Professional Documents

Culture Documents

Stopaq® Outerwrap PVC: Product Data Sheet

Stopaq® Outerwrap PVC: Product Data Sheet

Uploaded by

KUMAR ROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stopaq® Outerwrap PVC: Product Data Sheet

Stopaq® Outerwrap PVC: Product Data Sheet

Uploaded by

KUMAR RCopyright:

Available Formats

PRODUCT DATA SHEET

STOPAQ® OUTERWRAP PVC

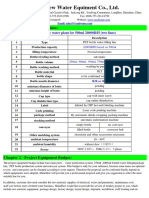

Product properties of Stopaq® Outerwrap PVC

Product Information Colour Black

Thickness Backing: 0,45 mm [18 mils] ± 10%

Product description: Stopaq® Outerwrap PVC is a UV-resistant flexible Total: 0,5 mm [20 mils] ± 10%

polyvinyl chloride tape, coated with a modified pressure sensitive rubber resin Temperatures Service: - 45 to +70 ºC [-49 to 158 °F]

adhesive. Stopaq® Outerwrap PVC is used for the mechanical protection of Short term max.: +90 ºC [194 °F]

corrosion preventing coating systems such as Stopaq® Wrappingband CZ and Peel strength between Before ageing (P0) A)

CZH. It is well suited for underground and submerged applications. The heavy- layers - @ +23 ºC [73 °F]: ≥ 0,20 N/mm *≥18 ozf/in]

duty adhesive layer provides good adhesion to the outer surface of the - @ +70 ºC [158 °F]: ≥ 0,02 N/mm *≥1.8 ozf/in]

Stopaq® Wrappingband as well as to its own backing. The Outerwrap has good

resistance to impacts, indentations and abrasion, and is also resistant to After thermal ageing for 100 days @ 90 ºC [194 °F]

chemicals like alkalis and acids. - P100 / P0 ≥ 0,50 A)

After hot water immersion for 100 days at 70 ºC [158 °F]

Features:

- P100 / P0 ≥ 0,75 A)

Easy to apply Thermal ageing Elastic modulus after thermal ageing for 100 days @ +90

Cold applied resistance ºC [194 °F]

Flexible, good conformability - E100 / E0 ≥ 0,75 A)

Good adhesion to Stopaq® Wrappingband as well as to its own backing

Excellent impact resistance Elongation at break after thermal ageing for 100 days @

Wide service temperature range 90 ºC [194 °F]

REACH compliant, does not contain Substances of Very High Concern - E’100 / E’0 ≥ 0,75 A)

(SVHC). Properties of coating system comprising Stopaq® Wrappingband CZH

and Stopaq® Outerwrap PVC

Benefits: Total thickness 3,0 mm ± 10%

Very well suited for manual application Self-healing test Self-healing of an artificial defect of Ø 6 mm *1/4”+:

Easy to stretch and to apply - @ -45 ºC [-49 °F]: no holiday (≤ 3 months)

Excellent mechanical protection of Stopaq® corrosion prevention products - @ +23 ºC [73 °F]: no holiday (≤ 24 hr.)

Resists impacts and indentations which may occur during installation and - @ +70 ºC [158 °F]: no holiday (≤ 24 hr.)

backfilling Impact resistance Tested at 15 J [132 in.lbf] and @ +23 ºC [73 °F] A)

- no holidays

Supports self-healing of completed coating system

Indentation resistance Tested at 1,0 N/mm² [145 psi] A)

Good resistance to ageing, even when exposed to maximum temperature

- @ +23 ºC [73 °F]: no holiday, residual coating

for longer periods of time thickness ≥ 0,6 mm [1/4”+

No curing or waiting time, ready for immediate service - @ +70 ºC [158 °F]: no holiday, residual coating

thickness ≥ 0,6 mm *1/4”+

Cathodic disbondment After 28 days A)

Application examples resistance @ +23 ºC [73 °F]: disbondment 0 mm, no holiday

@ +70 ºC [158°F]: disbondment 0 mm, no holiday

Pipes and Vessels: Mechanical protection of Stopaq® corrosion preventing In all cases self-healing completed within 24 hr.

A)

coating systems applied on carbon steel pipeline structures and reservoirs. ISO 21809-3:2016 coating type 13A

Field joints: Mechanical protection of Stopaq® corrosion preventing coating General order information

systems applied on carbon steel girth-weld joints of on-shore pipelines. Product Stopaq® Outerwrap PVC is available in rolls, wound

on cardboard cores, packed in cardboard boxes:

Pipe fittings: Mechanical protection of Stopaq® corrosion preventing coating Art. Nr.: Product dimensions (W x L) and contents:

systems applied on carbon steel pipe fittings like elbows, bends, tees, reducers Black – 1120: 50mm x 10m: 60 pcs/box;1800 pcs/pallet

and flanges. 1122: 50mm x 30m: 18 pcs/box; 630 pcs/pallet

1121: 75mm x 30m: 12 pcs/box; 420 pcs/pallet

1125: 100mm x 30m: 12 pcs/box;336 pcs/pallet

1126: 150mm x 30m: 6 pcs/box; 210 pcs/pallet

1124: 400mm x 40m: 4 pcs/box; 72 pcs/pallet

Handling Handle with care. Keep boxes upright.

Storage Store indoor, clean and dry, away from direct

sunlight in a cool place below +40°C [104°F].

V 11 / 20191007 (EN) Page 1 / 2

PRODUCT DATA SHEET STOPAQ® OUTERWRAP PVC

Application instruction - Job preparation Example - After application of the circumferential wraps,

Tools, equipment and Scissors, knife and measuring tape Pipe wrapping consecutive spiral wraps should have an overlap of ≥

auxiliaries (continued) 50%.

Additional coating Stopaq® Outerwrap PVC is applied on Stopaq® Avoid air inclusions. Avoid tenting and bridging

materials corrosion preventing coating materials, such as: Continue spiral wrapping until reaching the

Stopaq® Wrappingband CZ or CZH boundary of the area to be coated, leaving 3 mm

Stopaq® Paste CZ or CZH *1/8”+ of the previously applied Stopaq®

Additional mechanical protective materials may be Wrappingband visible at the boundary.

applied over the Outerwrap, e.g.:

Stopaq® Polyester When more than one roll of Outerwrap PVC is

Stopaq® Outerglass Shield XT Grey needed to continue wrapping, an overlap on the end

High humidity Stopaq® Outerwrap PVC can be applied in a humid of the previously applied Outerwrap PVC should be

atmosphere. The substrate should be free from created of at least 100 mm *4”+.

condensing water which can be reached by keeping End wrapping with two full circumferential wraps

the temperature at least 3 °C [6 °F] above dew point. perpendicular to the pipe. End with a quarter

Work area and The substrate should be dry, clean and protected circumferential wrap of Outerwrap PVC without

substrate against negative weather influences. Temperature of tension. In case of wrapping on horizontal pipes, the

the substrate should preferably be between +10 °C tape end should face downwards ending at 3 o’clock

[50 °F] and +70 °C [158°F]. position. Cut off in a tie-form.

Product conditions Stopaq® Outerwrap PVC should be dry and the The applied Outerwrap PVC must look smooth and

temperature should preferably be between +10 °C tight and should be shaped around all details and

[50 °F] and +30 °C [86 °F] for the ease of application. into corners..

Application instruction - Brief version Handling and commissioning

Specific application instructions are available at Seal For Life Industries, e.g. for Exposure to loads Objects coated with Stopaq® Outerwrap PVC should

wrapping of pipes, field joints, fittings, etc. not be exposed to excessive loads e.g. from

Example - Horizontal pipelines should be spirally wrapped from supports- or lifting equipment.

Pipe wrapping left-to-right or from right-to-left. Pipelines Immersion or burying Immersion or burying is possible immediately after

positioned with an angle deviating from horizontal completion of the coating application. Consult data

should be wrapped from bottom to top (e.g. risers). sheets for specific instructions of additional

In general Stopaq® Outerwrap PVC should be materials used. Backfill and compact with clean sand

applied with tension by gently pulling the roll of and filling material without sharp stones or hard

material, unless stated otherwise in specific lumps of soil.

application instructions.

Start wrapping Outerwrap PVC with two full Information

circumferential wraps perpendicular to the pipe, Documentation Extensive information is available on our web-site.

leaving 3 mm *1/8”+ of the previously applied Application instructions and other documentation

Stopaq® Wrappingband visible at the boundary. can be obtained by contacting our head office, from

our local distributor or by sending email to

info@stopaq.com

Certified staff Application of the described coating system should

be carried out by certified personnel.

Seal For Life Industries Mexico S de R.L. de C.V. Seal For Life Industries - Stopaq B.V. Seal For Life Industries BVBA Seal For Life India Private Ltd.

Tijuana, Mexico Stadskanaal, the Netherlands Westerlo, Belgium Baroda, India

USA Tel: +1 858 633 9797 Tel: +31 599 696 170 Tel: +32 14 722 500 Tel: +91 2667 264 721

Mx Tel: +52 664 647 4397 Fax: +31 599 696 177 Fax: +32 14 722 570 Fax: +91 2667 264 724

mexico@sealforlife.com info@sealforlife.com belgium@sealforlife.com india@sealforlife.com

Anodeflex™ - Stopaq® - Polyken® - Covalence® - Powercrete® - Sealtaq® - Blockr® - Easy.Qote® - SynergyQ®

DISCLAIMER: Seal For Life Industries warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when used in compliance with Seal For Life Industries’ written instructions. Because

many installation factors are beyond the control of Seal For Life Industries, the user shall determine the suitability of the products for the intended uses and assume all risks and liabilities in connection herewith. Seal for Life’s liability is stated in its General Terms and

Conditions of Sale. Seal For Life Industries makes no other warranty either express or implied. All information contained in this technical data sheet is to be used as a guide and is subject to change without notice. This technical data sheet supersedes all previous data

sheets on this product.

V 11 / 20191007 (EN) Page 2 / 2

You might also like

- NORMA GALIA Renault Packaging Spec PDFDocument45 pagesNORMA GALIA Renault Packaging Spec PDFmarcosmonterrosog100% (2)

- Stopaq Outerwrap PVCDocument2 pagesStopaq Outerwrap PVCDeepak YadavNo ratings yet

- Stopaq Outerwrap PVC PDFDocument2 pagesStopaq Outerwrap PVC PDFDeepak YadavNo ratings yet

- STOPAQ® Outerwrap PVC PDFDocument2 pagesSTOPAQ® Outerwrap PVC PDFEngTamerNo ratings yet

- 460 Pds Stopaq Outerwrap PVC v7 (En) PDFDocument2 pages460 Pds Stopaq Outerwrap PVC v7 (En) PDFEngTamerNo ratings yet

- PDS Stopaq Outerwrap HSPEX V1 enDocument2 pagesPDS Stopaq Outerwrap HSPEX V1 enAndyNo ratings yet

- Stopac Outer Wrap PE PDS-Stopaq-Outerwrap-PE-V8-ENDocument2 pagesStopac Outer Wrap PE PDS-Stopaq-Outerwrap-PE-V8-ENvaradarajck893No ratings yet

- PDS Stopaq Outerwrap HTPP V4 EN PDFDocument2 pagesPDS Stopaq Outerwrap HTPP V4 EN PDF今夕何夕No ratings yet

- PDS Stopaq Wrapping BandDocument2 pagesPDS Stopaq Wrapping BandSinan A AzizNo ratings yet

- PDS Stopaq High Impact Shield V5 enDocument2 pagesPDS Stopaq High Impact Shield V5 enAndyNo ratings yet

- PDS Stopaq Outerwrap HTPE V1ENDocument2 pagesPDS Stopaq Outerwrap HTPE V1ENAndyNo ratings yet

- PDS Stopaq Outerglass Shield V2 (En)Document2 pagesPDS Stopaq Outerglass Shield V2 (En)Gulf Trans PowerNo ratings yet

- 455 - Product - Data - Sheet - Stopaq - Wrapping Band - CZHDocument3 pages455 - Product - Data - Sheet - Stopaq - Wrapping Band - CZHFatin ZawawiNo ratings yet

- 460 Stopaq - Product Data Sheet - Stopaq Outerwrap PVC - Version April 2009 (Uk)Document2 pages460 Stopaq - Product Data Sheet - Stopaq Outerwrap PVC - Version April 2009 (Uk)EngTamerNo ratings yet

- PDS Stopaq Outerwrap PE V7 enDocument2 pagesPDS Stopaq Outerwrap PE V7 enAndyNo ratings yet

- PDS Stopaq Outerwrap HTPP V3 enDocument2 pagesPDS Stopaq Outerwrap HTPP V3 enAndyNo ratings yet

- PDS Stopaq Wrappingband CZH V8 enDocument2 pagesPDS Stopaq Wrappingband CZH V8 enMajid SattarNo ratings yet

- Stopaq® Paste CZH: Product Data SheetDocument2 pagesStopaq® Paste CZH: Product Data SheetKUMAR RNo ratings yet

- STOPAQ® CZH PasteDocument2 pagesSTOPAQ® CZH PasteEngTamerNo ratings yet

- PDS Stopaq Wrappingband CZ V6 ENDocument2 pagesPDS Stopaq Wrappingband CZ V6 ENDavid RodriguesNo ratings yet

- 503 Pds Stopaq Wrappingband CZHT v4 (En)Document2 pages503 Pds Stopaq Wrappingband CZHT v4 (En)EngTamerNo ratings yet

- Viscotaq PE Outer Wrap April 2011Document2 pagesViscotaq PE Outer Wrap April 2011JA BustosNo ratings yet

- PDS Stopaq Wrappingband CZ V5 enDocument2 pagesPDS Stopaq Wrappingband CZ V5 enAndyNo ratings yet

- VISCOTAQR PE Outer Wrap February 2014Document2 pagesVISCOTAQR PE Outer Wrap February 2014Sinan A AzizNo ratings yet

- PDS Stopaq Insulwrap FR V1 enDocument1 pagePDS Stopaq Insulwrap FR V1 enAndyNo ratings yet

- Sika SanisilDocument4 pagesSika SanisilA GlaumNo ratings yet

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- Thixoflex Orange & Thixoflex Gray: Product Information SheetDocument2 pagesThixoflex Orange & Thixoflex Gray: Product Information SheetValerio CadedduNo ratings yet

- 460 Pds Stopaq Outerwrap PVC v7 (En) PDFDocument2 pages460 Pds Stopaq Outerwrap PVC v7 (En) PDFRahmat RiskiNo ratings yet

- Sikahyflex 140 Construction Pds enDocument4 pagesSikahyflex 140 Construction Pds enReno MaulanaNo ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- Product Info Precote85 eDocument4 pagesProduct Info Precote85 etechietaddyNo ratings yet

- PDS Stopaq Outerglass Shield XT Grey V1 enDocument2 pagesPDS Stopaq Outerglass Shield XT Grey V1 enAndyNo ratings yet

- Viscotaq Pe Outer Wrap: Product Data SheetDocument2 pagesViscotaq Pe Outer Wrap: Product Data SheetFarid HarisNo ratings yet

- Sikahyflex 140 Construction - Pds enDocument4 pagesSikahyflex 140 Construction - Pds enPutra AfriadeNo ratings yet

- Zwaluw Gasket Sealant Red enDocument2 pagesZwaluw Gasket Sealant Red enAngelo Carlo MalabananNo ratings yet

- Catalogue Băng Keo Alberta 80 PertisDocument3 pagesCatalogue Băng Keo Alberta 80 PertisHà Trần MạnhNo ratings yet

- Gasket RTV Silicone 310 ML: Applications BenefitsDocument4 pagesGasket RTV Silicone 310 ML: Applications BenefitsNurcan BozkurtNo ratings yet

- PDS Stopaq Polyester V5 ENDocument2 pagesPDS Stopaq Polyester V5 EN今夕何夕100% (1)

- Sikahyflex®-140 Construction: Product Data SheetDocument4 pagesSikahyflex®-140 Construction: Product Data SheetNicholas WashingtonNo ratings yet

- MOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01Document2 pagesMOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01pmf engineering limitedNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- 772 Oracal8300Document2 pages772 Oracal8300bobby_flaviuNo ratings yet

- PDS-PITTWRAP B100 Jacket-EnDocument6 pagesPDS-PITTWRAP B100 Jacket-EnJorge Manuel MezaNo ratings yet

- QL3009 Aq21Document4 pagesQL3009 Aq21Andrew LeeNo ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- EN TDS Cybright - T22Document2 pagesEN TDS Cybright - T22Shashwata ChattopadhyayNo ratings yet

- 6AG10521FB087BA1 Datasheet enDocument2 pages6AG10521FB087BA1 Datasheet enMário NetoNo ratings yet

- Ultra High Temperature 100 HT Adhesive Transfer Tapes: 9082 9085 9082UV 9085UVDocument4 pagesUltra High Temperature 100 HT Adhesive Transfer Tapes: 9082 9085 9082UV 9085UVwilliaqNo ratings yet

- BASF MasterSeal CR 125 - Ficha Técnica PDFDocument3 pagesBASF MasterSeal CR 125 - Ficha Técnica PDFOsmar Amadeo Bejarano JimenezNo ratings yet

- Technical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDocument2 pagesTechnical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDacetIronForceNo ratings yet

- Fiche Technique Colle ThermiqueDocument2 pagesFiche Technique Colle ThermiqueAnouer BelkadiNo ratings yet

- Military Fuel HydrantDocument2 pagesMilitary Fuel HydrantJorge MuñizNo ratings yet

- PDS-PITTWRAP CW Plus Jacketing-US-enDocument3 pagesPDS-PITTWRAP CW Plus Jacketing-US-enJorge Manuel MezaNo ratings yet

- Product Data Sheet: Adhesive BackingDocument2 pagesProduct Data Sheet: Adhesive BackingAcil SopandiNo ratings yet

- 2-Protecfull SFP 108 - PE - Eng - v3 PDFDocument2 pages2-Protecfull SFP 108 - PE - Eng - v3 PDFLjubomirSinđelićNo ratings yet

- Interchar 2090: Acrylic IntumescentDocument4 pagesInterchar 2090: Acrylic IntumescentEngTamerNo ratings yet

- FS Na DDXDocument2 pagesFS Na DDXDhim131267No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Stopaq® Paste CZH: Product Data SheetDocument2 pagesStopaq® Paste CZH: Product Data SheetKUMAR RNo ratings yet

- Overview of Welding (Procedure and Personnel) Qualification As Per ASME Code Section IXDocument1 pageOverview of Welding (Procedure and Personnel) Qualification As Per ASME Code Section IXKUMAR RNo ratings yet

- MCX MarginDocument2 pagesMCX MarginKUMAR RNo ratings yet

- NFHTPL 19 Nghplhfhy RPWG G CZT JW FHG G Gapw RP KW WK RPFPR IrDocument1 pageNFHTPL 19 Nghplhfhy RPWG G CZT JW FHG G Gapw RP KW WK RPFPR IrKUMAR RNo ratings yet

- Corrugation Process: Product Data SheetDocument1 pageCorrugation Process: Product Data SheetKUMAR RNo ratings yet

- Asmaco RTV Silicone Gasket Maker PDSDocument2 pagesAsmaco RTV Silicone Gasket Maker PDSKUMAR RNo ratings yet

- INSPECTION of Galvanize Product PDFDocument24 pagesINSPECTION of Galvanize Product PDFNasikhatul AmanahNo ratings yet

- Shine Dew Water Equiment Co., LTD.: Chapter 1 - Project Basic DataDocument17 pagesShine Dew Water Equiment Co., LTD.: Chapter 1 - Project Basic Dataardhendu1No ratings yet

- 6240 SpecDocument2 pages6240 SpecCarlos Miguel Barrena TorresNo ratings yet

- Swara Industries ProfileDocument6 pagesSwara Industries ProfileKetan ArgadeNo ratings yet

- HDP Steelfab Corp-Company ProfileDocument5 pagesHDP Steelfab Corp-Company ProfileEric AldanaNo ratings yet

- Montageanleitung MR AMS enDocument60 pagesMontageanleitung MR AMS enRahim KhanNo ratings yet

- Packing in Outbound DeliveryDocument10 pagesPacking in Outbound DeliveryIshan AgrawalNo ratings yet

- Enclosure 6150 Installation ProceduresDocument155 pagesEnclosure 6150 Installation ProceduresJulio RoldanNo ratings yet

- Eagle Catalog 2013Document31 pagesEagle Catalog 2013awarehousefulllNo ratings yet

- GE 1975 Lamp CatalogDocument68 pagesGE 1975 Lamp CatalogAlan Masters100% (2)

- R7001e 21Document44 pagesR7001e 21TựĐộngHóaNo ratings yet

- BT Lifter: L23 STD Sales Guide enDocument18 pagesBT Lifter: L23 STD Sales Guide enporter1980No ratings yet

- TSplus Lift Transfer UnitsDocument10 pagesTSplus Lift Transfer UnitsHelena Nadine Mendes FerreiraNo ratings yet

- Natural RubberDocument15 pagesNatural Rubberphyrdows100% (1)

- TransferSystemTS5v3 0 PDFDocument174 pagesTransferSystemTS5v3 0 PDFAlex DincaNo ratings yet

- LP FFMP - 18%Document5 pagesLP FFMP - 18%Asma Mozaharul IslamNo ratings yet

- SW08344 Guide For Unpacking Shipping ContainersDocument14 pagesSW08344 Guide For Unpacking Shipping ContainersSamuel Ernesto OchoaNo ratings yet

- Evaluating Response Robot Capabilities: Logistics: Packaging For Urban Search and Rescue Task Force Equipment CachesDocument5 pagesEvaluating Response Robot Capabilities: Logistics: Packaging For Urban Search and Rescue Task Force Equipment CachesAlevj DbNo ratings yet

- Brochure PDFDocument60 pagesBrochure PDFexpairtiseNo ratings yet

- Assignment 2 Ikea Case Study.Document4 pagesAssignment 2 Ikea Case Study.ddlj1989No ratings yet

- Automatic Pallet Changer Operator's AddendumDocument18 pagesAutomatic Pallet Changer Operator's AddendumNam Ngô PhươngNo ratings yet

- Proef Presentatie - Phagoe ShuwarnaDocument32 pagesProef Presentatie - Phagoe ShuwarnaDaryll ShawnNo ratings yet

- Tipolen 244-55 162 - Tds - enDocument3 pagesTipolen 244-55 162 - Tds - endmilanovic5395No ratings yet

- 40.data Sheet Emc 110 b10 PDF DataDocument4 pages40.data Sheet Emc 110 b10 PDF Datashineangel93No ratings yet

- DS 8-1 Commodity Classification (Data Sheet) - FM GlobalDocument18 pagesDS 8-1 Commodity Classification (Data Sheet) - FM GlobalSam Khan0% (2)

- Food Delivery Truck Inspection 21-9-2016Document2 pagesFood Delivery Truck Inspection 21-9-2016SamerNo ratings yet

- Smypc Plastics CatalogDocument13 pagesSmypc Plastics CatalogRobin de VegaNo ratings yet

- Starbucks ManualDocument39 pagesStarbucks ManualChristopher HessingNo ratings yet

- Pallet Handling Technology: High Throughput RatesDocument6 pagesPallet Handling Technology: High Throughput RatesBülent KabadayiNo ratings yet

- Retail StoreDocument24 pagesRetail Store81000No ratings yet