Professional Documents

Culture Documents

Qw-482 Suggested Format For Welding Procedure Specification (WPS)

Qw-482 Suggested Format For Welding Procedure Specification (WPS)

Uploaded by

ING HARRINSON FERREBUSCopyright:

Available Formats

You might also like

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- SD 25TFDocument182 pagesSD 25TFjulianmata100% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps Demoharis saleemNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- ASME Numeric Index1Document12 pagesASME Numeric Index1ING HARRINSON FERREBUSNo ratings yet

- Inter Volume 48Document8 pagesInter Volume 48ING HARRINSON FERREBUSNo ratings yet

- 14nonmandatory AppendicesDocument62 pages14nonmandatory AppendicesING HARRINSON FERREBUSNo ratings yet

- Listado MSSDocument2 pagesListado MSSING HARRINSON FERREBUSNo ratings yet

- ASME B56-8 InterpretationsDocument3 pagesASME B56-8 InterpretationsING HARRINSON FERREBUSNo ratings yet

- ASME B56-6 InterpretationsDocument9 pagesASME B56-6 InterpretationsING HARRINSON FERREBUSNo ratings yet

- ASME B30-11 InterpretationsDocument2 pagesASME B30-11 InterpretationsING HARRINSON FERREBUSNo ratings yet

- Aws D1.1 Part 3 PDFDocument6 pagesAws D1.1 Part 3 PDFING HARRINSON FERREBUSNo ratings yet

- Ferrer Y Parente Mill SteelDocument1 pageFerrer Y Parente Mill SteelING HARRINSON FERREBUSNo ratings yet

- Subject Index: Item No. 21808Document8 pagesSubject Index: Item No. 21808ING HARRINSON FERREBUSNo ratings yet

- 01 EI - Jan12Document36 pages01 EI - Jan12ING HARRINSON FERREBUSNo ratings yet

- Amine SCC PDFDocument2 pagesAmine SCC PDFING HARRINSON FERREBUSNo ratings yet

- 17 Casing Design PDFDocument44 pages17 Casing Design PDFChristian Olascoaga Mori50% (2)

- Sulfuric AcidDocument195 pagesSulfuric AcidDivyamNo ratings yet

- Kokkonda AravindDocument12 pagesKokkonda AravindVB INTERNET AND GROCERY STORENo ratings yet

- Remote Radio Unit (RRU) DC Feed Protection: Document Technical Content Created by M J MaytumDocument26 pagesRemote Radio Unit (RRU) DC Feed Protection: Document Technical Content Created by M J MaytumdiditNo ratings yet

- Basics of Electrical EngineeringDocument18 pagesBasics of Electrical EngineeringPRAVEEN YADAWNo ratings yet

- Thermoeconomic Modeling and Analysis of sCO2 Brayton CycleDocument21 pagesThermoeconomic Modeling and Analysis of sCO2 Brayton Cycley_durNo ratings yet

- Transcript 2009Document22 pagesTranscript 2009Bình Minh TôNo ratings yet

- Ib0300133m Mitsubishi Modbus QJ71MB91Document264 pagesIb0300133m Mitsubishi Modbus QJ71MB91adi kurniawanNo ratings yet

- B.tech Chem 6-8 Aff26042010Document33 pagesB.tech Chem 6-8 Aff26042010Adithya KrishnanNo ratings yet

- Electromagnetic Performance Comparison of Halbach Array Configurations in Permanent Magnet Synchronous MachineDocument5 pagesElectromagnetic Performance Comparison of Halbach Array Configurations in Permanent Magnet Synchronous Machinefong jeffNo ratings yet

- Line Distance Protection Rel670 650Document8 pagesLine Distance Protection Rel670 650igorsfaceNo ratings yet

- Disassembly Deskto HP TouchSmart 520 PCDocument12 pagesDisassembly Deskto HP TouchSmart 520 PCJenniferdaniela LutzherreroNo ratings yet

- Aqa Pa02 W QP Jan07Document16 pagesAqa Pa02 W QP Jan07marshalhoqueNo ratings yet

- Chiller Operation ManualDocument14 pagesChiller Operation Manualeburbano12No ratings yet

- Electronic Unit Injector - Remove: C6.6 Industrial EngineDocument12 pagesElectronic Unit Injector - Remove: C6.6 Industrial EngineBassieNo ratings yet

- Solar Based Auto Irrigation System: Guided By: Prof. Rakesh B. VasaniDocument18 pagesSolar Based Auto Irrigation System: Guided By: Prof. Rakesh B. Vasanisandhya AlaneNo ratings yet

- Compresores Piston ATLASDocument3 pagesCompresores Piston ATLASSergi MartínezNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Power System OptimizationDocument23 pagesPower System Optimization08mpe026100% (1)

- Cracking of High Density Polyethylene Pyrolysis Waxes On HZSM 5Document9 pagesCracking of High Density Polyethylene Pyrolysis Waxes On HZSM 5SENG LEE LIMNo ratings yet

- Citystar 3Document627 pagesCitystar 3marco garcia100% (1)

- Fourth Mastery Test in Science and HealthDocument3 pagesFourth Mastery Test in Science and HealthEfra SageNo ratings yet

- Performance Analysis of Solar PV Modules With Dust Accumulation For Indian ScenarioDocument6 pagesPerformance Analysis of Solar PV Modules With Dust Accumulation For Indian ScenarioKomal SinghNo ratings yet

- Historyy of WeldingsDocument81 pagesHistoryy of WeldingsSuyash GatkalNo ratings yet

- Shell Abandonment Presentation IPark Workshop Feb'15Document13 pagesShell Abandonment Presentation IPark Workshop Feb'15CoolProphetNo ratings yet

- Gate 2019 MeDocument5 pagesGate 2019 MeVisakh RadhakrishnanNo ratings yet

- Environmental and Economic Impact Assessment of CDW Disposal PDFDocument9 pagesEnvironmental and Economic Impact Assessment of CDW Disposal PDFjcaldanabNo ratings yet

- 1012 - Turbine Lubricating OilDocument9 pages1012 - Turbine Lubricating OilAnonymous ieWpd823LgNo ratings yet

Qw-482 Suggested Format For Welding Procedure Specification (WPS)

Qw-482 Suggested Format For Welding Procedure Specification (WPS)

Uploaded by

ING HARRINSON FERREBUSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qw-482 Suggested Format For Welding Procedure Specification (WPS)

Qw-482 Suggested Format For Welding Procedure Specification (WPS)

Uploaded by

ING HARRINSON FERREBUSCopyright:

Available Formats

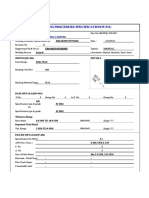

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name FERRER Y PARENTE ASOCIADOS By: Hernan Ferrer

Welding Procedure Specification No. 5A-5A-GTW-001 Date 05-20-2000 Supporting PQR No.(s) 0001

Revision No.__________________________Date_______________________

Welding Process(es) GTAW / SMAW Type(s) MANUAL

(Automatic, Manual, Machine, or Semi-Auto.)

JOINTS (QW-402) Details

Joint Design GROOVE AND FILLET

Backing (Yes) SMAW (No)____GTAW_______

SEE FABRICATION

Backing Material (Type) WELD/BASE METAL DRAWINGS

(Refer to both backing and retainers)

✘ Metal Nonfuding Metal

DETAILS, NO

RETAINERS USED

Nonmetallic Other

Sketches, Production Drawings, Weld Symbols or Written Description should

show the general arrangement of the parts to be welded. Where applicable, the

root spacing and the details of welded groove may be specified

(At the option of the Mfgr., sketches may be attached to illustrate joint design,

weld layers and bead sequence. e.g. for notch toughness procedures, for

multiple process procedures, etc.)

*BASE METALS(QW-403)

P – No. 5A Group No. 1,2 to P – No. 5A Group No. 1,2

OR

Specification type and grade_________________________________________________________________________

To Specification type and grade______________________________________________________________________

OR

Chem. Analysis and Mech. Prop. _____________________________________________________________________

To Chem. Analysis and Mech. Prop. __________________________________________________________________

Thickness Range:

Base Metal: Groove 3/16” – 1.688” Fillet ALL

Pipe Dia. Range: Groove ALL Fillet ALL

Other___NO PASS IN EXCESS OF ½” FOR SMAW

*FILLER METALS (QW-404) GTAW SMAW

Spec. No. (SFA) 5.28 5.5

AWS No. (Class.) ER 90 S B3 E-9018-B3

F – No. 6 4

A – No. 4 4

Size of Filler Metals 1/16”, 3/32”, 1/8” 3/32”, 1/8”, 5/32”

Weld Metal

Thickness Range:

Groove 0.25” MAXIMUM 1.438” MAXIMUM

Fillet ALL ALL

Electrode – Flux (Class.) N/A N/A

Flux Trade Name N/A N/A

Consumable Insert NONE N/A

Other ONLY WITH SOLID FILLER N/A

________________________________________________________________________________________________

QW-482 (Back)

WPS No. 5A-5A-GTW-001 . Rev. 0 .

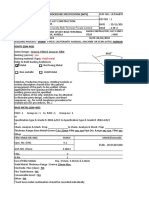

POSITIONS (QW-405) POSTWELD HEAT TREATMENT ( QW-407)

Position(s) of Groove ALL . Temperature Range 1300-1400 °F .

Welding Progression: Up YES Down NO . Time Range 2 HR. MINIMUM .

Position(s) of Fillet ALL .

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temp. Min. 350°F . Gas(es) (Mixture) Flow Rate

Interpass Temp. Max. VARIABLE .

Preheat Maintenance UP TO COMPLETE THE JOINT . Shielding . ARGON . . . . 20-30 CFH .

(Continuos or special heating where applicable should be recorded) Trailing . NONE . . . . .

Backing . NONE . . . . .

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC . Polarity RP/SP .

Amps (Range) SEE BELOW . Volts (Range) SEE BELOW .

(Amps and volts range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a

tabular form similar to that shown below.

Tungsten Electrode Size and Type EWTH-2, 3/32” .

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW N.A. .

(Spray arc, short circuiting arc, etc.)

Electrode Wire feed speed range N.A. .

TECHNIQUE (QW-410)

String or Weave Bead STRING / WEAVED .

Orifice or Gas Cup Size 3/8” –5/8 .

Initial and Interpass Cleaning (Brushing, Grinding, etc.) BRUSHING AND GRINDING .

. .

Method of Back Gouging ARC AIR .

Contact Tube to Work Distance N.A. .

Multiple or Single pass (per side) SINGLE AND MULTIPLE .

Multiple or Single Electrodes SINGLE .

Travel Speed (Range) VARIABLE .

Peening NOT ALLOWED .

Other NONE .

.

.

Filler Metal Current Other

Travel (e.g. Remarks, comments,

Weld Type Amp. Volt Speed Hot wire addition, Technique

Layer(s) Process Class Dia. Polar. Range Range Range Torch Angle. Etc.)

1 GTAW ER-90-S-B3 1/16” DC SP 70-90 15-20

1 GTAW ER-90-S-B3 3/32” DC SP 80-100 15-20

1 GTAW ER-90-S-B3 1/8” DC SP 90-110 15-20

2-N SMAW E-9018-B3 3/32” DC RP 70-90 20-25

2-N SMAW E-9018-B3 1/8” DC RP 90-120 20-25

2-N SMAW E-9018-B3 5/32” DC RP 130-160 20-25

You might also like

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- SD 25TFDocument182 pagesSD 25TFjulianmata100% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps Demoharis saleemNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- ASME Numeric Index1Document12 pagesASME Numeric Index1ING HARRINSON FERREBUSNo ratings yet

- Inter Volume 48Document8 pagesInter Volume 48ING HARRINSON FERREBUSNo ratings yet

- 14nonmandatory AppendicesDocument62 pages14nonmandatory AppendicesING HARRINSON FERREBUSNo ratings yet

- Listado MSSDocument2 pagesListado MSSING HARRINSON FERREBUSNo ratings yet

- ASME B56-8 InterpretationsDocument3 pagesASME B56-8 InterpretationsING HARRINSON FERREBUSNo ratings yet

- ASME B56-6 InterpretationsDocument9 pagesASME B56-6 InterpretationsING HARRINSON FERREBUSNo ratings yet

- ASME B30-11 InterpretationsDocument2 pagesASME B30-11 InterpretationsING HARRINSON FERREBUSNo ratings yet

- Aws D1.1 Part 3 PDFDocument6 pagesAws D1.1 Part 3 PDFING HARRINSON FERREBUSNo ratings yet

- Ferrer Y Parente Mill SteelDocument1 pageFerrer Y Parente Mill SteelING HARRINSON FERREBUSNo ratings yet

- Subject Index: Item No. 21808Document8 pagesSubject Index: Item No. 21808ING HARRINSON FERREBUSNo ratings yet

- 01 EI - Jan12Document36 pages01 EI - Jan12ING HARRINSON FERREBUSNo ratings yet

- Amine SCC PDFDocument2 pagesAmine SCC PDFING HARRINSON FERREBUSNo ratings yet

- 17 Casing Design PDFDocument44 pages17 Casing Design PDFChristian Olascoaga Mori50% (2)

- Sulfuric AcidDocument195 pagesSulfuric AcidDivyamNo ratings yet

- Kokkonda AravindDocument12 pagesKokkonda AravindVB INTERNET AND GROCERY STORENo ratings yet

- Remote Radio Unit (RRU) DC Feed Protection: Document Technical Content Created by M J MaytumDocument26 pagesRemote Radio Unit (RRU) DC Feed Protection: Document Technical Content Created by M J MaytumdiditNo ratings yet

- Basics of Electrical EngineeringDocument18 pagesBasics of Electrical EngineeringPRAVEEN YADAWNo ratings yet

- Thermoeconomic Modeling and Analysis of sCO2 Brayton CycleDocument21 pagesThermoeconomic Modeling and Analysis of sCO2 Brayton Cycley_durNo ratings yet

- Transcript 2009Document22 pagesTranscript 2009Bình Minh TôNo ratings yet

- Ib0300133m Mitsubishi Modbus QJ71MB91Document264 pagesIb0300133m Mitsubishi Modbus QJ71MB91adi kurniawanNo ratings yet

- B.tech Chem 6-8 Aff26042010Document33 pagesB.tech Chem 6-8 Aff26042010Adithya KrishnanNo ratings yet

- Electromagnetic Performance Comparison of Halbach Array Configurations in Permanent Magnet Synchronous MachineDocument5 pagesElectromagnetic Performance Comparison of Halbach Array Configurations in Permanent Magnet Synchronous Machinefong jeffNo ratings yet

- Line Distance Protection Rel670 650Document8 pagesLine Distance Protection Rel670 650igorsfaceNo ratings yet

- Disassembly Deskto HP TouchSmart 520 PCDocument12 pagesDisassembly Deskto HP TouchSmart 520 PCJenniferdaniela LutzherreroNo ratings yet

- Aqa Pa02 W QP Jan07Document16 pagesAqa Pa02 W QP Jan07marshalhoqueNo ratings yet

- Chiller Operation ManualDocument14 pagesChiller Operation Manualeburbano12No ratings yet

- Electronic Unit Injector - Remove: C6.6 Industrial EngineDocument12 pagesElectronic Unit Injector - Remove: C6.6 Industrial EngineBassieNo ratings yet

- Solar Based Auto Irrigation System: Guided By: Prof. Rakesh B. VasaniDocument18 pagesSolar Based Auto Irrigation System: Guided By: Prof. Rakesh B. Vasanisandhya AlaneNo ratings yet

- Compresores Piston ATLASDocument3 pagesCompresores Piston ATLASSergi MartínezNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Power System OptimizationDocument23 pagesPower System Optimization08mpe026100% (1)

- Cracking of High Density Polyethylene Pyrolysis Waxes On HZSM 5Document9 pagesCracking of High Density Polyethylene Pyrolysis Waxes On HZSM 5SENG LEE LIMNo ratings yet

- Citystar 3Document627 pagesCitystar 3marco garcia100% (1)

- Fourth Mastery Test in Science and HealthDocument3 pagesFourth Mastery Test in Science and HealthEfra SageNo ratings yet

- Performance Analysis of Solar PV Modules With Dust Accumulation For Indian ScenarioDocument6 pagesPerformance Analysis of Solar PV Modules With Dust Accumulation For Indian ScenarioKomal SinghNo ratings yet

- Historyy of WeldingsDocument81 pagesHistoryy of WeldingsSuyash GatkalNo ratings yet

- Shell Abandonment Presentation IPark Workshop Feb'15Document13 pagesShell Abandonment Presentation IPark Workshop Feb'15CoolProphetNo ratings yet

- Gate 2019 MeDocument5 pagesGate 2019 MeVisakh RadhakrishnanNo ratings yet

- Environmental and Economic Impact Assessment of CDW Disposal PDFDocument9 pagesEnvironmental and Economic Impact Assessment of CDW Disposal PDFjcaldanabNo ratings yet

- 1012 - Turbine Lubricating OilDocument9 pages1012 - Turbine Lubricating OilAnonymous ieWpd823LgNo ratings yet