Professional Documents

Culture Documents

25KVA Greaves DG Generator

25KVA Greaves DG Generator

Uploaded by

Vikaas JainCopyright:

Available Formats

You might also like

- Mercedes Benz C250 Car Full ManualDocument356 pagesMercedes Benz C250 Car Full ManualSclaffen100% (2)

- Boeing 767 Flight ControlsDocument6 pagesBoeing 767 Flight ControlsVishnu AnilkumarNo ratings yet

- PB CS533eDocument201 pagesPB CS533eFris Ainur100% (1)

- VTA28G6Document3 pagesVTA28G6chanchan100% (1)

- Gpwii - Pii - 100Document2 pagesGpwii - Pii - 100ashokghtNo ratings yet

- Gpwii - Pii - 75SDocument2 pagesGpwii - Pii - 75SashokghtNo ratings yet

- Gpwii - Pii - 62.5SDocument2 pagesGpwii - Pii - 62.5SashokghtNo ratings yet

- Gpwii - Pii - 160FDocument2 pagesGpwii - Pii - 160FashokghtNo ratings yet

- Gpwii - Pii - 82.5SDocument2 pagesGpwii - Pii - 82.5SashokghtNo ratings yet

- Gpwii - Pii - 200SDocument2 pagesGpwii - Pii - 200SashokghtNo ratings yet

- Gpwii - Pii - 40v-IDocument2 pagesGpwii - Pii - 40v-IashokghtNo ratings yet

- Gpwii - Pii - 125SDocument2 pagesGpwii - Pii - 125SashokghtNo ratings yet

- Gpwii - 250SDocument2 pagesGpwii - 250SashokghtNo ratings yet

- 125 kVA Greaves BrochureDocument2 pages125 kVA Greaves Brochurerakesh dalalNo ratings yet

- Gpwii - Pii-500Document2 pagesGpwii - Pii-500ashokghtNo ratings yet

- Diesel Generator Set Specifications Sheet-5 kVADocument2 pagesDiesel Generator Set Specifications Sheet-5 kVALizbeth TrujilloNo ratings yet

- QSK23-G3: Fuel OptimizedDocument3 pagesQSK23-G3: Fuel OptimizedYael Reinoso AriasNo ratings yet

- OE Spec MTU12V1600DS660 3B 50Hz 1 18Document5 pagesOE Spec MTU12V1600DS660 3B 50Hz 1 18Bao Le VietNo ratings yet

- Microsoft Word - 3516B XQ2000 Spec Sheet-Corpolec Rev3Document9 pagesMicrosoft Word - 3516B XQ2000 Spec Sheet-Corpolec Rev3AlbertoNo ratings yet

- 7 5 Kva Portable GeneratorDocument2 pages7 5 Kva Portable GeneratorventerhermanjNo ratings yet

- Specsheet-7 5Document2 pagesSpecsheet-7 5Ivo NkwetaNo ratings yet

- Specsheet-2 5Document2 pagesSpecsheet-2 5Ankur mittalNo ratings yet

- C150D5 - Data Sheet UKDocument2 pagesC150D5 - Data Sheet UKphonggensetNo ratings yet

- Diesel Generator Set C Series: Specification SheetDocument4 pagesDiesel Generator Set C Series: Specification Sheetrobinknit2009No ratings yet

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Document3 pagesQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- Diesel Generator Set Specifications Sheet-5 kVADocument2 pagesDiesel Generator Set Specifications Sheet-5 kVARagz ChNo ratings yet

- Nas 6124 en PDFDocument5 pagesNas 6124 en PDFFrankDeviePaculguenQueridoNo ratings yet

- 1250 1500kvaDocument4 pages1250 1500kvaAngon BhattacharjeeNo ratings yet

- OE Spec MTU12V1600DS730 3D 50Hz 2 14Document5 pagesOE Spec MTU12V1600DS730 3D 50Hz 2 14phuongNo ratings yet

- Power Your Future 4B3.9-G Cummins GeneratorDocument3 pagesPower Your Future 4B3.9-G Cummins GeneratorEman EdlesNo ratings yet

- 4BTAA3.3-G12: EPA Tier 3 CertifiedDocument3 pages4BTAA3.3-G12: EPA Tier 3 CertifiedLawternay Stevaneli BritoNo ratings yet

- OE Spec MTU6R1600DS330 3B 50Hz 2 14Document5 pagesOE Spec MTU6R1600DS330 3B 50Hz 2 14selleriverketNo ratings yet

- Caterpillar RC1000 Containerized Diesel Generator SetDocument4 pagesCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryNo ratings yet

- Ashok Leyland 125kva DG SetDocument5 pagesAshok Leyland 125kva DG SetMuthalagu J (Aravindh)No ratings yet

- 550 kVA/440 KW: AMGC 550Document5 pages550 kVA/440 KW: AMGC 550maherNo ratings yet

- Generator 10 KVADocument13 pagesGenerator 10 KVAhopeseb8No ratings yet

- Planta 45 KW - Cummins Gmp45c6sDocument6 pagesPlanta 45 KW - Cummins Gmp45c6sJorge Velandia Hernandez100% (1)

- QSX15-G9: EPA NSPS CertifiedDocument3 pagesQSX15-G9: EPA NSPS CertifiedMarcos Batista Dos SantosNo ratings yet

- K Series 750-1010 (K38)Document4 pagesK Series 750-1010 (K38)sameer_ponnadaNo ratings yet

- LG60CDocument3 pagesLG60CadatingenieriaNo ratings yet

- XQ Trailer Spec SheetDocument6 pagesXQ Trailer Spec Sheetmohammad hazbehzadNo ratings yet

- Emers 5884 enDocument5 pagesEmers 5884 enDeca2509No ratings yet

- F3514GSI: VHP Series Four Gas EngineDocument2 pagesF3514GSI: VHP Series Four Gas EngineferyNo ratings yet

- KTA50 Land-Based Drilling Power ModuleDocument4 pagesKTA50 Land-Based Drilling Power ModuleMuhammad RozzaqNo ratings yet

- MTU 12V1600 DS660: Diesel Generator SetDocument5 pagesMTU 12V1600 DS660: Diesel Generator Setabdelmoumene djafer beyNo ratings yet

- VHP Series Four Gas Engine: Standard EquipmentDocument2 pagesVHP Series Four Gas Engine: Standard EquipmentferyNo ratings yet

- AC72 Technical Data: AOSIF Cummins SeriesDocument9 pagesAC72 Technical Data: AOSIF Cummins SeriesfasdfsdNo ratings yet

- QSX15-G8: TA Luft CompliantDocument3 pagesQSX15-G8: TA Luft CompliantNguyen CuongNo ratings yet

- Mahindra PowerolDocument2 pagesMahindra Powerolsomen mondalNo ratings yet

- OE Spec MTU10V1600DS560 3D 50Hz 1 18Document5 pagesOE Spec MTU10V1600DS560 3D 50Hz 1 18Bao Le VietNo ratings yet

- VP Power 1500kva Cummins Genset SpecificatoinDocument6 pagesVP Power 1500kva Cummins Genset SpecificatoinCarlosNo ratings yet

- CAT Engine Specifications: 3516B Offshore Generator SetDocument6 pagesCAT Engine Specifications: 3516B Offshore Generator SetKarel GómezNo ratings yet

- LG90KF-LK110KF 2Document4 pagesLG90KF-LK110KF 2Min Min AungNo ratings yet

- Diesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousLwin PhyoNo ratings yet

- Grupos Electronicos Diesel Cat n3306 225ekw PrimeDocument4 pagesGrupos Electronicos Diesel Cat n3306 225ekw PrimejalexivanNo ratings yet

- QSX15 G9Document3 pagesQSX15 G9Gestión del Talento Humano GEMRANo ratings yet

- Technical Details For 62.5 KVA DGDocument3 pagesTechnical Details For 62.5 KVA DGTiwari PradeepNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- LED FLood Light-Specification SheetDocument10 pagesLED FLood Light-Specification SheetVikaas JainNo ratings yet

- Low Resistance Ohmmeter: Ducter D007Document2 pagesLow Resistance Ohmmeter: Ducter D007Vikaas JainNo ratings yet

- Digitally Signed by NADIM Nasir Ghanchi Date: 22.12.2020 12:30:16Document1 pageDigitally Signed by NADIM Nasir Ghanchi Date: 22.12.2020 12:30:16Vikaas JainNo ratings yet

- Miniature Linear Guideway: MSC Stainless Steel SeriesDocument10 pagesMiniature Linear Guideway: MSC Stainless Steel SeriesVikaas JainNo ratings yet

- KSH International-WEB SolutionsDocument8 pagesKSH International-WEB SolutionsVikaas JainNo ratings yet

- SMART Transmitter Power Supply KCD2-STC-Ex1: FunctionDocument6 pagesSMART Transmitter Power Supply KCD2-STC-Ex1: FunctionVikaas JainNo ratings yet

- KPM On Load Tap Changer Analyzer: FunctionalityDocument1 pageKPM On Load Tap Changer Analyzer: FunctionalityVikaas JainNo ratings yet

- Dimensions of MSC-M / MSC-LM: M M M L C H ØD LDocument2 pagesDimensions of MSC-M / MSC-LM: M M M L C H ØD LVikaas JainNo ratings yet

- Assembly Features: Removable Terminals GreenDocument4 pagesAssembly Features: Removable Terminals GreenVikaas JainNo ratings yet

- Ck5 0 Seri Si / Ck5 0 Seri EDocument5 pagesCk5 0 Seri Si / Ck5 0 Seri EVikaas JainNo ratings yet

- Product Data Sheet: SPD VT2 VT2 M TT 320 FM (955 325)Document1 pageProduct Data Sheet: SPD VT2 VT2 M TT 320 FM (955 325)Vikaas JainNo ratings yet

- Biovibez - Motion Sensor - Model - Mp-Ac1-R2: Save Energy and AutomateDocument8 pagesBiovibez - Motion Sensor - Model - Mp-Ac1-R2: Save Energy and AutomateVikaas JainNo ratings yet

- Entrelec Signal ConverterDocument2 pagesEntrelec Signal ConverterVikaas JainNo ratings yet

- Belt Sway Switch:: Emergency Safety Switch: SpecificationsDocument1 pageBelt Sway Switch:: Emergency Safety Switch: SpecificationsVikaas JainNo ratings yet

- Ck5 0 Seri Si / Ck5 0 Seri EDocument5 pagesCk5 0 Seri Si / Ck5 0 Seri EVikaas JainNo ratings yet

- 11 KV Bus DuctDocument1 page11 KV Bus DuctVikaas JainNo ratings yet

- R58E Series Expert Registration Mark Sensors: DatasheetDocument11 pagesR58E Series Expert Registration Mark Sensors: DatasheetVikaas JainNo ratings yet

- Ducati Energia-Capacitors PDFDocument68 pagesDucati Energia-Capacitors PDFVikaas JainNo ratings yet

- Solid Solution To Liquid Level Problems !: MumbaiDocument10 pagesSolid Solution To Liquid Level Problems !: MumbaiVikaas JainNo ratings yet

- Viscosity Compensated Flow Controller, MetallicDocument2 pagesViscosity Compensated Flow Controller, MetallicVikaas JainNo ratings yet

- Der Mat Ol Ogy: Der Ma Rol L ErDocument1 pageDer Mat Ol Ogy: Der Ma Rol L ErVikaas JainNo ratings yet

- D2MPR2 D2MPR3 S2CMR1 S2CTSDocument1 pageD2MPR2 D2MPR3 S2CMR1 S2CTSVikaas JainNo ratings yet

- ABB Surge Arrester POLIM-H..N - Data Sheet 1HC0075856 EN AF PDFDocument9 pagesABB Surge Arrester POLIM-H..N - Data Sheet 1HC0075856 EN AF PDFVikaas JainNo ratings yet

- AO2 Sensor PDFDocument3 pagesAO2 Sensor PDFVikaas JainNo ratings yet

- Indcoil Brochure 2013Document8 pagesIndcoil Brochure 2013Vikaas JainNo ratings yet

- Contactors SchaltbauDocument16 pagesContactors SchaltbauVikaas JainNo ratings yet

- Abb S2C-H6RDocument3 pagesAbb S2C-H6RVikaas JainNo ratings yet

- 14" Ansi 150# Flat Face Flange: Accessory CodeDocument1 page14" Ansi 150# Flat Face Flange: Accessory CodeparathasiNo ratings yet

- 20transit Tech SpecsDocument11 pages20transit Tech SpecsAlex PotemkinNo ratings yet

- Isuzu 4hk1x Sheet HR PDFDocument4 pagesIsuzu 4hk1x Sheet HR PDFanggieNo ratings yet

- Instruction Manual: Thank You For Choosing Black & Decker! To Register Your New ProductDocument7 pagesInstruction Manual: Thank You For Choosing Black & Decker! To Register Your New ProductMarco CreofiniNo ratings yet

- 09 Model Airplane News - SuperunitedkingdomDocument100 pages09 Model Airplane News - SuperunitedkingdomvalivilcuNo ratings yet

- Heavy Equipment ChecklistDocument1 pageHeavy Equipment ChecklistRejan LawrenceNo ratings yet

- 2008 Hyundai Azera QRGDocument9 pages2008 Hyundai Azera QRGIbrahim AL-SORAIHINo ratings yet

- Geling Catalog 2020-2021 New 34.1mDocument176 pagesGeling Catalog 2020-2021 New 34.1mSherwin0% (1)

- GRP Unit DescriptionDocument2 pagesGRP Unit DescriptionTuấn NeoNo ratings yet

- Operating Manual Wheel Alignment System MTH040150A V3 202101Document58 pagesOperating Manual Wheel Alignment System MTH040150A V3 202101Ivan FonsecaNo ratings yet

- Armoured Patrol CarDocument24 pagesArmoured Patrol CarRanjith SriNo ratings yet

- Reference Qty Designation: To Between 1.62 and 1.98 M.Dan (11.95 and 14.60 LBF - FT)Document6 pagesReference Qty Designation: To Between 1.62 and 1.98 M.Dan (11.95 and 14.60 LBF - FT)andreyorjuela jimenezNo ratings yet

- 522 Withdrawable Injection SpearDocument2 pages522 Withdrawable Injection SpearManikantan ThappaliNo ratings yet

- Mahle Master Gasket 1990 & NewerDocument1,128 pagesMahle Master Gasket 1990 & NewerMetis0% (1)

- Honeywell Sensing Latching Digital Hall Effect Sen 1846255Document7 pagesHoneywell Sensing Latching Digital Hall Effect Sen 1846255Jesus Alberto HidalgoNo ratings yet

- Manufacturing of Gear BoxesDocument15 pagesManufacturing of Gear BoxesVarad DateNo ratings yet

- S Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssDocument6 pagesS Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssNadeem MohdNo ratings yet

- Lendell - Engine CatalogueDocument27 pagesLendell - Engine CatalogueRommel Orozco CastellónNo ratings yet

- Generators: College of Engineering and Technology Department of Mechanical EngineeringDocument6 pagesGenerators: College of Engineering and Technology Department of Mechanical EngineeringKeanu EspinaNo ratings yet

- S ChakrabortyDocument3 pagesS ChakrabortyAB Block01No ratings yet

- Teste Freio e Acumulador 938HDocument10 pagesTeste Freio e Acumulador 938HCesar AugustoNo ratings yet

- Consolidated InvoiceDocument4 pagesConsolidated InvoiceNarendra NarshimamoorthyNo ratings yet

- Manual Motor Honda GCV200Document72 pagesManual Motor Honda GCV200soy1masNo ratings yet

- C13, C15, and C18 Engines - Event Codes - Caterpillar Engines TroubleshootingDocument18 pagesC13, C15, and C18 Engines - Event Codes - Caterpillar Engines TroubleshootingmihaivulpeNo ratings yet

- Catalogo Solo CBN Serie 3000Document230 pagesCatalogo Solo CBN Serie 3000LEONARDO DIAZNo ratings yet

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Axle AssemblyDocument12 pages205-02 Rear Drive Axle and Differential - Removal and Installation - Axle AssemblyCARLOS LIMADANo ratings yet

- Specifications Piston Pump (Implement)Document4 pagesSpecifications Piston Pump (Implement)البراق للتوريدات وصيانة المعداتNo ratings yet

25KVA Greaves DG Generator

25KVA Greaves DG Generator

Uploaded by

Vikaas JainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25KVA Greaves DG Generator

25KVA Greaves DG Generator

Uploaded by

Vikaas JainCopyright:

Available Formats

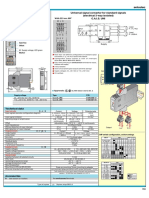

Compressors, Diesel Generator, Airline Piping

Annexure I : Salient Features of Greaves Engine and benefits

Very Low basic engine noise level, Contributes to bettering the statutory MoEF stipulated noise level of 75dB (A)

for the DG set.

Lowest Exhaust emission, Meets the next generation CPCBII norms.

Individual cylinder head design, Savings on maintains, cost and time (45Kva onwards)

Modular Design, High degree of commonality of hardware and components over entire range.

Easy accessibility of all maintenance parts.

Deep skirt crank case design, High degree of rigidity and ruggedness.

Higher reserve margins in the table and cooling circuit gives following benefits –

1. Increased wear life and extended Overhauling Periods.

2. Hassle-free operation in Low and High ambient temperatures from 0 degree C – 50 degree C

Wet liner construction eliminates time consuming and expensive block re-boring during overhauls.

Gear-driven water pump (45 kVA onwards) improves the reliability of the cooling system.

DG Sets – State of the art of Acoustic Enclosures

Smallest foot prints through most compact acoustic enclosures

Lowest vibration – Most suitable for roof top installation

Enclosures Louvers & Radiators are designed to ensure safe operation up to 50 degree C Ambient temperature

Silencers inside upto 200kVA Gensets lowering the height

Enclosures and doors are designed for ease of service, access and maintenance of DG set and Radiators.

CRCA steel material processed with CNC punching/laser cutting to ensure precision.

Surface treatment with 9 tank process to give high retention of surface finish.

Fully automatic, pure polyester and UV resistance powder coating process for outdoor installations and

corrosive environments.

Acoustic insulation with fire retardant foam/ Rockwool material confirming to IS 7888/IS 8183.

Water and lube oil drain outlets located on the outer surface leading to ease of maintenance and cleanliness.

Toughened glass inspection window for clear view of control panel.

Green passivated/stainless steel fasteners and hardware for trouble free operations

Compressors, Diesel Generator, Airline Piping

Annexure II Scope of supply

1. Engine with direct injection, water cooled engine, 3 cylinder, in-line, 4 stroke, rated at 1500 RPM, conforming to

ISO 3046 / BS 5514 has the following specifications: -

Mechanical FIP –

Mechanical governor –

Turbocharger, pulse tuned exhaust manifold, stainless steel exhaust flexible connection –

Radiator Cooled, turbo charged after cooled -

Plate type, lube oil, cooler –

Filters-fuel, lube oil –

Dry type replaceable paper element air cleaner -

Flywheel housing and flywheel to suit single bearing alternator –

Starting motor –

Electric, battery charging alternator –

First fill lube oil and coolant

2. Alternator: Crompton Greaves (optional-Stamford/equivalent) -

brushless alternator –

Self-excited, self-regulated –

Class ‘H’ insulation limited to temperature rise of class H –

Salient pole revolving field –

Single bearing –

Automatic voltage regulator

3. Acoustic enclosure – Engine alternator assembly mounted on AVM with Silencer and S.S exhaust bellow suitably

optimized to meet stringent sound emission standards as laid down by MOEF / CPCB –

Base rail with draw-out type fuel tank is provided with a drain plug, air Vent, inlet and outlet

connections, level indicator, manhole etc. –

Sub-base fuel tank with 13 hours capacity at 75% load. –

12V dry, batteries with connecting leads and terminals –

90% gloss RAL9003 white pure polyester powder coated, base in black colour.

4. Control panel: RAL 9003 White Powder coated control panel manufactured with CRCA sheet provides: -

Water and lube oil drain outlets located on the outer surface- Leading to ease of maintenance

and cleanliness. -

MCCB of suitable rating with short circuit protection –

Controller which displays voltage, current, KW, PF, Frequency, KWh. –

Indicating lamps for “Load On” and “Set Running” –

Current transformers of suitable ratings -

Copper Cables of suitable capacity with incoming and Outgoing terminations –

Control fuses duly wired and ferruled

5. Power cables: Uninvent copper conductor cables between Alternator & Control panel inside the canopy.

6. Literature: Operation Manual General maintenance & installation Guideline

7. Foundation Drawing

8. Parts manual

Annexure III Technical specifications

Compressors, Diesel Generator, Airline Piping

Ready for operation, Stationary, Soundproofed 30 kVA Greaves Power Generator with Standard Panel

Genset Manufacturer Greaves Power

Genset Rating Prime Power

Genset output (kVA / KW ) 25/20

Genset model GPWII-PII-25E

Engine rating or Max Power at Rated RPM in KW (BHP) 25.5(34.2)

Engine Model G-25-II

Engine Type TCAC

No of cylinders / cylinder arrangements 3/ Inline

Compression Ratio 17.5

Rated RPM 1500

Over speed trip 1650

Maximum allowable back pressure .kPa 5.5

Charging alternator Voltage / Current (DC) 12V / 35 Amps

Starter motor rated voltage (DC) 12

Battery voltage (DC)/ Capacity (AH) 12 V , 88AH

Recommended fuel HSD

Fuel tank capacity Ltrs 75 Ltrs

Fuel consumption: 100%/ 75% In Ltrs / hr 6.3/5

Lubricating oil sump capacity ltrs 6.5

Oil change period 500Hrs

Recommended oil 15W40 Greaves Maxtherm API CI4

Cooling system designed for max Amb temp in Deg C at

rated load 50

Radiator System capacity including engine (L) 12.5Ltrs

Alternator Type 4 Pole rotating field

Insulation Class H

One step load acceptance 100% of Rating

Unbalance load capability 25 % of rated current

Dimension ( L x W x H ) in mm 1650x930x1242

Weight in kg 860

You might also like

- Mercedes Benz C250 Car Full ManualDocument356 pagesMercedes Benz C250 Car Full ManualSclaffen100% (2)

- Boeing 767 Flight ControlsDocument6 pagesBoeing 767 Flight ControlsVishnu AnilkumarNo ratings yet

- PB CS533eDocument201 pagesPB CS533eFris Ainur100% (1)

- VTA28G6Document3 pagesVTA28G6chanchan100% (1)

- Gpwii - Pii - 100Document2 pagesGpwii - Pii - 100ashokghtNo ratings yet

- Gpwii - Pii - 75SDocument2 pagesGpwii - Pii - 75SashokghtNo ratings yet

- Gpwii - Pii - 62.5SDocument2 pagesGpwii - Pii - 62.5SashokghtNo ratings yet

- Gpwii - Pii - 160FDocument2 pagesGpwii - Pii - 160FashokghtNo ratings yet

- Gpwii - Pii - 82.5SDocument2 pagesGpwii - Pii - 82.5SashokghtNo ratings yet

- Gpwii - Pii - 200SDocument2 pagesGpwii - Pii - 200SashokghtNo ratings yet

- Gpwii - Pii - 40v-IDocument2 pagesGpwii - Pii - 40v-IashokghtNo ratings yet

- Gpwii - Pii - 125SDocument2 pagesGpwii - Pii - 125SashokghtNo ratings yet

- Gpwii - 250SDocument2 pagesGpwii - 250SashokghtNo ratings yet

- 125 kVA Greaves BrochureDocument2 pages125 kVA Greaves Brochurerakesh dalalNo ratings yet

- Gpwii - Pii-500Document2 pagesGpwii - Pii-500ashokghtNo ratings yet

- Diesel Generator Set Specifications Sheet-5 kVADocument2 pagesDiesel Generator Set Specifications Sheet-5 kVALizbeth TrujilloNo ratings yet

- QSK23-G3: Fuel OptimizedDocument3 pagesQSK23-G3: Fuel OptimizedYael Reinoso AriasNo ratings yet

- OE Spec MTU12V1600DS660 3B 50Hz 1 18Document5 pagesOE Spec MTU12V1600DS660 3B 50Hz 1 18Bao Le VietNo ratings yet

- Microsoft Word - 3516B XQ2000 Spec Sheet-Corpolec Rev3Document9 pagesMicrosoft Word - 3516B XQ2000 Spec Sheet-Corpolec Rev3AlbertoNo ratings yet

- 7 5 Kva Portable GeneratorDocument2 pages7 5 Kva Portable GeneratorventerhermanjNo ratings yet

- Specsheet-7 5Document2 pagesSpecsheet-7 5Ivo NkwetaNo ratings yet

- Specsheet-2 5Document2 pagesSpecsheet-2 5Ankur mittalNo ratings yet

- C150D5 - Data Sheet UKDocument2 pagesC150D5 - Data Sheet UKphonggensetNo ratings yet

- Diesel Generator Set C Series: Specification SheetDocument4 pagesDiesel Generator Set C Series: Specification Sheetrobinknit2009No ratings yet

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Document3 pagesQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- Diesel Generator Set Specifications Sheet-5 kVADocument2 pagesDiesel Generator Set Specifications Sheet-5 kVARagz ChNo ratings yet

- Nas 6124 en PDFDocument5 pagesNas 6124 en PDFFrankDeviePaculguenQueridoNo ratings yet

- 1250 1500kvaDocument4 pages1250 1500kvaAngon BhattacharjeeNo ratings yet

- OE Spec MTU12V1600DS730 3D 50Hz 2 14Document5 pagesOE Spec MTU12V1600DS730 3D 50Hz 2 14phuongNo ratings yet

- Power Your Future 4B3.9-G Cummins GeneratorDocument3 pagesPower Your Future 4B3.9-G Cummins GeneratorEman EdlesNo ratings yet

- 4BTAA3.3-G12: EPA Tier 3 CertifiedDocument3 pages4BTAA3.3-G12: EPA Tier 3 CertifiedLawternay Stevaneli BritoNo ratings yet

- OE Spec MTU6R1600DS330 3B 50Hz 2 14Document5 pagesOE Spec MTU6R1600DS330 3B 50Hz 2 14selleriverketNo ratings yet

- Caterpillar RC1000 Containerized Diesel Generator SetDocument4 pagesCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryNo ratings yet

- Ashok Leyland 125kva DG SetDocument5 pagesAshok Leyland 125kva DG SetMuthalagu J (Aravindh)No ratings yet

- 550 kVA/440 KW: AMGC 550Document5 pages550 kVA/440 KW: AMGC 550maherNo ratings yet

- Generator 10 KVADocument13 pagesGenerator 10 KVAhopeseb8No ratings yet

- Planta 45 KW - Cummins Gmp45c6sDocument6 pagesPlanta 45 KW - Cummins Gmp45c6sJorge Velandia Hernandez100% (1)

- QSX15-G9: EPA NSPS CertifiedDocument3 pagesQSX15-G9: EPA NSPS CertifiedMarcos Batista Dos SantosNo ratings yet

- K Series 750-1010 (K38)Document4 pagesK Series 750-1010 (K38)sameer_ponnadaNo ratings yet

- LG60CDocument3 pagesLG60CadatingenieriaNo ratings yet

- XQ Trailer Spec SheetDocument6 pagesXQ Trailer Spec Sheetmohammad hazbehzadNo ratings yet

- Emers 5884 enDocument5 pagesEmers 5884 enDeca2509No ratings yet

- F3514GSI: VHP Series Four Gas EngineDocument2 pagesF3514GSI: VHP Series Four Gas EngineferyNo ratings yet

- KTA50 Land-Based Drilling Power ModuleDocument4 pagesKTA50 Land-Based Drilling Power ModuleMuhammad RozzaqNo ratings yet

- MTU 12V1600 DS660: Diesel Generator SetDocument5 pagesMTU 12V1600 DS660: Diesel Generator Setabdelmoumene djafer beyNo ratings yet

- VHP Series Four Gas Engine: Standard EquipmentDocument2 pagesVHP Series Four Gas Engine: Standard EquipmentferyNo ratings yet

- AC72 Technical Data: AOSIF Cummins SeriesDocument9 pagesAC72 Technical Data: AOSIF Cummins SeriesfasdfsdNo ratings yet

- QSX15-G8: TA Luft CompliantDocument3 pagesQSX15-G8: TA Luft CompliantNguyen CuongNo ratings yet

- Mahindra PowerolDocument2 pagesMahindra Powerolsomen mondalNo ratings yet

- OE Spec MTU10V1600DS560 3D 50Hz 1 18Document5 pagesOE Spec MTU10V1600DS560 3D 50Hz 1 18Bao Le VietNo ratings yet

- VP Power 1500kva Cummins Genset SpecificatoinDocument6 pagesVP Power 1500kva Cummins Genset SpecificatoinCarlosNo ratings yet

- CAT Engine Specifications: 3516B Offshore Generator SetDocument6 pagesCAT Engine Specifications: 3516B Offshore Generator SetKarel GómezNo ratings yet

- LG90KF-LK110KF 2Document4 pagesLG90KF-LK110KF 2Min Min AungNo ratings yet

- Diesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousLwin PhyoNo ratings yet

- Grupos Electronicos Diesel Cat n3306 225ekw PrimeDocument4 pagesGrupos Electronicos Diesel Cat n3306 225ekw PrimejalexivanNo ratings yet

- QSX15 G9Document3 pagesQSX15 G9Gestión del Talento Humano GEMRANo ratings yet

- Technical Details For 62.5 KVA DGDocument3 pagesTechnical Details For 62.5 KVA DGTiwari PradeepNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- LED FLood Light-Specification SheetDocument10 pagesLED FLood Light-Specification SheetVikaas JainNo ratings yet

- Low Resistance Ohmmeter: Ducter D007Document2 pagesLow Resistance Ohmmeter: Ducter D007Vikaas JainNo ratings yet

- Digitally Signed by NADIM Nasir Ghanchi Date: 22.12.2020 12:30:16Document1 pageDigitally Signed by NADIM Nasir Ghanchi Date: 22.12.2020 12:30:16Vikaas JainNo ratings yet

- Miniature Linear Guideway: MSC Stainless Steel SeriesDocument10 pagesMiniature Linear Guideway: MSC Stainless Steel SeriesVikaas JainNo ratings yet

- KSH International-WEB SolutionsDocument8 pagesKSH International-WEB SolutionsVikaas JainNo ratings yet

- SMART Transmitter Power Supply KCD2-STC-Ex1: FunctionDocument6 pagesSMART Transmitter Power Supply KCD2-STC-Ex1: FunctionVikaas JainNo ratings yet

- KPM On Load Tap Changer Analyzer: FunctionalityDocument1 pageKPM On Load Tap Changer Analyzer: FunctionalityVikaas JainNo ratings yet

- Dimensions of MSC-M / MSC-LM: M M M L C H ØD LDocument2 pagesDimensions of MSC-M / MSC-LM: M M M L C H ØD LVikaas JainNo ratings yet

- Assembly Features: Removable Terminals GreenDocument4 pagesAssembly Features: Removable Terminals GreenVikaas JainNo ratings yet

- Ck5 0 Seri Si / Ck5 0 Seri EDocument5 pagesCk5 0 Seri Si / Ck5 0 Seri EVikaas JainNo ratings yet

- Product Data Sheet: SPD VT2 VT2 M TT 320 FM (955 325)Document1 pageProduct Data Sheet: SPD VT2 VT2 M TT 320 FM (955 325)Vikaas JainNo ratings yet

- Biovibez - Motion Sensor - Model - Mp-Ac1-R2: Save Energy and AutomateDocument8 pagesBiovibez - Motion Sensor - Model - Mp-Ac1-R2: Save Energy and AutomateVikaas JainNo ratings yet

- Entrelec Signal ConverterDocument2 pagesEntrelec Signal ConverterVikaas JainNo ratings yet

- Belt Sway Switch:: Emergency Safety Switch: SpecificationsDocument1 pageBelt Sway Switch:: Emergency Safety Switch: SpecificationsVikaas JainNo ratings yet

- Ck5 0 Seri Si / Ck5 0 Seri EDocument5 pagesCk5 0 Seri Si / Ck5 0 Seri EVikaas JainNo ratings yet

- 11 KV Bus DuctDocument1 page11 KV Bus DuctVikaas JainNo ratings yet

- R58E Series Expert Registration Mark Sensors: DatasheetDocument11 pagesR58E Series Expert Registration Mark Sensors: DatasheetVikaas JainNo ratings yet

- Ducati Energia-Capacitors PDFDocument68 pagesDucati Energia-Capacitors PDFVikaas JainNo ratings yet

- Solid Solution To Liquid Level Problems !: MumbaiDocument10 pagesSolid Solution To Liquid Level Problems !: MumbaiVikaas JainNo ratings yet

- Viscosity Compensated Flow Controller, MetallicDocument2 pagesViscosity Compensated Flow Controller, MetallicVikaas JainNo ratings yet

- Der Mat Ol Ogy: Der Ma Rol L ErDocument1 pageDer Mat Ol Ogy: Der Ma Rol L ErVikaas JainNo ratings yet

- D2MPR2 D2MPR3 S2CMR1 S2CTSDocument1 pageD2MPR2 D2MPR3 S2CMR1 S2CTSVikaas JainNo ratings yet

- ABB Surge Arrester POLIM-H..N - Data Sheet 1HC0075856 EN AF PDFDocument9 pagesABB Surge Arrester POLIM-H..N - Data Sheet 1HC0075856 EN AF PDFVikaas JainNo ratings yet

- AO2 Sensor PDFDocument3 pagesAO2 Sensor PDFVikaas JainNo ratings yet

- Indcoil Brochure 2013Document8 pagesIndcoil Brochure 2013Vikaas JainNo ratings yet

- Contactors SchaltbauDocument16 pagesContactors SchaltbauVikaas JainNo ratings yet

- Abb S2C-H6RDocument3 pagesAbb S2C-H6RVikaas JainNo ratings yet

- 14" Ansi 150# Flat Face Flange: Accessory CodeDocument1 page14" Ansi 150# Flat Face Flange: Accessory CodeparathasiNo ratings yet

- 20transit Tech SpecsDocument11 pages20transit Tech SpecsAlex PotemkinNo ratings yet

- Isuzu 4hk1x Sheet HR PDFDocument4 pagesIsuzu 4hk1x Sheet HR PDFanggieNo ratings yet

- Instruction Manual: Thank You For Choosing Black & Decker! To Register Your New ProductDocument7 pagesInstruction Manual: Thank You For Choosing Black & Decker! To Register Your New ProductMarco CreofiniNo ratings yet

- 09 Model Airplane News - SuperunitedkingdomDocument100 pages09 Model Airplane News - SuperunitedkingdomvalivilcuNo ratings yet

- Heavy Equipment ChecklistDocument1 pageHeavy Equipment ChecklistRejan LawrenceNo ratings yet

- 2008 Hyundai Azera QRGDocument9 pages2008 Hyundai Azera QRGIbrahim AL-SORAIHINo ratings yet

- Geling Catalog 2020-2021 New 34.1mDocument176 pagesGeling Catalog 2020-2021 New 34.1mSherwin0% (1)

- GRP Unit DescriptionDocument2 pagesGRP Unit DescriptionTuấn NeoNo ratings yet

- Operating Manual Wheel Alignment System MTH040150A V3 202101Document58 pagesOperating Manual Wheel Alignment System MTH040150A V3 202101Ivan FonsecaNo ratings yet

- Armoured Patrol CarDocument24 pagesArmoured Patrol CarRanjith SriNo ratings yet

- Reference Qty Designation: To Between 1.62 and 1.98 M.Dan (11.95 and 14.60 LBF - FT)Document6 pagesReference Qty Designation: To Between 1.62 and 1.98 M.Dan (11.95 and 14.60 LBF - FT)andreyorjuela jimenezNo ratings yet

- 522 Withdrawable Injection SpearDocument2 pages522 Withdrawable Injection SpearManikantan ThappaliNo ratings yet

- Mahle Master Gasket 1990 & NewerDocument1,128 pagesMahle Master Gasket 1990 & NewerMetis0% (1)

- Honeywell Sensing Latching Digital Hall Effect Sen 1846255Document7 pagesHoneywell Sensing Latching Digital Hall Effect Sen 1846255Jesus Alberto HidalgoNo ratings yet

- Manufacturing of Gear BoxesDocument15 pagesManufacturing of Gear BoxesVarad DateNo ratings yet

- S Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssDocument6 pagesS Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssNadeem MohdNo ratings yet

- Lendell - Engine CatalogueDocument27 pagesLendell - Engine CatalogueRommel Orozco CastellónNo ratings yet

- Generators: College of Engineering and Technology Department of Mechanical EngineeringDocument6 pagesGenerators: College of Engineering and Technology Department of Mechanical EngineeringKeanu EspinaNo ratings yet

- S ChakrabortyDocument3 pagesS ChakrabortyAB Block01No ratings yet

- Teste Freio e Acumulador 938HDocument10 pagesTeste Freio e Acumulador 938HCesar AugustoNo ratings yet

- Consolidated InvoiceDocument4 pagesConsolidated InvoiceNarendra NarshimamoorthyNo ratings yet

- Manual Motor Honda GCV200Document72 pagesManual Motor Honda GCV200soy1masNo ratings yet

- C13, C15, and C18 Engines - Event Codes - Caterpillar Engines TroubleshootingDocument18 pagesC13, C15, and C18 Engines - Event Codes - Caterpillar Engines TroubleshootingmihaivulpeNo ratings yet

- Catalogo Solo CBN Serie 3000Document230 pagesCatalogo Solo CBN Serie 3000LEONARDO DIAZNo ratings yet

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Axle AssemblyDocument12 pages205-02 Rear Drive Axle and Differential - Removal and Installation - Axle AssemblyCARLOS LIMADANo ratings yet

- Specifications Piston Pump (Implement)Document4 pagesSpecifications Piston Pump (Implement)البراق للتوريدات وصيانة المعداتNo ratings yet