Professional Documents

Culture Documents

Annex 30 Tool - Design - Waste Stabilization Ponds Maco

Annex 30 Tool - Design - Waste Stabilization Ponds Maco

Uploaded by

limwellOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex 30 Tool - Design - Waste Stabilization Ponds Maco

Annex 30 Tool - Design - Waste Stabilization Ponds Maco

Uploaded by

limwellCopyright:

Available Formats

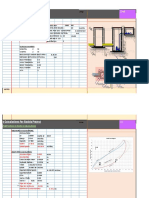

TOOL FOR DESIGN OF STP BASED ON ANAEROBIC AND

FACULTATIVE PONDS

Capacity Average Flow 25 MLD

Guidance: Yellow cells are the input information to be suitably filled. Green cells

are to be reviewed and modified/updated if need be. Red letters to be suitably

corrected.

Ground level at STP Site at Inlet chamber 209.5 Mtr

Drain level at outlet at chainage 11325 206.2 Mtr

IL of Out fall Sewer(1000 mm) with slope 1 in 1100 at STP 215.68 Mtr

Average Flow 4.18 MLD

Average Flow 0.05 M3/sec

Peak Flow : Peak Factor 2.25 9.396 MLD

Peak Flow : 0.11 M3/sec

Minimum Flow Factor 2 2.088 MLD

Minimum Flow 0.02 M3/sec

DESIGN OF INLET CHAMBER

Peak Flow 9.396 MLD

Peak Flow 0.11 M3/sec

Detention time 15 Sec

Volume required 1.63 cum

Liquid depth taken 0.8 Mtr

Area 2.04 M2

Width taken 1.4 Mtr

Length 1.4 Mtr

Provide free board to ensure that raw sewage will not

overflow even when the 1000 mm out fall sewer run full 0.8 Mtr

DESIGN OF COARSE SCREEN

Peak Flow 0.11 M3/sec

Coarse Screen Opening 50 mm

Depth of water in screen 0.9 Mtr.

velocity through screen 0.7 M/sec

Area of screen 0.16 M2

Angle of inclination with the horizontal 45 degree

Sin (Angle of Inclination) 0.71

Free Board 0.60 m

Length of screen 2.12

Width of opening 0.17 mtr

No of opening 3 nos

Number of bars 2 nos

Let width of each bar be 10 mmx75 mm

Total width of channel 197 mm

Let width of each side be 50 mm

Total width of channel: Provide 298 mm

Openings 5

No of bars 4

Size of Coarse Screen-Width 0.3 m

Size of Coarse Screen-Length 4 m

Velocity in Channal u/s of Screen 0.41

Velocity through Screen 0.47

Head Loss No Clogging 0.003 m

Velocity when 50% clogging 0.94 m/sec

Head Loss when 50% clogging 0.037 m

DESIGN OF FINE SCREEN

Peak Flow 0.11 M3/sec

Nos of screen(Each for handling peak flow) 2 Nos

Velocity(taking) through screen, Assume 0.8 M/sec

Area 0.14 M2

Depth of flow taken 0.7 Mtr.

Hence width of opening 0.19 Mtr.

No of Openings 13

No of Bars 12

Width of Channal 314

Angle of inclination with the horizontal 75 degree

Clear opening between adjacent bars of screen 15 mm

Bars thickness of screen 10 mm x50mm

Taking width of screen 2000 mm

Nos of opening will be 80 Nos

Nos of bars(10 mm thickness) 79 Nos

Free Board 0.6 m

Sin (Angle of Inclination with horizontal) 0.966

Inclined length of Screen 1.35 m

Length of chamber before screen 1.5 m

Total Length of chamber 2.85

Total width of channel 2 Mtr.

Velocity in Channal u/s of Screen 0.08 m/sec

Velocity through Screen 0.13 m/sec

Head Loss through screen 0.001 m

Velocity through screen when 50% clogged 0.258

Head Loss when 50% clogging 0.003

Size-2.85 (L)x2(W)x1.7(D)

DESIGN OF GRIT CHAMBER

GRIT REMOVAL SYSTEM

Two grit removal tank (1 w +1 S) each capable of handling peak flow, will be

provided. They are designed to remove grit particle of size of 0.15 mm size and

above with a specific gravity of 2.3

Q/A=VS x n/(1-η)-n-1

Where-η-Desired efficiency of removal of grit particle

VS -settling velocity of minimum size of grit particle to be removed

Q/A--Design surface overflow rate applicable for grit chamber to be designed

n-an index which a measure of the basin performance

Here η value taken 75 %

Say 0.75

Here VS value taken 1225 m3/m2/day

Here n value taken-1/8(for very good performance) 0.13

Hence surface over flow 806.42 m3/m2/day

rate(Q/A)=(Vs*n)/(((1-η)^-n)-1)

Say 810 m3/m2/day

This Q/A value has to be reduced to allow for 10.00% %

deposition of sand during sand strom by

Then design overflow rate 729 m3/m2/day

Peak flow(m3/day) 9396 (m3/day)

Hence area required for peak flow 12.89 m2

Each side of square grit chamber 3.59 mtr.

Hence provide tank length 4.00 mtr.

Hence provide tank Width 4 mtr.

Detention time taken is 1 minute

Depth of tank will be 0.08 mtr.

However in order to provide adequate depth for the 0.9 mtr.

grit scraping mechanism, increase to

This gives detention time is 11.17 minute

the detention time of 1.87(slightly higher) minute is immaterial for mechanically

cleaned grit removal tank

Hence size of grit removal chamber is 9 x9x0.9

Flow height above, H 0.06 m

weir,Q=(2/3)*Cd*L*H^1.5*((2g)^.5),Cd=.6,L=9

DESIGN OF CHANNEL FROM GRIT CHAMBER TO DISTRIBUTION

CHAMBER

Peak flow 0.65 M3/sec

velocity taken 0.8 M/sec

Area required 0.81 m2

Depth taken 0.7 mtr.

Then width of channel will be 1.16 mtr.

DESIGN OF ANAEROBIC POND

No of Anaerobic ponds to provide flexibility in O&M of 1 Nos

these ponds

Each handling flow of(25000m3 per day/3) 4176 (m3/day)

say 4176 (m3/day)

Volume of anaerobic pond V=Li xQ/λ

Li-Raw sewage BOD(1000 XB/q) 300 mg/l

Q- average flow 4176 (m3/day)

λ- volumetric BOD loading(Range between 100-400 gm/m3/day)

λ=20T-100(as per MEAFNRCD)

T=mean temperature in coldest month in 0C (The manual by 20

DANIDA ENRECA suggests T as mean in coldest month or

quarter. In quarter it is 15.55)

hence λ is 300 kg/ha/day

Hence Volume of tank(V) 4176 m3

Detention time 1.00 day

Detention time of 2 days or more is desirable to achieve 1.00 day

sufficient BOD removal

Hence Volume of each tank (V) 4176 m3

Hence Volumetric BOD loading(λ) is 300 gm/m3/day

BOD removal efficiency(in %)=2T+20 60 %

For liquid depth 3 mtr.

Area at mid depth 1392 m2

Length shall be L=2B

Hence mid depth width B=(area/2) 1/2 26.4 mtr.

Hence mid length L- 52.8 mtr.

Side slope of pond is 1V :2.5 H 2.5 mtr.

Depth for Sludge 1 mtr.

bottom below Mid depth 2 mtr.

Free Board 1 mtr.

Top of embankment above mid depth 3

Hence total top length(L) 67.8 mtr.

Hence total top width(W) 41.4 mtr.

Area at top 2804 m2

Hence total bottom length (L) 42.8 mtr.

Hence total bottom width(W) 16.4 mtr.

Area at Bottom 701 m2

Provide three anaerobic pond each of 108.8mx63.1m at top surface and

78.8mx33.1 m surface at bottom

DESIGN OF FACULTATIVE POND

Nomber of Tanks 2 No

Average flow in each tank 2088 cum/sec

BOD enter at Facultative pond after 2 days detention period 120 mg/l

at anaerobic pond

Minimum mean monthly temperature 0c 20

Volumetric BoD loading:-

λs=350 x(1.107-0.002T)(T-20) this value of BOD loading rate 350.00 kg/ha/day

recommended as MEAFNRCD( Refer DANIDA)

λs=60(1.099)^T (Refer Jodhpur design) 396.37

λs=20 T-120 280.00

λs=20T-60 340.00

λs=375-6.25L, where L-latitude(28.73), Refer manual 195.44 kg/ha/day

Correction for above MSL=(1+(3 x10-5)xE)

where E is elevation in meters= 210 1.0063

then λs is 194.21 kg/ha/day

Influent BOD to facultative pond 120 mg/l

value of λs is considered recommended as MEAFNRCD 350.00 kg/ha/day

From equation (as per world bank paper) facultative mid depth area can be calculated

as(A)

A=10 x Li x Q/λs

A-facultative area at mid depth in m 2

Li-influent BOD concentration in mg/l, Li is BOD to be

removed

Effluent to be used for restricted irrigation as such 100 75

effluent BOD is ok however on safe side design for effluent

BOD of

Li= 45

then A is 8949 M2

Divide the area in two ponds(area of each facultative pond) 4474 M2

at middle of tank

Take L=2B

Then width B=(A/2)1/2 47 M

Then L is at mid depth 95 M

Hence area at mid depth is 4474 M2

Adopt liquid depth 3 m

Adopt depth for sludge 0.5 m

Adopt Free Board 1 m

Total Depth of tank 4.5

Area at bottom embankment slope H/V 2.5

Length at bottom 83.3 m

width at bottom 36.0 m

Hence area at bottom is - 3005 m2

Length at top including 1.0 mt free board 105.8 m

width at top including 1.0 mt free board 58.5 m

Area at top including 1.0 mtr free board- 6197 m2

Volume of pond V=h/6(S0+4S1+S2)

h-height(liquid depth) 3.5 m

S0-area at top 6197 m2

S1-area at mid water depth 4474 m2

S2-area at bottom 3005 m2

Hence V of each tank is 15808 m3

Then detention time of each tank is 7.57 days

Total detention time of anaerobic + facultative pond is 8.57 days

Total area of ll afacultative ponds at top 12394 m2

Total area of all anaerobic ponds at top 2804 m2

Total area 15199 m2

Assuming footprint area of units as % of total area 60.00% %

Hence total area is- 25331 sqm

Hence total area in hectare taken as 2.53 hactare

3

Total BOD removal in facultative pond 45 mg/l

Hence Effluent BOD is 75 mg/l

Sludge Storage andCleaning requirement

Population equivalent at 108 LPCD waste 38667

cum per

For anaerobic pond sludge volume 0.04 capita/year

For anaerobic pond sludge volume 1546.67 cum/year

Sludge volume provided in all anaerobic ponds 2563.98 cum

Cleaning required period 0.60 years

say 1 years

Distribution tank for Anaerobic Pond

Consider one anerobic pond not working,

Flow height above weir, H

,Q=(2/3)*Cd*L*H^1.5*((2g)^.5),Cd=.6,L=1.2

Q per tank 0.054375 cum/sec

Assume weir length 1.5 m

H 0.07 m

Allow free fall of 0.1 m

Total Head loss 0.17 m

Free Board 0.30 m

Pipe from distribution tank to anaerobic pond inlet

Flow when one tank not working 0.05 cum/sec

Pipe dia 0.75 m

velocity of flow 0.12 m/sec

Length of pipe 60.00 m

head loss flq^2/10*d^5 0.001 m

entry/exit loss 0.001 m

Total Losses 0.002 m

Overflow Weir for Inlet to Anaerobic Pond

Flow when one tank not working 0.054 cum/sec

Length of weir 3m

Flow height above weir, H

,Q=(2/3)*Cd*L*H^1.5*((2g)^.5),Cd=.6 0.05 m

Allow free fall 0.1 m

Total Head loss 0.15 m

Pipe from Anaerobic Pond Inlet to Anaerobic Pond

Peak Flow when one tank not working 0.054 cum/sec

Pipe dia 0.750 m

velocity in pipe 0.12 m/sec

Length of pipe 40.00 m

head loss flq^2/10*d^5 0.000 m

entry/exit loss 0.001 m

Total Losses 0.002 m

Overflow Weir for Inlet to Facultative Pond

Average flow when one tank not working 0.024 cum/sec

Length of weir

Flow height above weir, H 3 m

,Q=(2/3)*Cd*L*H^1.5*((2g)^.5),Cd=.6 0.03 m

Allow free fall 0.1 m

Total Head loss 0.13 m

Half flow from one anaerobic pond, Length of weir 1.50 m

Pipe from Facultative Pond Inlet to Facultative Pond

Average flow when one tank not working 0.024 cum/sec

Pipe Dia 0.600 m

velocity of flow 0.09 m/sec

Length of pipe 40.00 m

head loss flq^2/10*d^5 0.000 m

entry/exit loss 0.001 m

Total Losses 0.001 m

Overflow Weir for Outlet to Facultative Pond

Average flow 0.024 cum/sec

Length of weir

Flow height above weir, H 3 m

,Q=(2/3)*Cd*L*H^1.5*((2g)^.5),Cd=.6 0.03 m

Allow free fall 0.1 m

Total Head loss 0.13 m

Pipe from Facultative Pond outlet to Outlet Chamber 1

Average flow 0.024 cum/sec

Assume pipe dia 0.600 m

velocity of flow 0.09 m/sec

Length of pipe 40.00 m

head loss flq^2/10*d^5 0.000 m

entry/exit loss 0.001 m

Total Losses 0.001 m

Pipe from outlet Chamber 1to outlet Chamber 2

Flow 0.024 cum/sec

Assume pipe dia 0.600 m

velocity of flow 0.09 m/sec

Length of pipe 40.00 m

head loss flq^2/10*d^5 0.000 m

entry/exit loss 0.001 m

Total Losses 0.001 m

Pipe from Outlet Chamber 2 to Sewage Pump House

Flow 0.048 cum/sec

Pipe dia 0.80 m

velocity 0.10

Length of pipe 160.00 m

head loss flq^2/10*d^5 0.001 m

entry/exit loss 0.001 m

Total Losses 0.002 m

Alternately Provide channal

Velocity 1.0 m/sec

Area 0.048 sqm

Taking, Width=2*Height, H= 0.2 m

Width 0.3 m

Slope required, V=1/n*R^.67*S*.5, n=0.013, S= 0.000090

say 0.1 in 1000

Sewage pumping for Irrigation and Disposal

Flow 0.048 cum/sec

Flow in LPS 48.33 LPS

say 50.00 LPS

Head 15.00 m

Pump working 2.00 No

Pump stand bye 2.00 No

Flow in each pump 25.00 lps

pump efficiency 60.00 %

Pump KW 6.13 KW

Motor KW 6.74

Say 10.00

Total No of pumps working + stand by 4.00

Delivery Pipe velocity 0.75 m/sec

Pipe Area for combined flow of two pumps 0.067 sqm

Pipe dia 0.291 m

Say 750 mm

Pipe dia of delivery for each pump, velocity 2.25 m/sec

Pipe Dia 0.12 m

Say 300 mm

Suction Pipe dia 250 mm

Sump for Effluent pumping station

flow 4.176 MLD

Sump storage 30 minutes

Sump Capacity 87 cum

Sump depth 4 m

Sump Dia 5.26 m

Provide Sump Dia 6.00 m

Sump Capacity Provided 113 cum

Free Board

F=(log10 A)^.5-1, F= 0.95

Wave height,H, (g*H)/V^2=.0026((gFe/V^2)^0.47, Fe is

fetch,V is wind velocity, H= 0.04

Faecal Coliform Removal

Ne/Ni=1/(1+ktθa)(1+Ktθf), Ni=5*10^7, Ne= 2798412.9

Kt=2.6(1.19)^(T-20), T=13.89, kt= 0.898

Helminth Removal

R % removal=100(1-0.14 Exp(-0.38θ)) 99.33 %

R % removal as per the table in book by DANIDA 98.6 %

25

4,176.00

4.18

300

13.89

You might also like

- 3.1 Final Process Design of 6 MLD - Stp.sbr.Document8 pages3.1 Final Process Design of 6 MLD - Stp.sbr.Minakshi SinghNo ratings yet

- ASP - Process Design CalculationDocument21 pagesASP - Process Design Calculationvishu100% (1)

- Design Calculation - STPDocument23 pagesDesign Calculation - STPForam ParekhNo ratings yet

- Extended AerationDocument5 pagesExtended Aerationgautam guptaNo ratings yet

- 35 MLD WTP EstimateDocument78 pages35 MLD WTP EstimateaneeshmeloottuNo ratings yet

- Oxidation Ditch Design and OperationsDocument19 pagesOxidation Ditch Design and Operationsashok100% (1)

- Treatment Plant HydraulicsDocument11 pagesTreatment Plant HydraulicsMadhavan DurairajNo ratings yet

- Design Sheet STPDocument17 pagesDesign Sheet STPBhagyashree Rath0% (1)

- Astm Uniformat LLDocument18 pagesAstm Uniformat LLAly AnisNo ratings yet

- Waste Water Management PlanDocument41 pagesWaste Water Management PlanAsif100% (1)

- Saff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Document4 pagesSaff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Rakesh Verma100% (3)

- Design of Slow Sand Filter KinfraDocument2 pagesDesign of Slow Sand Filter KinframajeedctNo ratings yet

- Pumpstation Input Data: Sewer Pumpstation Design Calculations For Alqibla ProjectDocument18 pagesPumpstation Input Data: Sewer Pumpstation Design Calculations For Alqibla ProjectTahirJabbar50% (2)

- Sps and Wetwell NTLDocument3 pagesSps and Wetwell NTLProject ManagerStructuresNo ratings yet

- Asp-Ea - 21 MLDDocument12 pagesAsp-Ea - 21 MLDDev Kumar Dwivedi100% (1)

- Hydraulic Design of Sewage Treatment PlantDocument9 pagesHydraulic Design of Sewage Treatment PlantSCR_010101No ratings yet

- 4b., 5. & 6. PDC, HDC & LCUDocument16 pages4b., 5. & 6. PDC, HDC & LCUepe civil1No ratings yet

- ETP DesignDocument49 pagesETP DesignMayank Mani100% (1)

- Peak Flow Calculations XYZ Dec 16,2003Document7 pagesPeak Flow Calculations XYZ Dec 16,2003Amit BhamreNo ratings yet

- For Submission - Process - With Formule - R1Document30 pagesFor Submission - Process - With Formule - R1Kamod Rai100% (1)

- Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Document12 pagesPlant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Dev Kumar DwivediNo ratings yet

- 4) Design of Pumping Machinery - Head CalculationsDocument7 pages4) Design of Pumping Machinery - Head CalculationsNaveen NagisettiNo ratings yet

- WTP Calc.Document23 pagesWTP Calc.abhishek5810No ratings yet

- Ate Huber-1Document47 pagesAte Huber-1Ravena RemaditaNo ratings yet

- Tool For Master Plan Formulation - Water Supply With Surface Water SourceDocument25 pagesTool For Master Plan Formulation - Water Supply With Surface Water SourceaneeshmeloottuNo ratings yet

- Annexure 16 - Tool For Design of Tube SettlerDocument1 pageAnnexure 16 - Tool For Design of Tube SettlerWikaz FiansyahNo ratings yet

- Sewer Pump Calculation ReportDocument4 pagesSewer Pump Calculation Reportarguteconsultants0% (1)

- Inlet Chamber DesignDocument2 pagesInlet Chamber DesignThirumalesh100% (1)

- 45MLD WTP@20 GLDocument25 pages45MLD WTP@20 GLSwaminathan Thayumanavan100% (1)

- Design of Sewage Treatment PlantDocument7 pagesDesign of Sewage Treatment PlantBill Harley Vinsmoke100% (1)

- Pump Stationvvvvvvvvvvvv (Recovered)Document28 pagesPump Stationvvvvvvvvvvvv (Recovered)TahirJabbarNo ratings yet

- 13 Tertiary TreatmentDocument27 pages13 Tertiary TreatmentMohammed BarniNo ratings yet

- Hydraulic CalculatorDocument13 pagesHydraulic CalculatorShady Azzam Abu HaidyNo ratings yet

- WTP CalculationsDocument10 pagesWTP CalculationsAngshuman Roy ChoudhuryNo ratings yet

- STP Design PDFDocument151 pagesSTP Design PDFMark Anthony AcangNo ratings yet

- WTP Report - 1.5MLD PDFDocument97 pagesWTP Report - 1.5MLD PDFDesign TeamNo ratings yet

- Design Inputs QTY Unit: CalculationDocument7 pagesDesign Inputs QTY Unit: CalculationHemant Kale100% (1)

- Sewage Treatment PlantDocument22 pagesSewage Treatment PlantJordan Allen BarriosNo ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationJong Dollente Jr.100% (1)

- Air Bersih, IPA, Rapid Sand Filter, Design CalculationDocument15 pagesAir Bersih, IPA, Rapid Sand Filter, Design CalculationAndrizal KotoNo ratings yet

- Rapid Sand Filter and Tube SettlersDocument16 pagesRapid Sand Filter and Tube Settlersnp27031990No ratings yet

- MBBR AgraDocument44 pagesMBBR Agrasanjeevsharma9999100% (1)

- Process Design Calculation3 - NDDocument14 pagesProcess Design Calculation3 - NDabhishek5810No ratings yet

- MBBR Calculation SpreadsheetDocument4 pagesMBBR Calculation SpreadsheetRoger T Somundoh100% (2)

- Hydraulic Water TreatmentDocument5 pagesHydraulic Water TreatmentHolaNo ratings yet

- Process Calculations 1 MLD SBRDocument168 pagesProcess Calculations 1 MLD SBRAngelo Endozo100% (1)

- Planning, Designing, Quantity Estimating and Costing of Grey Water Treatment Plant For Svcet Hostel A Mini ProjectDocument40 pagesPlanning, Designing, Quantity Estimating and Costing of Grey Water Treatment Plant For Svcet Hostel A Mini ProjectCallesNo ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationKalyca Nazhifa SalwaNo ratings yet

- Bhaggyam Pragathi - STP 180KLD Technical DetailsDocument18 pagesBhaggyam Pragathi - STP 180KLD Technical DetailsenvsandyNo ratings yet

- 0.90 MLD MechanicalDocument8 pages0.90 MLD Mechanicalkiran raghukiranNo ratings yet

- Clarifier SizingDocument50 pagesClarifier SizingPandu Dewa AsmaraNo ratings yet

- STP Biochip Package PlantDocument2 pagesSTP Biochip Package PlantDavid LambertNo ratings yet

- Clarifier DesignDocument12 pagesClarifier DesignAbinashNo ratings yet

- Hyd - Cal. WTP BaggiDocument27 pagesHyd - Cal. WTP BaggiChief Engineer PMUNo ratings yet

- Water Treatment Plant Design: SedimentationDocument38 pagesWater Treatment Plant Design: SedimentationnasaritaNo ratings yet

- Spreadsheet For Activated Sludge ProcessDocument31 pagesSpreadsheet For Activated Sludge ProcessAl Patrick Dela CalzadaNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Attachment 9 - Pipeline Stream Crossing Construction Mode DeterminationDocument48 pagesAttachment 9 - Pipeline Stream Crossing Construction Mode DeterminationAly AnisNo ratings yet

- Recitation 6 - Problems: Problem 1Document11 pagesRecitation 6 - Problems: Problem 1Aly AnisNo ratings yet

- SPS Book PDFDocument75 pagesSPS Book PDFAly AnisNo ratings yet

- Force Main Design Data ChecklistDocument1 pageForce Main Design Data ChecklistAly AnisNo ratings yet

- (Jeffrey K. Pinto, Jeffrey W. Trailer) EssentialsDocument216 pages(Jeffrey K. Pinto, Jeffrey W. Trailer) EssentialsMuhammad Farhan ArainNo ratings yet

- Air and Air Valves in PipingDocument11 pagesAir and Air Valves in PipingAly AnisNo ratings yet

- Air Release Vacuum Breaker ValveDocument16 pagesAir Release Vacuum Breaker ValveLao Zhu100% (1)

- Air Release 2014Document4 pagesAir Release 2014Aly AnisNo ratings yet

- Crack Width Evaluation For Flexural RC MembersDocument10 pagesCrack Width Evaluation For Flexural RC MembersAly AnisNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument16 pagesJournal of Environmental Chemical Engineering: SciencedirectradNo ratings yet

- Environmental Engineering ManualDocument209 pagesEnvironmental Engineering ManualSivamani Selvaraju100% (1)

- NEERI N N RaoDocument25 pagesNEERI N N Raorahul_sexyNo ratings yet

- Environmental EngineeringDocument6 pagesEnvironmental EngineeringPatricia de LeonNo ratings yet

- G VSD D Quality Control Annual ReportDocument289 pagesG VSD D Quality Control Annual Reportنيرمين احمدNo ratings yet

- DO Sag KurveDocument19 pagesDO Sag KurveAllen KurniawanNo ratings yet

- Civil EngDocument4 pagesCivil Engvijaykadam_ndaNo ratings yet

- EVT577 Wastewater Exp3 BODDocument6 pagesEVT577 Wastewater Exp3 BODFadzrilNo ratings yet

- Star-Series Meter Manual Multilingual PDFDocument285 pagesStar-Series Meter Manual Multilingual PDFJheraldyn CastroNo ratings yet

- Waste WaterDocument8 pagesWaste WaterSamantha ManimtimNo ratings yet

- The Appropriate Biochemical Oxygen Demand Concentration For Designing Domestic Wastewater Treatment PlantDocument8 pagesThe Appropriate Biochemical Oxygen Demand Concentration For Designing Domestic Wastewater Treatment PlantabdulNo ratings yet

- COD Fractionation in Wastewater Characterization-The State of The ArtDocument11 pagesCOD Fractionation in Wastewater Characterization-The State of The ArtRicardo CostanziNo ratings yet

- Ethanol From Sugarcane JuiceDocument23 pagesEthanol From Sugarcane JuiceShrikrishna Gadkar100% (2)

- Grade I Operator Certification Examination Information and Sample QuestionsDocument4 pagesGrade I Operator Certification Examination Information and Sample QuestionsVineet ChaudharyNo ratings yet

- Wastewater Disposal.Document266 pagesWastewater Disposal.FarazNo ratings yet

- TEST - 7 (TEXTBOOK) SolDocument88 pagesTEST - 7 (TEXTBOOK) SolShivam Rajendra ThokalNo ratings yet

- Fifth Schedule: (Regulation 10)Document3 pagesFifth Schedule: (Regulation 10)hazimNo ratings yet

- Aquaculture Principles1Document50 pagesAquaculture Principles1Jewel AtanganNo ratings yet

- Civil Engineering Site AdministrationDocument34 pagesCivil Engineering Site AdministrationTatenda PaduzeNo ratings yet

- Tutorial Sheet - Water PollutionDocument8 pagesTutorial Sheet - Water PollutionAbdoo YasserNo ratings yet

- Advanced Biological Treatment Processes For Industrial WastewatersDocument359 pagesAdvanced Biological Treatment Processes For Industrial WastewatersVu Hoanghau100% (3)

- Project Report 1Document94 pagesProject Report 1arunNo ratings yet

- Microbiology Thesis DownloadDocument8 pagesMicrobiology Thesis DownloadNaomi Hansen100% (2)

- Ec Compliance Tata Steel Kalinganagar Apr17 Sep17Document17 pagesEc Compliance Tata Steel Kalinganagar Apr17 Sep17Anonymous zy3rAYHNo ratings yet

- What Is The Difference Between COD and BOD?: Home About Products Services Case Studies Blog Get QuoteDocument1 pageWhat Is The Difference Between COD and BOD?: Home About Products Services Case Studies Blog Get QuoteSearchNo ratings yet

- of IncubatorDocument22 pagesof IncubatorSarah PavuNo ratings yet

- BANTEDocument53 pagesBANTEangelNo ratings yet

- Water ChemistryDocument14 pagesWater ChemistryDr Olayinka OkeolaNo ratings yet

- SM 4500 OdDocument8 pagesSM 4500 OdThainy BressanNo ratings yet