervision at every time.

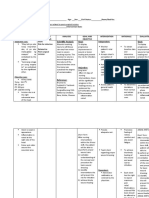

WORK ON SCAFFOLDING

- Scaffold must only be erected, dismantled or altered by competent personnel under supervision. Scuff tag system shall be implemented. Competent

person must check Scaffold prior to use and then every seven days. Ladders should be used to climb scaffolds and it should be tied. Full body harness

must be worn. Guardrails and toe-boards are required to all working platforms where a person may fall from 2 meters or more and must not be

9 Scaffold collapse; overloading of scaffolds; - Serious injuries to the people and asset 3x3 9M removed by any unqualified personnel. Supervisor 3Low

Personnel or materials falling from Scaffold; damage

Inadequate access to the scaffold. - Do not overload scaffold. The minimum width requirement of a working platform is 600 mm. The area under the scaffold should be barricaded to

avoid entry of personnel in the danger area. All the hazards associated to the work shall be informed to the workers. Adequate supervision.

Unstable ground causing outriggers to sink and - All Cranes are to be inspected, and certified by the third party. The outriggers are fully extended and position on to the firm ground

machine to tip over. Rigging failure and

dropped loads. Overloading. Striking against - Banks man should give signal to the operator during lifting operation. A competent riggers shall rig the materials to be lifted

10 MOBILE CRANE 3x4 12M Supervisor 4Low

adjacent structures. High wind causing loss of

control of the load. Serious bodily injuries to - All lifting slings must be checked for its capacity and condition before lifting. The area of the operation shall be barricaded. All activity shall be fully

personnel. Damage to machine and property. supervised and well coordinated.

- Lifting of heavy awkward objects causes back

injury, foot injury, and slip, trip and falls. - Operatives must follow manual handling techniques while manually handling materials. Gloves must be worn to avoid cut/ abrasion injuries. Should

`11 Manual Lifting 3x4 12M seek assistance for handling loads beyond the individuals limit. Use trolley and mechanical aids as far as possible. Supervisor 4Low

- Sharp edges can cause cut injuries to hands.

- Tools left lying on around.

- Tripping hazards, eye injury from foreign - When not in use all hand tools must be stored in the toolbox to avoid tripping hazard. Damaged tools must be discarded or replaced. All hand tools

`12 Hand Tools 3x4 12M Supervisor 4Low

particles. must be in good condition and checked regularly. Suitable hand gloves must be worn.

- Cut injury by using sharp tools..

- Only qualified Electricians must install, maintain and repair electrical supplies / tools.

- Electrocution, Burns, - Trailing electrical leads must be suitably protected.

13 Power Tools 3x4 12M Supervisor 4Low

- Cuts or lacerations, injuries.

- All electrically operated tools must be center tapped to earth and they are checked regularly and serviced. Competent person shall only operate

power tools following the operating practices. Do not improvise. Wear eyes and hearing protection.

- Contact with rotating disc. Injury due to

improperly secured disc. - Tighten the disc with right tool. Only competent person shall operate the grinder.

- Use of incorrect / defective / poorly - Check disc for signs of excessive wear / tear, replaced if required.

maintained power tool.

14 Disc Cutting/ Grinding 2z4 8M - All equipment should be well maintained. Regular inspection by supervisor / foreman prior to use. Supervisor 4Low

- Injury due to defective disc leading to disc

shattering - Portable grinding machines shall be provided with Safety guards. Grinding wheels shall not be operated beyond its rated safe speed. Damaged

grinder must be removed from work place. Wear eye and hearing protection. The hazard associated with job shall be conveyed to the operatives.

- Flying metal fragments. Adequate supervision to oversee all the activities.

- Eye injury and body parts injury.

- Sufficient cold water to drink daily.

- Provide suitable energy drink like polite/ glucose/ etc.

Work in hot weather

15 - Exhaustion, Fainting, fatigue, Stroke, cramps. 2x4 8M - Cotton dress is essential to wear in summer. Supervisor 4Low

Heat Related health problems.

- Don’t drink alcohol or drinks with caffeine.

- Don’t eat heavy meals before working in the heat.

PREPARED BY :

Project Manager SIGNATURE: REV. No: 0

…………………………………………………………………………..

APPROVED BY :

QHSE OFFICER SIGNATURE: REV. DATE: / /2019

…………………………………………………………………………..

You might also like

- LocalOrder61of1991English PDFDocument42 pagesLocalOrder61of1991English PDFAnge Juan100% (1)

- Jha Tree Cutting, Felling, Balling v. 2Document10 pagesJha Tree Cutting, Felling, Balling v. 2arsenio100% (1)

- Dengue NCP (Risk For Bleeding)Document5 pagesDengue NCP (Risk For Bleeding)Bernadette Malamug50% (6)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- Risk Assessment For Waste Management: SL No Potential Hazard Risk Persons at Risk Control Measures Risk RatingDocument3 pagesRisk Assessment For Waste Management: SL No Potential Hazard Risk Persons at Risk Control Measures Risk Ratingطارق رضوان100% (1)

- Working-at-Height RADocument10 pagesWorking-at-Height RADan NixonNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- Adc MCQ Sep 2006 Paper1Document28 pagesAdc MCQ Sep 2006 Paper1api-2629165189% (19)

- Buks IDIP Unit D Assignment, Rev. 03Document43 pagesBuks IDIP Unit D Assignment, Rev. 03Saqib Rasool100% (5)

- Neurologic Examination of The Newborn - UpToDateDocument40 pagesNeurologic Examination of The Newborn - UpToDateAMIT TYAGINo ratings yet

- Boiler InstallationDocument2 pagesBoiler InstallationRod Kenneth LubongNo ratings yet

- Cement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsDocument1 pageCement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Scaffold Risk AssissmentDocument4 pagesScaffold Risk AssissmentSaleem AkhtarNo ratings yet

- Site Safety Supervisor - Lifting OperationDocument10 pagesSite Safety Supervisor - Lifting Operationflex xibleNo ratings yet

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- JHA Tower Crane ErectionDocument4 pagesJHA Tower Crane Erectionmark jayson yabesNo ratings yet

- JSA - Winstar Pipeline CrossingDocument6 pagesJSA - Winstar Pipeline CrossingRidha Bennasr100% (1)

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Jsa For Air Flushin Amp Mech Cleaning of Pipes PDF FreeDocument17 pagesJsa For Air Flushin Amp Mech Cleaning of Pipes PDF FreeAbdullah FazilNo ratings yet

- Job Safety Analysis: Manually Lover Post Erection (300kg)Document2 pagesJob Safety Analysis: Manually Lover Post Erection (300kg)Mahamudul HasanNo ratings yet

- New Job Hazard Analysis (JHA) Hot Water Geyser InstallationDocument2 pagesNew Job Hazard Analysis (JHA) Hot Water Geyser Installationwaqar naeemNo ratings yet

- Risk Assessment For Installation & Testing of HDPE PipesDocument9 pagesRisk Assessment For Installation & Testing of HDPE PipesLawrence adeleke OmisakinNo ratings yet

- CraneOperations PDFDocument2 pagesCraneOperations PDFIrshad AkhterNo ratings yet

- R F (H W C) :: ED Lags OLD Ork Until OrrectedDocument4 pagesR F (H W C) :: ED Lags OLD Ork Until OrrectedtusharDJNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- Pile Load Test Pile No2Document3 pagesPile Load Test Pile No2M Waqas HabibNo ratings yet

- Ready Reckoner For Safety Precaution During Loading, Unloading & Transport of Mat PDFDocument1 pageReady Reckoner For Safety Precaution During Loading, Unloading & Transport of Mat PDFArvind MeenaNo ratings yet

- AHA-004, Earth Work Site PrepDocument6 pagesAHA-004, Earth Work Site PrepBuddhikaNo ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- Pile Load Test Pile No2Document4 pagesPile Load Test Pile No2Sanjeet SinghNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtNo ratings yet

- Job Safety Analysis For STR-01Document1 pageJob Safety Analysis For STR-01M Waqas HabibNo ratings yet

- JsA Installation-of-Fence-Area-GradingDocument6 pagesJsA Installation-of-Fence-Area-GradingadeelshahksaNo ratings yet

- Drain Line Work JSADocument2 pagesDrain Line Work JSAm.rehanhseNo ratings yet

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- JHA Crushing OperationsDocument3 pagesJHA Crushing Operationsabdullah ashrafNo ratings yet

- Drain Line Work JSA HSE ProfessionalsDocument2 pagesDrain Line Work JSA HSE ProfessionalsSamadov 13No ratings yet

- Generic Risk Assessment - RA01: General Work at Height Page 1 of 3Document3 pagesGeneric Risk Assessment - RA01: General Work at Height Page 1 of 3RamNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- BOSHDocument5 pagesBOSHJeffrey RegondolaNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- Job Safety Analysis - Cement SiloDocument7 pagesJob Safety Analysis - Cement SiloArgi Bramantara100% (1)

- Sener/Sepcoiii Consortium Noor Iii Project: Risk AssessmentDocument7 pagesSener/Sepcoiii Consortium Noor Iii Project: Risk AssessmentmessaoudiNo ratings yet

- Wah InductionDocument38 pagesWah InductionkashralNo ratings yet

- S60370 Nur Ain Farhani Binti Mohamad YazidDocument3 pagesS60370 Nur Ain Farhani Binti Mohamad YazidAin frhnniiiNo ratings yet

- RA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFDocument8 pagesRA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFIbrahim EsmatNo ratings yet

- Job Hazard Analysis (ASSEMBLY)Document4 pagesJob Hazard Analysis (ASSEMBLY)Syafiq NorizanNo ratings yet

- Porta Cabin Loading - Unloading by Two Hydra JSA HSE ProfessionalsDocument2 pagesPorta Cabin Loading - Unloading by Two Hydra JSA HSE ProfessionalsSamadov 13No ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- Screening and Crushing Operations 2016 VersionDocument4 pagesScreening and Crushing Operations 2016 Versionkmohamedkeita906No ratings yet

- Loading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsDocument1 pageLoading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsSamadov 13No ratings yet

- GeneralscaffoldingworkDocument3 pagesGeneralscaffoldingworkwisdom ukuejeNo ratings yet

- Risk Assess T-07 - Mobile Crane OperationsDocument2 pagesRisk Assess T-07 - Mobile Crane OperationsMAB AliNo ratings yet

- RA-SurveyingDocument7 pagesRA-SurveyingAbdul LatheefNo ratings yet

- Crane AssemblyDocument3 pagesCrane AssemblyM Waqas HabibNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Erection of Fabricated Staircase JSA HSE ProfessionalsDocument2 pagesErection of Fabricated Staircase JSA HSE ProfessionalsSamadov 13No ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Ra01 GeneralscaffoldingworkDocument3 pagesRa01 GeneralscaffoldingworkMD Akhtar Hussain/UV/Abu DhabiNo ratings yet

- 5 Rack Safety Training ModuleDocument7 pages5 Rack Safety Training ModuleBhaskar ShuklaNo ratings yet

- HSE FM 05 First Information ReportDocument1 pageHSE FM 05 First Information ReportAjith Pillerkatill AntonyNo ratings yet

- Hazard and Risk Assessment Form: Prepared On 10/29/2019Document4 pagesHazard and Risk Assessment Form: Prepared On 10/29/2019Ajith Pillerkatill AntonyNo ratings yet

- Fire Pump Room - Weekly Inspection Report: Item Result Action Taken/Required by WhomDocument1 pageFire Pump Room - Weekly Inspection Report: Item Result Action Taken/Required by WhomAjith Pillerkatill AntonyNo ratings yet

- Tool Box Attendence SheetDocument1 pageTool Box Attendence SheetAjith Pillerkatill AntonyNo ratings yet

- Indction Attendence SheetDocument1 pageIndction Attendence SheetAjith Pillerkatill AntonyNo ratings yet

- Line Management Declaration Form)Document1 pageLine Management Declaration Form)Ajith Pillerkatill AntonyNo ratings yet

- Training Attendance SheetDocument1 pageTraining Attendance SheetAjith Pillerkatill AntonyNo ratings yet

- Air Condition Daily Consumption Checklist: Thermosta T No. SAT SUN MON TUE WED THUDocument2 pagesAir Condition Daily Consumption Checklist: Thermosta T No. SAT SUN MON TUE WED THUAjith Pillerkatill AntonyNo ratings yet

- Daily Environmental Inspection Check ListDocument1 pageDaily Environmental Inspection Check ListAjith Pillerkatill AntonyNo ratings yet

- Local Order No. (11) of 2003 Concerning Public. Health and Safety of The Society in The Emirate of Dubai PDFDocument41 pagesLocal Order No. (11) of 2003 Concerning Public. Health and Safety of The Society in The Emirate of Dubai PDFAjith Pillerkatill AntonyNo ratings yet

- Torts Doctrines Part IIDocument6 pagesTorts Doctrines Part IIG FNo ratings yet

- Biolevox HA TENDON Extended PresentationDocument32 pagesBiolevox HA TENDON Extended PresentationABUBAKER ZANBOUZINo ratings yet

- Mrs. Olive Dindo v. Grand Union Company, 331 F.2d 138, 2d Cir. (1964)Document5 pagesMrs. Olive Dindo v. Grand Union Company, 331 F.2d 138, 2d Cir. (1964)Scribd Government DocsNo ratings yet

- Viewpoints 1 ANK WBSpaDocument111 pagesViewpoints 1 ANK WBSpalopezclavijo100% (7)

- Axminster EX-21 Scroll Saw ManualDocument36 pagesAxminster EX-21 Scroll Saw ManualSquinkleNo ratings yet

- Opteva 740 Operating Guide TP 820896 001FDocument74 pagesOpteva 740 Operating Guide TP 820896 001FDaniel Sanchez NavaNo ratings yet

- MoS BrickworkDocument4 pagesMoS BrickworkIvan DjordjicNo ratings yet

- TMJ & Its MovementsDocument26 pagesTMJ & Its Movementsdeepinder27100% (1)

- Five BreathsDocument14 pagesFive BreathselhisabethNo ratings yet

- Chicken Plucker Plumeuse À Volaille Desplumadora de PollosDocument44 pagesChicken Plucker Plumeuse À Volaille Desplumadora de PollosLudmiller van MoranNo ratings yet

- Grade 9 HEALTH Q3 - M2Document16 pagesGrade 9 HEALTH Q3 - M2Krizzane AcierdaNo ratings yet

- Recreational Group Report DDDocument9 pagesRecreational Group Report DDAzraff SeniorNo ratings yet

- Tobpc72060001 PDFDocument72 pagesTobpc72060001 PDFTrần Quang TuyênNo ratings yet

- Health and WellnessDocument13 pagesHealth and WellnessArsal MushtaqNo ratings yet

- Case Brief and Synthesis On ParricideDocument3 pagesCase Brief and Synthesis On Parricidemma100% (1)

- Test Bank For Medical Terminology and Anatomy For Coding 3rd Edition by ShilandDocument17 pagesTest Bank For Medical Terminology and Anatomy For Coding 3rd Edition by ShilandAlbertSmitheozmw100% (34)

- Anatomy Final Exam Questions: CS. An Osteon IsDocument47 pagesAnatomy Final Exam Questions: CS. An Osteon IsMOHAMMED RIYASNo ratings yet

- Scientific Analysis Goal: Goal:: Subjective CuesDocument2 pagesScientific Analysis Goal: Goal:: Subjective CuesChloie Marie RosalejosNo ratings yet

- Weekend Warrior P1M1 TRX PDFDocument8 pagesWeekend Warrior P1M1 TRX PDFpainfree888No ratings yet

- Lean Muscle ProgramDocument2 pagesLean Muscle ProgramtonypodmoreNo ratings yet

- Ruks Konsult Vs AdworldDocument1 pageRuks Konsult Vs AdworldKling King100% (1)

- Tool Box Talk 1Document12 pagesTool Box Talk 1liyaquathaliNo ratings yet

- Case Comment (Law of Torts Project)Document14 pagesCase Comment (Law of Torts Project)VedantDikshit100% (4)

- DiaphragmDocument17 pagesDiaphragmSyafi'ie Syukri100% (2)

- Offshore SafetyDocument114 pagesOffshore SafetyGNo ratings yet

- Legal MedicineDocument40 pagesLegal Medicinerochelle posadasNo ratings yet