Professional Documents

Culture Documents

Valvulas Cedaspe PDF

Valvulas Cedaspe PDF

Uploaded by

Victor LeónOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvulas Cedaspe PDF

Valvulas Cedaspe PDF

Uploaded by

Victor LeónCopyright:

Available Formats

THROTTLE VALVES FOR RELAYS AND RADIATORS

Series 2009

1General Features

1.1Characteristics

The butterfly valves, metal to metal sealing withy thin blade(or full tightening type, with o-ring blade), are

used on power transformer with the scope to allow disconnection of a component of the circuit (ie

buchholz relay or radiator) without having to lower the oil below the level of the component itself.

This kind of valve are preferred to the conventional gate valves for their compact overall dimension in the

direction of the oil flow.

1.2Field of Use

The butterfly valves (standard execution) may be used with the following characteristic values:

• Fluid: mineral oil

• operating pressure max 10 bar

• working temperature from 20°C to + 110°C

2Construction Features, Finish and Accessories

2.1Construction Features

Butterfly valves are constructed as follows (please refer to drawings):

• Body made in forged mild steel

• Spindle made in steel

• Drive and gland made in brass

• Open/close position indicated by a n aluminium plate.

• S/steel screws

• Throttle made in carbon steel (thin blade) or made in brass (o-ring blade)

• O/Rings made in oil resistant rubber

2.2Finish

Body of wafer type is zinc plated first and after is protected by one coat of epoxy primer and one coat of

polyurethane paint (total thickness 80 µm), final colour RAL 7030; in all types screws and pins are in

stainless steel; brass parts and aluminium parts are self colour.

In any case the device is suitable for outdoor installation in tropical climate and with normal industrial

pollution.

Body of welding neck type is self colour without any coating or painting

2.3Accessories

The valve is supplied with one (or two) O/Ring flange gasket

2.4Special executions

Special execution are available for very low temperatures or very corrosive ambient. Please contact our

technical department.

File : 24-BUTTERFLY VALVES.doc rev. 04 dtd 15/09/2008 UNCONTROLLED COPY Page 1 di 4

3Operating features

3.1Tightness of spindle

The tightness to oil leakage from the spindle on the butterfly valve, is guaranteed by a set of o/rings on

the spindle and on the gland obtaining an excellent tightness and at the same time allowing an easy

replacement of the gasket

No leakage is tolerated from the spindle in any case.

3.2Tightness of butterfly

3.2.1Metal to metal sealing (thin blade throttle)

The oil tightness of the butterfly is obtained by contact metal to metal, thus assuring a constant

performance even after a long use .

Leakage at the butterfly is checked during assembly, testing with oil at 20° C, 1 bar and viscosity of

30,5 cSt.

Following values of max admitted leakage:

Nominal diameter of valve in mm ≤ 100 100 < > 175 ≥ 175

Admitted leakage in dm /h measured in 1 hour ≤ 0,5

3

≤ 1,0 ≤ 2,0

3.2.2Full tightening sealing (TW80 with o-ring blade)

The oil tightness of the butterfly is obtained by contact of an o/ring (mounted on the throttle) and the

metal body, thus assuring full sealing between throttle and body.

No leakage is present between throttle and body in closed position.

3.3Operating Torque

The operating torque measured by dynamometric spanner are the following :

Nominal diameter of valve in mm ≤ 100 100 < > 150 ≥ 150

Operating torque in Nm. ≤ 10 ≤ 30 ≤ 30

Closing torque in Nm. ≤ 70 ≤ 100 ≤ 150

Opening torque in Nm. ≤ 40 ≤ 50 ≤ 50

Operating torque: Torque necessary to turn the shaft from the open to the closed position;

Closing torque: Torque necessary to obtain the complete closure of the valve;

Opening torque: Torque necessary to open the valve, after complete closure.

File : 24-BUTTERFLY VALVES.doc rev. 04 dtd 15/09/2008 UNCONTROLLED COPY Page 2 di 4

4Admitted operating conditions

4.1Standard execution (N) – Nitrile rubber gaskets

• Ambient conditions:

◊ Ambient temperature: -20°C to +50°C

◊ Relative humidity: 95% to 20°C - 80% to 40°C - 50% to 50°C

• Insulating liquid and it's temperature:

◊ Mineral oil: -20°C to +110°C

◊ Silicone oil: -20°C to +110°C

4.2Execution H – H-NBR rubber gaskets

• Ambient conditions:

◊ Ambient temperature: -40°C to +50°C

◊ Relative humidity: 95% to 20°C - 80% to 40°C - 50% to 50°C

• Insulating liquid and it's temperature:

◊ Mineral oil: -40°C to +140°C

◊ Silicone oil: not admitted

4.3Execution V – Fluor-rubber gaskets (Viton V)

• Ambient conditions:

◊ Ambient temperature: -15°C to +50°C

◊ Relative humidity: 95% to 20°C - 80% to 40°C - 50% to 50°C

• Insulating liquid and it's temperature:

◊ Mineral oil: -15°C to +160°C

◊ Silicone oil: -15°C to +160°C

5Mounting, Adjustment and Maintenance

5.1Mounting

The throttle valve has to be mounted on pipe as shown on reference drawings or at page 5.86

Valve has to be mounted using screws or rods, washers and nuts and putting the o/ring on the

groove for flange tightening

5.2Operating instructions

The design of the operating system is common to all valves; to open and close the valve operate as

follows (please refer to drawings):

• The visible symbol or inscription on plate (10) indicates the valve position;

• To close the valve first remove the seal or padlock (if present),

• With the appropriate spanner turn the drive (2) clockwise 90° to close the valve; counter clockwise

90°

to open the valve

• The visible part of plate (10) indicates the new valve position;

5.3Maintenance

The Throttle valves do not need periodic maintenance; however it is advisable to check regularly the

external tightening of valve

File : 24-BUTTERFLY VALVES.doc rev. 04 dtd 15/09/2008 UNCONTROLLED COPY Page 3 di 4

6Range of types and reference drawings

The butterfly valves have standard execution flanges according to UNI PN10 and PN6; flanges according

to other standards can be supplied as special execution.

Nominal diameters (DN) are 25;50;80;100;125;150;200;250;300

Below detailed list of available types

6.1Series SW for radiators– metal to metal sealing (square flange – thin blade)

• Nominal diameter: 80 mm

• Execution

- A1 Welding neck

- B1 Wafer type for mounting between two flanges

• Reference drawing : page 5.82

• Mounting sketch

- A1 Welding neck : page 5.86 fig. A or B

- B1 Wafer type for mounting between two flanges : page 5.86 fig. C or D

6.2Series TW for radiators – full tightening valve (square flange – o/ring blade)

• Nominal diameter: 80 mm

- Execution wafer type for mounting between two flanges

• Reference drawing : page 5.81

- Mounting sketch: page 5.86 fig. C or D

6.3Series DN – round flange

• Nominal diameter: 25; 50; 80 mm

• Execution wafer type for mounting between two flanges

- PN6 max operating pressure 6 bar bolt circle diameter acc to UNI2276-67

- PN10 max operating pressure 10 bar bolt circle diameter acc to UNI2277-67

• Reference drawing : page 5.84

• Note : this kind of valves are equipped with HNBR gaskets

6.4Series JU – large round flange

• Nominal diameter: 100;125;150;200;250;300 mm

• Execution wafer type for mounting between two flanges

- PN10 max operating pressure 10 bar bolt circle diameter acc to UNI2277-67

• Reference drawing : page 5.85

7Order Specifications

When ordering it is necessary to indicate

• Series (type)

• Size

• Operating conditions (if not indicated, we will consider standard N)

• Special requirements

Example :

To order nr. 1 Throttle valve type DN50 PN6 standard execution please indicate the following:

Nr 1 Throttle valve DN50 PN6

File : 24-BUTTERFLY VALVES.doc rev. 04 dtd 15/09/2008 UNCONTROLLED COPY Page 4 di 4

You might also like

- Reinforced Concrete Design Solution Manual 7th Edition PDFDocument5 pagesReinforced Concrete Design Solution Manual 7th Edition PDFEdmond Orena BautistaNo ratings yet

- Valvula Lo TorcDocument16 pagesValvula Lo TorcBelen FernandezNo ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Architectural Evaluation Checklist (For Building Permit)Document1 pageArchitectural Evaluation Checklist (For Building Permit)Gabriel C. ObiasNo ratings yet

- Cedaspe - Dn-Full-Catalogue-Valvulas MariposaDocument7 pagesCedaspe - Dn-Full-Catalogue-Valvulas MariposaRenato Almache FloresNo ratings yet

- Cedaspe - Dn-Full-Catalogue-Valvulas Mariposa CuadradasDocument8 pagesCedaspe - Dn-Full-Catalogue-Valvulas Mariposa CuadradasRenato Almache FloresNo ratings yet

- Butterfly Valves Series U: Cat: 16UCATR08-E Rev: 08 - 08/2009Document22 pagesButterfly Valves Series U: Cat: 16UCATR08-E Rev: 08 - 08/2009starlaysNo ratings yet

- Inside Sales For Valves Part 3Document6 pagesInside Sales For Valves Part 3niket honnalliNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Schrader VentiliDocument8 pagesSchrader VentiliSLANO77No ratings yet

- DCV Spirax PDFDocument2 pagesDCV Spirax PDFVaitheeswaran PalaniNo ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- PressureDocument84 pagesPressureHangloque GabanoNo ratings yet

- KDC InstallationDocument2 pagesKDC InstallationJIANG LUNo ratings yet

- Buchholz RelayDocument18 pagesBuchholz RelaysvismaelNo ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- BFV STD - SpecdamperDocument39 pagesBFV STD - Specdamperkselvan_1No ratings yet

- Butterfly Valve ConcentricDocument6 pagesButterfly Valve ConcentricpramodtryNo ratings yet

- Valve0114 PDFDocument14 pagesValve0114 PDFbinhjukiNo ratings yet

- VALVULA DE SOLENOIDE HS7 BulletinDocument4 pagesVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNo ratings yet

- Model Number Structure: General-Purpose Limit SwitchDocument9 pagesModel Number Structure: General-Purpose Limit SwitchHung LeNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- American Block Swivels Model A-200Document20 pagesAmerican Block Swivels Model A-200aldino020203100% (2)

- Kent IntrolDocument15 pagesKent IntrolVladimir VuletinNo ratings yet

- SV97Document2 pagesSV97nclogesh_1981No ratings yet

- Cryogenic Stainless Steel Globe Valve DN6 DN50Document2 pagesCryogenic Stainless Steel Globe Valve DN6 DN50Anonymous rRGTKl6z4No ratings yet

- Rele A Gas BuchholtsDocument18 pagesRele A Gas BuchholtsMarco GiraldoNo ratings yet

- Flowcon ABM InstructionDocument4 pagesFlowcon ABM InstructionJeff Anderson CollinsNo ratings yet

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzNo ratings yet

- Alco ComponentDocument76 pagesAlco Componenttamolisandip1No ratings yet

- Valves SpecificationDocument13 pagesValves Specificationkselvan_1No ratings yet

- Rotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceDocument36 pagesRotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceSaurav DasNo ratings yet

- Sec1.2 Iso LF FlangesDocument17 pagesSec1.2 Iso LF FlangesMauricio MelloNo ratings yet

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- Cedaspe Gas AnalyserDocument20 pagesCedaspe Gas AnalyserokyNo ratings yet

- AI236986444669en 001203Document17 pagesAI236986444669en 001203Gojek OkNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Butterfly Valve TorqueDocument8 pagesButterfly Valve TorqueShyam KrishnanNo ratings yet

- Oventrop DRVDocument15 pagesOventrop DRVblindjaxxNo ratings yet

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDocument5 pagesEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Category Comments Surface Finish: H Z C C H Z 15°Document10 pagesCategory Comments Surface Finish: H Z C C H Z 15°Mikel1020No ratings yet

- Heavy Duty Actuator - BrochureDocument16 pagesHeavy Duty Actuator - BrochureRedzaNo ratings yet

- Pressure Relief Valves Standard Range: Safety DevicesDocument2 pagesPressure Relief Valves Standard Range: Safety DevicesPaweł HejmowskiNo ratings yet

- TFP1511 09 2015Document8 pagesTFP1511 09 2015Enrique MurgiaNo ratings yet

- ANSI Version: T 8091-1 EN Type 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow ValveDocument10 pagesANSI Version: T 8091-1 EN Type 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow ValveagrovadoNo ratings yet

- VALVULAS - Series2200, NORRISEALDocument8 pagesVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNo ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- Model BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionDocument8 pagesModel BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionMERCURE GARINDOLPGNo ratings yet

- Butterfly Valve-Concentric DesignDocument6 pagesButterfly Valve-Concentric Designbharadwaj037No ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- Allweiler SN SeriesDocument12 pagesAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNo ratings yet

- ECF-SSF Actuator Catalogue DTD 08 11Document20 pagesECF-SSF Actuator Catalogue DTD 08 11manmohansingh1999No ratings yet

- PRV Catlogue-Samson (09!06!09)Document6 pagesPRV Catlogue-Samson (09!06!09)pkrishna984No ratings yet

- Loctite 243™: Technical Data SheetDocument4 pagesLoctite 243™: Technical Data SheetRadu_ISNo ratings yet

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocument20 pagesLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Name - Code - and Works Across Skills of Trade Divisions 英Document9 pagesName - Code - and Works Across Skills of Trade Divisions 英chi hin choyNo ratings yet

- Strain Guages ManualDocument48 pagesStrain Guages Manualaishwarya badkulNo ratings yet

- Conveyor Chain ManualDocument172 pagesConveyor Chain ManualRoni SaputraNo ratings yet

- High Efficiency High AmbientGeneral Sales BrochureDocument30 pagesHigh Efficiency High AmbientGeneral Sales BrochureJosue Alvarez GomezNo ratings yet

- Design ProblemsDocument50 pagesDesign ProblemsAngel Mae OndovillaNo ratings yet

- B1 Beam DesignDocument7 pagesB1 Beam DesignakhilNo ratings yet

- DX Split Unit - YorkDocument200 pagesDX Split Unit - YorkFaiyaz Bin Mazid AhmedNo ratings yet

- Catalogo de Regillas D Eretorno Titus de AluminioDocument46 pagesCatalogo de Regillas D Eretorno Titus de AluminiojoravicaNo ratings yet

- Cathodic Disbonding of Pipeline Coatings: Standard Test Methods ForDocument9 pagesCathodic Disbonding of Pipeline Coatings: Standard Test Methods FormarciobispoalmeidaNo ratings yet

- Sikadur 30Document3 pagesSikadur 30Hakiki SaputraNo ratings yet

- KT GB 2012 2013 KLDocument305 pagesKT GB 2012 2013 KLhey_hopNo ratings yet

- Assignmentbasedquestions II 1 PDFDocument2 pagesAssignmentbasedquestions II 1 PDFSathish NayakaNo ratings yet

- CFB Boiler Erection Persentation Rev-2Document33 pagesCFB Boiler Erection Persentation Rev-2juarsa r100% (2)

- PCCL Cement CourseDocument3 pagesPCCL Cement CourseAmr A. NaderNo ratings yet

- E DBL 008 Ol SteelceramicDocument4 pagesE DBL 008 Ol SteelceramicCostas AggelidisNo ratings yet

- A Step by Step Construction Guide How To Build A Home 1Document9 pagesA Step by Step Construction Guide How To Build A Home 1vdrizzilsNo ratings yet

- A-743 - 98Document6 pagesA-743 - 98José Ramón GutierrezNo ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerRajesh KumarNo ratings yet

- Water TankDocument1 pageWater TankProject ManagerStructuresNo ratings yet

- Soil Details: Enter Both Length and WidthDocument5 pagesSoil Details: Enter Both Length and WidthDiana CristinaNo ratings yet

- FIPREP 0058 1986 E Tensioning of Tendons Force Elongation RelationshipDocument25 pagesFIPREP 0058 1986 E Tensioning of Tendons Force Elongation Relationshipdinhhuy214No ratings yet

- Bimetal Thermometers: - 5 Year Limited Warranty - Gold Service AvailableDocument8 pagesBimetal Thermometers: - 5 Year Limited Warranty - Gold Service AvailableMuhammad AsadNo ratings yet

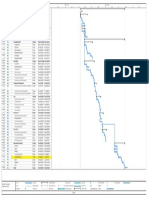

- Schedule Excavation r1Document1 pageSchedule Excavation r1Yosses Sang NahkodaNo ratings yet

- The Configuration FactorDocument2 pagesThe Configuration Factorapi-287730449No ratings yet

- WOOD As A BUILDING MATERIAL 2Document9 pagesWOOD As A BUILDING MATERIAL 2Jays Tioxon IIINo ratings yet

- TANK Design DetailingDocument17 pagesTANK Design DetailingTiffany Vabiola100% (8)

- Intro Examples Manual DRAFT PDFDocument229 pagesIntro Examples Manual DRAFT PDFEren KalayNo ratings yet