Professional Documents

Culture Documents

Job Risk Assessment For Defect Item No. E398: Provision of Electrical & Instrument Rectification Service

Job Risk Assessment For Defect Item No. E398: Provision of Electrical & Instrument Rectification Service

Uploaded by

Aous HOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Risk Assessment For Defect Item No. E398: Provision of Electrical & Instrument Rectification Service

Job Risk Assessment For Defect Item No. E398: Provision of Electrical & Instrument Rectification Service

Uploaded by

Aous HCopyright:

Available Formats

Project Title: Provision of Electrical & Instrument Rectification Services Revis

Contract No: KPC1901-0000-PRC-TP-027 ion:

Document Title Job Risk Assessment for Defect Item No. E1310 00

Document Title: Document No.: KPC027-JRA-KPS1-021-00 Page

1 of 5

Job Risk Assessment for Defect Item No. E398

Project:

Provision of

Electrical & Instrument Rectification Service

(KPC1901-0000-PRC-TP-027)

Document No.: KPC027-JRA-KPS1-037-00

Purpose:

□ For Information ☐ For Review ☒For Approval ☐For Construction ☐As-Built

00 First Issue 26/09/2019 A. Mohammed A. Hussein M. Ibrahim

Revision Description Date Drafted Reviewed Approved

Client:

KURDISTAN PIPELINE COMPANY

Contractor:

UNI-TECH EPC SOLUTIONS

Doc. No.: KPC027-JRA-KPS1-037-00 Page 1 of 5

Project Title: Provision of Electrical & Instrument Rectification Services Revision: 00

Contract No: KPC1901-0000-PRC-TP-027

Document Title Job Risk Assessment for Defect Item No. E398

Document No.: KPC027-JRA-KPS1-037-00 Page 2 of 5

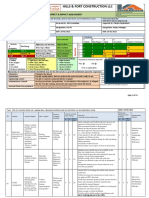

RISK ASSESSMENT

Activity: ELECTRICAL AND CUTTING Date: Risk Assessment Ref: 00

UniTech document code:

A – Very Unlikely B - Unlikely C - Possible D - Likely E – Very Likely Risk Level Rating Required Authority of Approval

1 - Negligible 1 2 3 4 5 Low Risk Supervisor

2 - Slight 2 4 6 8 10 Medium Risk Field Manager

3 - Moderate 3 6 9 12 15 Low Frequency High Risk Production Manager, Field Manager, HSE Manager

4 - Major 4 8 12 16 20 High Risk Not Approved

5- Catastrophic 5 10 15 20 25

What is the hazard Who it may be harmed How might people be harmed? L C Rating Additional thing to Control the hazard NL N New Action mentioned

C Rating by who

Electrocution incidents •

can be fatal, while non- • Proper training, only those persons

who have been adequately trained

fatal shocks can result and experienced in the work of

in serious and electricity to allow for the same.

permanent burn • Electrical work shall not carry out in

injuries to skin, internal wet Conditions.

• LOTO procedure to be followed

tissues and damage to during testing & commissioning.

the heart depending on • Communicate to all personnel about

the length and severity testing & commissioning.

Electrical • Don’t use homemade electrical

of the shock. accessories and use industrial type

Shock& flash only.

Engineer and 4 4 20 • Disconnect main supply before

technician commencing the work.

• Defective tools and equipment 4 2 8 Supervisor

should not be used, report it and

replaced it immediately.

• Barricade the location and signage

to be placed where circuits and

equipment’s are energized.

• PPE should be worn at all-time

where working in energized circuits.

(Insulated gloves, Electric resistivity

shoe)

• Ensure that proper isolation is done

during the activity.

Doc. No.: KPC027-JRA-KPS1-037-00 Page 2 of 5

Project Title: Provision of Electrical & Instrument Rectification Services Revision: 00

Contract No: KPC1901-0000-PRC-TP-027

Document Title Job Risk Assessment for Defect Item No. E398

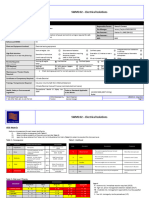

Document No.: KPC027-JRA-KPS1-037-00 Page 3 of 5

-Eye damage

-cuts • Proper PPE.

4 4 16 • No unauthorized people close to the

Cutting of The person who -crushed toes and work area.

Material cutting metal fingers • suitable fire extinguisher at the job

(grinding) area. 2 2 4 Supervisor

(Grinding) -Fire

• The grinder must be guarded.

• supervisor for monitoring the job.

People are working -Losing hearing. • The people should wear ear plug at

among the machine -lack communication. the noisy are and during grinding

Noise and and during grinding. 3 4 12 operation. 2 3 6

• Choose low-noise tools and Supervisor

Vibration machinery.

• Using grinder and vibratory at

workshop.

Caused by the

passage of heavy

currents through the • Inspection and check equipment

Engineer and related to worked and certified from

technician body or by direct 3 3 9 inspector.

Burns

contact with an • Follow the RA. 3 1 3 Electrical e.g.

electrically heated

surface.

Explosion and fire • Barricading work area by caution

caused by electrical type with some other safety signs

that relating to electrical activity.

Teamwork

sparks, short circuits or • check the cable and wire not

EXPLOSION overload heating, old crashed.

wiring in the presence 3 4 12 • Clean are from flammable material. 3 1 3 Supervisor

of flammable material. • good supervising

• Follow the RA.

-All operators. may • Good housekeeping maintained at

suffer sprains, bruising all time practices.

• Safety footwear provided to all

or fracture if they trip workers.

Slips, trips and Technician, over objects. such as • waste disposed of in skip.

work debris, or slip on • Look at the terrain and be aware

falls Work team uneven, or slippery surfaces.

Electrical Eng. spillages 4 3 12 • Trained first aiders and suitable first 1 3 3 Team

- slippery ground aid kit with all survey parties. members

- uneven surfaces.

Doc. No.: KPC027-JRA-KPS1-037-00 Page 3 of 5

Project Title: Provision of Electrical & Instrument Rectification Services Revision: 00

Contract No: KPC1901-0000-PRC-TP-027

Document Title Job Risk Assessment for Defect Item No. E398

Document No.: KPC027-JRA-KPS1-037-00 Page 4 of 5

-Not using portable gas • All personnel working at the live

detector. area must attend to the H2S and

HSE Induction.

- didn’t get h2s training. • Inform HSE specialist to issue the

-didn’t inducted by H2S PTW and the Performing Authority

team. to conduct a Toolbox talk covering

-Not attended at the Permit Requirements to ensure

5 4 20 all personnel fully understand the 2 4 8

toolbox talk. work sequence, risk and control

measures.

• Initial gas test to be undertaken to

ensure there are no gas

Working in Live leaks/venting activities within the

Technician team local area prior to issuing the Permit

Area to Work (PTW).

H2S and LEL • Personal H2S monitors to be issued

to all personnel who working on the HSE

live plan. Supervisor

• Following wind sock and got to

opposite of wind master point.

• All personnel should to understand

the action to be taken if an alarm

sounds (plant or personal H2S

monitor – go across wind and then

up wind go to safe muster point and

wait further instruction from the

HSE Specialist person at the muster

point.

Unqualified -Using equipment as • Expert employee

person Who aren’t

wrong way. • Provide first aider, Project

Effect to other people 3 5 15 • HSE induction, 3 2 6 manager

Inexperienced qualified to job

who are working with • Attendance at toolbox talking.

user • Focus on the job.

him

Environmental Environment Poor housekeeping. • Good housekeeping

Leaking liquid material • Use proper spill kit.

hazard 2 3 6 1 2 2 Everyone

People -The people getting • Wearing suitable PPE.

injury by using wrong • Manufacture equipment.

Worker 4 2 8 • While work from high get Scaffold 2 2 4

INJURY equipment. and harness.

• Inspect all tools for damage and

Hand Injury faults before use.

Strike Injuries • Ensure all tools are stored and Monitor

transported appropriately.

• Maintain awareness of counterfeit

tools.

Doc. No.: KPC027-JRA-KPS1-037-00 Page 4 of 5

Project Title: Provision of Electrical & Instrument Rectification Services Revision: 00

Contract No: KPC1901-0000-PRC-TP-027

Document Title Job Risk Assessment for Defect Item No. E398

Document No.: KPC027-JRA-KPS1-037-00 Page 5 of 5

• Carry out power tool pre use checks

(Cables, switches, handles etc.)

• Do not overstress tools.

• Where necessary double protection,

e.g. safety googly glasses and face

shields.

• Use suitably and correct way for

cable connections.

• Do not use in wet weather.

• Ensure firefighting equipment

available for hot work

• Fire watchman for hot work.

ASSESSED BY APPROVED BY

Name Position Signature Date Name Position Signature Date

Ali Mohammed HSE Manager

Doc. No.: KPC027-JRA-KPS1-037-00 Page 5 of 5

You might also like

- 20) Pumping of WaterDocument7 pages20) Pumping of WaterMobin Thomas Abraham77% (13)

- DSLP CalculationDocument23 pagesDSLP CalculationMunusamyKarthikeyan100% (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Risk Assessment Project Iosh - Ms PDF Welding Construction PDFDocument1 pageRisk Assessment Project Iosh - Ms PDF Welding Construction PDFMustafa Flayyih100% (1)

- RA For Sump PumpsDocument9 pagesRA For Sump PumpsAnonymous ubta67y6eNo ratings yet

- Demolition Works: Loyal Building Contracting LLCDocument23 pagesDemolition Works: Loyal Building Contracting LLCjones75% (4)

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkip100% (1)

- Safe Operating ProcedureDocument155 pagesSafe Operating ProcedureLincon Patel100% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- DRRR ReviewerDocument3 pagesDRRR ReviewerJennifer SuarezNo ratings yet

- SoBo - Site Inspection ChecklistDocument5 pagesSoBo - Site Inspection ChecklistAndrada Roxana IonescuNo ratings yet

- Nebosh DefinitionsDocument1 pageNebosh Definitionstheoptimist00No ratings yet

- (Guide) Fire Safety and Prevention SeminarDocument179 pages(Guide) Fire Safety and Prevention Seminardgp50% (2)

- RISK ASSESMENT FOR JET FUEL PIPING REV1 16 June 2021Document15 pagesRISK ASSESMENT FOR JET FUEL PIPING REV1 16 June 2021Moh'd SameerNo ratings yet

- Incident No 28. Fire Incident Notification at 52tk56a Prezicon - 3rd Aug. 023Document2 pagesIncident No 28. Fire Incident Notification at 52tk56a Prezicon - 3rd Aug. 023islamhse10No ratings yet

- Hazards Identification Risk AssessmentRRRRDocument7 pagesHazards Identification Risk AssessmentRRRRArshad KhanNo ratings yet

- RA For Power Cable - EEPSP RA SWRO 008 - 00A SignedDocument9 pagesRA For Power Cable - EEPSP RA SWRO 008 - 00A Signedfayaz fayazhotmail.comNo ratings yet

- Inspection & Test Plan For Defect Item No. E398: Provision of Electrical & Instrument Rectification ServiceDocument4 pagesInspection & Test Plan For Defect Item No. E398: Provision of Electrical & Instrument Rectification ServiceAous HNo ratings yet

- S2-F31-Emergency Test in Case of Facility Power OutageDocument2 pagesS2-F31-Emergency Test in Case of Facility Power OutageJHUPEL ABARIALNo ratings yet

- Nearmiss Incident Report - Off-Site Substation 15 MontegoDocument4 pagesNearmiss Incident Report - Off-Site Substation 15 Montegoislamhse10No ratings yet

- RA Civil Works T 1006Document12 pagesRA Civil Works T 1006fayaz fayazhotmail.comNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- Eepsp Ra Swro 003 - 00aDocument9 pagesEepsp Ra Swro 003 - 00afayaz5233No ratings yet

- IM-08-B EHS Risk Assessment DC WorkDocument4 pagesIM-08-B EHS Risk Assessment DC WorkAndrés PacompíaNo ratings yet

- Risk Assessment ProjectDocument4 pagesRisk Assessment Projectحموده فراس عبيداتNo ratings yet

- Method Statement of Rectification of Defect No. E398Document13 pagesMethod Statement of Rectification of Defect No. E398Aous HNo ratings yet

- PTES Sample IR Scan ReportDocument22 pagesPTES Sample IR Scan ReportAkshay GatkalNo ratings yet

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriNo ratings yet

- J S A Electrical Distributaton Board MaintenenceDocument4 pagesJ S A Electrical Distributaton Board MaintenenceASLAM MULANINo ratings yet

- Preventing and Minimizing Arc Flash Risk in Power System NetworkDocument14 pagesPreventing and Minimizing Arc Flash Risk in Power System NetworkIJAR JOURNALNo ratings yet

- 00-TAA-ABG-107008-00 Discipline ProcedureDocument8 pages00-TAA-ABG-107008-00 Discipline ProcedureSalman GhaffarNo ratings yet

- RA - Electrical WorksDocument9 pagesRA - Electrical WorksShezi Bhatti0% (1)

- AE278WTS-TRN-009 - HSE Inspection Report No. 10 - 18 Aug 2022Document4 pagesAE278WTS-TRN-009 - HSE Inspection Report No. 10 - 18 Aug 2022pramodsomanNo ratings yet

- CTU Rescue (Risk Assessment)Document7 pagesCTU Rescue (Risk Assessment)NurNo ratings yet

- 02PQ Services - TNBESDocument83 pages02PQ Services - TNBESkyle0910No ratings yet

- 7.08 Lightning Risk Assessment Study and LP Design RC - PV PlantDocument27 pages7.08 Lightning Risk Assessment Study and LP Design RC - PV PlantChang Lee100% (2)

- risk assessment for cradle useDocument12 pagesrisk assessment for cradle usevictorNo ratings yet

- JHA - 163 Removal of Boundary Wall Using Boom Truck For Extension of Station WorkDocument12 pagesJHA - 163 Removal of Boundary Wall Using Boom Truck For Extension of Station WorkM.k.BurhanNo ratings yet

- Notes U3Document14 pagesNotes U3Alejandro Toledo CamposNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Hazard Identification & Risk AssessmentDocument9 pagesHazard Identification & Risk AssessmentLathakula RajashekharNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- PR Upl 200091374Document5 pagesPR Upl 200091374p VarNo ratings yet

- Welding SopDocument6 pagesWelding SopNikhil VaidyaNo ratings yet

- Power Quality Overview IEEMA MonographDocument12 pagesPower Quality Overview IEEMA MonographSunil VaishnavNo ratings yet

- CMD-18Document8 pagesCMD-18Huy Dao QuangNo ratings yet

- JSA-Cold Cuting NJYN 94-30Document7 pagesJSA-Cold Cuting NJYN 94-30DLPS HSENo ratings yet

- Asl C GD Lps Spec 01 r0Document13 pagesAsl C GD Lps Spec 01 r0Agrawal PrajaktaNo ratings yet

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety AnalysishkaruvathilNo ratings yet

- 10 - Lift Car ElectricalDocument8 pages10 - Lift Car Electricalyoen_anNo ratings yet

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety Analysispartho banerjeeNo ratings yet

- 8 Flushing and Chemical Cleaning MS-AC-08Document3 pages8 Flushing and Chemical Cleaning MS-AC-08Marwan NizarNo ratings yet

- SWMS 02 - Electrical Isolation - Qantas Flight SimulatorDocument9 pagesSWMS 02 - Electrical Isolation - Qantas Flight SimulatorhangatualiyNo ratings yet

- General Data:: Inspection Testing and Secondary Injection of Differential Protection Relay Type P-632Document3 pagesGeneral Data:: Inspection Testing and Secondary Injection of Differential Protection Relay Type P-632MASUD RANANo ratings yet

- Electrical Marine Thermal Imaging Survey Sample ReportDocument14 pagesElectrical Marine Thermal Imaging Survey Sample ReportRachit SharmaNo ratings yet

- MS - Earth Grid Measurement FinalDocument10 pagesMS - Earth Grid Measurement FinalKaruppusamy MariNo ratings yet

- Safe Work Method Statement: Electrical TestingDocument4 pagesSafe Work Method Statement: Electrical TestingMehrab AliNo ratings yet

- RA Report - UPS Activity in SS5Document3 pagesRA Report - UPS Activity in SS5Mohamed MostafaNo ratings yet

- Equipment Maintenance Filled UpDocument6 pagesEquipment Maintenance Filled UpShanto ChowdhuryNo ratings yet

- Safetyra-527 Fal EgyDocument6 pagesSafetyra-527 Fal EgymujuburrNo ratings yet

- 0188CP N DG DG05 HS JSA (Pipe Rack Structure)Document14 pages0188CP N DG DG05 HS JSA (Pipe Rack Structure)Imran KhanNo ratings yet

- 01installation of Construction SupplyDocument2 pages01installation of Construction SupplyRues AgNo ratings yet

- Essential Requirement For OJT Training ProjectDocument4 pagesEssential Requirement For OJT Training ProjectAous HNo ratings yet

- 1 System DynamicsDocument60 pages1 System DynamicsAous HNo ratings yet

- Introduction To Control Valve & Its Main Components Rev.1Document30 pagesIntroduction To Control Valve & Its Main Components Rev.1Aous HNo ratings yet

- CT ExplanationDocument9 pagesCT ExplanationAous HNo ratings yet

- 2 - 5463350992110094476 Comp EXDocument236 pages2 - 5463350992110094476 Comp EXAous H100% (1)

- Electrical Breakdown Testing of Polymeric Materials Intended For Use in PV Modules IEC Standard Development and Progress Bernt Ake SultanDocument29 pagesElectrical Breakdown Testing of Polymeric Materials Intended For Use in PV Modules IEC Standard Development and Progress Bernt Ake SultanAous HNo ratings yet

- Testing of Power Transformers - Routine Tests - 240325 - 082449Document15 pagesTesting of Power Transformers - Routine Tests - 240325 - 082449Aous HNo ratings yet

- CompEx Presentation PDF - Version 10 - Updated Jan 2020Document223 pagesCompEx Presentation PDF - Version 10 - Updated Jan 2020Aous H100% (1)

- Compex TrainingDocument166 pagesCompex TrainingAous H100% (1)

- Leybold Vacuum Pump Instruction ManualDocument46 pagesLeybold Vacuum Pump Instruction ManualAous H0% (1)

- Technical Specifications of YUNENG ZJA6KYDocument12 pagesTechnical Specifications of YUNENG ZJA6KYAous HNo ratings yet

- Electrical Technician Competencies Matrix - GROUP 2 Completed Tasks As 0n 15 Nov 2023Document742 pagesElectrical Technician Competencies Matrix - GROUP 2 Completed Tasks As 0n 15 Nov 2023Aous HNo ratings yet

- Useful For Instrument Technicians 1703260505 231226 182658Document123 pagesUseful For Instrument Technicians 1703260505 231226 182658Aous HNo ratings yet

- Contractor Organization Chart: (KPC1901-0000-PRC-TP-027)Document2 pagesContractor Organization Chart: (KPC1901-0000-PRC-TP-027)Aous HNo ratings yet

- ZJA6BY Instuction ManualDocument22 pagesZJA6BY Instuction ManualAous H100% (1)

- 3003-FP110 Att.09 - TESTING OF DRY TYPE TRANSFORMERDocument1 page3003-FP110 Att.09 - TESTING OF DRY TYPE TRANSFORMERAous HNo ratings yet

- Morley-IAS Catalogue 2020 UK 0120Document96 pagesMorley-IAS Catalogue 2020 UK 0120Aous HNo ratings yet

- Project Title: Contract No: From: To:: Document TransmittalDocument1 pageProject Title: Contract No: From: To:: Document TransmittalAous HNo ratings yet

- Check List For Panels Function Test: Project NoDocument1 pageCheck List For Panels Function Test: Project NoAous HNo ratings yet

- Check List For Installation of Lighting SystemDocument1 pageCheck List For Installation of Lighting SystemAous HNo ratings yet

- Method Statement of Rectification of Defect No. E398Document13 pagesMethod Statement of Rectification of Defect No. E398Aous HNo ratings yet

- KPC1901 0000 Elc CS 0043 01Document2 pagesKPC1901 0000 Elc CS 0043 01Aous HNo ratings yet

- Tools & Instruments List: # I N D Q - (U)Document2 pagesTools & Instruments List: # I N D Q - (U)Aous H100% (1)

- 3003-FP110 Att.06 - Installation LV-MV-HV CablesDocument2 pages3003-FP110 Att.06 - Installation LV-MV-HV CablesAous HNo ratings yet

- Inspection & Test Plan For Defect Item No. E398: Provision of Electrical & Instrument Rectification ServiceDocument4 pagesInspection & Test Plan For Defect Item No. E398: Provision of Electrical & Instrument Rectification ServiceAous HNo ratings yet

- Mechanical Completion Instrument Cable DN-I013-ADocument1 pageMechanical Completion Instrument Cable DN-I013-AAous HNo ratings yet

- Inspection Check List For Rectification of Defect No. E398Document2 pagesInspection Check List For Rectification of Defect No. E398Aous H100% (1)

- Sika Armatec®-110 Epocem® Part C: Safety Data SheetDocument11 pagesSika Armatec®-110 Epocem® Part C: Safety Data SheetHamkarNo ratings yet

- GAO Report On Airport Perimeter SecurityDocument85 pagesGAO Report On Airport Perimeter SecuritylizNo ratings yet

- Material Safety Data Sheet Zinc Sulfate Monohydrate: Section 1 Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Zinc Sulfate Monohydrate: Section 1 Chemical Product and Company IdentificationPatricia Joyce Malabanan SunglaoNo ratings yet

- MSDS GOJO NATURAL ORANGE Pumice HandDocument14 pagesMSDS GOJO NATURAL ORANGE Pumice HandJAVIERNo ratings yet

- Nebosh-Igc1 2 PapersDocument4 pagesNebosh-Igc1 2 Papersabcxyz779983% (6)

- G5842 Magnaprint Easyprint Neutral ExtraDocument7 pagesG5842 Magnaprint Easyprint Neutral ExtraDishen SoobenNo ratings yet

- Barhale Inductions Visitor Site Induction Module 3Document15 pagesBarhale Inductions Visitor Site Induction Module 3Ochä MegaSukmaNo ratings yet

- Fire Alarm System DesginDocument13 pagesFire Alarm System DesginRazzak RafiNo ratings yet

- Abu Dhabi Occupational Safety and Health System Framework (Oshad-Sf) Code of PracticeDocument10 pagesAbu Dhabi Occupational Safety and Health System Framework (Oshad-Sf) Code of PracticeKushNo ratings yet

- Health & Safety at Work Guide: First Aid at Work Regulations Save Moving & Handling Personal Protective Equipment (Ppe)Document1 pageHealth & Safety at Work Guide: First Aid at Work Regulations Save Moving & Handling Personal Protective Equipment (Ppe)gabriella veronicaNo ratings yet

- GOTS 3.0-4.0 Positive List 1Document8 pagesGOTS 3.0-4.0 Positive List 1Kushagradhi DebnathNo ratings yet

- LAX Active Shooter Incident and Resulting Airport Disruption: A Review of Response OperationsDocument99 pagesLAX Active Shooter Incident and Resulting Airport Disruption: A Review of Response OperationsSouthern California Public Radio100% (2)

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDocument2 pagesMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeNo ratings yet

- API 580 Mock ExamDocument5 pagesAPI 580 Mock ExamRandyCha100% (2)

- Labour Regulations 29 AprilDocument20 pagesLabour Regulations 29 AprilBusinessTech77% (13)

- Haccp For CateringDocument2 pagesHaccp For CateringLamama Foods Professional Industrial CatererNo ratings yet

- Jadwal TrainingDocument14 pagesJadwal TrainingPrayogo ImamNo ratings yet

- BeautycareDocument16 pagesBeautycareJoseph Arcega MolinaNo ratings yet

- SOP DevelopmentDocument3 pagesSOP DevelopmentMithileshNo ratings yet

- Confined Space Questions and AnswersDocument8 pagesConfined Space Questions and AnswersHaseeb100% (1)

- Shell - Clavus RDocument14 pagesShell - Clavus Radvantage025No ratings yet

- Use and Refuelling of Portable GeneratorDocument4 pagesUse and Refuelling of Portable GeneratorJonasNo ratings yet

- Job Safety Analysis Template - BatteryDocument3 pagesJob Safety Analysis Template - BatteryvenkateshbitraNo ratings yet

- MSDS Apiezon L GreaseDocument5 pagesMSDS Apiezon L GreasesebadansNo ratings yet

- Sop Template OperationsDocument2 pagesSop Template OperationsAlex BetancaNo ratings yet