Professional Documents

Culture Documents

TCAS-GBT-Process Flow PDF

TCAS-GBT-Process Flow PDF

Uploaded by

nazi1945Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TCAS-GBT-Process Flow PDF

TCAS-GBT-Process Flow PDF

Uploaded by

nazi1945Copyright:

Available Formats

Site Allocation From CLient

Test need to be conducted(External

affiliated agencies/ MTC) and Site Marking/Demarcation

Documents need to be carried :

Soil Investigation

1) Material Test Need to be done and test

certificates need to be collected:

a) Fine aggregate & Coarse aggregate

testing and certificates.

Submission of Soil Investigation Reports and foundation

design to Approvals .

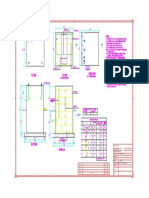

GBT Foundation

b) Cememnt MTC/ Lab test certificates.

c) Steel MTC/Lab test certificates.

Process Flow

Team Mobilization & Vegitation CLearing.

2) Concrete Tests:

a) Cube test - 7 days.

b) Cube test - 28 days. Site Final Marking

Test need to be conducted on Site:

Site Excavation

1) Physical Observation of Raw Materials:

a) Silt presence Fine aggregate(Both by Physical

Observation & Sieve Analysis)

RFI-1

b) Flakiness in Coarse aggregate

PCC Casting

c) Cement physical properties (Like color, temperature in

cement, lumps in cement...etc)

d) Steel Physical appearance( Type of rusting observed ,

Granule formation on surface,pitting etc.. Leveling should be done as per

e) Concrete (Slump Cone test, Workability...etc) norms and Pit depth should be Fail

corrected as per drawing.

f) Structure Verticality and Level Testing (Using water level

and Spirit Level)

Pass Inspection-1

Slump TestSlumP Cone Test Procedure:

Place frustum on the base plate.

Fill the wet concrete mixture in the cone in three equal layers. BBS (Bar bending

Compact each layer 25 times using compacting steel rod and Schedule)

the top surface is struck off by means of a sawing and rolling

motion of the tamping rod. Steel Placing& fixing and

The cone is slowly lifted and observed the slump. form work fixing need to

be corrected as per

Invert the frustum and place it close to the collapsed Steel Placing and fixing

instructions of Railway

(Including Stage-1

concrete. formwork) Inspector.

Measure and record the slump and type of slump.

Fail

RFI-2

Cube Test: Inspection -2

Mould and base plate must be clean and applied with oil

to prevent concrete from sticking to the side of the cube. Pass

Base plate is attached to the mould by using bolt and nut.

Fill the cube with concrete in three layers. RCC Casting Stage-1

Steel Placing& fixing

Every layer must be compacted for 25 times. This process and form work fixing

is carried out systematically and compaction is done need to be corrected Fail

as per instructions of

uniformly to all surfaces of the concrete. RFI-3 Railway Inspector.

Compaction can also be conducted using machine. RCC Casting Stage-2

The surface of concrete must be smoothen so it will has

the same level with the upper side of the mould.

Inspection -3

Cubes which are made at construction site must be

covered with plastic cover for a period of 24 hours before Backfilling upto 2nd stage

of concreting.

the moulds can be dismantled.

After remoulded, the concrete cubes are submerged in

Pass

water for curing.

Compression strength test must be carried out for

Form work stage-3 &CIP Steel Placing& fixing and form

concrete at age 7, 14, and 28 days by using compression Fixing. work fixing need to be corrected

test machine. as per instructions of Railway Fail

Inspector. CIP Levels &Plumb

reverification.

Material Details Need to used:

RCC Casting Stage-3 RFI-4

Steel: Fe 500- HYSD . Inspection -4

Cement: OPC-53

Aggregates: Should confine to IS: 383:1970.

Curing and stripping of

form work. Pass

Backfilling and

Compacting stage-3

Site Readiness for Tower Erection

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Telangana SSR 2018 19Document474 pagesTelangana SSR 2018 19nazi1945100% (5)

- Umer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationDocument4 pagesUmer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationSaqib Ali100% (1)

- Rockland HospitalDocument13 pagesRockland Hospitalvartika chaudhary100% (1)

- Level-5: Service Room 20'-1 " X 5'-9"Document1 pageLevel-5: Service Room 20'-1 " X 5'-9"nazi1945No ratings yet

- Multipurpose Building ConstructionDocument5 pagesMultipurpose Building Constructionnazi1945No ratings yet

- Qdoc - Tips - Ramachandra Rao Tantra Mantra YantraDocument84 pagesQdoc - Tips - Ramachandra Rao Tantra Mantra Yantranazi19450% (1)

- Typical Foundation Layout Plan at Expansion Gap at Every 30MtrDocument1 pageTypical Foundation Layout Plan at Expansion Gap at Every 30Mtrnazi1945No ratings yet

- V2R LiDAR Perception Solution Brochure EN 20200311Document2 pagesV2R LiDAR Perception Solution Brochure EN 20200311nazi1945No ratings yet

- RS-LiDAR-16 Brochure EN 20200306Document2 pagesRS-LiDAR-16 Brochure EN 20200306nazi1945No ratings yet

- Vishnujith InfraDocument76 pagesVishnujith Infranazi1945No ratings yet

- RS-LiDAR-32 Brochure EN 20200306Document2 pagesRS-LiDAR-32 Brochure EN 20200306nazi1945No ratings yet

- Medium-Low Speed AD LiDAR Perception Solution Brochure EN 20200312Document2 pagesMedium-Low Speed AD LiDAR Perception Solution Brochure EN 20200312nazi1945No ratings yet

- Modified STR - TMTDocument8 pagesModified STR - TMTnazi1945No ratings yet

- RoboTaxi LiDAR Perception Solution Brochure EN 20200311Document2 pagesRoboTaxi LiDAR Perception Solution Brochure EN 20200311nazi1945No ratings yet

- Date: 8 1 18Document77 pagesDate: 8 1 18nazi1945No ratings yet

- XIBMS Brochure 2017 PDFDocument48 pagesXIBMS Brochure 2017 PDFdinesh_haiNo ratings yet

- 2250e CatalogDocument4 pages2250e Catalognazi1945No ratings yet

- XIBMS Brochure 2017 PDFDocument48 pagesXIBMS Brochure 2017 PDFdinesh_haiNo ratings yet

- Advance-Stamped-Receipt - English A S R FormDocument1 pageAdvance-Stamped-Receipt - English A S R Formnazi1945No ratings yet

- JB FoundationDocument1 pageJB Foundationnazi1945No ratings yet

- Cart Information - Reference Number: FPU0TN3RE49: Booking ConfirmationDocument1 pageCart Information - Reference Number: FPU0TN3RE49: Booking Confirmationnazi1945No ratings yet

- Ehs Weekly Report - Byagwat Raichur - 14.08.2017Document5 pagesEhs Weekly Report - Byagwat Raichur - 14.08.2017nazi1945No ratings yet

- MDB & SMDBDocument3 pagesMDB & SMDBnazi1945No ratings yet

- Cash Payment & CER FormatDocument3 pagesCash Payment & CER Formatnazi1945No ratings yet

- Data Center Projects: Standardized Process: White Paper 140Document16 pagesData Center Projects: Standardized Process: White Paper 140nazi1945No ratings yet

- PWC India TP Code of ConductDocument5 pagesPWC India TP Code of Conductnazi1945No ratings yet

- Bilanat Salt0L (Ar Illg$L IltdttesDocument21 pagesBilanat Salt0L (Ar Illg$L Iltdttesnazi1945No ratings yet

- DB Schedule & SUM (10-11-2015)Document14 pagesDB Schedule & SUM (10-11-2015)nazi1945No ratings yet

- IRS Concrete Bridge Code - CS 9 PDFDocument3 pagesIRS Concrete Bridge Code - CS 9 PDFfaumijkNo ratings yet

- SOAL UTS Kelas VII 2021Document2 pagesSOAL UTS Kelas VII 2021rosafitriani86 rosafitriani86No ratings yet

- 2017 Brochure Pluvia Final Singles - 2Document20 pages2017 Brochure Pluvia Final Singles - 2Asoka Kumarasiri JayawardanaNo ratings yet

- History Quiz 2.0Document3 pagesHistory Quiz 2.0Ria Frania Dela CruzNo ratings yet

- Aiamem 1963 10Document20 pagesAiamem 1963 10tranbaotran240505No ratings yet

- Luxury Hotel Thesis PresenationDocument7 pagesLuxury Hotel Thesis PresenationShaik UmaruddinNo ratings yet

- Hotel Library StudyDocument27 pagesHotel Library StudyNikita Dhingra100% (1)

- Leed v4 For Homes Design and Construction ChecklistDocument3 pagesLeed v4 For Homes Design and Construction Checklistapi-302573361No ratings yet

- Estimated Cost of Different Types of Bridge Structure Per Linear Meter (Pesos) 2019Document7 pagesEstimated Cost of Different Types of Bridge Structure Per Linear Meter (Pesos) 2019robeusef costacortaNo ratings yet

- Cont. To Next Sheet 6: LegendDocument1 pageCont. To Next Sheet 6: LegendIrvan ApriliandiNo ratings yet

- D&W DetailsDocument1 pageD&W DetailsBrenndale SusasNo ratings yet

- Theatres of Architectural Imagination RoDocument9 pagesTheatres of Architectural Imagination RoSarah Rivera PacNo ratings yet

- Portfolio Beatriz OrozcoDocument16 pagesPortfolio Beatriz OrozcobeaorozcovNo ratings yet

- All Plants Production Report (Section - I Chaka)Document14 pagesAll Plants Production Report (Section - I Chaka)DeepakNo ratings yet

- Inspection Items, Focused Points, Inspection Method and Diagnosis CriteriorDocument35 pagesInspection Items, Focused Points, Inspection Method and Diagnosis CriteriorSon PhanNo ratings yet

- CT Frame Glass Back WallDocument1 pageCT Frame Glass Back Wallkako2006No ratings yet

- Aster: CladdingDocument13 pagesAster: CladdingQOQO TEAMNo ratings yet

- Chapter-2 Thermal InsulationDocument29 pagesChapter-2 Thermal InsulationDawit TesfayNo ratings yet

- Legend:: Drawing TitleDocument1 pageLegend:: Drawing TitleSonah AlcarazNo ratings yet

- Notes On ExcavationDocument3 pagesNotes On Excavationvegaangelika1No ratings yet

- Site Zoning: Cafeteria Design: Concept SheetDocument1 pageSite Zoning: Cafeteria Design: Concept SheetShruti JhaNo ratings yet

- WynwoodhausDocument34 pagesWynwoodhausNone None None100% (1)

- JENCKS Charles (The Iconic Building Is Here To Stay)Document19 pagesJENCKS Charles (The Iconic Building Is Here To Stay)odradek_666No ratings yet

- Bid Form: Civil / Structural / Architectural WorksDocument54 pagesBid Form: Civil / Structural / Architectural WorksShadin Asari ArabaniNo ratings yet

- Arhaeologia Na Balgarskite Zemi - 2 - 2006Document289 pagesArhaeologia Na Balgarskite Zemi - 2 - 2006gosho100% (1)

- Box CulvertsDocument9 pagesBox CulvertsRas Ramanujam100% (1)

- Solarmotion CatalogDocument7 pagesSolarmotion CatalogTeodor BaniskiNo ratings yet

- Malay HousesDocument6 pagesMalay HousesPuan MaryNo ratings yet