Professional Documents

Culture Documents

Dreadnought Type 2 in 1 Brake Ejector

Dreadnought Type 2 in 1 Brake Ejector

Uploaded by

Vikk SuriyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dreadnought Type 2 in 1 Brake Ejector

Dreadnought Type 2 in 1 Brake Ejector

Uploaded by

Vikk SuriyaCopyright:

Available Formats

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

DREADNOUGHT TYPE

2 in 1 Brake ejector

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

Primetech has developed a replacement for the Gresham and Craven Dreadnought Ejector

in association with Indian Railways for the function on the heritage steam locomotive

network in India. This product is now available for sale to heritage Railways worldwide.

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

OPERATION

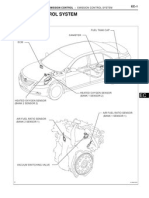

The diagram above illustrates the ejector in the" Brake Off" position, the cam (a) on the main shaft

being raised to open the large ejector steam valve (b) and admit steam to the large cone (c) At the same

time steam passes to the small cone (d) through the small ejector steam valve (e) This valve is set by

hand so 2.S to wire draw and reduce the steam pressure to about 120 lbs., which is the pressure at which

this cone is designed to give its greatest efficiency.

Under the Influence of both cones air is drawn rapidly from the train pipe past the large ejector air

clack (f), the small ejector air clack (g) main air clack (h), and through cavity "D" in the air disc by

way of ports "C" and "B," these ports being in full register in this position of the handle. At the same

time air is drawn from the vacuum chamber on the engine and tender past release valve (n).

In the "Running Position" of the handle cam (a) lowers the large ejector steam valve (b), on to its seat,

thus cutting off the supply of steam to the large ejector. The connection between the small cone and

the train pipe through cavity. "D" in the air disc remains open and the small ejector maintains the working

Vacuum while the train is running. Operation of the auxiliary application valve (j) in this position admits

air to the train pipe and enables light brake applications to be made for controlling the train speed.

As the handle is moved towards the "Brake On" position the connection through cavity "D" is progressively

c1osed. At the same time ports "E" and 'F' in the air disc gradually uncover ports "B" and "A" in the ejector

face and air is admitted to the train pipe to apply the brake. This air is prevented from passing to the engine

and tender vacuum chambers by the non-return valve in release valve (n).

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

ln the full "Brake On" position, ports "A" and "B" in the ejector face are completely open to atmosphere

through ports "F" and "E" in the disc and the brake is rapidly applied. At the same time the wall of cavity

(D) cuts off the connection between ports "B" and "c" so that the small ejector is isolated from the train

pipe and draws only on the engine and tender vacuum chambers past release valve (n). In this way the

maximum possible locomotive brake power is assured in emergency applications. The air passages in the

ejector are so arranged that, in all cases, air from the train pipe is drawn past two gunmetal clacks before

coming in contact with the steam. When steam is cut off from the cones and a vacuum is left in the train

pipe, these clacks prevent moisture, and more especially smokebox gases, being drawn into the train pipe.

The ball valve (k), located below the relief valve (m) communicates with the chamber between the two

ejector clacks and the main clack. When a vacuum is created in the instrument the ball is drawn to its seat,

but falls off as soon as steam is shut off and the vacuum drops. Should clacks (f) and (g) be leaking, it

provides an outlet for any vapour or steam. Should the main clack (h) leak it admits of air from the

atmosphere being drawn into the train pipe, and so prevents any tendency to draw vapour and smokebox

gases through clacks (f) and (g).

The vacuum relief valve (m) is a spring loaded valve which limits the degree of vacuum carried in the train

pipe. When the point is reached at which it is set, atmospheric pressure above the valve overcomes the

tension in the spring and the valve opens to admit air to the space above the main clack (h) thus preventing

the creation of a higher vacuum in the train pipe. The release valve (n) enables atmosphere to be admitted

direct to the vacuum chambers so that the locomotive brake can be released by hand when the locomotive

is uncoupled and when steam is not available.

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

30/20 mm DREADNOUGHT EJECTOR

LIST OF PARTS

Part No.

Description.

1' Body, Left hand.

1x' Body, Right hand.

1b Inner Exhaust barrel.

1c Grub screw for Inner Exhaust barrel.

1d Shaft bushes (2 per ejector).

1e Cap nut for Inner Exhaust barrel.

1f Inside fixing Exhaust barrel.

1gt Outside (alternative to 1f).

1h Pins for shaft bushes (2 per ejector).

AIR DISC AND HANOLE COMPLETE WITH AUXILIARY APPLICATION VALVE. LEFT

2S HAND Ejector. (Items 2. 2a. 2b. 25, ·26. 26a. 26b. 26c. 27,27a. to 27j).

AIR DISC AND HANDLE COMPLETE WITHAUXILIARY APPLICATION VALVE, RIGHT

2XS HAND Ejector. (Items 2. 2a, 2b, 25, 26, 26a, 2'6b, 26c, 27, 27a. to 27j).

2T AIR DISC AND HANDLE. LEFT HAND Ejector (Items 2, 2a, 2b).

2XT AIR DISC AND HANDLE. RIGHT HAND Ejector (Items 2, 2a, 2b).

2 Air Disc and handle only, Left hand Ejector.

2X Air Disc and handle only, Right hand Ejector.

2a Air Disc and handle only, handle washer.

2b Air Disc and handle only, wood handle.

3S MAIN SHAFT COMPLETE WITH CAM, NUT AND WASHER. (Items 3, 3b, 3c, 3d. and 3e).

3 Main Shaft only.

3b Main Shaft Cam

3c Main Shaft Nut

3d Main Shaft, Spring washer.

3e Main Shaft, Locating pin.

4 Large Ejector steam valve guide nut.

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

Part No.

Description

5 Large Ejector steam valve

6 Large Ejector steam valve Seating.

7 Large Ejector steam valve Spindle.

8 Large Ejector steam valve Packing Box.

9 Large Ejector steam valve Gland.

SMALL Ejector STEAM VALVE COMPLETE WITH HANDLE. SEATING. PACKING

10S BOX AND GLAND. (Items 10. 11. 12, 13, 14,14a, 15, 15a, 15b, and 15c).

10 Small Ejector Steam Valve Spindle.

11 Small Ejector Steam Valve Spindle end.

12 Small Ejector Steam Valve Seating.

13 Small Ejector Steam Valve Packing Box.

14 Small Ejector Steam Valve Gland.

14a Small Ejector Steam Valve Packing box ring.

15S SMALL EJECTOR STEAM VALVE HANDLE COMPLETE. (Items 15, 15a, 1Sb. 1Sc).

15 Small Ejector Steam Valve handle only.

15a Small Ejector Steam Valve handle screw.

15b Small Ejector Steam Valve handle rivet pin.

15c Small Ejector Steam Valve handle Wood Handle.

16S LARGE Ejector COMPLETE. (Items 16 and 16a).

16 Large Cone, inner part.

16a Large Cone, outer part.

18S SMALL Ejector COMPLETE. (Items 18.18a).

18 Small Cone, inner part.

18a Small Cone, outer part.

19 Large Ejector cap.

19a Small Ejector cap.

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

Part No

Description

DRIP CONNECTION COMPLETE WITH NUT AND BALL. (Items 20, 20a, 20c and

20S 20d).

20 Drip connection only.

20T DRIP CONNECTION UNION NUT AND RING. (Items 20a and 20c).

20a Drip Connection Union Nut.

20c Drip Connection Union Nut Brazing Ring.

20d Drip Connection ball 1/2" dia

21S RELIEF VALVE COMPLETE. (Items 21 to 21j).

21 Relief Valve body.

21a Relief Valve cap.

21b Relief Valve seating.

21c Relief Valve spindle.

21d Relief Valve spring nut

21e Relief Valve nut.

21f 5/8" Air lock ball valve.

21g Cage for Air tock ball valve.

21h Set Screw for Air lock ball valve.

21j Relief Valve Spring.

23 Large Air Clacks. (2 per Ejector).

24 Large Ejector Air Clack Guide.

25 Auxiliary Application Valve Body.

AUXILIARY APPLICATION VALVE. COMPLETE WITH EYE – BOLT, WASHER

26S AND GUIDE. (Items 26 to 26c).

26 Auxiliary Application Valve Only.

26a Auxiliary Application Valve guide.

26b Auxiliary Application Valve eye - bolt.

26c Auxiliary Application Valve Washer.

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

AUXILIARY APPLICATION VALVE LEVER.COMPLETE WITH LINK AND PINS.

27 S LEFT HAND EJECTOR. (Items 27 to 27j).

AUXILIARY APPLICATION VALVE LEVER. SPRING AND HANDLE. LEFT

27 x S HAND EJECTOR. (Items 27, 27, 27d. 27e, 27f. 27g).

SPRING AND HANDLE. LEFT HAND

27 T EJECTOR. (Items 27, 27c 27d. 27e, 27f, 27g).

AUXILIARY APPLICATION VALVE LEVER.

SPRING AND HANDLE. RIGHT HAND

27XT EJECTOR. (Items 27, 27c, 27d, 27e. 27f, 27g).

27 Auxiliary Application Valve handle only. Left hand Ejector.

27 X Auxiliary Application Valve Right hand Ejector

27 a Auxiliary Application Valve link

27 b Auxiliary Application Valve link pins (2 per ejector)

27 c Auxiliary Application Valve flat spring

27 d Screw for wood pad of auxiliary application Valve Lever.

27 e Screw for wood pad of auxiliary application.

27 f Screw for wood pad of auxiliary application Valve Lever.

27 g Wood pad for Auxiliary Application Valve Lever.

27 h Auxiliary Application Valve Lever Pin.

27 i Split Pins for Auxiliary Application Valve (4 per ejector).

28 S UNION NUT AND RING FOR STEAM INLET. (Items 28 and 28a).

28 Union nut only for steam inlet.

28a Brazing ring for steam inlet.

29s UNION NUT AND RING FOR TRAIN PIPE. (Items 29 and 29a).

29 Union nut only for train pipe

29a Brazing ring for train pipe

30s UNION NUT AND RING FOR EXHAUST PIPE (Item 30 and 30a)

30 Union nut only for exhaust pipe

30a Brazing ring for Exhaust pipe

32 Small Air Clack

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

Part No

Description

33 Small Air Clack Guide

34 Vacuum Chamber Pipe plug(When release valve is not used)

31S Release Valve Complete (Items 31 to 31r)

31 Release Valve body

31a Release Valve body air clack

31b Release Valve body air clack guide

31c Release Valve body spindle

31d Release Valve body spindle guide nut

31e Release Valve body lever

31fs Release Valve Gauge Connection Union Nut and Ring (Items 31f and 31g)

31f Release valve gauge connection union nut.

31g Brazing Ring for release valve gauge connection unit.

31hs Release Valve Vacuum Chamber Pipe Union Nut and Ring (Items 31 h and 31)

31h Release Valve Vacuum Chamber pipe union nut

31j Brazing Ring for release valve gauge connection unit Union Nut

31k Release Valve lever pin

31m Release valve spring

31n Release valve connecting nipple

31p Release valve Lever split pin

31r Release valve spindle bearing pin

35 Ball cage for ejector steam brake valve flange

35a Ball seating for ejector steam brake valve flange

20d Brass ball for ejector steam brake valve flange

36s Combined Stop Valve Spindle Complete with guide handle and seating (Items 36 to 36c)

www.primetechejectors.com ; Email: sales@primetechejectors.com

VACUUM AUTOMATIC BRAKE EJECTOR

FOR STEAM LOCOMOTIVES

36 Combined Stop Valve Spindle.

36a Combined Stop Valve Spindle guide.

36b Combined Stop Valve Spindle seating

36c Combined Stop Valve Spindle handle.

Type of Body must be specified. Outside diameter of exhaust pipe should be given

Spares for the 20/13 mm. Ejector are equivalent to the 30, 20 mm , and should be specified to the

same item numbers.

Increased by 100.

EXAMPLES:-102XT = Air disc and handle for 20/13 mm. Ejector, right hand.

118 = Small cone inner part. for 20/13mm, Ejector

www.primetechejectors.com ; Email: sales@primetechejectors.com

You might also like

- Transportation Systems A Canadian PerspectiveDocument566 pagesTransportation Systems A Canadian PerspectiveNguyễn Nhã ThiNo ratings yet

- Multi Zone Outdoors Service ManualDocument56 pagesMulti Zone Outdoors Service Manualcmorley505775% (4)

- Pierburg 2E3 - MassterDocument43 pagesPierburg 2E3 - MassterGjorgi Ljubotenski79% (14)

- Sound Transit - MLK Corridor Rail at Grade Crossing Safety Review Technical Memorandum - 2022Document112 pagesSound Transit - MLK Corridor Rail at Grade Crossing Safety Review Technical Memorandum - 2022The UrbanistNo ratings yet

- Pierburg 2e3 Maintenance and RepairDocument11 pagesPierburg 2e3 Maintenance and Repairq1q1q1q1100% (2)

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- Question Bank For P.Way: Objective QuestionsDocument5 pagesQuestion Bank For P.Way: Objective QuestionsJAYDIB RANANo ratings yet

- EAF BasicsDocument29 pagesEAF BasicsAndavilli Srihari KumarNo ratings yet

- CAMERON France S.A.S: Front SheetDocument24 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- ValvesDocument6 pagesValvesAnimesh RoyNo ratings yet

- 03-01C Engine, 4.0L V-66ford 4.0 Repair ManualDocument206 pages03-01C Engine, 4.0L V-66ford 4.0 Repair ManualMike GunionNo ratings yet

- Bhel EsvDocument4 pagesBhel EsvKarthi Keyan100% (1)

- 150 Carburetor Service GuideDocument5 pages150 Carburetor Service GuideGustavo RodríguezNo ratings yet

- Chapter 20 - Exhaust SystemDocument10 pagesChapter 20 - Exhaust SystemnikolasthermosolutionsNo ratings yet

- 2660CE37-807 & 2660CGHI42-807: Compressor Field Service ManualDocument24 pages2660CE37-807 & 2660CGHI42-807: Compressor Field Service ManualHenry ArguettNo ratings yet

- Losses in Bends FittingsDocument26 pagesLosses in Bends FittingsKunalNo ratings yet

- Tech Manual 1314C: 3.06", 10M, Side Door Stripper PackerDocument13 pagesTech Manual 1314C: 3.06", 10M, Side Door Stripper PackerAngel MarinNo ratings yet

- Electri RelifDocument18 pagesElectri Relifsuleman247No ratings yet

- Assignment KhanDocument3 pagesAssignment KhanAnand SinghNo ratings yet

- 2GR-FE Emission ControlDocument23 pages2GR-FE Emission ControlLuks FernandezNo ratings yet

- Treadle ValveDocument8 pagesTreadle ValveBOB100% (1)

- Home Videos Contact Us Ordering FAQ Our Customers Price List DocumentationDocument12 pagesHome Videos Contact Us Ordering FAQ Our Customers Price List DocumentationguillermoNo ratings yet

- DSA4 15M Tandem SidedoorDocument11 pagesDSA4 15M Tandem SidedoorДудла СтаніславNo ratings yet

- Coolant: InspectionDocument32 pagesCoolant: InspectionAiman NasirNo ratings yet

- Beginner's Guide PneumaticsDocument57 pagesBeginner's Guide PneumaticsDryRotNo ratings yet

- Losses in Bends FittingsDocument26 pagesLosses in Bends Fittingsdainer08No ratings yet

- M38a1 Carb Chapt9Tm9-1826aDocument13 pagesM38a1 Carb Chapt9Tm9-1826aGeorge PowersNo ratings yet

- Tadano TR 500e 3 00101 ManualDocument22 pagesTadano TR 500e 3 00101 Manualmichaellittle030786drb100% (124)

- Rolls Royce Workshop Manual CH.CDocument54 pagesRolls Royce Workshop Manual CH.Cara.mon872No ratings yet

- Main Control ValveDocument32 pagesMain Control ValveDaniel TekleNo ratings yet

- Pressure Reducing Valve GP-2000Document8 pagesPressure Reducing Valve GP-2000Anonymous jEXSJ0ebNo ratings yet

- Part Number RD2105 04-06 Scion Xa 04-06 Scion XB 1.5L 4 CylDocument4 pagesPart Number RD2105 04-06 Scion Xa 04-06 Scion XB 1.5L 4 CylHarshal PatelNo ratings yet

- 01-Engine - 2.8L DieselDocument211 pages01-Engine - 2.8L DieselGustavoNo ratings yet

- Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7Document3 pagesVacuum Pulling 1. Preliminary Checks:: SM6 & SM7Shaon majiNo ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 2Document12 pagesDrrdock Repair Jobs (Excluding DD Routines) No 2Amit Raj AnandNo ratings yet

- SDS1230 21 51 00Document30 pagesSDS1230 21 51 00นาถวัฒน์ ฉลาดแย้มNo ratings yet

- QuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFDocument6 pagesQuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFmds9185No ratings yet

- 07nafta y Emision de Gases Suzuki IntruderDocument34 pages07nafta y Emision de Gases Suzuki Intruderbenjapana100% (2)

- Catalog Open and Close EquipmentDocument84 pagesCatalog Open and Close EquipmentRafael Charry Andrade100% (1)

- 2AZ-FE Emission ControlDocument25 pages2AZ-FE Emission ControlLuks FernandezNo ratings yet

- 1341903547012-E chp8Document109 pages1341903547012-E chp8Vijay KumarNo ratings yet

- Tech 1183 Man StripperDocument19 pagesTech 1183 Man StripperDonna Gray100% (1)

- TOYOTA 1CD-FTV D4D Cooling SystemDocument28 pagesTOYOTA 1CD-FTV D4D Cooling SystemLuis Daniel CortesNo ratings yet

- Wilden h800 EomDocument28 pagesWilden h800 Eomanon_819441268No ratings yet

- CarburetorDocument23 pagesCarburetorKarina Leyva GuerreroNo ratings yet

- Idle Air Control (Iac) Valve: On-Vehicle InspectionDocument12 pagesIdle Air Control (Iac) Valve: On-Vehicle InspectionhazchuenNo ratings yet

- Guida Alla Revisione EnglezaDocument21 pagesGuida Alla Revisione EnglezaDodea NicuNo ratings yet

- Replacement: 1. Remove Battery 2. Remove Battery TrayDocument2 pagesReplacement: 1. Remove Battery 2. Remove Battery TraydiemnganNo ratings yet

- Chapter 9Document15 pagesChapter 9Harjith Vaibav100% (1)

- Steam Jet Ejector Is A Device For Producing Vacuum Which Is Achieved by Using A High Pressure Motive SteamDocument8 pagesSteam Jet Ejector Is A Device For Producing Vacuum Which Is Achieved by Using A High Pressure Motive Steamneerajtrip1230% (1)

- Fury 20 HST Technical ManualDocument8 pagesFury 20 HST Technical ManualAlejandro ChavarriaNo ratings yet

- Pages From HVAC Design Handbook (301 450)Document150 pagesPages From HVAC Design Handbook (301 450)zaffar731No ratings yet

- Tips For An Effective Acetylene Generator Clean OutDocument10 pagesTips For An Effective Acetylene Generator Clean OutRheaLeeNo ratings yet

- SECTION 5.20: TurbochargersDocument17 pagesSECTION 5.20: TurbochargersLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Ejector FunctionsDocument8 pagesEjector Functionsuyire8100% (2)

- Constrcucion Helvex PDFDocument16 pagesConstrcucion Helvex PDFHernandez JhonnyNo ratings yet

- Chapter 20Document8 pagesChapter 20sezarNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- English-French and French-English dictionary of the motor car, cycle, and boatFrom EverandEnglish-French and French-English dictionary of the motor car, cycle, and boatNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Electric Vaporisers For CO: Carbon DioxideDocument4 pagesElectric Vaporisers For CO: Carbon DioxideVikk SuriyaNo ratings yet

- Experimental Investigation On Diffusion Bonding of Dissimilar MetalsDocument8 pagesExperimental Investigation On Diffusion Bonding of Dissimilar MetalsVikk SuriyaNo ratings yet

- Mid Term Examination IbsDocument10 pagesMid Term Examination IbsVikk SuriyaNo ratings yet

- Replacement To Nathan DV4Document2 pagesReplacement To Nathan DV4Vikk SuriyaNo ratings yet

- Sewer Odor Control: Master PlanDocument168 pagesSewer Odor Control: Master PlanVikk SuriyaNo ratings yet

- Readiness For ProductionDocument5 pagesReadiness For ProductionVikk SuriyaNo ratings yet

- Pulverized Coal BurnerDocument8 pagesPulverized Coal BurnerVikk SuriyaNo ratings yet

- Hydrostatic Lubricator For Steam LocomotivesDocument6 pagesHydrostatic Lubricator For Steam LocomotivesVikk SuriyaNo ratings yet

- The Problem: Chakr InnovationDocument13 pagesThe Problem: Chakr InnovationVikk Suriya100% (1)

- Jet Blowers and Blast Nozzles: - Ventilating, Exhausting, Purging - Low Vacuum ApplicationsDocument2 pagesJet Blowers and Blast Nozzles: - Ventilating, Exhausting, Purging - Low Vacuum ApplicationsVikk SuriyaNo ratings yet

- Vtug-G enDocument200 pagesVtug-G enVikk SuriyaNo ratings yet

- Angle Seat Valve Fest Data SheetDocument41 pagesAngle Seat Valve Fest Data SheetVikk SuriyaNo ratings yet

- Primetech Dta 08-03-2019Document2 pagesPrimetech Dta 08-03-2019Vikk SuriyaNo ratings yet

- Illuminating Seals, Square Design: Subject To Change - 2018/07Document3 pagesIlluminating Seals, Square Design: Subject To Change - 2018/07Vikk SuriyaNo ratings yet

- Festo Solenoid ValveDocument11 pagesFesto Solenoid ValveVikk SuriyaNo ratings yet

- IP Pump DataSheet CNLBDocument2 pagesIP Pump DataSheet CNLBVikk Suriya100% (1)

- Solenoid/pneumatic Valves, ISO 15407-1: Look For The Star!Document81 pagesSolenoid/pneumatic Valves, ISO 15407-1: Look For The Star!Vikk SuriyaNo ratings yet

- Jain PVCWell Casing Screen PipesDocument12 pagesJain PVCWell Casing Screen PipesVikk SuriyaNo ratings yet

- Condensor PDFDocument3 pagesCondensor PDFVikk SuriyaNo ratings yet

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikk Suriya100% (2)

- Primetech Priming EjectorDocument3 pagesPrimetech Priming EjectorVikk SuriyaNo ratings yet

- API582Document23 pagesAPI582Vikk Suriya100% (2)

- Marine Ejectors PDFDocument11 pagesMarine Ejectors PDFVikk SuriyaNo ratings yet

- Dornier Jet Pump 9271Document6 pagesDornier Jet Pump 9271Vikk Suriya100% (1)

- TOA Bandpass FilterDocument1 pageTOA Bandpass FilterTaulan SyahNo ratings yet

- Maint Instructions For Ferrule FittingsDocument13 pagesMaint Instructions For Ferrule FittingsLakhwant Singh KhalsaNo ratings yet

- CC Rakes 130814Document2 pagesCC Rakes 130814Er Rajesh BuraNo ratings yet

- New TSI Ammendment CELEX 32019R0776 enDocument204 pagesNew TSI Ammendment CELEX 32019R0776 enNazli SubasiNo ratings yet

- Mumbai MetroDocument5 pagesMumbai Metropoiuji jina100% (1)

- RB Safety DriveDocument6 pagesRB Safety DriveSRDEEOP BSPNo ratings yet

- EN ColtExpress Conveyors-ArmoredTrain RulesDocument12 pagesEN ColtExpress Conveyors-ArmoredTrain Ruleshectorcp86No ratings yet

- Railway Engineering (CL-410) : Traction and Tractive ResistanceDocument28 pagesRailway Engineering (CL-410) : Traction and Tractive Resistancearpit_089No ratings yet

- Indian Railways Coach Maintenance Manual For BG CoachesDocument204 pagesIndian Railways Coach Maintenance Manual For BG CoachesSrinivas Guduru86% (7)

- Pavement AnalysisDocument19 pagesPavement AnalysisGodino ChristianNo ratings yet

- Joypurhat To Parbatipur - Train ScheduleDocument6 pagesJoypurhat To Parbatipur - Train ScheduleRFL-RFL-OP-M MoshiurNo ratings yet

- Rate Advice No 1 of 2009Document216 pagesRate Advice No 1 of 2009Navaneeth IyerNo ratings yet

- Sleepers and Fasteners - Work On Asset PDFDocument14 pagesSleepers and Fasteners - Work On Asset PDFCK TangNo ratings yet

- The Phenomenology of The PNR, LRT and MRTDocument19 pagesThe Phenomenology of The PNR, LRT and MRTGabrielle May LacsamanaNo ratings yet

- Horsham Truck Bypass OptionsDocument5 pagesHorsham Truck Bypass OptionsRex MartinichNo ratings yet

- ToleranceDocument1 pageTolerancegaru2529No ratings yet

- TFL Annual Report and Statement of Accounts 2017 18 PDFDocument170 pagesTFL Annual Report and Statement of Accounts 2017 18 PDFShubham SrivastavaNo ratings yet

- Part A Te 2Document4 pagesPart A Te 2muhammed mundhirNo ratings yet

- CORE/Prayagraj,: CLW/Chittaranjan, RCF/Kapurthala, MCF/Raebareli, DLW/Varanasi, RWF/Bangalore Railway/KolkataDocument2 pagesCORE/Prayagraj,: CLW/Chittaranjan, RCF/Kapurthala, MCF/Raebareli, DLW/Varanasi, RWF/Bangalore Railway/KolkataGopalakrishnanNo ratings yet

- Kalyan To Pune - Train Time TableDocument1 pageKalyan To Pune - Train Time Tableravishete2001100% (2)

- Braking System Used in Indian Railways 0Document43 pagesBraking System Used in Indian Railways 0cccrdmscrNo ratings yet

- Schematic - WIFI Wall Switch 2 WayDocument1 pageSchematic - WIFI Wall Switch 2 WayMarius MihaiNo ratings yet

- Table of Roadway JurisdictionDocument8 pagesTable of Roadway JurisdictionMichael LeinerNo ratings yet

- Transportation Engineering - Chapter 1.0Document10 pagesTransportation Engineering - Chapter 1.0kai dcNo ratings yet

- Draft: Qatar Integrated Railways Project Final Tender Design (FT)Document1 pageDraft: Qatar Integrated Railways Project Final Tender Design (FT)Sherif Sabri, PMPNo ratings yet

- Arch Bridge Code-ACS-8 PDFDocument8 pagesArch Bridge Code-ACS-8 PDFshobhit mohtaNo ratings yet

- Steel Crash Barriers: Current ProvisionDocument9 pagesSteel Crash Barriers: Current ProvisionNIBEDITA DEYNo ratings yet