Professional Documents

Culture Documents

HS 019 Control of Records

HS 019 Control of Records

Uploaded by

grantOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HS 019 Control of Records

HS 019 Control of Records

Uploaded by

grantCopyright:

Available Formats

REFERENCE REVISION PAGE

SOUTH AFRICA REGION

SERVICES H&S 019 5 1 OF 13

HEALTH & SAFETY SYSTEM OPERATIONAL ORIGINATOR H&S MANAGER

PROCEDURE

CONTROL OF RECORDS

DESIGNATION PRINT NAME SIGNATURE DATE

COMPILED BY H&S OFFICER S THERON Original Signed 2/08/2012

(SYSTEMS)

REVIEWED BY SNR H&S OFFICER J S D CRONJÉ Original Signed 2/08/2012

AUTHORISED BY H&S MANAGER J SODEN Original Signed 2/08/2012

TABLE OF CONTENTS PAGE ADDENDA PAGE

1. PURPOSE 2 ANNEXURE 1 – RECORD MATRIX 6

2. SCOPE 2 ANNEXURE “X” – DEFINITIONS AND ABBREVIATIONS 7 - 11

3. DEFINITIONS AND 2 ANNEXURE “XX” - REFERENCES 12

ABBREVIATIONS

4. REFERENCES 2 RECORD OF AMENDMENTS 13

5. RESPONSIBILITY / 2

ACCOUNTABILITY

6. CONTROL OF RECORDS 3

7. TRAINING 5

8. RECORDS APPLICABLE TO 5

THIS PROCEDURE

REVISION DESCRIPTION OF REVISION DATE

5 REVISION DUE TO AUDIT REQUIREMENTS 2 AUG 2012

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of Records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 1 of 13

1. PURPOSE

This procedure is developed to assist with the common understanding of the document control

procedure. The control and management of H&S and SA Region Services Risk Management System

related documentation relates to:

• The approval of documents for adequacy prior to issuing;

• The review and update of the documents as required and the identification of the document

status e.g. revision number and whether controlled, uncontrolled or obsolete.

The maintenance of the relevant versions of applicable documents at appropriate locations.

2. SCOPE

This procedure applies to all identified records as stated in the SARSSS procedures, in hard copy or

electronic format, within SA Region Services.

3. DEFINITIONS AND ABBREVIATIONS

Refer to Annexure “X”

4. REFERENCES

Refer to Annexure “XX”

5. RESPONSIBILITY / ACCOUNTABILITY

DESIGNATION RESPONSIBILITIES AND ACCOUNTABILITIES

• Ensure that adequate resources are available to facilitate a record control

process

H&S Manager

• Managing documentation & records keeping

• Responsible for the management of records, identification, storage, protection,

retrieval, retention, and disposal of records at SARSSS.

• Conduct a document and data survey to identify what records must be kept,

where, how long and in what format it must be filed.

• Ensure records are secure and protected against fire where required, pestilence

and unauthorized access as determined in the document and data survey.

• Identify the records that need to be kept in terms of Legal requirements,

H&S Officer

OHSAS requirements as well as any document referred to by any other

(Systems)

procedure required to be controlled.

• Audit records not kept in the legal admin centre for any reason

• Identify and list all records of external origin relevant to the Safety Management

System.

• Take responsibility of all records in the H&S Department to prevent inadvertent

access.

• Conduct inspections to verify that records are being kept and managed

Snr. H&S Officer according to this procedure

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 2 of 13

DESIGNATION RESPONSIBILITIES AND ACCOUNTABILITIES

• Ensure availability of resources to implement the OH&S programme

• Ensure that analysis is made of information pertinent to OH&S

• Compare information with objectives, evaluate effectiveness of controls and

Management where targets are not met change controls to achieve desired results

Representative • Ensure information is distributed and communicated to employees relevant to

the work they perform

• Ensure that personnel are aware of applicable legal and other requirements

• Ensure H&S Officer (Systems) keep and maintain records

6. CONTROL OF RECORDS

6.1 Records storage requirements

Records shall be kept in a safe, secure environment that is:

a) Protected from moisture and pests.

b) Prevents unauthorized access.

The main focus is to identify the records, store it properly, protect the records from elements,

ensure that they can be accessed easily, and remain legible, identifiable and traceable. Identified

documents will be kept at the H&S department.

6.2 SA Region Services Safety System Records

The following are examples of records not limited to that should be kept in terms of the SARSSS

For full detail refer to the record matrix kept at the H&S department. (Annexure 1 example)

-

Pre-use inspection checklists (e.g. double drum winch, mono winch, etc.) *

-

Logbooks *

-

Crane Logbooks

-

Employee personal files (containing training records, induction documents, etc.) *

-

DME correspondence (Permits, exemptions, Section 54 notifications, permissions, etc)

-

Issue based risk assessments

-

Mine Responsibility plans*

-

Technical Inspections / Evaluations*

-

Legal appointments

-

Incident reports

-

Occupational Hygiene Measurements (airborne pollutants, noise, illumination, vibration,

ergonomics, radiation and thermal stress)

- Occupational Hygiene Measurements (other)*

- Month end reports

- Annual Medical Report*

- Quarterly/Annual H&S report

- Hazard identification

- Calibration and maintenance of H&S equipment*

- Records of corrective and preventative action

- Audit reports

- NNR documentation and all relevant radiation documentation

- Occupational Health & Safety minutes

- Management review*

- Reports on emergency response*

- PPE maintenance records*

* Records kept by disciplines and not the H&S department

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 3 of 13

6.2.1 Storing and archiving of records:

6.2.1.1 Records will be stored in both electronic and hardcopy formats “back-up” where possible at the

H&S Department. Some records e.g. archived mine responsibility plans are kept at the surface

survey department. Training and personal records will be kept at Training department (ATDS).

6.2.1.2 No record may leave the H&S Department unless with permission form the H&S Officer

(Systems) and H&S Manager. Before the record may be removed, it must be signed out in the

legal admin control book.

6.2.1.3 The retention time and archiving period of these records may be depicted on record, or

relevant procedure. Where it is not stated, records should be stored as a minimum for 1 year

and archived for a minimum of 3 years where after it will be destroyed via paper recycling.

6.2.1.4 The H&S Officer (Systems) will keep record of all archived document identified in the Data

control survey sheet.

6.2.1.5 The records of workplace inspections reports conducted are kept in the H&S department office.

6.2.1.6 All the incident investigation report records are kept in the H&S department.

6.3 Disposal of records

6.3.1 A register will be kept of all records disposed of at the H&S Department.

6.3.2 All records will be disposed of in the following manner:

• Records defined / classified as confidential by the HOD by means of archiving.

• All other records will be sent to waste paper recycling.

6.4 H&S Department records audit / census

6.4.1 The H&S Department will conduct an audit / census to determine compliance to:

• Identification of records.

• Storage of records.

• Protection of records.

• Retrieval of records.

• Retention of records.

• Disposal of records.

• Legal requirement

• Confidentiality

• Access

• Responsible person

The document / record census will identify the level of confidentiality with regards to those

records.

Confidential documents:

• Will be managed by the H&S Officer (Systems) – approved by H&S Manager.

• Will be stored in a locked cabinet and facility

• Will be destroyed by virtue of shredding, following approval by the H&S Manager.

• Will be removed from storage only on approval from the H&S Manager.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 4 of 13

6.5 Monitoring and Auditing

The records system shall be monitored by the Snr. H&S Officer. The system shall be audited /

reviewed on an annual basis to confirm relevance and consider whether changes are required.

7. TRAINING

It is the responsibility of SA Region Services management to ensure that person/s are suitably trained

and found competent to carry out their duties. Training records of all employees, including contractors,

are kept in the Training department (ATDS) and a copy at HOD’s as record of proof.

8. RECORDS APPLICABLE TO THIS PROCEDURE

The following records are applicable to this procedure and shall be maintained:

Retention Time (yrs)

Records Location

Life Period Archiving

Register of records stored Responsible HOD / H&S Department 2 5

Register of records archived Legal Administration Department 2 5

Register of records destroyed H&S Department 2 5

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 5 of 13

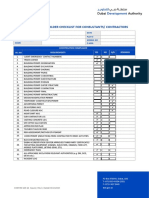

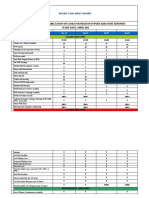

Annexure 1

DATE:

DEPARTMENT:

High Cabinet and facility locked

Medium Cabinet locked

Low Cabinet not locked

Confidentiality /

Security Level MANAGER

TYPE OF RESPONSIBLE LOCATION OF RETENTION METHOD OF

NO NAME OF RECORD DEPARTMENT WHERE LOCATED High AUTHORISING

RECORD PERSON COPY RETAINED TIME DISPOSAL

Medium DISPOSAL

Low

1 Pre-use inspections Inspection Departments Supervisors Specific Department Low Specific Department 6 months Recycle H&S Manager

Safety Officers legal

2 inspection reports Inspection Health & Safety H&S Officers H&S Department Low Store room 12 months Recycle H&S Manager

3 Logbooks Inspection Departments Supervisors Specific Department Low Specific Department 12 Months Recycle H&S Manager

4 Crane Logbooks Inspection Departments Supervisors Specific Department Low Specific Department 40 Years Recycle H&S Manager

H&S Officer Systems / Snr.

5 WITW Meeting minutes Minutes Health & Safety H&S Officer H&S Department Low Filing Cabinet 12 months Recycle H&S Manager

6 Training records Training Training Training Manager Training Department Low Training Department 40 Years Recycle H&S Manager

7 Achievements Statistics Health & Safety H&S Officer Systems H&S Department Low Electronic 24 months Recycle H&S Manager

8 Injury Stats Statistics Health & Safety H&S Officer Systems H&S Department Low Electronic 40 Years Recycle H&S Manager

Leading and lagging

9 Monthly reports indicators Health & Safety Snr. H&S Officer H&S Department Low Electronic 12 months Recycle H&S Manager

10 Hierarchy Statistics Health & Safety H&S Officer Systems H&S Department Low Electronic / Filing cabinet 40 Years Recycle H&S Manager

11 LTIFPD Statistics Health & Safety H&S Officer Systems H&S Department Low Electronic 40 Years Recycle H&S Manager

12 Planned task observations Observation Departments HOD's / Supervisor Specific Department Low Specific Department 12 months Recycle H&S Manager

13 RPM Log Books Inspection Departments RPM / Supervisor Specific Department Low Specific Department 40 Years Recycle H&S Manager

Procedures and NNR

14 Radiation File Audits Health & Safety RPM / Supervisor H&S Department Low Specific Department 40 Years Recycle H&S Manager

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of Records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 6 of 13

Annexure X

DEFINITIONS AND ABBREVIATIONS

DEFINITIONS:

DOCUMENT

Information and its supporting medium (The medium can be paper, magnetic, electronic or optical computer

disc, photograph or master sample, or a combination thereof.)

RECORD

Document stating results achieved or providing evidence of activities performed

CONTROLLED DOCUMENT

Any document that needs to be controlled in terms of its distribution and use, such as the Policy and

documented procedures. These documents are either signed in original ink and/or signed for on a

distribution list. These documents will be signed off after evaluation has been done to determine that they

are adequate for purpose. The document will be signed off by the relevant members as depicted on the

distribution list.

Once copies are printed of the database, they are considered to be “uncontrolled”.

OBSOLETE DOCUMENTS

Documents that have been replaced by later revisions or those that is no longer relevant or valid, and has

been cancelled from the system. These documents will be identified either by crossing them out and writing

obsolete or rubber stamp obsolete document.

UNCONTROLLED DOCUMENTS

Any documents that have not been issued under the circumstances under “controlled documents” are

categorised as uncontrolled. This includes, but may not be limited to:

• Documents that do not need to be controlled such as the monthly safety topic.

• Documents not distributed by the authorised person as per the procedures “authority and

responsibility” table and signed for by the recipient.

• Documents printed from the electronic database. (Watermarked “uncontrolled document)

• Documents duplicated or photocopied from controlled documents.

• Photocopies of the Occupational Health and Safety policy as issued to the public or other

Interested and Affected Parties

It is not possible to judge from an uncontrolled copy whether it is the latest version. It is the responsibility of

the person holding the documentation to ensure that (s) he has the latest version.

INJURY

Physical harm or damage

OCCUPATIONAL HEALTH AND SAFETY

Conditions and factors that affect, or could affect the health and safety of employees or other workers

(including temporary workers and contractor personnel), visitors, or any other person in the workplace

Occupational Health and Safety hazards, which include airborne pollutants, noise, illumination, vibration,

ergonomics, radiation, as well as thermal stress.

OH&S MANAGEMENT SYSTEM

Part of an organization’s management system used to develop and implement its OH&S policy and manage

its OH&S risks

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of Records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 7 of 13

SEVERITY / CONSEQUENCE

Outcome of an event. There may be one or more consequences from an event. May be expressed

qualitatively or quantitatively may range from positive to negative (Speculative).

FREQUENCY

Occurrence per unit time, (May be expressed qualitatively or quantitatively).

EXPOSURE

How often and for how long employees are exposed to a hazard/s.

LIKELIHOOD

Means the chance of an event occurring.

DUE DILIGENCE

Taking reasonable care to protect the health and safety of all employees. Provide equipment, maintain the

equipment, use equipment as prescribed, provide information relating to the equipment, and provide

competent supervision.

INCIDENT

An undesired event which under slightly different circumstances could result in harm to people. Damage to

property or loss to process or an undesired event that could or does result in a loss.

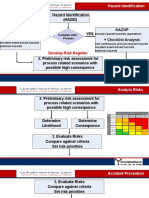

RISK MATRIX

A Risk index can be determined by plotting likelihood and severity indices on the y and x-axis respectively

and then using them to obtain a risk ranking.

HIRA

Process of recognizing that a hazard exists and defining its characteristics

• H = HAZARD

Anything around us that we can see as well as those energy sources we cannot see e.g. Gas and

radiation that can cause harm

• I = IDENTIFICATION

Identify the significant hazards (Process and recognition)

• R = RISK

Risk imagining (Likelihood and consequence if risk materializes)

• A = ASSESSMENT

Determine the magnitude of the risk if materialized

ROUTINE ACTIVITY

An activity which is performed on a regular basis (day to day)

NON ROUTINE

An activity performed on an adhoc basis

ACCOUNTABILITY

Principle that, individuals, organizations, and the community are responsible for their actions and may be

required to explain them to others.

RESPONSIBLE

Liable to be called to respond to a person for issues to be done.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 8 of 13

ILL HEALTH

Identifiable adverse physical or mental condition arising from and/or made worse by a work activity and/or

work-related situation.

INTERESTED PARTIES

Person or group, inside or outside the workplace, concerned with or affected by the SARSSS performance.

NONCONFORMITY

Non-fulfilment of a requirement – can be any deviation from:

Relevant work standards, practices, procedures, legal requirements.

SARSSS OBJECTIVES

SARSSS goals, in terms of OHS performance, that SA Region Services sets itself to achieve. Objectives are

quantified wherever practical.

SARSSS PERFORMANCE

Measurable results of SA Region Services management of its risks.

Note: Performance measurement includes measurement the effectiveness of controls.

OHS POLICY

Overall intention and direction which will be followed for the management of health and safety.

RECORD

Document stating results achieved or providing evidence of activities performed

HAZARD

A condition or practice with the potential to cause harm, or exposure to danger. (Immediate Causes,

Substandard Act or Substandard Condition)

RISK ASSESSMENT

Process of evaluating the risk(s) arising from a hazard(s), taking into account the adequacy of any existing

controls, and deciding whether or not the risk(s) is acceptable

PREVENTATIVE ACTION

Action to eliminate the cause of a potential nonconformity or other undesirable potential situation.

CORRECTIVE ACTION

Action taken to rectify a non-conformance or deviation

CONTINUAL IMPROVEMENT

To constantly improve on current Health and Safety standards

PROCEDURE

Specified way to carry out an activity or a process.

RISK ASSESSMENT

Process of evaluating the risk arising from a hazard, taking into account the adequacy of any existing

controls, and deciding whether or not the risk is acceptable.

WORKPLACE

Any physical location in which work related activities are performed under the control of SA Region Services

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 9 of 13

AUDIT

Independent and documented process for obtaining “audit evidence” and evaluating it objectively to

determine the extent to which “audit criteria” are fulfilled.

SAFETY MONTH

Period from the 20th of a particular month up to the 19th of the following month.

EFFORT BASED OBJECTIVES

Objectives set to improve program related issues

EFFECT BASED OBJECTIVES

Objectives set to improve severity or injury rates

MANCOM

Management Committee

EXCO

Executive Committee

SUPERVISOR

Within SA Region Services – One who supervise or has charge and direction of i.e. Foreman, Clerk of

works, Training Officer, Residence Manager, Security Officer etc.

EMPLOYEE

Person working under the control of the organisation and includes contractors.

MANAGEMENT REPRESENTATIVE

A Person appointed in writing ensuring that the OH&S management system is established, implemented

and maintained in accordance with this OHSAS Standard;

and ensuring that reports on the performance of the OH&S management system are presented to top

management for review and used as a basis for improvement of the OH&S management system.

VISITOR

Any person who enters the premises of the mine who is not a full time employee or Contractor paid by the

mine

CONTRACTOR

Any person who perform work for the mine and is paid for his/her service.

ACCEPTABLE RISK

Risk that has been reduced to a level that can be tolerated by the organization having regard to its legal

obligations and its own

HEALTH AND SAFETY COMMITTEE

A committee as required by law M H & S Act Section 25(2)

VERIFICATION

Verification is the act of reviewing, inspecting, testing, etc. to establish and document that a product, service,

or system meets the regulatory, standard, or specification requirements.

VALIDATION

Validation refers to meeting the needs of the intended end-user or customer to

prove the truth or to determine or test the accuracy. Also, validation is the process of checking if something

satisfies a certain criterion.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 10 of 13

ABBREVIATIONS:

M H & S Act - Mine Health & Safety Act

MA&R - Mineral Act & Regulations

OHASA - Occupational Health and Safety Act

DMR - Department of Mineral Resources

DOL - Department of Labour

SADS - Southern Africa Region Services

ESW - Engineering Services Workshops

WITW - Wellness in the Workplace

H&S - Health and Safety

LTIFPD - Loss Time Injury Free Production Days

IFPD - Injury Free Production Days

AGAH - AngloGold Ashanti Health

TMM - Trackless Mobile Machinery

COP - Code of Practice

ATDS - AngloGold Ashanti Training and Development Services

CRA - Continuous Risk Assessment

SARSSS - Southern Africa Region Services Safety System

NNR - National Nuclear Regulator

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 11 of 13

Annexure XX

REFERENCES

• Roles and responsibilities are depicted in each system procedure and updated as and when

required in table format

• OHSAS 18001:2007 (Occupational Health and Assessment Series)

• The Mine Health and Safety Act 29 of 1996

• The Minerals Act 50 of 1991

• Occupational Health and Safety Act (Act 86 of 1993)

• COIDA

• AGA Strategic Objectives

• Implex Legal Register

• ATDS Training Matrix

• AGA RCAT

• Corporate Procedure Directive

• Health and Safety Agreement

• SAR/OESH/P/A/001.01 – AGA Incident reporting

• H&S 004 – Incident investigation

• H&S 006 – Emergency preparedness and response

• H&S 014 – Issue based risk assessment

• H&S 018 – Baseline risk assessment H&S 019 – Control of records

• H&S 023 – Control of documents

• H&S 027 – Competence, training and awareness

• H&S 028 – Continuous risk assessment

• H&S 029 – Communication, participation and consultation

• H&S 030 – Management review

• H&S 031 – Internal audit

• H&S 037 – Management of change

• H&S 055 – SA Region Services Scope

• H&S 058 – Legal and other requirements

• H&S 059 – Performance measurement and monitoring

• H&S 060 – Evaluation of compliance

• H&S 061 – Nonconformity, corrective and preventative action

• H&S 065 – Objectives and programme(s)

• H&S 067 – Resources, roles, responsibility, accountability and authority

• H&S 069 – Operational control

• H&S 070 – Documentation

• H&S 071 – H&S Policy

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 12 of 13

RECORD OF AMENDMENTS

PROCEDURE DATE OF

CHANGES TO PROCEDURE

REVISION NUMBER APPROVAL

Purpose, Definitions and Abbreviations,

H&S 019 - Revision 3 References, Confidentiality issue, Back-up 4 June 2009

H&S 019 – Revision 4 Name Changes 1 October 2009

H&S 019 – Revision 5 Name Changes and audit requirements 2 August 2012

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Control of records REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 019 05 August 2012 3 August 2012 Page 13 of 13

You might also like

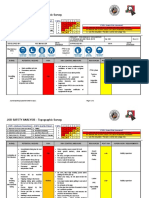

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 pagesJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Basic OSHA Compliance ChecklistDocument2 pagesBasic OSHA Compliance ChecklistMary NicksNo ratings yet

- Benzene: 1. Purpose 2. ScopeDocument8 pagesBenzene: 1. Purpose 2. ScopeKandhasamy888No ratings yet

- RAA Matrix All WorkersDocument2 pagesRAA Matrix All WorkersLucy RegaladoNo ratings yet

- BP Code of Conduct EnglishDocument28 pagesBP Code of Conduct EnglishAhmed El batalNo ratings yet

- CS Respiratory ProtectionDocument2 pagesCS Respiratory ProtectionSajid HussainNo ratings yet

- HS 071 HS PolicyDocument12 pagesHS 071 HS PolicygrantNo ratings yet

- HS 031 Internal AuditDocument16 pagesHS 031 Internal AuditgrantNo ratings yet

- MUDASSIRDocument1 pageMUDASSIRSn AhsanNo ratings yet

- Sample of JHADocument5 pagesSample of JHAfarizaziz77No ratings yet

- MOSH Health & Safety 14-01-2021Document31 pagesMOSH Health & Safety 14-01-2021Mahmood AliNo ratings yet

- Job StudyDocument3 pagesJob StudyVictor PhiriNo ratings yet

- Chelston Decorators Health and Safety PolicyDocument13 pagesChelston Decorators Health and Safety PolicySam MurrayNo ratings yet

- Compliance Record Folder Checklist For Consultants/ ContractorsDocument1 pageCompliance Record Folder Checklist For Consultants/ ContractorsNijasNo ratings yet

- Traffic PlanDocument1 pageTraffic PlanJayvee Baradas ValdezNo ratings yet

- General Information For Hazardous MaterialsDocument8 pagesGeneral Information For Hazardous MaterialsAshraf shaikhNo ratings yet

- 88Document60 pages88muthuswamy77No ratings yet

- HSE Management System ArenscoDocument22 pagesHSE Management System ArenscoJaber AmariNo ratings yet

- Workplace Risk Assessment PDFDocument14 pagesWorkplace Risk Assessment PDFSyarul NizamzNo ratings yet

- Ohs PR 09 19 f10 (A) Chain Block InspectionDocument2 pagesOhs PR 09 19 f10 (A) Chain Block InspectionShafie ZubierNo ratings yet

- Naseem & Son: Emergency Response PlanDocument6 pagesNaseem & Son: Emergency Response PlanSagar SharmaNo ratings yet

- Mayon Hazardous SubstancesDocument14 pagesMayon Hazardous Substancesjerold esponillaNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument13 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- GNPOC List ofDocument3 pagesGNPOC List ofHSE S4No ratings yet

- Sample Ppe ProgramDocument4 pagesSample Ppe ProgramRizal DaudNo ratings yet

- Safe Use of Chemicals: 1.0 PurposeDocument10 pagesSafe Use of Chemicals: 1.0 PurposeFuzail AyazNo ratings yet

- Fire Inspector Memo From Town StaffDocument2 pagesFire Inspector Memo From Town StaffFauquier NowNo ratings yet

- Manual HandlingDocument14 pagesManual HandlingLenin JambhulkarNo ratings yet

- Emergency Evacuation Drill & Fire DrillDocument15 pagesEmergency Evacuation Drill & Fire DrillMahmoud SaiedNo ratings yet

- RA - Transport ERPDocument8 pagesRA - Transport ERPAllocation ResourceNo ratings yet

- Covid 19 Emergency Handling ProcedureDocument9 pagesCovid 19 Emergency Handling ProcedureDhananjay PatilNo ratings yet

- Compressed Fire Risk Assessment TemplateDocument9 pagesCompressed Fire Risk Assessment TemplateReaz UddinNo ratings yet

- Risk Assessment ChecklistDocument1 pageRisk Assessment ChecklistSyed Irtiza HassanNo ratings yet

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- Industrial HygieneDocument3 pagesIndustrial HygieneKukuh WidodoNo ratings yet

- Hse Plan 3Document14 pagesHse Plan 3YcRij SeYerNo ratings yet

- Construction Assessment Checklist: Green TagDocument2 pagesConstruction Assessment Checklist: Green TagRyan GillespieNo ratings yet

- ED2 SampleDocument53 pagesED2 SampleadelNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Dashboard Data: Safety Inspections Safety Walkthroughs Hazard HuntsDocument4 pagesDashboard Data: Safety Inspections Safety Walkthroughs Hazard HuntsTFattah0% (1)

- Safety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Document12 pagesSafety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Priyo Djatmiko100% (1)

- Safety Program (d1)Document21 pagesSafety Program (d1)elvis hidalgoNo ratings yet

- EP QA FM 015 Risk Assessment Register Form AdminDocument4 pagesEP QA FM 015 Risk Assessment Register Form AdminEcoPrasinosNo ratings yet

- Risk Management or Environmental Health and Safety or Safety ManDocument3 pagesRisk Management or Environmental Health and Safety or Safety Manapi-121419389No ratings yet

- IOSH Managing SafelyDocument3 pagesIOSH Managing Safelyhsecouncil100% (1)

- 2.22 - Hazard Identification Form - HandDocument3 pages2.22 - Hazard Identification Form - HandSn AhsanNo ratings yet

- (Inspection Inprocess)Document15 pages(Inspection Inprocess)loserambujNo ratings yet

- 2020 ProQual NVQ L6 Candidate Eligibility QuestionaireDocument2 pages2020 ProQual NVQ L6 Candidate Eligibility QuestionaireMohamed BasbasNo ratings yet

- Flooding Fast Facts: What Is A Flood?Document5 pagesFlooding Fast Facts: What Is A Flood?George KingNo ratings yet

- Swot Analysis By: Elizabeth CrusanDocument4 pagesSwot Analysis By: Elizabeth Crusanlizzyannr0cksNo ratings yet

- EHS AgreementDocument37 pagesEHS AgreementSantosh KumarNo ratings yet

- Confind SpaceDocument11 pagesConfind Spacesolomonbeg100% (1)

- HSE Policy Requirements (Client's Perspective) : Contractor To Refer To The ISO 45001 and 14001 Element 5Document1 pageHSE Policy Requirements (Client's Perspective) : Contractor To Refer To The ISO 45001 and 14001 Element 5Victor Thembinkosi MakhubeleNo ratings yet

- (598295696) 08.0 Article 3.0 Section D - HSE (27012015)Document17 pages(598295696) 08.0 Article 3.0 Section D - HSE (27012015)NabilahNo ratings yet

- Msc-Qhsef-04 Masterlist - Documents and RecordsDocument4 pagesMsc-Qhsef-04 Masterlist - Documents and RecordsAdil Abdulkhader100% (1)

- 6 - 2.emergency Drill Record Form - ExampleDocument1 page6 - 2.emergency Drill Record Form - ExampleJaijeev PaliNo ratings yet

- Sop - FoggingDocument2 pagesSop - FoggingQS KCJNo ratings yet

- Epl159 Emergency Response PlanDocument39 pagesEpl159 Emergency Response Planrahul kavirajNo ratings yet

- Safety AuditSDocument5 pagesSafety AuditSsanjeev kumarNo ratings yet

- Work Health and Safety Regulations 2012 (SA) : A Guide To Chapter 10 - MinesDocument24 pagesWork Health and Safety Regulations 2012 (SA) : A Guide To Chapter 10 - MinestalabiraNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- 217 Confined Space LaminatingDocument11 pages217 Confined Space LaminatinggrantNo ratings yet

- 216 Fire PreventionDocument12 pages216 Fire PreventiongrantNo ratings yet

- 218 Site EstablishmentDocument14 pages218 Site EstablishmentgrantNo ratings yet

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- Prj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundDocument2 pagesPrj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundgrantNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

- ISO Training List - ConstructionDocument2 pagesISO Training List - ConstructiongrantNo ratings yet

- PM Site 15b - Site Materials Control - REVISED JHLDocument2 pagesPM Site 15b - Site Materials Control - REVISED JHLgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- Section 4 - Index - Revised JHLDocument1 pageSection 4 - Index - Revised JHLgrantNo ratings yet

- Section 9 - Check Out - Test & Acceptance Certificates - REVISED JHLDocument3 pagesSection 9 - Check Out - Test & Acceptance Certificates - REVISED JHLgrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- 6 PM PROJ 06 - Change of Scope FormDocument2 pages6 PM PROJ 06 - Change of Scope FormgrantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- PM Site 02b - Revised JHL #Document1 pagePM Site 02b - Revised JHL #grantNo ratings yet

- Section 1 Index - Revised JHLDocument1 pageSection 1 Index - Revised JHLgrantNo ratings yet

- Section 6 - Index - Revised JHLDocument1 pageSection 6 - Index - Revised JHLgrantNo ratings yet

- Section 7 - Index - Revised JHLDocument1 pageSection 7 - Index - Revised JHLgrantNo ratings yet

- 4.RAMS Machine Installations 2023Document14 pages4.RAMS Machine Installations 2023grantNo ratings yet

- Section 2 - Index - Revised JHLDocument1 pageSection 2 - Index - Revised JHLgrantNo ratings yet

- 1.conveyors Risk AssessmentDocument19 pages1.conveyors Risk AssessmentgrantNo ratings yet

- Sectiion 8 - Index - Quality Forms - Revised JHLDocument1 pageSectiion 8 - Index - Quality Forms - Revised JHLgrantNo ratings yet

- Section 2 - Execution Plan - REVISED JHLDocument1 pageSection 2 - Execution Plan - REVISED JHLgrantNo ratings yet

- Dokumen - Tips - Manual Mantenimiento Celdas 8bk20 PDFDocument16 pagesDokumen - Tips - Manual Mantenimiento Celdas 8bk20 PDFLoilson VieiraNo ratings yet

- Toxicology Risk and HazardDocument21 pagesToxicology Risk and HazardAizat AsyhNo ratings yet

- COVID 19: Infection Prevention and ControlDocument29 pagesCOVID 19: Infection Prevention and ControlJp Rizal IPCCNo ratings yet

- JD Lead Asset Integrity Engineer - R02 - WoDocument3 pagesJD Lead Asset Integrity Engineer - R02 - WoInalegwu23No ratings yet

- Carlin Barrie Direct PipeDocument50 pagesCarlin Barrie Direct PipeSobe ThapaNo ratings yet

- Curriculam Vitae: K.D.J.PradeepDocument5 pagesCurriculam Vitae: K.D.J.PradeepsudumanikamanjuNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument7 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingNabilahNo ratings yet

- Hazards and Risk Identification and ManagementDocument2 pagesHazards and Risk Identification and Managementsai ramNo ratings yet

- IRC sp-87-2010 PDFDocument180 pagesIRC sp-87-2010 PDFStark JNo ratings yet

- 1) What Is A Preventive Controls Qualified Individual (PCQI) ?Document7 pages1) What Is A Preventive Controls Qualified Individual (PCQI) ?Ciandeb GracianoNo ratings yet

- Mitsubishi FX1N Yj ManualDocument124 pagesMitsubishi FX1N Yj ManualSandi PratamaNo ratings yet

- MNS PrequalificationDocument71 pagesMNS PrequalificationEngineering MNSNo ratings yet

- AMEC Coating Specification 01Document35 pagesAMEC Coating Specification 01cenkturker100% (1)

- BA BT300 DLT1200 11 aEN 001 PDFDocument84 pagesBA BT300 DLT1200 11 aEN 001 PDFRonnie Ayala SandovalNo ratings yet

- Hse Audit ReportDocument2 pagesHse Audit Reportfinbar iluobeNo ratings yet

- Pinellas County Fire Department Standard Operating Procedures Wildland/urban Interface FiresDocument46 pagesPinellas County Fire Department Standard Operating Procedures Wildland/urban Interface Firesthomasmay1No ratings yet

- Product and Company Identification: 04/15/2014 Revision: 01/27/2016 PrintedDocument5 pagesProduct and Company Identification: 04/15/2014 Revision: 01/27/2016 Printedmx401974No ratings yet

- User Manual Bandsaw N2-35: (Translation)Document60 pagesUser Manual Bandsaw N2-35: (Translation)Akshay SharmaNo ratings yet

- Control PanelsDocument4 pagesControl Panelssupinya bieNo ratings yet

- Slide-2 - Elect MaintenanceDocument30 pagesSlide-2 - Elect MaintenanceSaff Md100% (1)

- Sika PDS - E - Sikadur-Combiflex SG TapeDocument4 pagesSika PDS - E - Sikadur-Combiflex SG Tapelwin_oo2435No ratings yet

- 2023 SOP CentrifugeDocument7 pages2023 SOP CentrifugeParomita SarkerNo ratings yet

- G-Enex Video Installation Manual CA-003Document321 pagesG-Enex Video Installation Manual CA-003rafaNo ratings yet

- Short Notes 5 Days To Examto ExamDocument3 pagesShort Notes 5 Days To Examto ExamAmin UllahNo ratings yet

- Sharing Performance Based Fire Design Yulianto Oktober 2014 B WDocument34 pagesSharing Performance Based Fire Design Yulianto Oktober 2014 B WayyishNo ratings yet

- Manual Construction+SafetyDocument462 pagesManual Construction+SafetyCody Mantyka100% (9)

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroNo ratings yet

- Hazard Identification, Risk Assessment and Risk ControlDocument17 pagesHazard Identification, Risk Assessment and Risk ControlMarr Allonar SumagangNo ratings yet