Professional Documents

Culture Documents

TDS - MT 950 - en

TDS - MT 950 - en

Uploaded by

To RaCopyright:

Available Formats

You might also like

- Bag Filter Calculation PDFDocument4 pagesBag Filter Calculation PDFArun Gupta71% (7)

- Norpol GS enDocument2 pagesNorpol GS enMuruga SriNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- Silicone Elastomer SeriesDocument10 pagesSilicone Elastomer SeriesTo RaNo ratings yet

- Silicone Elastomer SeriesDocument10 pagesSilicone Elastomer SeriesTo RaNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Technical Datasheet LITEN FB 75 - EngDocument2 pagesTechnical Datasheet LITEN FB 75 - EngTo RaNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- Tpo 0030 RTP 4920 1620 Uv IsoDocument2 pagesTpo 0030 RTP 4920 1620 Uv IsoVenkata ChadaNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Ultradur: Product InformationDocument3 pagesUltradur: Product InformationirisNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Colpoly 7167 8A TDSDocument2 pagesColpoly 7167 8A TDSKristjan PosavecNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- Starflam PA66 25VDocument2 pagesStarflam PA66 25VjahabarsathickNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Colpoly 736 WAT TDSDocument2 pagesColpoly 736 WAT TDSKristjan PosavecNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Radilon S Hs 105 M NT: Product InformationDocument3 pagesRadilon S Hs 105 M NT: Product InformationOptimuz TsNo ratings yet

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- Styro Lution Tds 200400070620Document3 pagesStyro Lution Tds 200400070620gv_ScribdNo ratings yet

- Desmopan 3059D - en - 00898365 00000542 20011347Document2 pagesDesmopan 3059D - en - 00898365 00000542 20011347sosal salvadosNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- PDS HEX4460p PE80 1Document3 pagesPDS HEX4460p PE80 1art72 talNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Total 1540Document1 pageTotal 1540sercanworkNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Colpoly 7331 LV TDSDocument2 pagesColpoly 7331 LV TDSKristjan PosavecNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Colpoly 7167 TDSDocument2 pagesColpoly 7167 TDSKristjan PosavecNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Atlac 430 - 010389Document2 pagesAtlac 430 - 010389Mounir ZerroukNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Technical Datasheet LITEN FB 75 - EngDocument2 pagesTechnical Datasheet LITEN FB 75 - EngTo RaNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Mosten EN - Web PDFDocument2 pagesMosten EN - Web PDFTo RaNo ratings yet

- A Handbook of CosmeticsDocument134 pagesA Handbook of CosmeticsTo Ra100% (2)

- Industria Chimica Panzeri S.R.L. Cosmetic-CatalogueDocument18 pagesIndustria Chimica Panzeri S.R.L. Cosmetic-CatalogueTo Ra100% (2)

- Galaxy Surfactants - Product Range BrochureDocument15 pagesGalaxy Surfactants - Product Range BrochureTo Ra100% (4)

- SUNJIN Surfactant Catalogue - Fabric SoftenerDocument36 pagesSUNJIN Surfactant Catalogue - Fabric SoftenerTo Ra100% (3)

- Spray Applied Coating For High Temperature ImmersionDocument2 pagesSpray Applied Coating For High Temperature ImmersionimtiazNo ratings yet

- Screening On The Phytochemical Constituents in Luffa Acutangula (L.) Roxb. (Kha We)Document11 pagesScreening On The Phytochemical Constituents in Luffa Acutangula (L.) Roxb. (Kha We)ေအာင္ ေက်ာ္ စြာNo ratings yet

- 28.3 Physica UG Question Paper Pattern of 5 & 6 Sem PDFDocument41 pages28.3 Physica UG Question Paper Pattern of 5 & 6 Sem PDFthomasgunaseelanNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- Exam 23Document4 pagesExam 23raymond baliteNo ratings yet

- Introduction To Polymerase Chain Reaction (PCR)Document33 pagesIntroduction To Polymerase Chain Reaction (PCR)max2711No ratings yet

- Amc CR 650 PDSDocument1 pageAmc CR 650 PDSShooWin Allen JohnNo ratings yet

- Thermal EquilibriumDocument9 pagesThermal EquilibriumHarsh WaliaNo ratings yet

- UTP A 8051 Ti: ClassificationsDocument1 pageUTP A 8051 Ti: ClassificationsGustavo OrozcoNo ratings yet

- Trampa de Vapor Tipo Boya Modelo FTEDocument4 pagesTrampa de Vapor Tipo Boya Modelo FTEMaicol CarrascoNo ratings yet

- SPH3U Grade 11 University Physics Final Exam Study NotesDocument14 pagesSPH3U Grade 11 University Physics Final Exam Study Notessamuthiram771198100% (1)

- Its All About LG 102Document105 pagesIts All About LG 102sossy046No ratings yet

- Cement T3 TheoryDocument6 pagesCement T3 TheoryslchemNo ratings yet

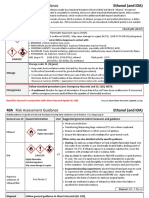

- Ethyl Alcohol: CH CH OH (46.07)Document2 pagesEthyl Alcohol: CH CH OH (46.07)Nina FairuzNo ratings yet

- CompotecLine CrytocecDocument2 pagesCompotecLine CrytocecSeptian FirdausNo ratings yet

- Lab Report CG FIDDocument10 pagesLab Report CG FIDkhadijahhannah2707No ratings yet

- Master FormulaDocument3 pagesMaster FormulaChristianNo ratings yet

- Phosphors For LED-based Solid-State Lighting: by Anant A. SetlurDocument5 pagesPhosphors For LED-based Solid-State Lighting: by Anant A. SetlurArun AchalamNo ratings yet

- KZ2320Document1 pageKZ2320Arvind NagarajanNo ratings yet

- Mechanical Design DP2Document6 pagesMechanical Design DP2Paen ZulkifliNo ratings yet

- Jee Main Part Test - 4 Solutions Part - I Physics: Iitian'S TapasyaDocument17 pagesJee Main Part Test - 4 Solutions Part - I Physics: Iitian'S TapasyaAKASH GOYALNo ratings yet

- MATERIAL SPECIFICATION Electrodo Seleccion PDFDocument1 pageMATERIAL SPECIFICATION Electrodo Seleccion PDFCarlos Africano CastilloNo ratings yet

- Review of Energy Dispersion Relations in Solids: ReferencesDocument9 pagesReview of Energy Dispersion Relations in Solids: Referencespopeye313No ratings yet

- First Law of ThermodynamicsDocument21 pagesFirst Law of ThermodynamicsMariam50% (2)

- United States Patent (19) : Related U.S. Application DataDocument17 pagesUnited States Patent (19) : Related U.S. Application DataTARIK VNo ratings yet

- PPT - RadiationDocument40 pagesPPT - Radiationarik chattopadhyayNo ratings yet

- Chemical Reactions and Chemical EquationsDocument18 pagesChemical Reactions and Chemical EquationsproodootNo ratings yet

- Chlorinated ParaffinsDocument1 pageChlorinated Paraffinsdow2008No ratings yet

- Density Meters SH - VariDens - Data-Sheet - ENG - 0523Document2 pagesDensity Meters SH - VariDens - Data-Sheet - ENG - 0523emusimaNo ratings yet

TDS - MT 950 - en

TDS - MT 950 - en

Uploaded by

To RaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS - MT 950 - en

TDS - MT 950 - en

Uploaded by

To RaCopyright:

Available Formats

PP MOSTEN® MT 950

TECHNICAL DATASHEET

RANDOM COPOLYMER FOR INJECTION MOULDING MFR (230/2,16): 50 g/10 min

Mosten MT 950 is a polypropylene produced by Unipetrol RPA using INNOVENE™ PP gas-phase technology.

Characteristics

• antistatic agent

• phthalates free

International designation

ISO 19069-PP-R,,MTZ,10-05-400

Application

• thin-walled transparent products

• household articles

• food packages

Material properties (typical values, do not represent a specification of given grade)

Parameter Test Method Unit Value

RHEOLOGICAL PROPERTIES

Melt Mass Flow Rate (230 °C/2,16 kg) ISO 1133-1 g/10 min 50

Moulding Shrinkage Parallel 2,16

ISO 294-3,4 %

Moulding Shrinkage Normal 2,25

MECHANICKÉ VLASTNOSTI

Flexural Modulus ISO 178 MPa 1050

Tensile Modulus MPa 1000

Yield Stress MPa 27

ISO 527-1,2

Yield Strain % 12

Elongation at Break % 350

23 °C 5

Charpy Notched Impact Strength at ISO 179-1 kJ/m2

-20 °C 1,5

THERMAL PROPERTIES

Melting Temperature (DSC) ISO 11357-1, 3 °C 135 - 140

Vicat Softening Temperature (VST) ISO 306 °C 130

HDT (1,8 MPa) ISO 75-1,2 °C 48

OTHER PROPERTIES

Shore D Hardness ISO 868 - 60

Haze Internal Method % 10

Processing Conditions

Parameter Recommended Value Unit

Melt Temperature 200 - 280 °C

Mould Temperature 20 - 60 °C

Hold Pressure (60 - 80) % of injection pressure %

Screw Length (15 - 25) d *

-

*

Screw Diameter

PP MOSTEN®

TECHNICAL DATASHEET

Appearance properties

PP Mosten is delivered in the form of natural stabilized pellets. Typical pellet length is (2 - 6) mm, typical bulk density of PP pellets

is (450 - 600) kg/m3.

Thermal properties

PP Mosten exhibits good thermal-isolation properties. With decreasing temperature, the toughness of the material decreases and

below -20 °C, the materials becomes substantially brittle. In the area of low temperatures, it is more suitable to use copolymers,

which have generally their glass transition temperature Tg shifted towards lower temperatures compared to homopolymers. In

the area of high temperatures, PP Mosten can permanently be used up to 100 °C, grades with heat stabilization (LTHS) can be

used up to 105 °C. The level of temperature stability of all PP Mosten grades is such that during common processing method, no

material degradation occurs.

Physical-chemical properties

PP Mosten exhibits high chemical resistance at both normal and raised temperatures, due to its non-polar character. Within

a broad range of temperatures and concentrations it resists to majority of acids, bases and salt solutions. It dissolves only in

some solvents at raised temperature (e.g. in aromatic and halogenated hydrocarbons); furthermore, it doesn’t resist to strongly

oxidizing agents (e.g. nitric acid, oleum, halogens). PP Mosten has practically no hygroscopicity, so it can be used in environments

with variable relative humidity, without any risk of dimensional changes or changes of mechanical properties of the products.

During processing, problems may be caused by moisture condensation during transfer of the material from a cooler to a warmer

environment. At storage temperatures below 20 °C it is recommended to condition the material about 24 hours prior to processing

in the production hall.

Hygienic approval

PP Mosten meets the requirements of the following regulations (as amended):

• Decree of the Ministry of health No. 38/2001 • Commission Regulation (EU) No. 10/2011;

of the Journal of Laws;

• Regulation of EP and the Council (ES) No.

• Regulation of the European Parliament 1907/2006 (REACH) – for production of the PP

and the Council No. 1935/2004; Mosten grade, no phthalates have been used.

Fire & Safety Characteristics

PP Mosten is not classified as a dangerous substance in accordance with the Regulation (EC) 1272/2008 (CLP), nor does it satisfy

any of the other conditions set out in Article 31 of the Regulation (EC) 1907/2006 (REACH). Therefore, the producer is not obliged

to provide a Material Safety Datasheet. Necessary information according to Article 32 of the Regulation (EC) 1907/2006 (REACH)

and further details are provided in “Announcement”, available on www.unipetrolrpa.cz or upon request.

Packaging, storage, transportation and delivery

PP Mosten is delivered in PE-LD (>PE-LD<) bags, mass 25 kg. 55 pieces of these bags are deposited on one pallet, fixed by a

shrinkable PE-LD (>PE-LD<) film, protecting the product from damage and extending its lifetime. The pallets are intended for

stocking into two, exceptionally into three layers. PP Mosten can be alternatively delivered bulk loaded in car tanks. Alternative

packaging or transportation is possible based on agreement with the customer.

PP Mosten is stored in dry, ventilated, roofed storing facility, the premises of which are protected against direct sunlight.

Recommended range of storage temperatures is -20 °C to +50 °C. The product distance from any source of heat shall be at least

1 m. The recommended storage time for PP Mosten in closed (sealed) bags at defined storage conditions is one year. At longer

storage time, it is recommended to check the material properties prior to processing.

Packages

The packages used by producer for packaging of PP Mosten grades are designed and manufactured in compliance with technical

regulations for weight and volume of the product. Material of the packages does not contain any classified hazardous substances.

The total amount of heavy metals (Pb, Cd, Hg and CrVI) does not exceed the limiting value of 100 ppm. Recommended methods

of waste utilization are material utilization, energy utilization.

Instructions for waste disposal from PE processing

Products and non-contaminated waste during PP Mosten processing can be recycled and further processed into products.

Material designation >PE< is used in compliance with ISO 11469. Material designation on products enables material identification

during collecting, classification, utilization or disposal of consumer waste. PP Mosten does not contain any lead, cadmium,

mercury or hexavalent chromium, i.e. total amount of these heavy metals does not exceed 100 ppm.

The PE waste is classified by the waste producer in accordance with the valid legal regulations.

Recommended methods of waste utilization are material utilization and energy utilization.

You might also like

- Bag Filter Calculation PDFDocument4 pagesBag Filter Calculation PDFArun Gupta71% (7)

- Norpol GS enDocument2 pagesNorpol GS enMuruga SriNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- Silicone Elastomer SeriesDocument10 pagesSilicone Elastomer SeriesTo RaNo ratings yet

- Silicone Elastomer SeriesDocument10 pagesSilicone Elastomer SeriesTo RaNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Technical Datasheet LITEN FB 75 - EngDocument2 pagesTechnical Datasheet LITEN FB 75 - EngTo RaNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- Tpo 0030 RTP 4920 1620 Uv IsoDocument2 pagesTpo 0030 RTP 4920 1620 Uv IsoVenkata ChadaNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Ultradur: Product InformationDocument3 pagesUltradur: Product InformationirisNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Colpoly 7167 8A TDSDocument2 pagesColpoly 7167 8A TDSKristjan PosavecNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- Starflam PA66 25VDocument2 pagesStarflam PA66 25VjahabarsathickNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Colpoly 736 WAT TDSDocument2 pagesColpoly 736 WAT TDSKristjan PosavecNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Radilon S Hs 105 M NT: Product InformationDocument3 pagesRadilon S Hs 105 M NT: Product InformationOptimuz TsNo ratings yet

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- Styro Lution Tds 200400070620Document3 pagesStyro Lution Tds 200400070620gv_ScribdNo ratings yet

- Desmopan 3059D - en - 00898365 00000542 20011347Document2 pagesDesmopan 3059D - en - 00898365 00000542 20011347sosal salvadosNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- PDS HEX4460p PE80 1Document3 pagesPDS HEX4460p PE80 1art72 talNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Total 1540Document1 pageTotal 1540sercanworkNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Colpoly 7331 LV TDSDocument2 pagesColpoly 7331 LV TDSKristjan PosavecNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Colpoly 7167 TDSDocument2 pagesColpoly 7167 TDSKristjan PosavecNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Atlac 430 - 010389Document2 pagesAtlac 430 - 010389Mounir ZerroukNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Technical Datasheet LITEN FB 75 - EngDocument2 pagesTechnical Datasheet LITEN FB 75 - EngTo RaNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Mosten EN - Web PDFDocument2 pagesMosten EN - Web PDFTo RaNo ratings yet

- A Handbook of CosmeticsDocument134 pagesA Handbook of CosmeticsTo Ra100% (2)

- Industria Chimica Panzeri S.R.L. Cosmetic-CatalogueDocument18 pagesIndustria Chimica Panzeri S.R.L. Cosmetic-CatalogueTo Ra100% (2)

- Galaxy Surfactants - Product Range BrochureDocument15 pagesGalaxy Surfactants - Product Range BrochureTo Ra100% (4)

- SUNJIN Surfactant Catalogue - Fabric SoftenerDocument36 pagesSUNJIN Surfactant Catalogue - Fabric SoftenerTo Ra100% (3)

- Spray Applied Coating For High Temperature ImmersionDocument2 pagesSpray Applied Coating For High Temperature ImmersionimtiazNo ratings yet

- Screening On The Phytochemical Constituents in Luffa Acutangula (L.) Roxb. (Kha We)Document11 pagesScreening On The Phytochemical Constituents in Luffa Acutangula (L.) Roxb. (Kha We)ေအာင္ ေက်ာ္ စြာNo ratings yet

- 28.3 Physica UG Question Paper Pattern of 5 & 6 Sem PDFDocument41 pages28.3 Physica UG Question Paper Pattern of 5 & 6 Sem PDFthomasgunaseelanNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- Exam 23Document4 pagesExam 23raymond baliteNo ratings yet

- Introduction To Polymerase Chain Reaction (PCR)Document33 pagesIntroduction To Polymerase Chain Reaction (PCR)max2711No ratings yet

- Amc CR 650 PDSDocument1 pageAmc CR 650 PDSShooWin Allen JohnNo ratings yet

- Thermal EquilibriumDocument9 pagesThermal EquilibriumHarsh WaliaNo ratings yet

- UTP A 8051 Ti: ClassificationsDocument1 pageUTP A 8051 Ti: ClassificationsGustavo OrozcoNo ratings yet

- Trampa de Vapor Tipo Boya Modelo FTEDocument4 pagesTrampa de Vapor Tipo Boya Modelo FTEMaicol CarrascoNo ratings yet

- SPH3U Grade 11 University Physics Final Exam Study NotesDocument14 pagesSPH3U Grade 11 University Physics Final Exam Study Notessamuthiram771198100% (1)

- Its All About LG 102Document105 pagesIts All About LG 102sossy046No ratings yet

- Cement T3 TheoryDocument6 pagesCement T3 TheoryslchemNo ratings yet

- Ethyl Alcohol: CH CH OH (46.07)Document2 pagesEthyl Alcohol: CH CH OH (46.07)Nina FairuzNo ratings yet

- CompotecLine CrytocecDocument2 pagesCompotecLine CrytocecSeptian FirdausNo ratings yet

- Lab Report CG FIDDocument10 pagesLab Report CG FIDkhadijahhannah2707No ratings yet

- Master FormulaDocument3 pagesMaster FormulaChristianNo ratings yet

- Phosphors For LED-based Solid-State Lighting: by Anant A. SetlurDocument5 pagesPhosphors For LED-based Solid-State Lighting: by Anant A. SetlurArun AchalamNo ratings yet

- KZ2320Document1 pageKZ2320Arvind NagarajanNo ratings yet

- Mechanical Design DP2Document6 pagesMechanical Design DP2Paen ZulkifliNo ratings yet

- Jee Main Part Test - 4 Solutions Part - I Physics: Iitian'S TapasyaDocument17 pagesJee Main Part Test - 4 Solutions Part - I Physics: Iitian'S TapasyaAKASH GOYALNo ratings yet

- MATERIAL SPECIFICATION Electrodo Seleccion PDFDocument1 pageMATERIAL SPECIFICATION Electrodo Seleccion PDFCarlos Africano CastilloNo ratings yet

- Review of Energy Dispersion Relations in Solids: ReferencesDocument9 pagesReview of Energy Dispersion Relations in Solids: Referencespopeye313No ratings yet

- First Law of ThermodynamicsDocument21 pagesFirst Law of ThermodynamicsMariam50% (2)

- United States Patent (19) : Related U.S. Application DataDocument17 pagesUnited States Patent (19) : Related U.S. Application DataTARIK VNo ratings yet

- PPT - RadiationDocument40 pagesPPT - Radiationarik chattopadhyayNo ratings yet

- Chemical Reactions and Chemical EquationsDocument18 pagesChemical Reactions and Chemical EquationsproodootNo ratings yet

- Chlorinated ParaffinsDocument1 pageChlorinated Paraffinsdow2008No ratings yet

- Density Meters SH - VariDens - Data-Sheet - ENG - 0523Document2 pagesDensity Meters SH - VariDens - Data-Sheet - ENG - 0523emusimaNo ratings yet